Tire dust removing used for new energy automobile

A technology of new energy vehicles and cleaning devices, applied in the direction of cleaning methods using gas flow, combined devices, cleaning methods and appliances, etc., which can solve problems such as economic losses, large stains on placement time, and affecting the health of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

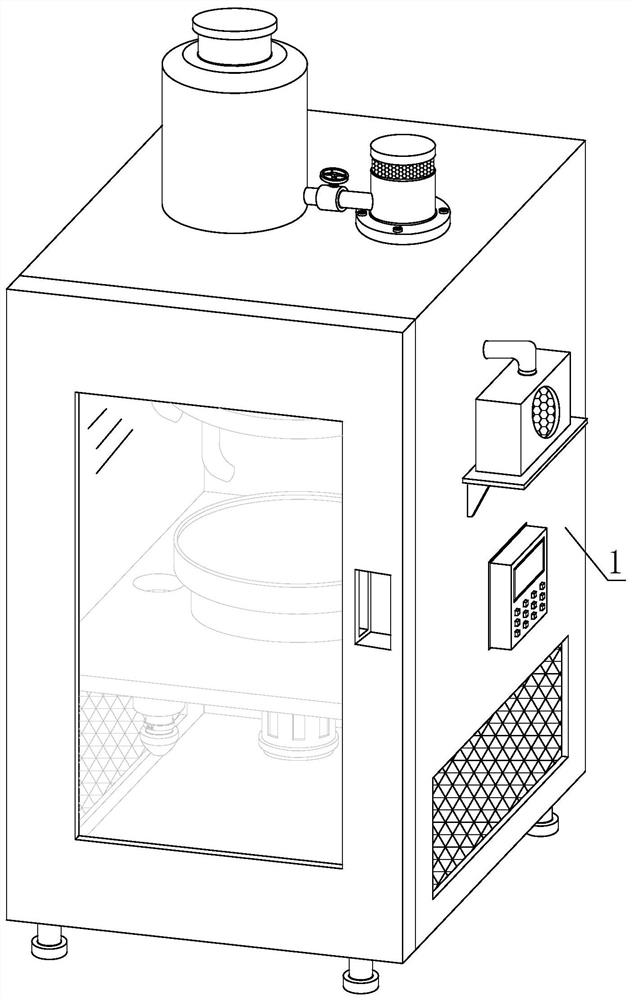

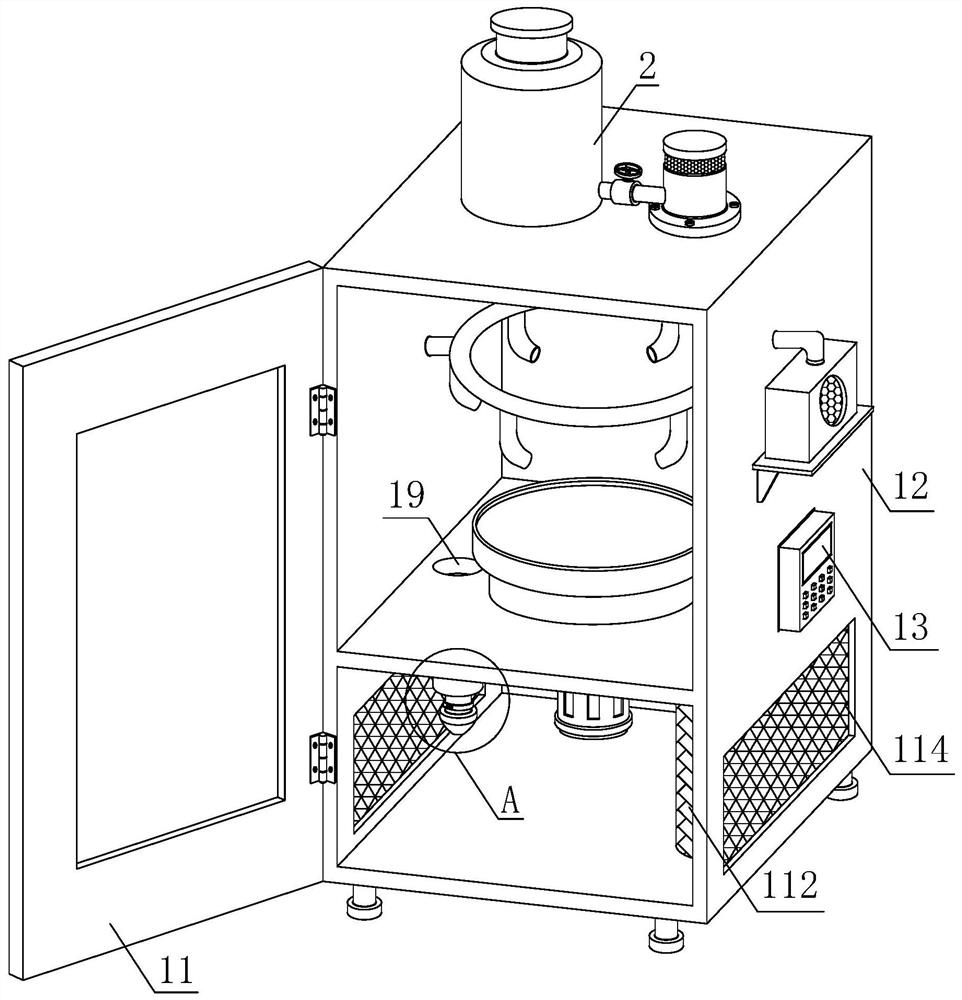

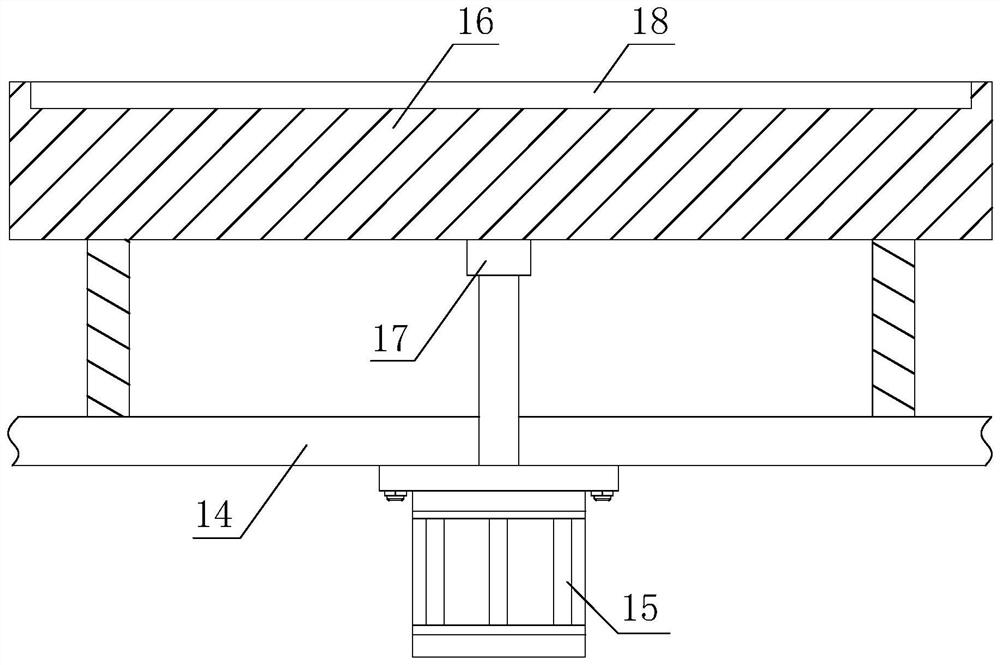

[0031] see Figure 1-3 , a tire cleaning device for new energy vehicles, comprising a cleaning box 1 and a soot blowing device 2, the soot blowing device 2 is arranged in the inner cavity of the cleaning box 1, and the cleaning box 1 includes a door panel 11, a box body 12, a controller 13. Partition plate 14, drive motor 15, storage table 16, fixed sleeve 17 and storage shallow groove 18, one side outer wall of door panel 11 is fixedly connected with the side outer wall of box body 12 port through hinge, and box body 12 A controller 13 is arranged on one side of the outer wall, and the partition 14 is installed between the inner walls of both sides of the box body 12, and the partition 14 and the box body 12 are in an integrated structure, and the bottom of the partition 14 is installed with a drive Motor 15, the drive shaft of drive motor 15 runs through the partition 14 and extends upwards, and the end extends to the inside of the cavity at the bottom of the storage table 1...

Embodiment 2

[0033] see figure 2 , Figure 4 and Figure 5, a tire cleaning device for new energy vehicles, the upper ends of the partitions 14 on both sides of the storage table 16 are respectively provided with ash discharge ports 19, and the outer walls of the partitions 14 at the lower ends of the ash discharge ports 19 are respectively provided with ash discharge pipes 110 , the bottom of the ash discharge pipe 110 is respectively provided with an integrated nozzle 111, the outer wall of the nozzle 111 is sleeved with a filter bag 112, the nozzle 111 is a top-thin and bottom-thick gyro-shaped structure, and the filter bag 112 passes through the elastic belt provided at the port 1121 is socketed and bound on the outer wall of the thin tube of the nozzle 111, and the outer wall of the port of the filter bag 112 is also provided with a hoop mechanism 113 for fixing, and the ash cleaning airflow drives the dust through the ash discharge port 19 and the ash discharge port while blowing t...

Embodiment 3

[0035] see Figure 6-7 , a tire cleaning device for new energy vehicles, the hoop mechanism 113 includes a left half ring 1131, a right half ring 1132, a movable link 1133, a fixed shaft 1134, a swivel ring 1135 and a limit rod 1136, the left half One end of the ring 1131 and the right half ring 1132 is fixedly connected by a movable connector 1133, and a fixed shaft 1134 is fixedly connected to the outer wall of the port at the other end of the left half ring 1131, and a swivel ring 1135 is sleeved on the outer wall of the fixed shaft 1134, and One end of the stop bar 1136 is fixedly connected to one side of the swivel 1135; the outer wall of the port at the other end of the right half ring 1132 is provided with a U-shaped clip 1137, and one end of the U-shaped clip 1137 has a telescopic structure. And on the outer wall of the right half ring 1132 ports corresponding to the end of the other end leg end, limit hole 1138 is offered. The piece 1137 cooperates with the limit hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com