Sewage treating method for chitin production process

A sewage treatment method and production process technology, which can be used in neutralization water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of pollution and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

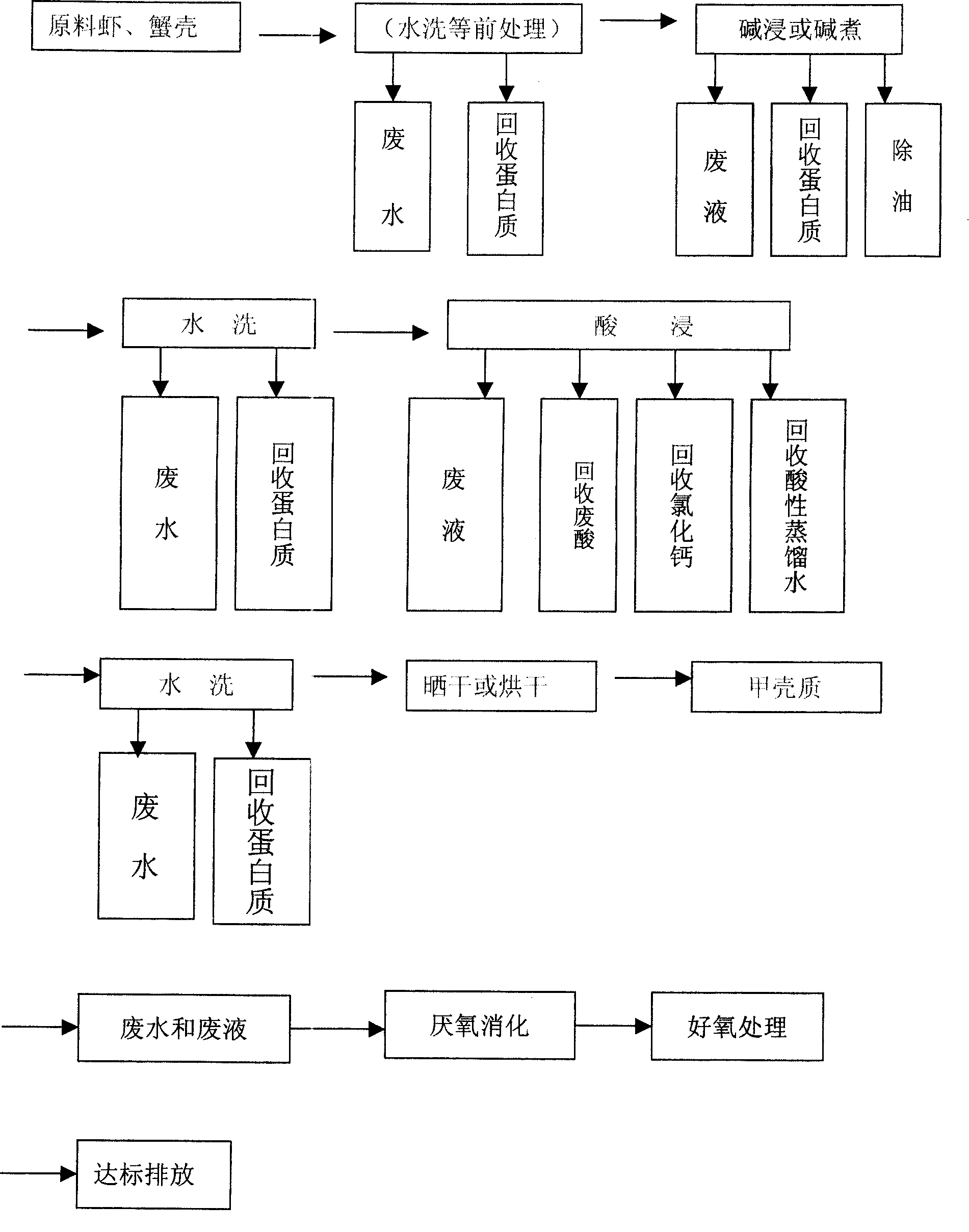

Method used

Image

Examples

Embodiment 1

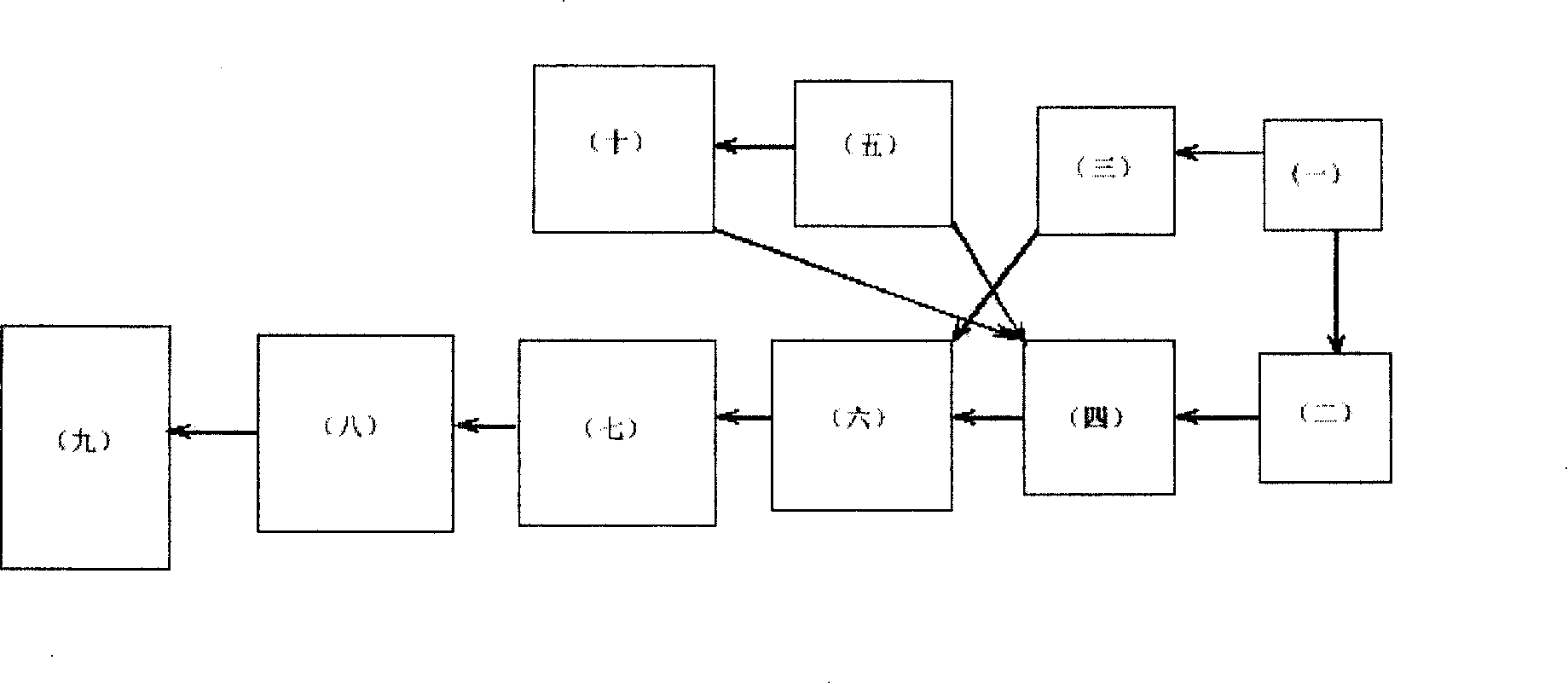

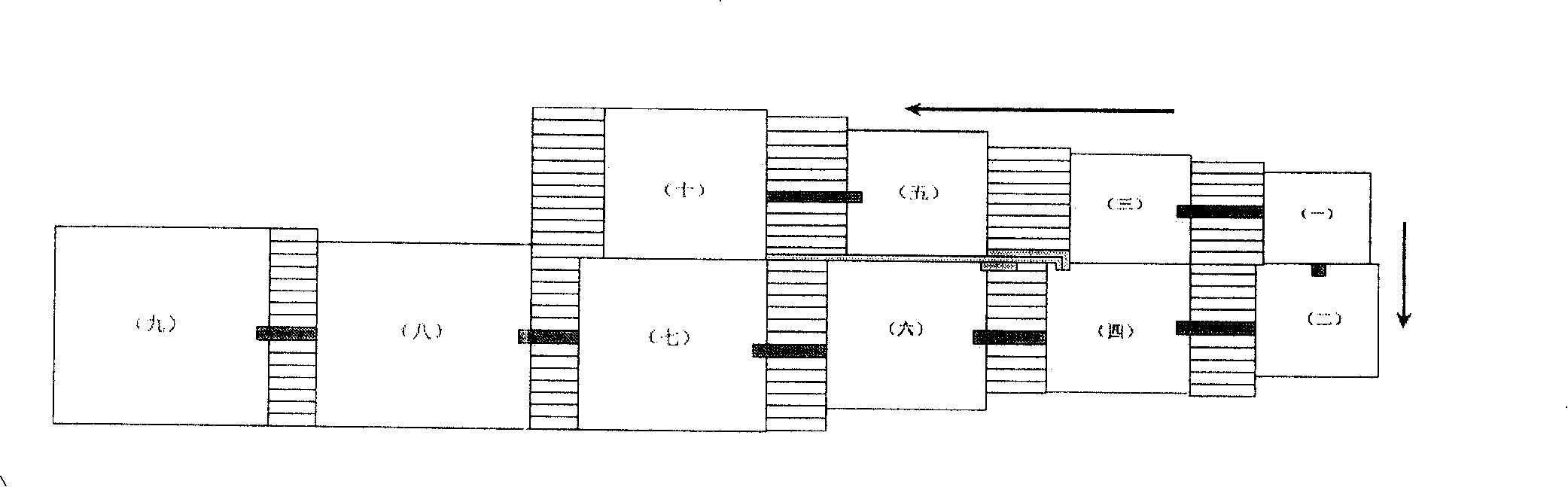

[0022] Embodiment 1: a kind of sewage treatment method in the production process of chitin, comprising the following steps: the raw material shrimp shells are extruded and washed with comprehensive wastewater in the comprehensive wastewater regulating tank, and the raw material shrimp shells after washing are drained in alkali Boil with 8% sodium hydroxide solution in the boiling pool for 2 hours, separate the shell from the alkaline waste liquid, drain, introduce the alkaline waste liquid into the alkali treatment waste liquid storage tank, and use the acidic waste liquid in the alkali treatment waste liquid storage tank Adjust the pH value of the alkali boiling waste liquid to the isoelectric point, after recovering the protein and oil separation treatment, the clear liquid is introduced into the washing tank of the alkali treatment shell, and the alkali boiling shell is washed two to three times in the washing tank of the alkali treatment shell (the acid washing water is not ...

Embodiment 2

[0023] Embodiment 2: a sewage treatment method in the production process of chitin, comprising the following steps: soak the raw shrimp shells in an alkali immersion tank with 8% sodium hydroxide solution for 2 days, separate the shells from the alkaline waste liquid, and The alkaline waste liquid is introduced into the alkali treatment waste liquid storage tank, and the acidic solution is used to neutralize the alkaline immersion waste liquid in the alkali treatment waste liquid storage tank to the isoelectric point. After the oil separation treatment, the clear liquid is introduced into the alkali treatment shell water washing tank, After the treated clear liquid and acidic shell washing water wash the shell after alkali treatment for two to three times (when the washing water is not enough, it can be washed with tap water), then introduce the alkaline washing wastewater into the comprehensive wastewater regulating tank, and use flocculant in the comprehensive wastewater regul...

Embodiment 3

[0024]Embodiment 3: a kind of sewage treatment method in chitin production process, comprises the following steps: the raw material shrimp shell is soaked with 10% sodium hydroxide solution for 2 days in the alkaline immersion pool, the shell is separated from the alkaline waste liquid, and The alkaline waste liquid is introduced into the alkali treatment waste liquid storage tank, and the alkaline leaching waste liquid is neutralized with an acidic solution in the alkali treatment waste liquid storage tank to the isoelectric point, and then introduced into the alkali treatment shell washing pool after oil separation treatment, and the acidic wastewater is used for alkali leaching shell After washing two to three times, the washing water is precipitated with a flocculant to recover protein, and then the treated wastewater is introduced into the comprehensive wastewater tank adjustment tank; the cleaned alkali-treated shell is drained and then used in the acid leaching tank with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com