Shipboard aircraft oil wedge two-stage type catapult

A two-stage, catapult technology, applied in the direction of launching/dragging transmissions, etc., can solve the problems of large space occupation, troublesome cooling equipment, waste of fresh water, etc., and achieve the effect of convenient maintenance, small space occupation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

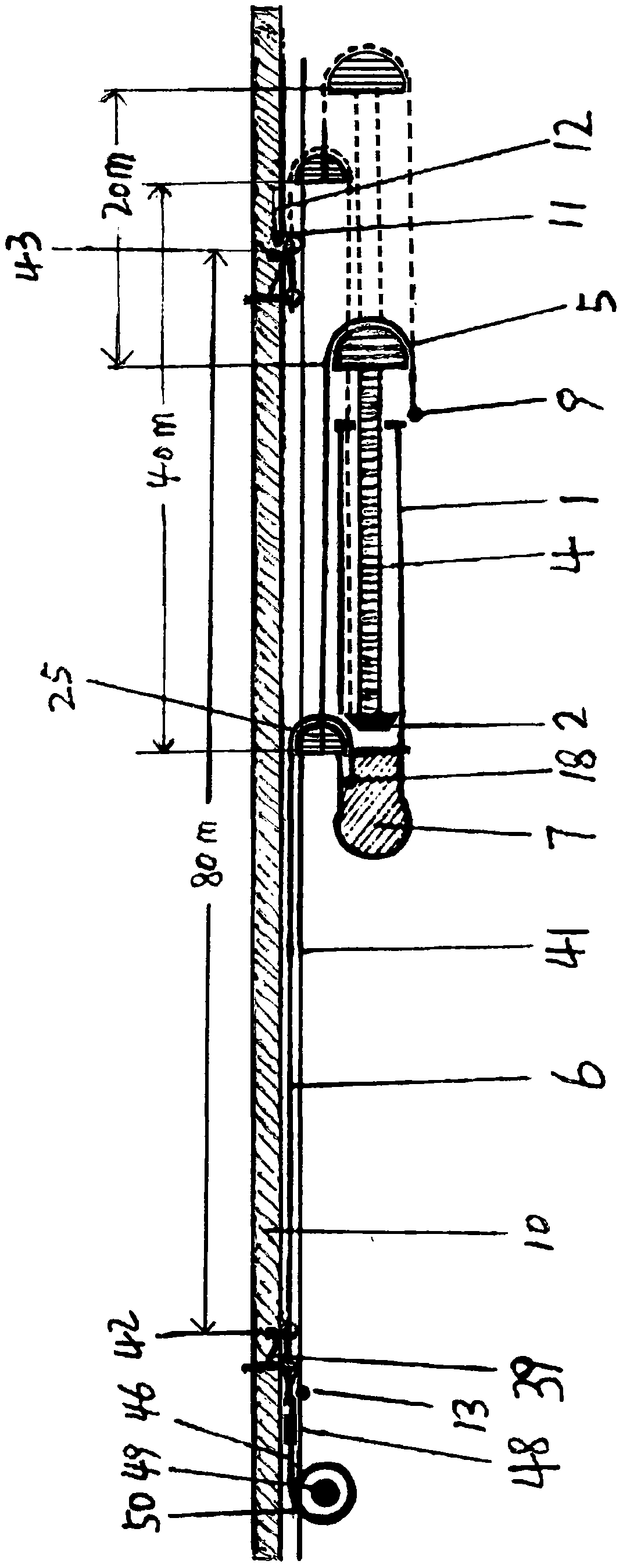

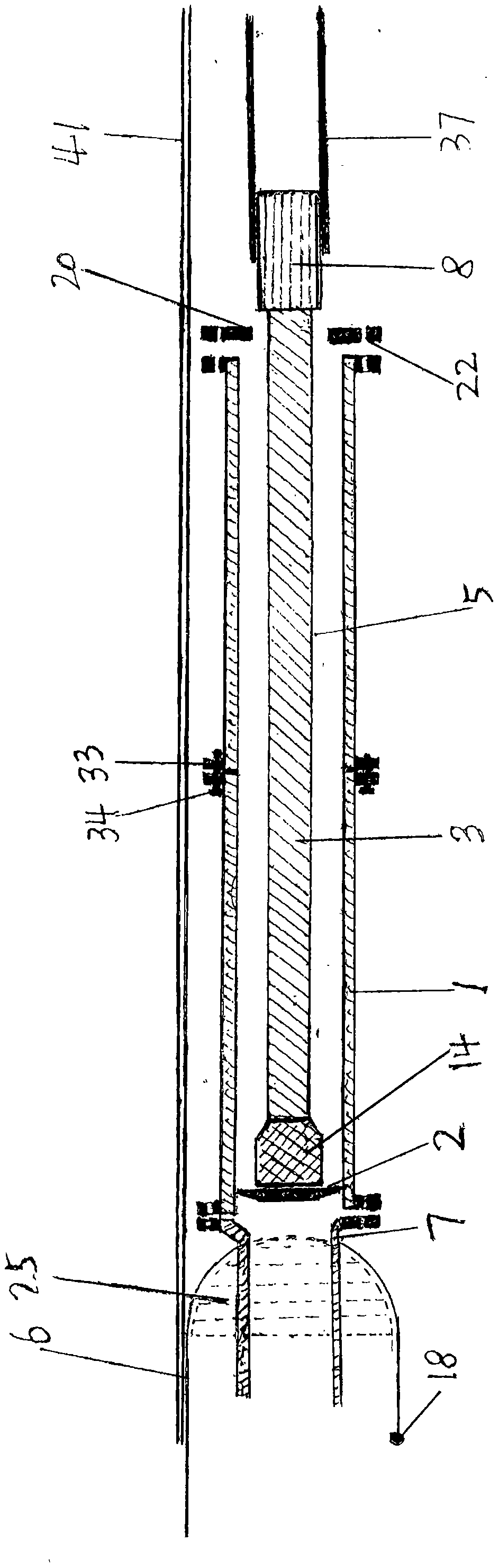

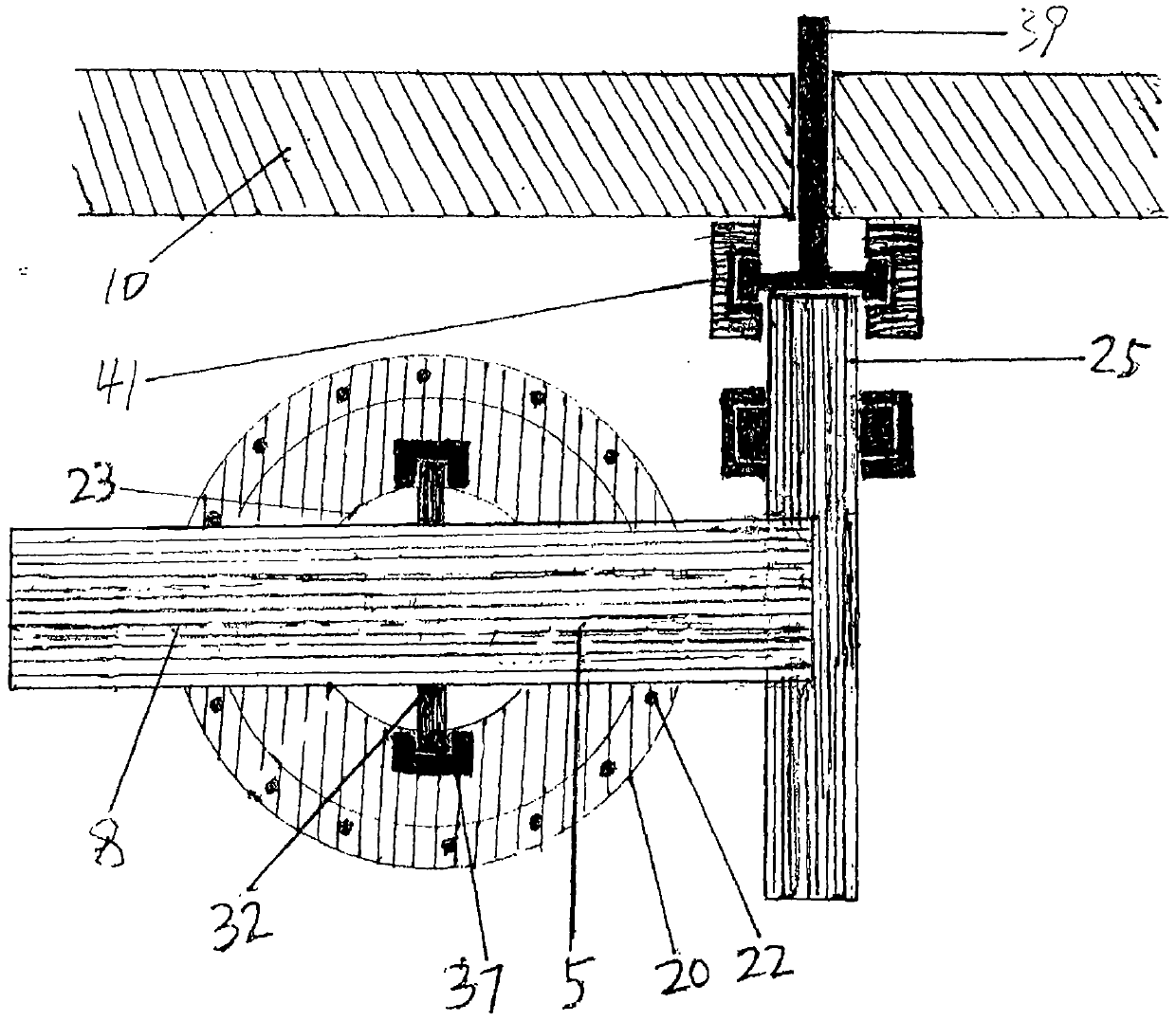

[0031] Look Figure 6 , Figure 7 , a section of oil wedge slider (8) semicircular body is designed as a steel frame structure according to mechanical design, and the compressive capacity can reach the safety factor requirement, and the quality should be reduced as much as possible. Make a lubricating oil pot (30) in the empty space of the frame, and the arc surface of a section of oil wedge slider (8) should be smooth, and the sealing of the lubricating oil groove (29), the oil wedge groove (27) and the edge should be done well on the arc surface Along (26), lubricating oil pot (30) is communicated with lubricating oil tank (29) with fine oil pipe (28). One section of oil wedge slide block (8) rear side stress surface (45) is connected with force bar (3). A section of oil wedge slider (8) is installed on both sides with steel belt stoppers (31) to prevent the steel belt (4) from shifting, and the two sides of an section of oil wedge slider (8) are properly positioned as par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com