Two-stage type pulley block catapult of carrier-based aircraft

A carrier-based aircraft, two-stage technology, applied in the direction of launch / tow transmission, etc., can solve the problems of wasting fresh water, occupying a large space, and troublesome cooling equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

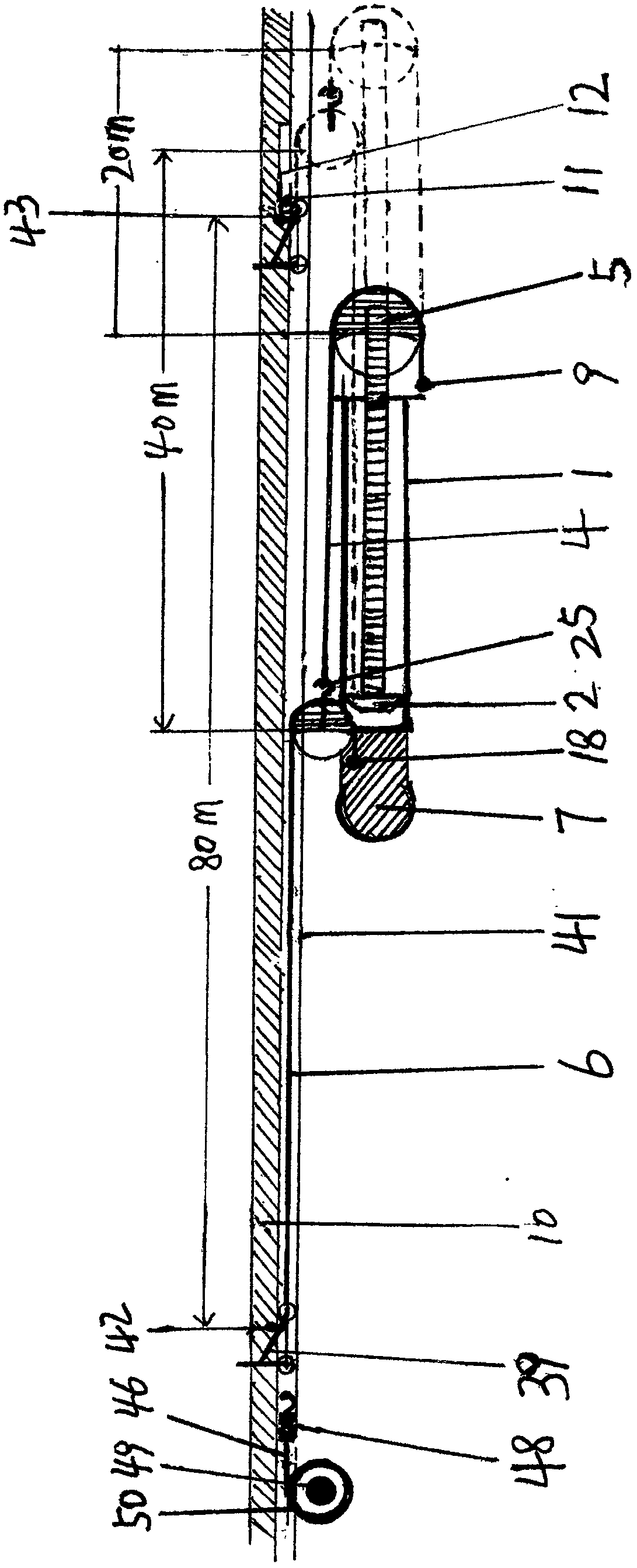

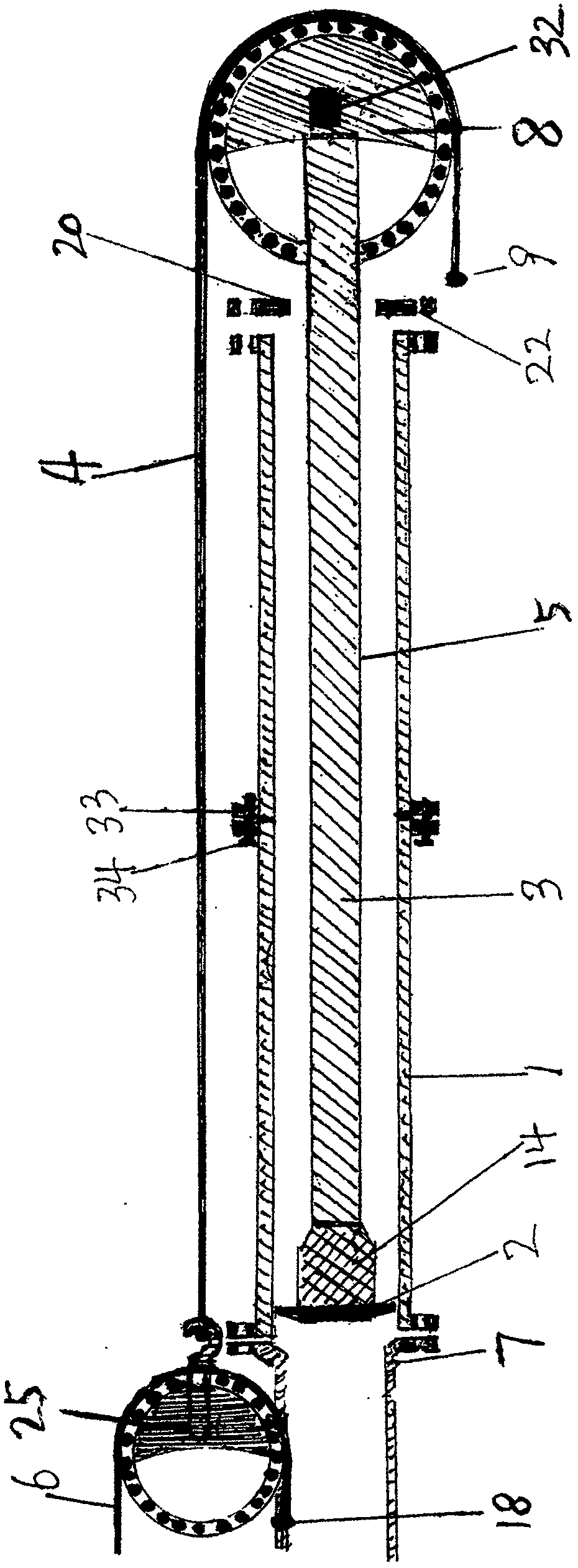

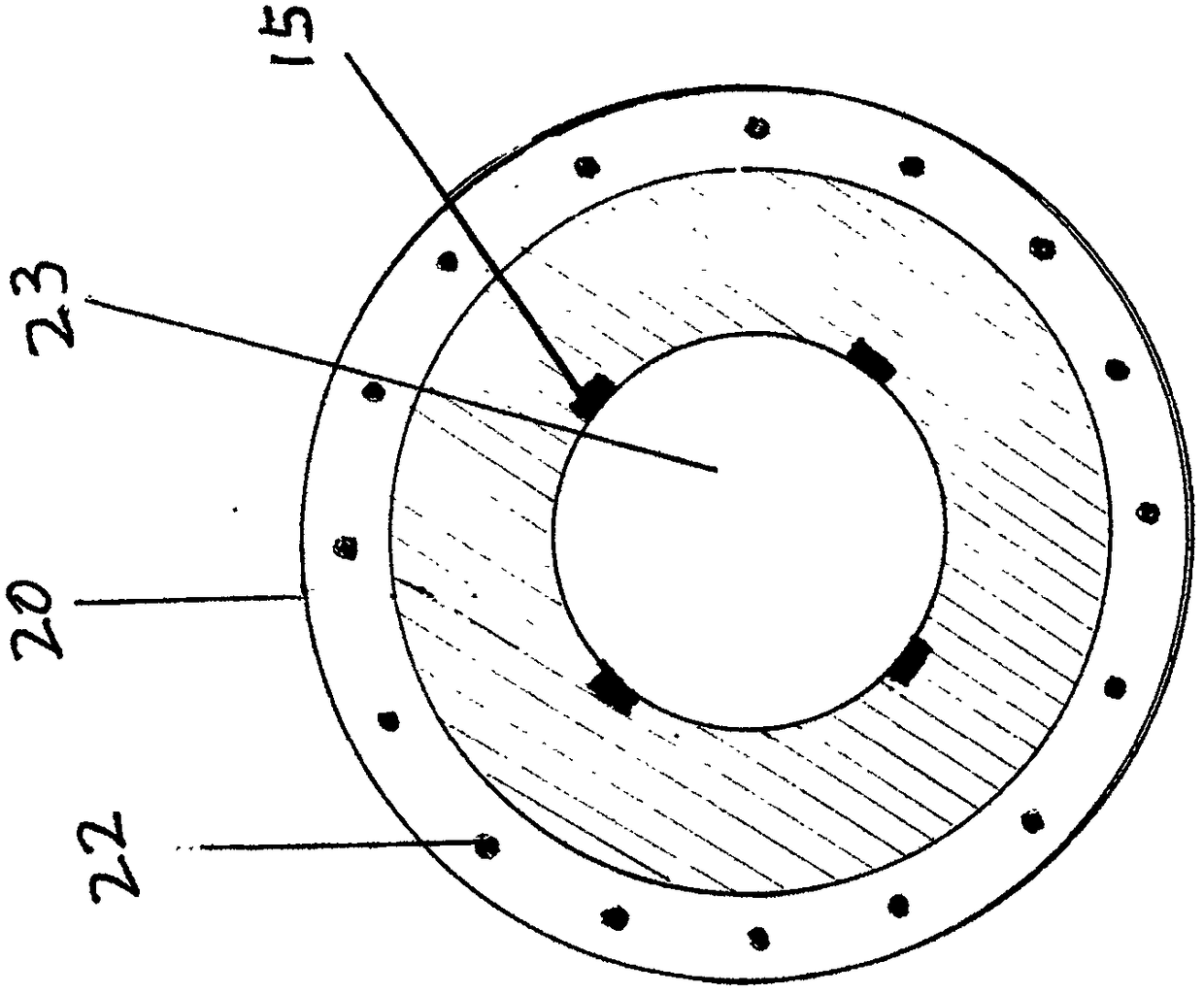

[0021] Look Figure 5 Eccentric outer ring type pulley (5) has pulley body (28), ball (29), pulley outer ring (27), pulley inner ring (30) is formed, pulley space (45) is done according to the figure, pulley body (28) Two prominent parallel slide blocks (32) are to be done on both sides. The diameter of the eccentric outer ring type pulley (8): one section pulley (5) diameter 220cm, and the second section pulley (25) diameter about 160cm is more appropriate. Rope is steel wire rope, and one section rope (4) rope diameter 140mm, about two sections rope (6) rope diameter 100mm, the design pulley diameter is less, and the rope service life will shorten to some extent. Wire ropes for other engineering purposes can be used tens of thousands of times, and hundreds of thousands of times can be used repeatedly on the pulley. The frequency of the carrier-based aircraft will not be so frequent every day, and the replacement period of the rope should be more than one year. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com