Powder-feeding type electronic beam additive manufacturing device arranged in front

A technology of additive manufacturing and electron beam, which is applied in the field of front-end powder-feeding electron beam additive manufacturing device, can solve the problem of low powder utilization rate, achieve the effect of improving utilization rate, avoiding waste, and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

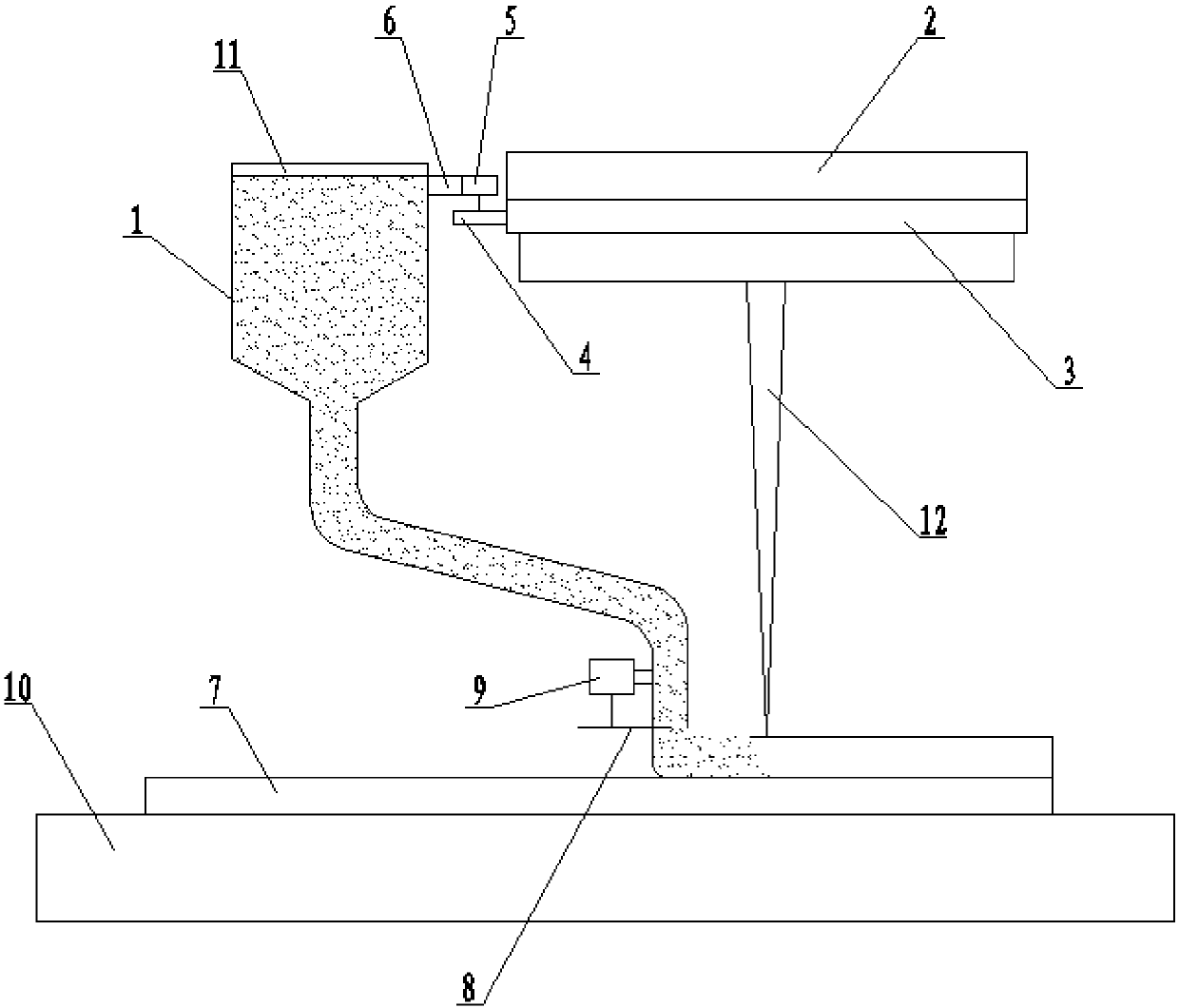

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes funnel 1, electron gun 2, annular fixed gear guide rail 3, rotating gear 4, servo motor 5, servo motor bracket 6, flow adjustment damper 8 and damper adjustment motor 9, annular fixed gear guide rail 3 is fixedly installed on the shell of the electron gun 2, the rotating gear 4 meshes with the annular fixed gear guide rail 3, the rotating gear 4 is fixed on the output shaft of the servo motor 5, and the servo motor 5 is fixed to the shell of the funnel 1 through the servo motor bracket 6 Then, the outlet of the funnel 1 is vertically facing the upper surface of the substrate 10, the flow regulating flap 8 is arranged at the outlet position of the funnel 1, the flow regulating flap 8 is fixed on the output end of the flap adjusting motor 9, and the flap adjusting motor The shell of 9 is fixedly connected with the lower end outer wall of funnel 1.

[0012] The servo moto...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, in this embodiment, the cross-sectional shape of the lower mouth of the funnel 1 is square or circular. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment is that the shutter adjusting motor 9 is a stepper motor or a servo motor. Such setting can ensure that the position of the shutter can be accurately controlled under the action of the shutter adjusting motor 9, and the shutter adjusting motor 9 must have sufficient torque to ensure that the position of the shutter is not affected by the powder flow. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com