Flat-plate bleacher

A technology of flat-plate and rinsing machines, applied in the directions of magnetic separation, solid separation, wet separation, etc., which can solve the problems of low iron ore grade, low production efficiency, and low output, and achieve high grade, large production volume, and low cost. The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

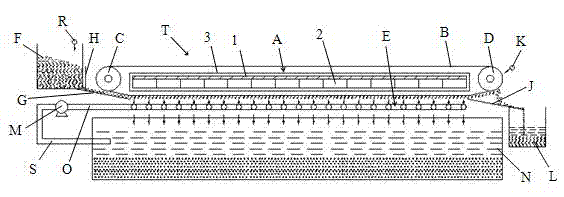

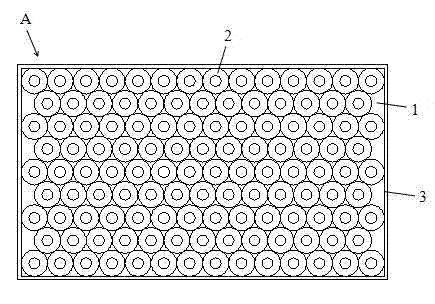

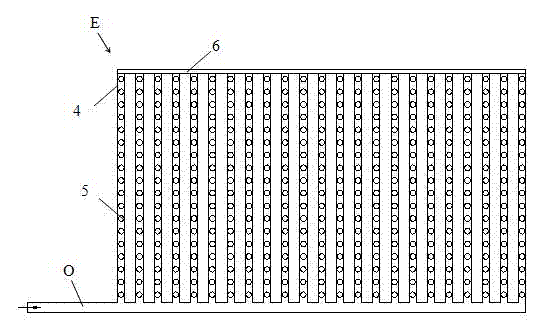

[0011] Such as figure 1 As shown, the flat rinsing machine of the present invention includes a feed hopper F and a transmission mechanism T, the transmission mechanism T is placed along the horizontal direction, and its head and tail ends are provided with non-magnetic transmission drums C and D; the non-magnetic transmission An annular non-porous transmission belt B is set on the periphery of the drums C and D; a flat-plate magnetic field system A is arranged between the annular non-porous transmission belts B; Permanent magnet cylinder 2; the top of the feed hopper F is provided with a water spray pipe R for lubrication and thrust, and the bottom is provided with a feeding guide plate G to facilitate the delivery of magnetic iron ore to the bottom of the endless non-porous transmission belt B, so that The magnetic iron ore is taken away by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com