Electron beam additive manufacturing device

A technology of additive manufacturing and electron beam, which is applied in the field of additive manufacturing, can solve the problems of reduced production efficiency, unfavorable additive manufacturing, and inability to ensure welding wire feeding, etc., to achieve the effect of improving the effect and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

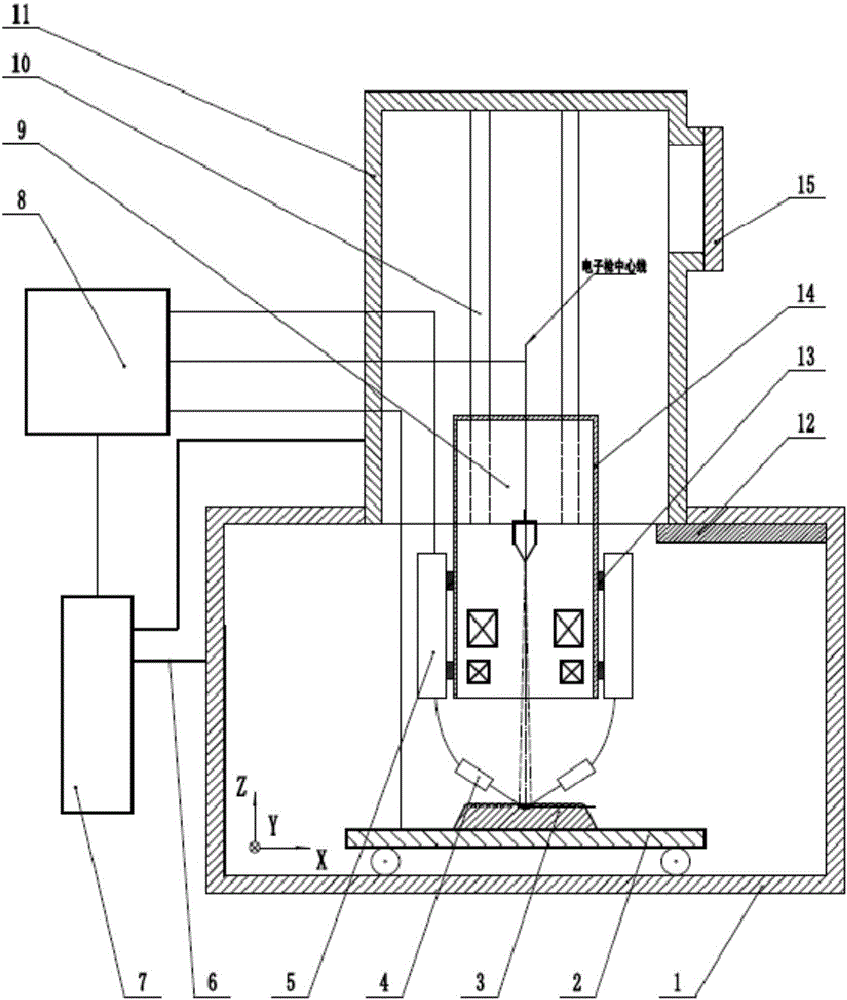

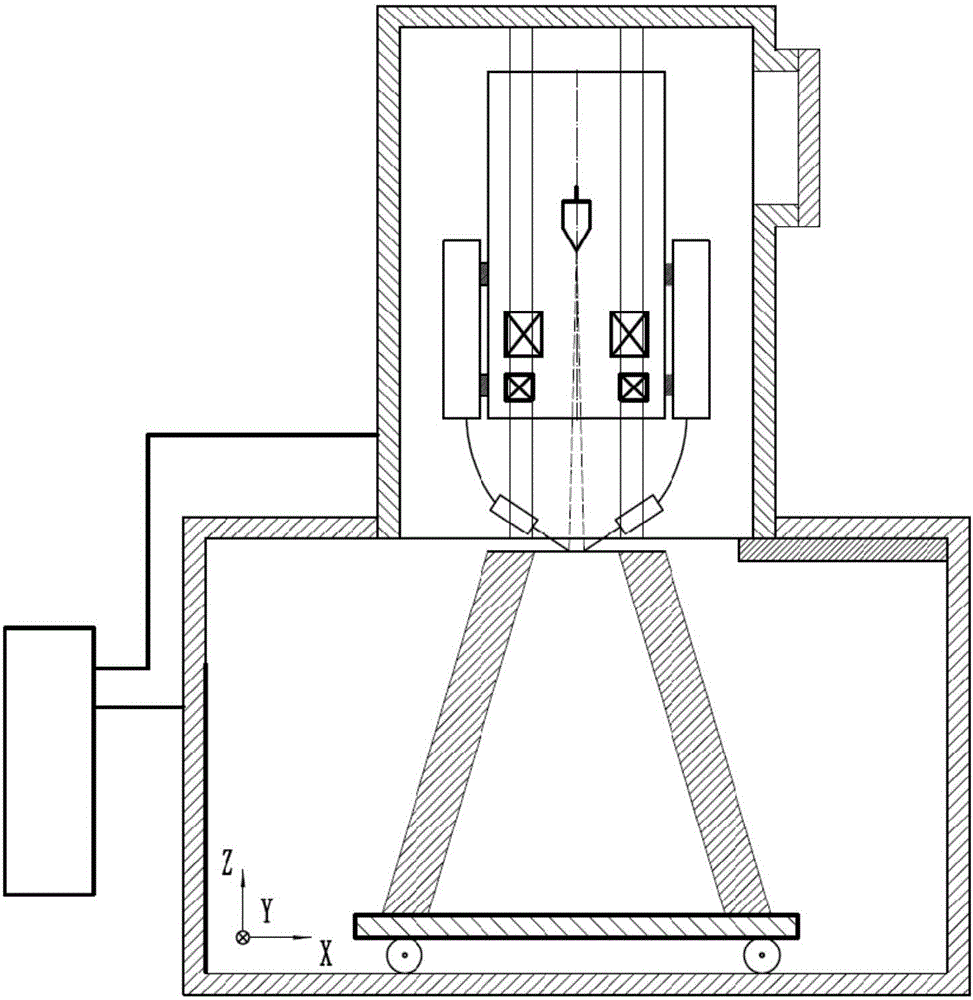

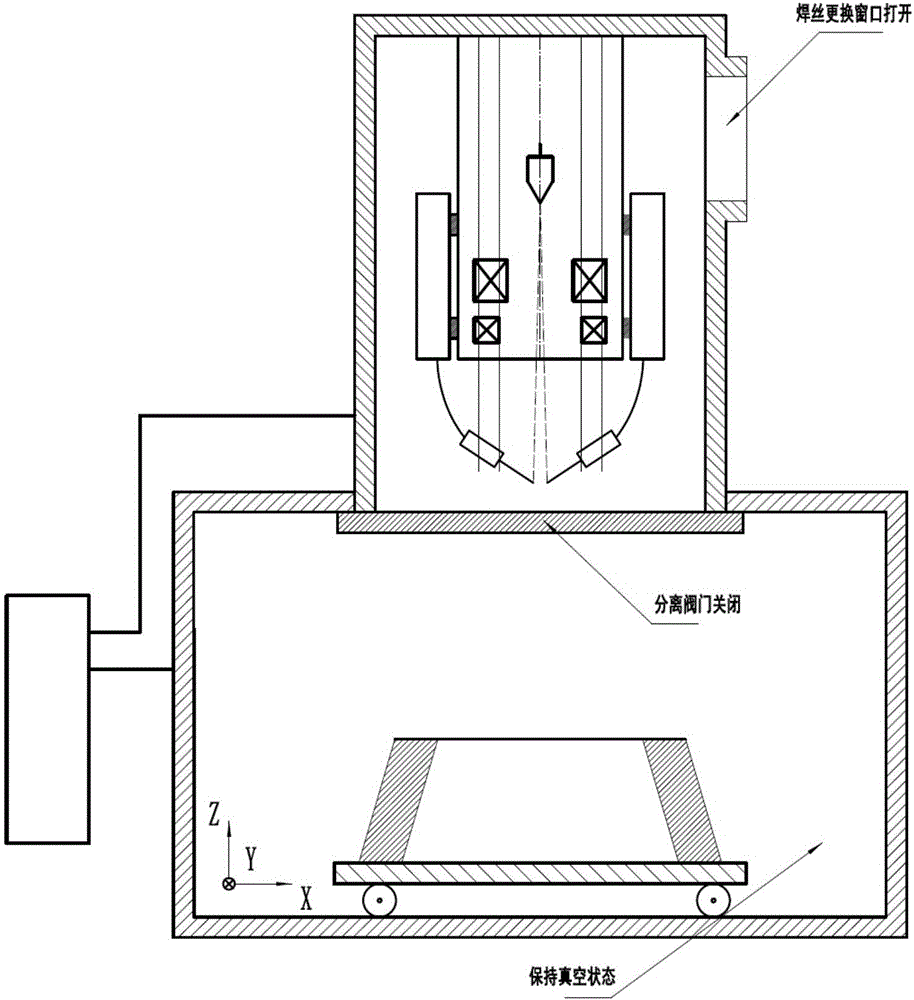

[0024] Such as figure 1 As shown, the electron beam fuse additive manufacturing device provided by the embodiment of the present invention includes: a vacuum forming chamber 1, a part carrying platform 2, a wire feed gun 4, a wire feed reel 5, a vacuum pipeline 6, a vacuum system 7, and a power control system 6. Electron gun 9, electron gun lifting guide rail 10, electron gun vacuum chamber 11, separation valve 12, wire feeding disc circular motion device 13, welding wire replacement window 15. The electron gun 9 includes an electron gun housing 14 .

[0025] The electron gun vacuum chamber 11 is installed on the top outside of the forming vacuum chamber 1 and communicated with the forming vacuum chamber 1 . The part carrying platform 2 is installed inside the vacuum forming chamber 1 and can move precisely in the horizontal direction. The wire feed gun 4 , the wire feed reel 5 , the electron gun 9 , the electron gun elevating rail 10 , and the wire feed reel circular moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com