Softened water treatment system and method

A treatment system, a technology for softening water, applied in ion exchange water/sewage treatment, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of increasing reliability and safety, waste of fresh water, etc. The effect of safety, saving fresh water and water, reducing production cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

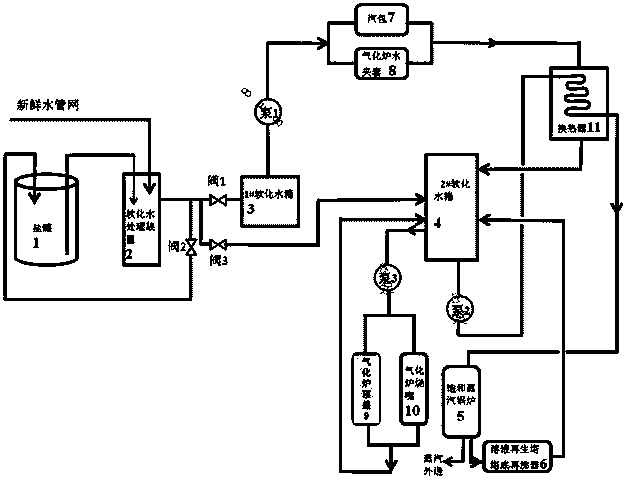

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A softened water treatment system, including salt tank 1, softened water treatment device 2, 1# softened water tank and 2# softened water tank, heat exchanger 11, steam boiler 5, external cooling device (steam drum 7, gasifier water Jacket 8, gasifier top cover 9, gasifier burner 10) and external heating device (solution regeneration tower bottom reboiler 6). The softened water treatment device is connected to the salt tank through valve 2, and the softened water treatment device is connected to 1# softened water tank and 2# softened water tank through valve 1 and valve 3 respectively.

[0022] One or more softened water tanks send softened water to the cooling device through one or more pumps, and the softened water heated by the cooling device enters one or more softened water tanks, or enters one or more cooling devices after passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com