Magnesium hydroxide washing water recovery technology

A technology of magnesium hydroxide and washing water, which is applied in the fields of magnesium hydroxide, chemical industry, alkali metal chloride, etc., can solve the problems of blank recycling of magnesium hydroxide washing water, low product quality, and low technical level, and achieve the realization of Economic and environmental win-win, lower production costs, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

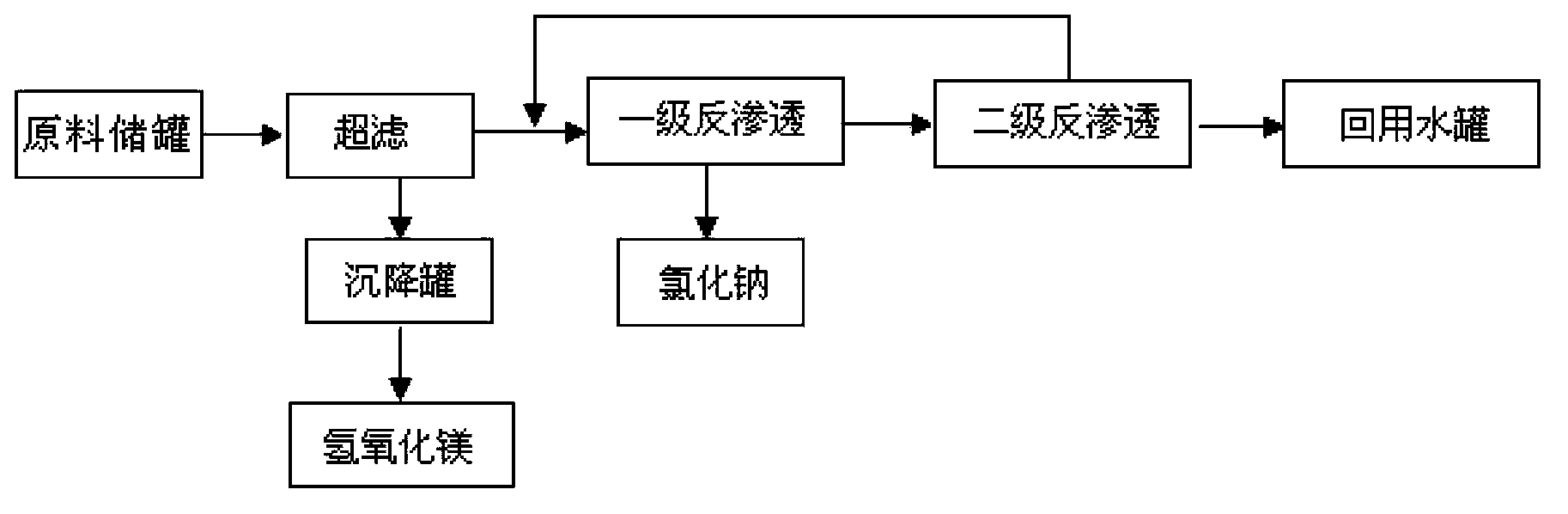

[0059] A kind of magnesium hydroxide washing water recovery process, such as figure 1 As shown, the process includes the following steps:

[0060] (1) feed the magnesium hydroxide washing water into the raw material storage tank, add lye to adjust the pH value in the raw material storage tank, so that the magnesium hydroxide washing water produces magnesium hydroxide colloid;

[0061] (2) The magnesium hydroxide washing water flowing out from the raw material storage tank is filtered through the ultra / microfiltration unit, the magnesium hydroxide colloid and fine particles are trapped in the ultra / microfiltration unit, and the filtrate containing sodium chloride leaves the ultra / microfiltration unit unit, into the reverse osmosis unit;

[0062] (3) In the reverse osmosis unit, sodium chloride is concentrated and introduced into the sodium chloride concentrate storage tank, and the filtrate passing through the reverse osmosis unit is industrial water.

[0063] Step (1) compri...

Embodiment 2

[0077] A kind of magnesium hydroxide washing water recovery process, such as figure 1 As shown, the process includes the following steps:

[0078] (1) feed the magnesium hydroxide washing water into the raw material storage tank, add lye to adjust the pH value in the raw material storage tank, so that the magnesium hydroxide washing water produces magnesium hydroxide colloid;

[0079] (2) The magnesium hydroxide washing water flowing out from the raw material storage tank is filtered through the ultra / microfiltration unit, the magnesium hydroxide colloid and fine particles are trapped in the ultra / microfiltration unit, and the filtrate containing sodium chloride leaves the ultra / microfiltration unit unit, into the reverse osmosis unit;

[0080](3) In the reverse osmosis unit, sodium chloride is concentrated and introduced into the sodium chloride concentrate storage tank, and the filtrate passing through the reverse osmosis unit is industrial water.

[0081] Step (1) compris...

Embodiment 3

[0089] A kind of magnesium hydroxide washing water recovery process, such as figure 1 As shown, the process includes the following steps:

[0090] (1) feed the magnesium hydroxide washing water into the raw material storage tank, add lye to adjust the pH value in the raw material storage tank, so that the magnesium hydroxide washing water produces magnesium hydroxide colloid;

[0091] (2) The magnesium hydroxide washing water flowing out from the raw material storage tank is filtered through the ultra / microfiltration unit, the magnesium hydroxide colloid and fine particles are trapped in the ultra / microfiltration unit, and the filtrate containing sodium chloride leaves the ultra / microfiltration unit unit, into the reverse osmosis unit;

[0092] (3) In the reverse osmosis unit, sodium chloride is concentrated and introduced into the sodium chloride concentrate storage tank, and the filtrate passing through the reverse osmosis unit is industrial water.

[0093] Step (1) compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com