Preparation method of light-color cold polymerized C9 petroleum resin

A polycarbon nine petroleum and resin technology, applied in the preparation of carbon nine petroleum resin, can solve the problems of inability to obtain high-quality performance resin products, resin hue, poor compatibility, and inability to meet the needs of high-end markets, and achieve post-processing The effect of simple process, good compatibility and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

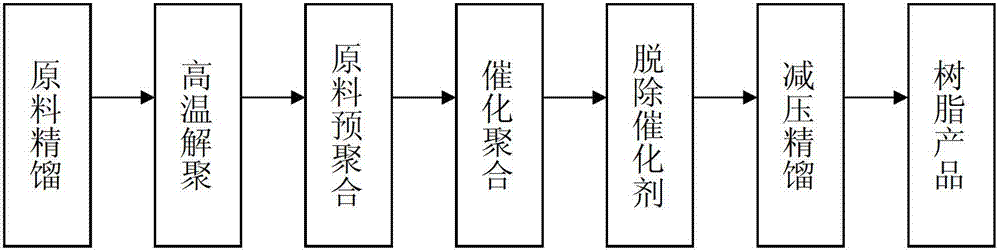

Method used

Image

Examples

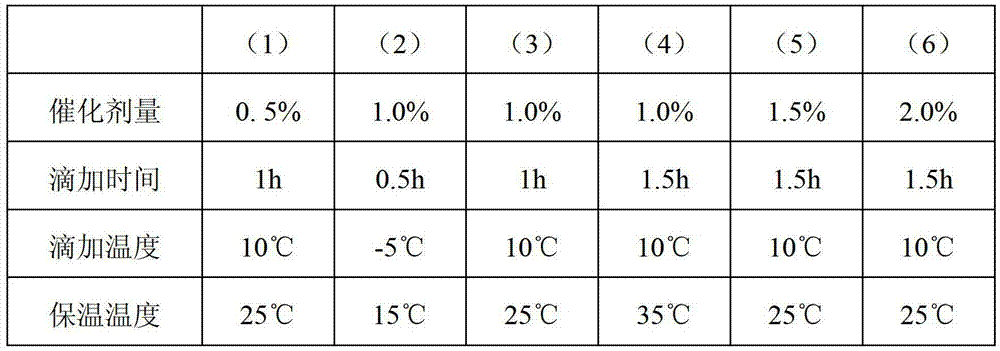

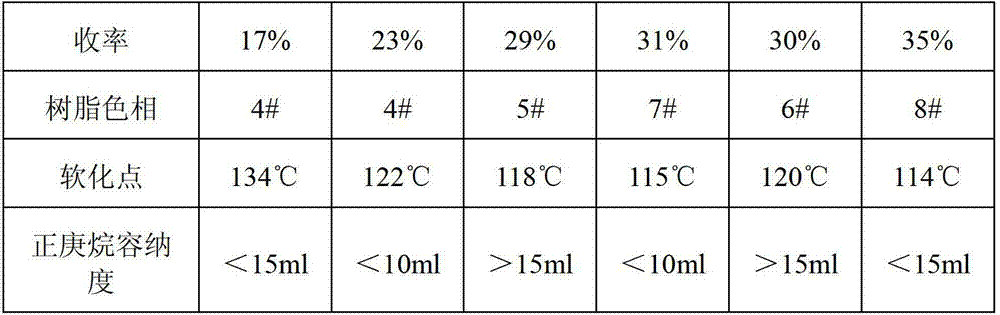

Embodiment 1~6

[0056] Embodiment 1~6 depolymerization technology influences on fraction B

[0057]

[0058] DCPD*: High temperature depolymerization is mainly based on α-DCPD depolymerization, and this depolymerization rate corresponds to α-DCPD.

[0059] Examples 7 to 9 all use fraction C with the same content as the raw material to prepare cold polycarbonate nine resins. The material preparation process is: ethylene cracking fraction C9 is subjected to vacuum rectification at a vacuum degree of -0.085MPa, and the cut-off boiling point is 140-190°C C9 fraction A, wherein, the C9 fraction content is 0.8wt% cyclopentadiene, 5.3wt% styrene, 13.5wt% methylstyrene, 17.9wt% α-dicyclopentadiene, 8.8wt% indene, CPD- MCPD dimer, methylcyclopentadiene dimer (DMCPD) 22.1wt%, naphthalene 2.6wt%, and the rest are C8-C12 hydrocarbons;

[0060] Fraction A contains 0.5wt% cyclopentadiene, 4.2wt% styrene, 15.6wt% methylstyrene, 25.8wt% α-dicyclopentadiene, 15.0wt% indene, CPD-MCPD dimer, methyl Cyclope...

Embodiment 7

[0064] The fraction C obtained from the prepolymerization was mixed with the solvent toluene at a mass ratio of 1:1, and then used as a polymerization raw material, and put into a stirred polymerization reactor, and at -5°C, 1.5wt% of the total material was slowly added dropwise. Boronium diethyl ether catalyst was added dropwise for 1 hour, and then polymerized at 25° C. for 1 hour to obtain a polymerization liquid. Add a calcium hydroxide / methanol mixture 2.5 times the catalyst amount of boron trifluoride ether into the polymerization solution, stir thoroughly for 30 minutes, and then filter to obtain a resin solution. Distill the resin liquid under reduced pressure at -0.085 MPa to 130° C., and remove the solvent to obtain C9 petroleum resin with a softening point of 113° C. and Gardner color number 4#.

Embodiment 8

[0066] The fraction C obtained from the prepolymerization was mixed with the solvent toluene at a mass ratio of 2:1, and then used as a polymerization raw material, and put into a stirred polymerization reactor, and slowly added dropwise at a temperature of 15°C, accounting for 1.0wt% of the total material. The boroether catalyst was added dropwise for 1 hour, and then polymerized at 25° C. for 1 hour to obtain a polymerization solution. Add a calcium hydroxide / methanol mixture 2.5 times the catalyst amount of boron trifluoride ether into the polymerization solution, stir thoroughly for 30 minutes, and then filter to obtain a resin solution. The resin liquid was distilled to 130° C. under reduced pressure at a vacuum degree of -0.09 MPa, and the C9 petroleum resin with a softening point of 122° C. and a Gardner color number of 5# was obtained after the solvent was removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com