Method for extraction of deep-seated intercrystalline bittern of salt lake mining area

A kind of brine and intercrystalline technology, applied in the direction of alkali metal chloride, etc., can solve the problems of insoluble extraction of solid potassium chloride, decline of brine water level in mining areas, depletion of high-grade solid potassium resources, etc., to achieve outstanding comprehensive utilization and saving Fresh water, the effect of increasing the dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

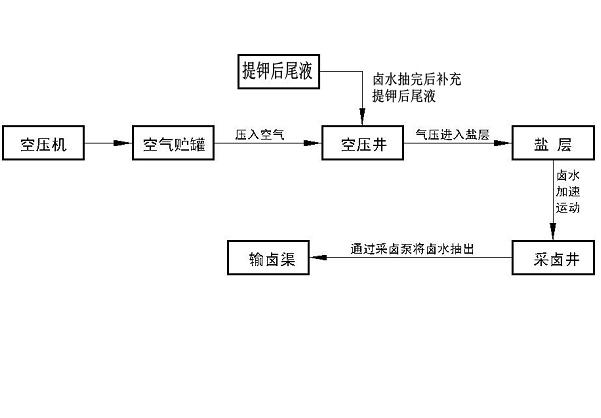

[0027] like image 3 Shown, a kind of method for extracting the deep layer intergranular brine of salt lake mining area, comprises the following steps:

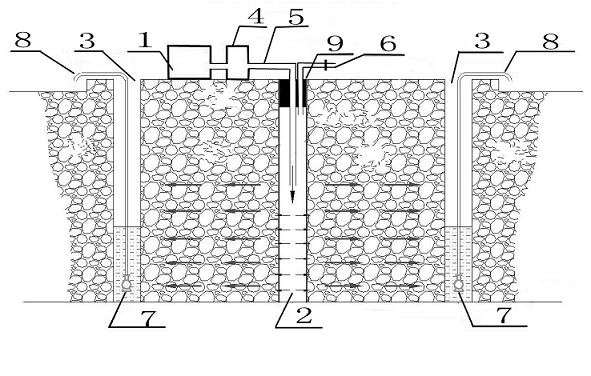

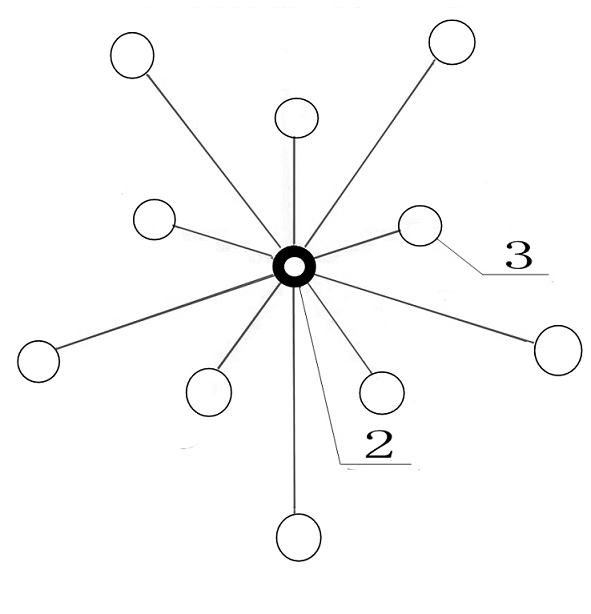

[0028] (1) Excavate a gas injection well 2, a brine extraction well 3 and a brine transport channel on the salt lake mine layer, and install an air compressor 1 on the salt lake mine layer; a brine tail liquid injection pipeline 6 is arranged in the gas injection well 2, and brine extraction pipes are evenly distributed around it. Well 3, a brine delivery pipeline 8 is arranged in each brine extraction well 3; a brine extraction pump 7 is placed in each brine extraction well 3, and the brine extraction pump 7 is connected with one end of the brine delivery pipeline 8; the brine delivery pipeline 8 The other end is connected to the brine channel (see figure 1 ).

[0029] Wherein: the air compressor 1 is arranged on the salt lake mine layer between the gas injection well 2 and the brine extraction well 3 .

[0030] The depth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com