Method for preparing potassic-magnesian fertilizer

A technology of potassium magnesium fertilizer and potassium chloride, which is applied in the field of utilization of salt lake resources, can solve the problems of idle waste of resources, high production costs, and long time consumption, and achieve the effects of reducing economic costs, shortening production cycles, and saving fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

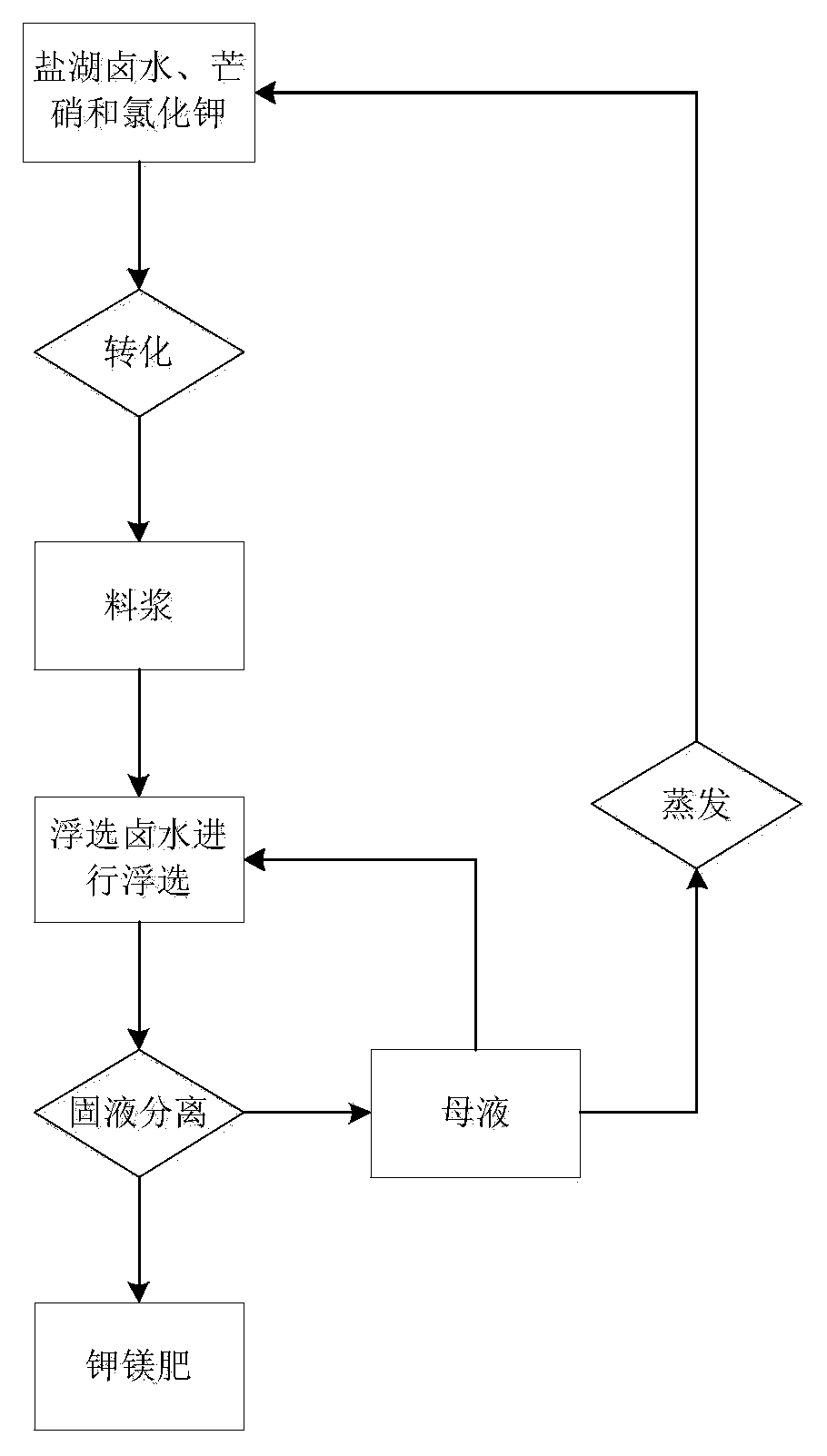

[0029] Such as figure 2 Shown, a kind of preparation method of potassium magnesium fertilizer, described method comprises the following steps:

[0030] 1) Mix potassium chloride, Glauber's salt and high-magnesium salt lake brine at a mass ratio of 1-2:1-2:5-15, stir and react at room temperature for 0.5-1.5 hours, and control the stirring rate at 350-400r / min, Fully react and convert raw materials to obtain slurry;

[0031] 2) Add the slurry obtained in step 1) into the flotation brine according to the mass ratio of 1:4 to 6, then add the flotation agent, and use two fine and one sweep flotation separation to obtain high-grade potassium magnesium fertilizer and mother liquor;

[0032] 3) The mother liquor is returned to the salt field after being evaporated and then used as high-magnesium salt lake brine to react with Glauber's salt and potassium chloride, or the mother liquor is directly used as flotation brine for flotation separation;

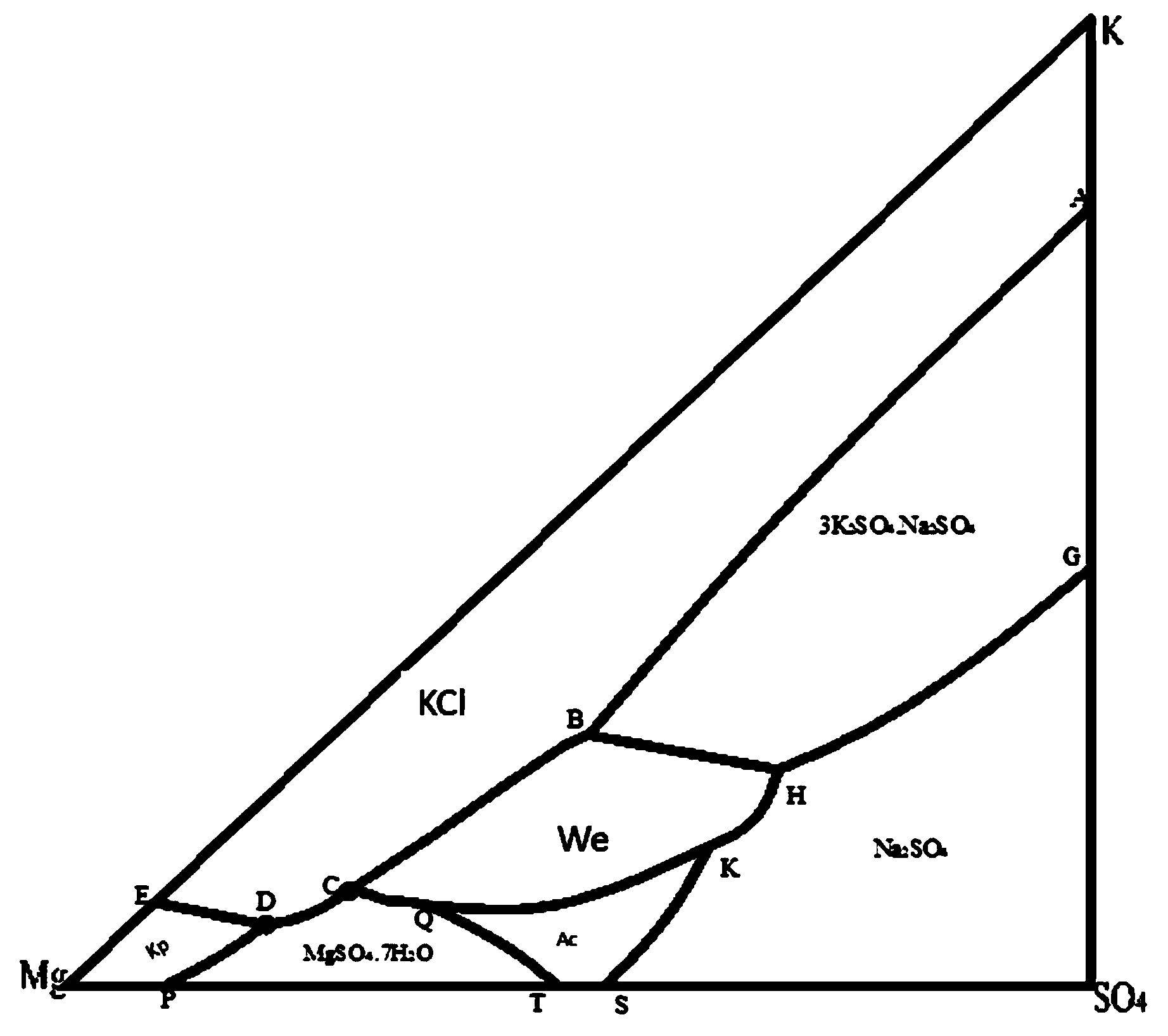

[0033] Wherein, the composition of...

Embodiment 1

[0035] Potassium chloride, Glauber's salt and high-magnesium salt lake brine (composed of: 1.5-2.1% K + , 6.5-8.5% of Mg 2+ , 18.0~22.0% Cl - , 4.0-5.2% SO 4 2- , 0.5~1.0% Na + , 66.0-69.5% H 2 O) fully mix according to the ratio of mass ratio 1:2:5, the stirring speed is controlled at 350r / min, and the stirring reaction at room temperature is 30min to obtain the slurry, and the slurry and flotation brine are mixed evenly according to the mass ratio of 1:4, using two Fine sweeping process, flotation separation, to obtain high-grade potassium magnesium fertilizer and mother liquor.

[0036] Among them, in potassium and magnesium fertilizers: K + : 17.5%, Mg 2+ : 5.56%. Potassium recovery rate is 90%.

Embodiment 2

[0038]Potassium chloride, Glauber's salt and high-magnesium salt lake brine (composed of: 1.5-2.1% K + , 6.5-8.5% of Mg 2+ , 18.0~22.0% Cl - , 4.0-5.2% SO 4 2- , 0.5~1.0% Na + , 66.0-69.5% H 2 O) fully mix according to the ratio of mass ratio 1:2:10, the stirring rate is controlled at 400r / min, and the stirring reaction at room temperature is 60min to obtain the slurry, and the slurry and the flotation brine (the mother liquor obtained in Example 1) are mixed according to the mass ratio of 1 :5 Mix evenly, adopt two-finishing and one-sweeping process, flotation separation, and obtain high-grade potassium and magnesium fertilizer and mother liquor.

[0039] Among them, in potassium and magnesium fertilizers: K + : 18.5%, Mg 2+ : 5.25%. Potassium recovery rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com