Patents

Literature

31results about "Regeneration of sulfite lye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

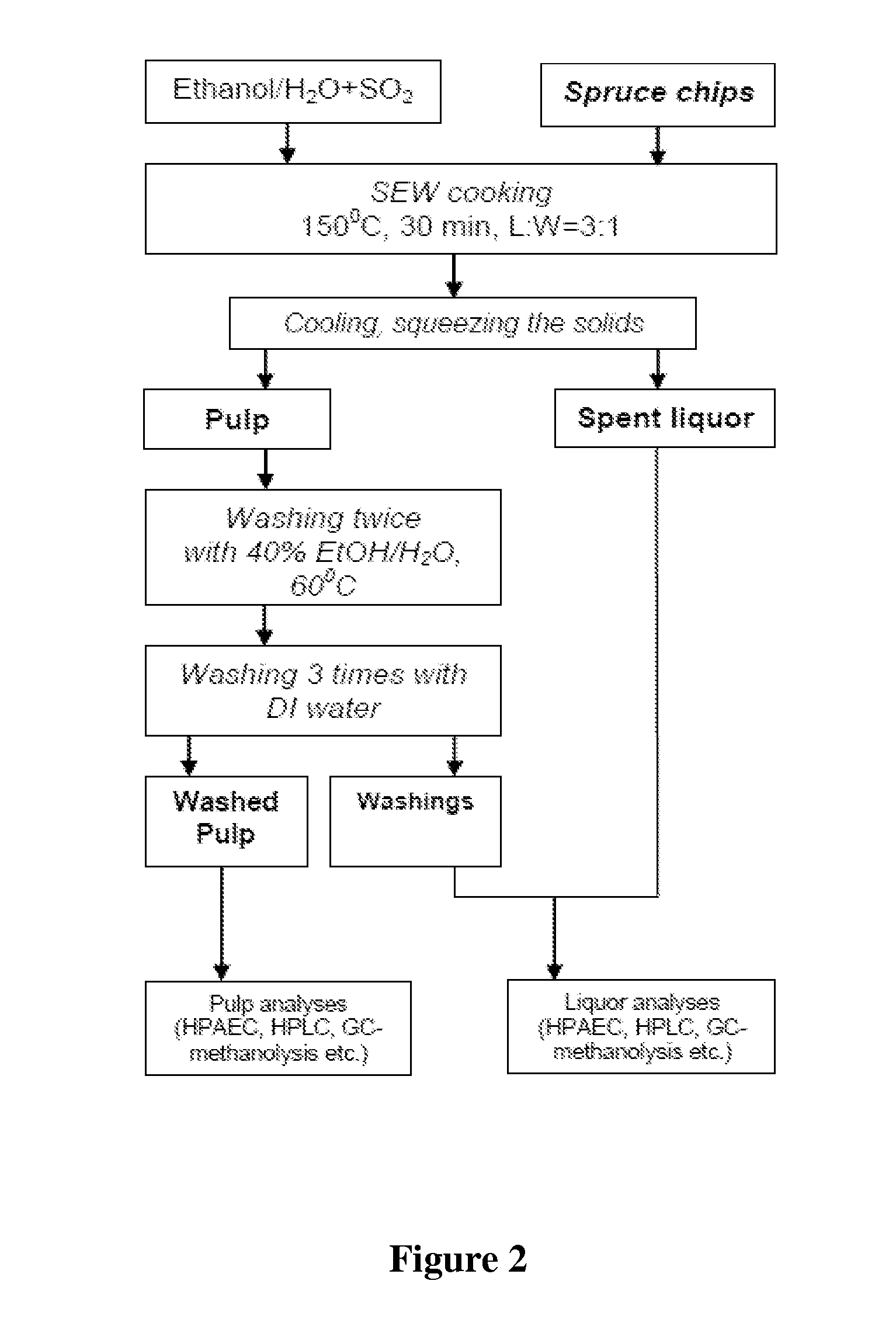

Separation of lignin from hydrolyzate

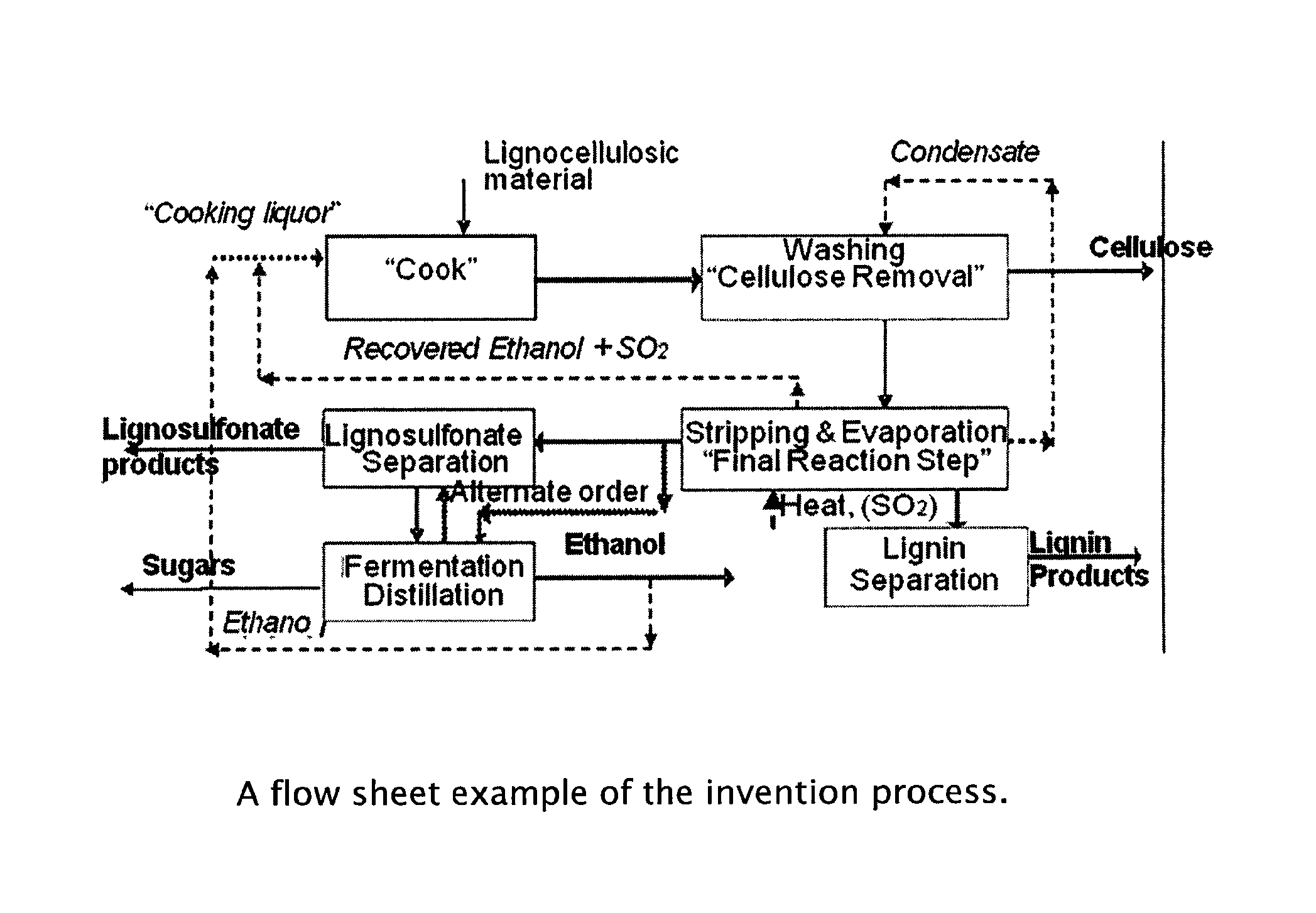

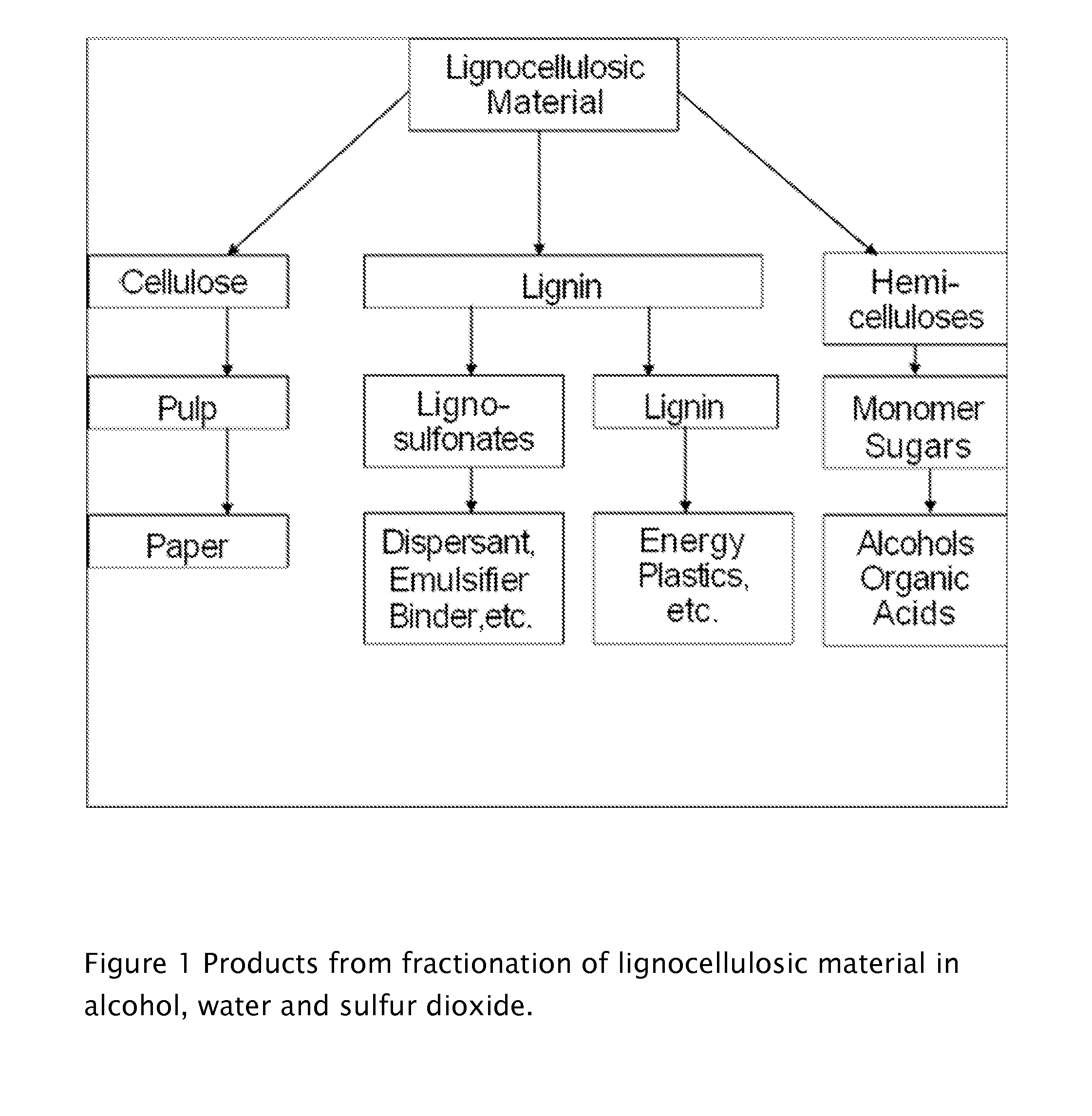

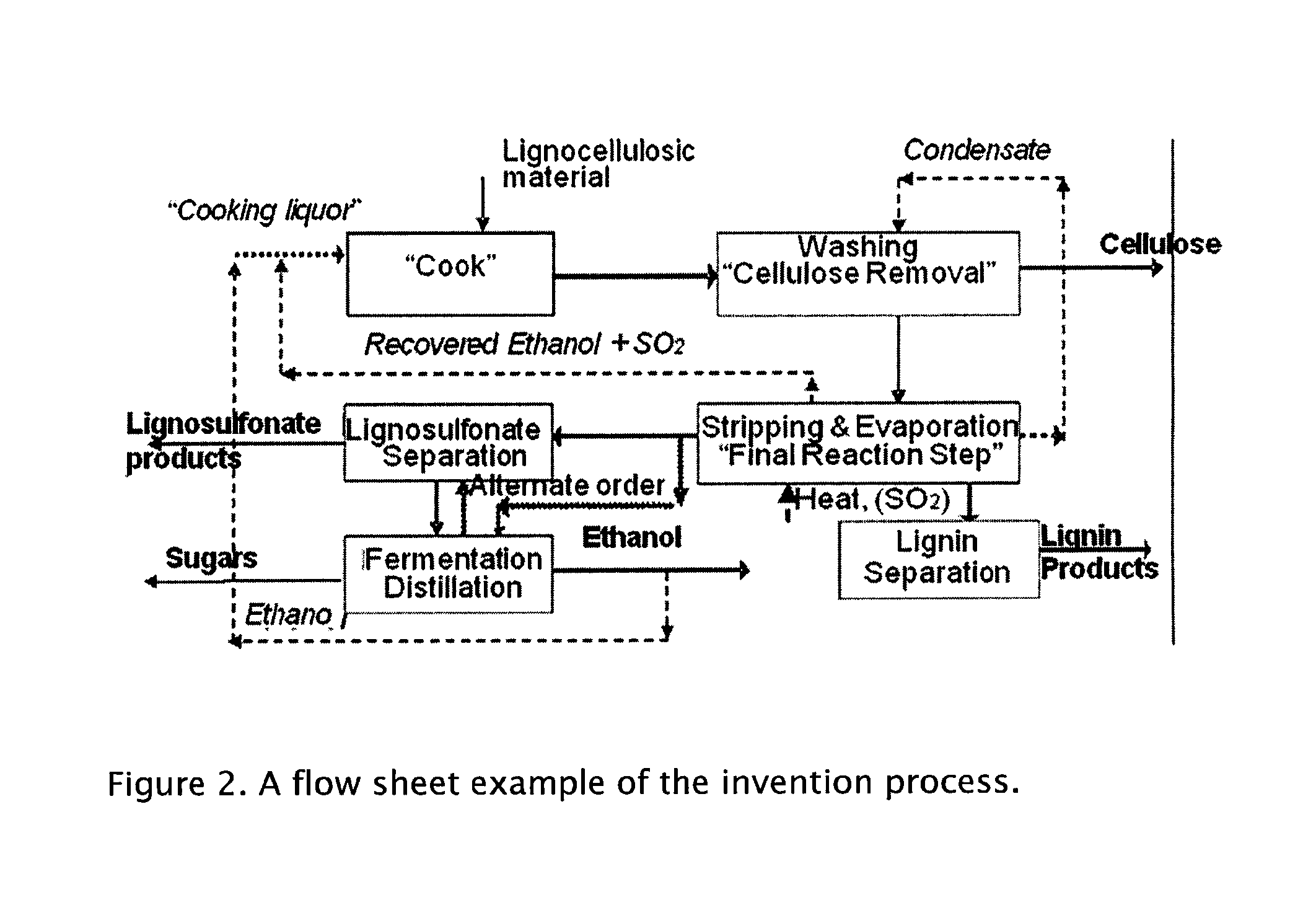

A method for the production water insoluble reactive lignin having low sulfur content and lignosulfonates from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated to produce water insoluble native lignin and lignosulfonates in various ratios, while preserving the cellulose and hydrolyzed hemicelluloses using water, ethanol and sulfur dioxide.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Papermaking red liquor sugar component using method

InactiveCN102493251AGlucose productionRegeneration of sulfite lyeUltrafiltrationSimulated moving bed

The invention relates to a red liquor using method, namely a sulfite pulping papermaking waste liquid method, in particular to a papermaking red liquor sugar component using method. The papermaking red liquor sugar component using method is characterized in that the red liquor is neutralized, a bag type filter is used for removing macromolecule solid contents and colloid in the red liquor, lignosulfonate in the papermaking red liquor is removed by adopting an ultrafiltration system and a nanofiltration membrane system, and the liquid obtains sugar liquor with the transmittance of 90%, the sugar content in solute of 90% and the conductivity of 200muS / m finally after decoloration and desalination. The sugar liquor can be used for preparing acetone butanol, ethanol, methane and biopesticide in a fermentation mode, or preparing ethylene glycol, propylene glycol and other polyatomic alcohol through hydrogenation and hydrogenolysis, or preparing sweet dew sugar and wood sugar in a grading concentration and purification mode by using a simulation moving bed chromatograph. The papermaking red liquor sugar component using method solves the pollution problem of the papermaking red liquor existing for a long period, and achieves high-efficient and high-value use of the red liquor resources, especially the sugar resources.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

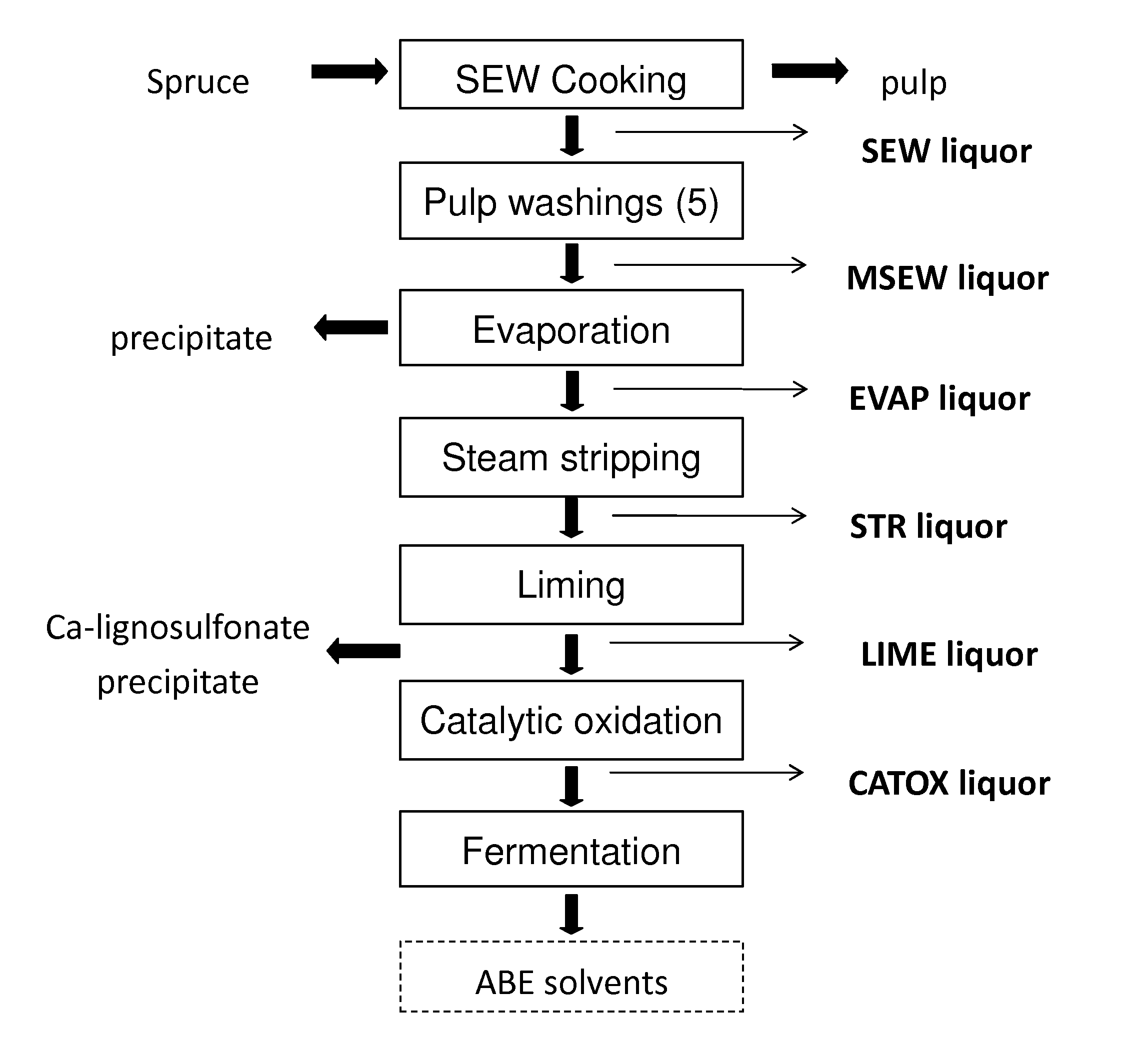

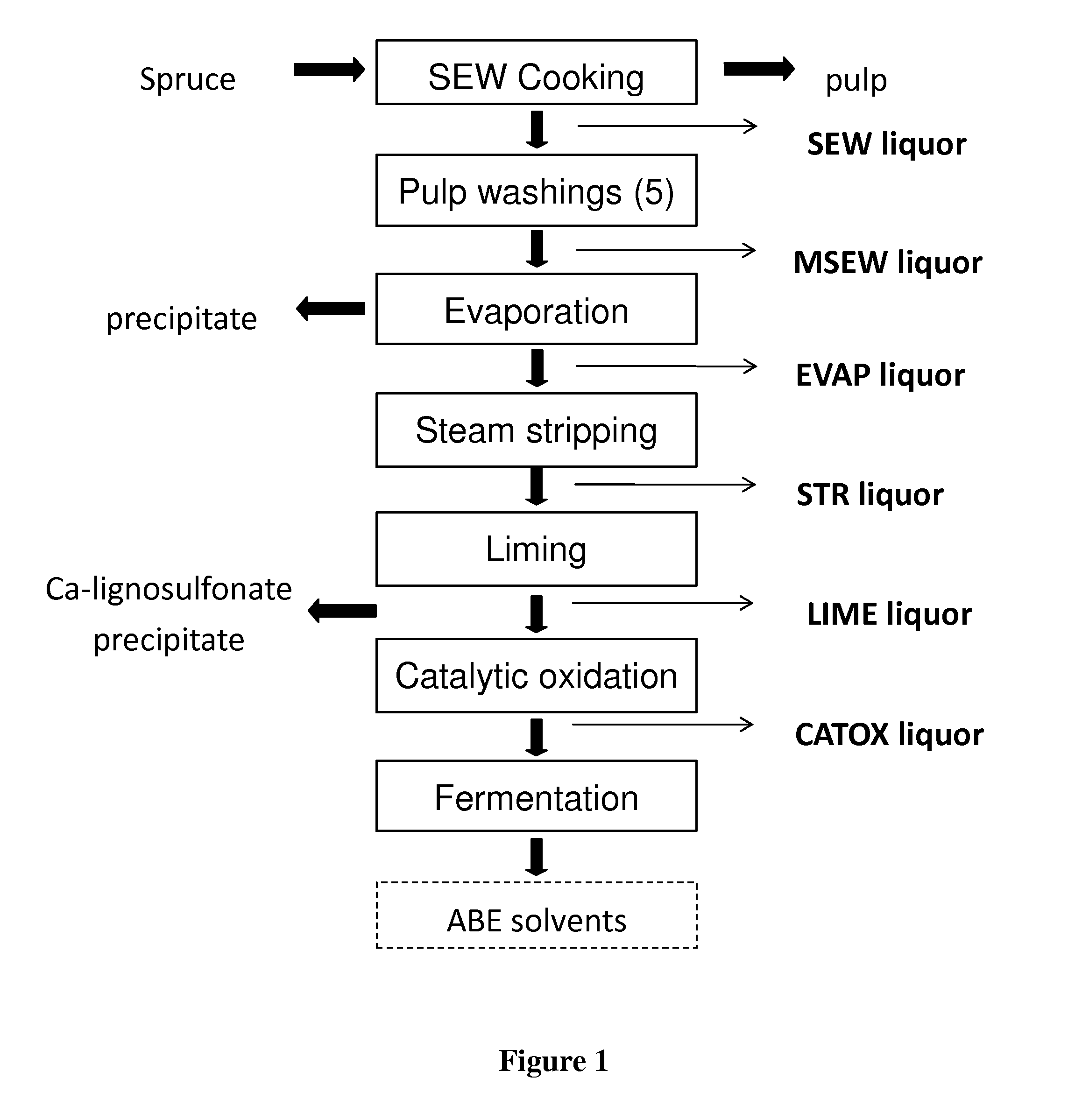

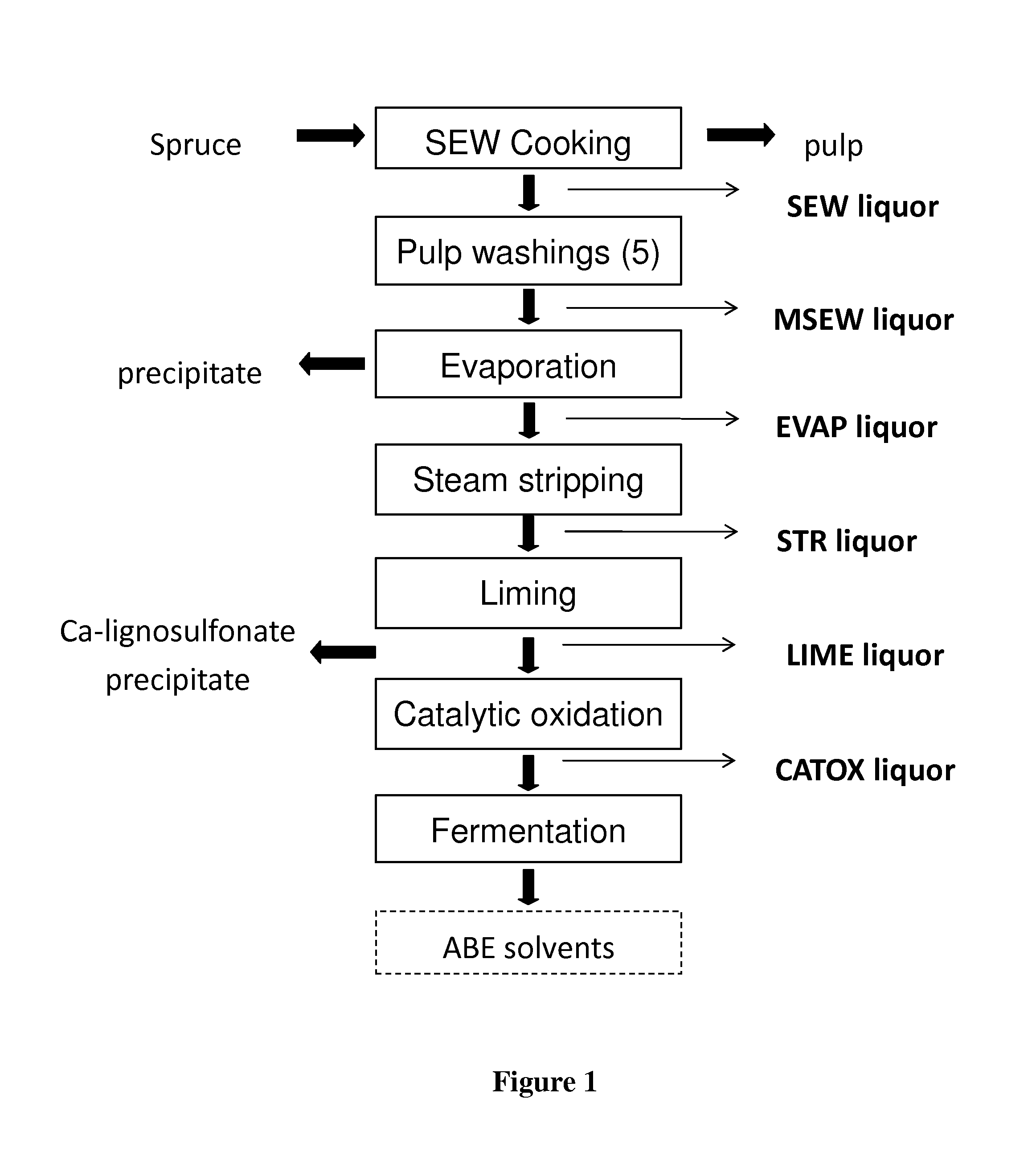

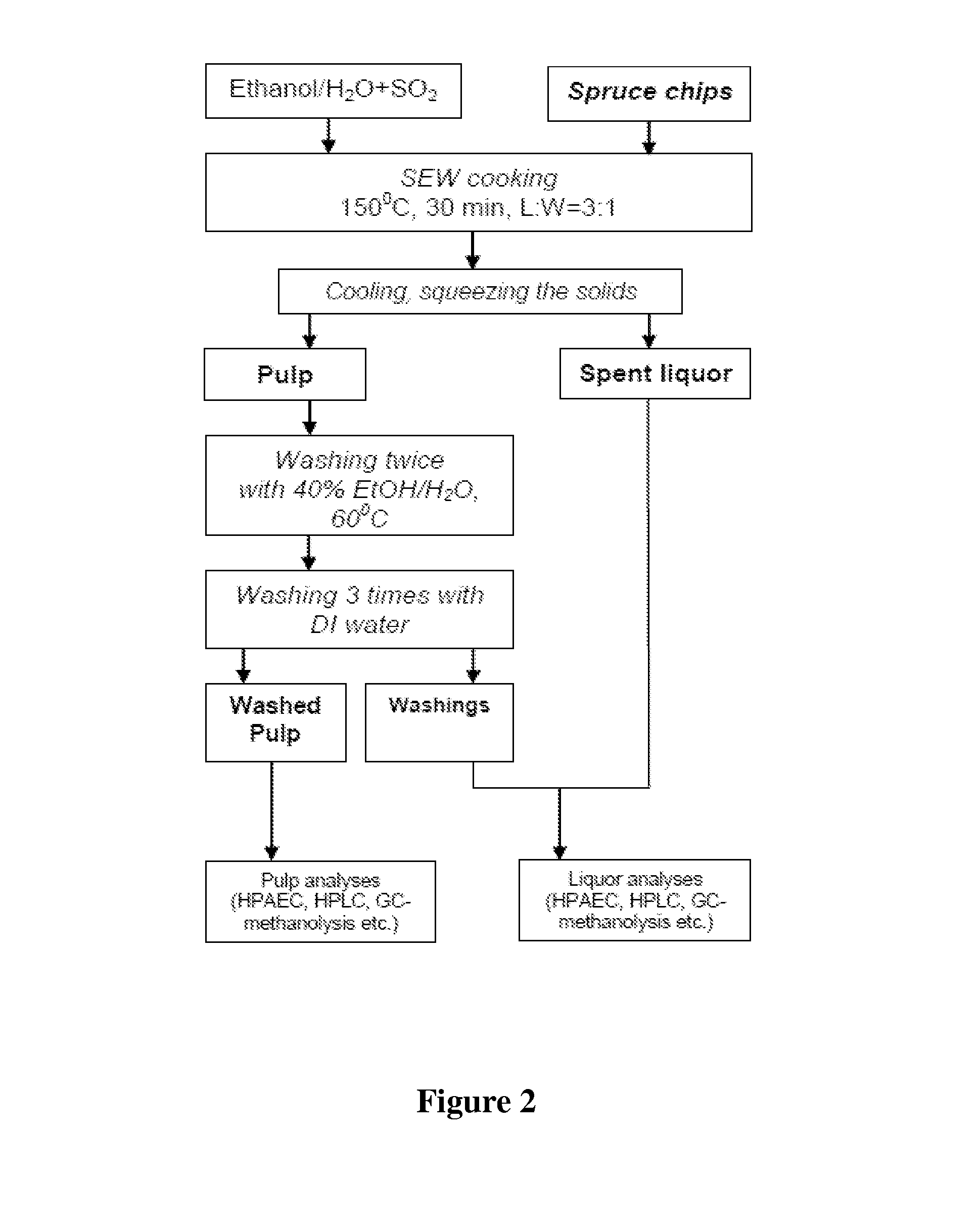

Conditioning of SO2-ethanol-water spent liquor for fermentation by clostridia

The present invention relates to producing chemicals and biofuels from wood material, e.g. mixed forest biomass. Specifically, the invention concerns a process for conditioning spent liquor produced by SO2-ethanol-water (SEW) fractionation of wood chips for fermentation to butanol, ethanol and acetone / isopropanol (so called ABE process) by Clostridia bacteria.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

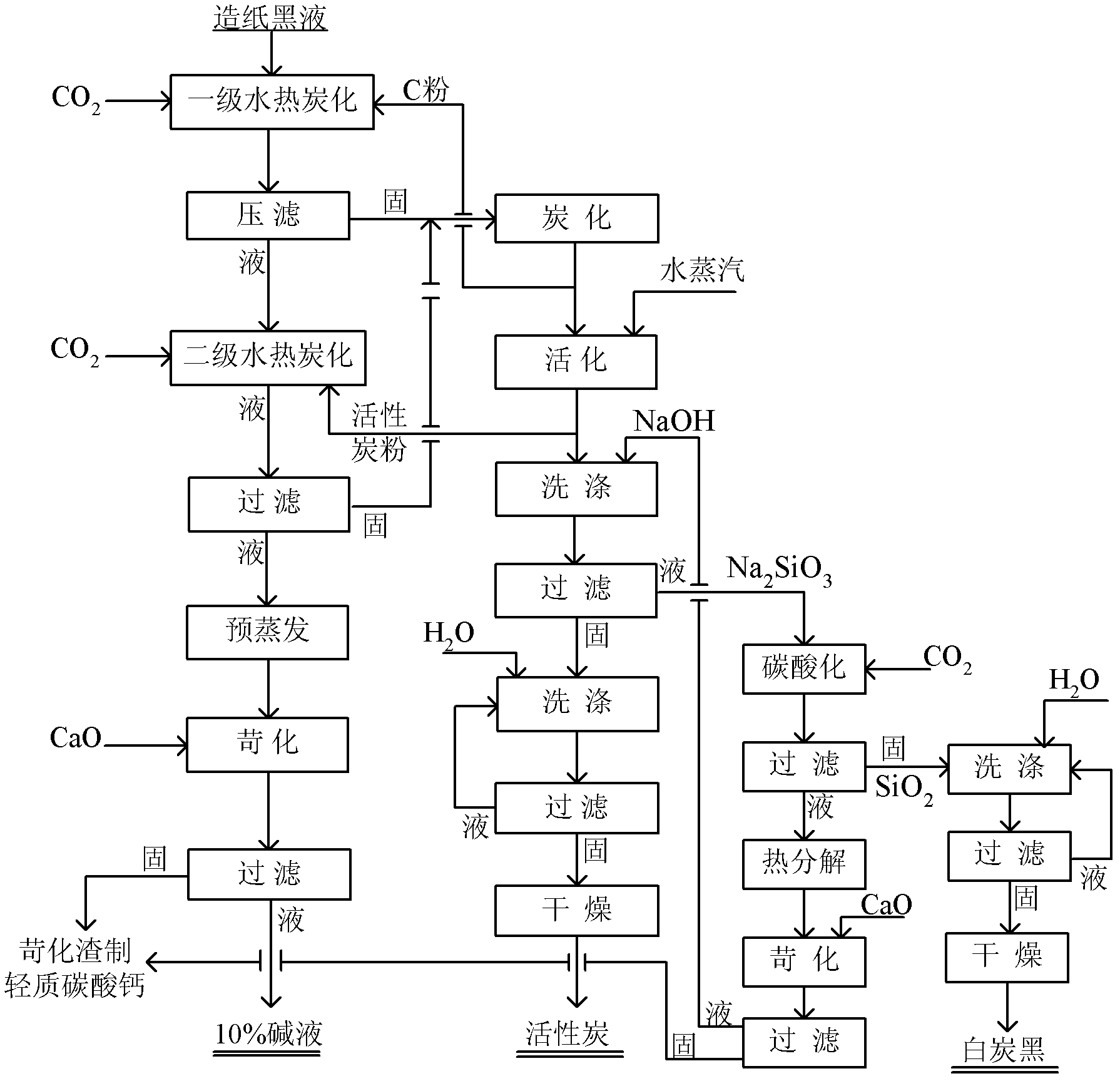

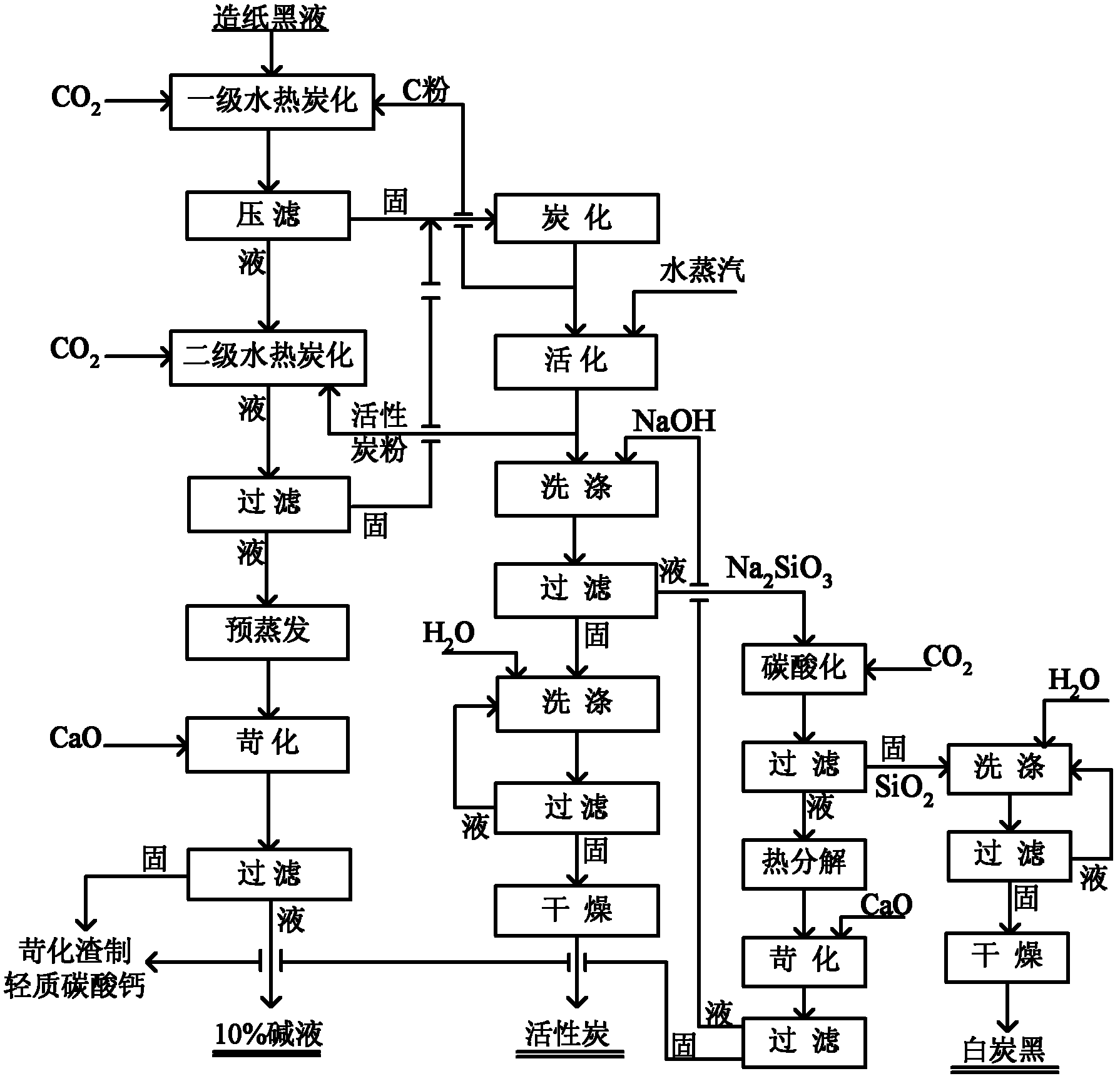

Alkali recovery method for by-producing activated carbon and white carbon black by using paper making black liquid

InactiveCN102587187AEfficient separationImprove evaporation efficiencySilicaCarbon compoundsRecovery methodActivated carbon

The invention relates to paper making industry clean production, in particular to an alkali recovery method based on paper making black liquid. The method comprises the following steps of: 1) adding carbon powder in paper making black liquid, introducing CO2 gas for carrying out primary hydrothermal carbonization, and carrying out filtering to obtain primary hydrothermal carbonization liquid and primary hydrothermal carbonization materials; 2) adding crude activated carbon into the primary hydrothermal carbonization liquid obtained in the first step, carrying out secondary hydrothermal carbonization under the CO2 gas introduction condition, carrying out filtering to obtain secondary hydrothermal carbonization liquid and secondary hydrothermal carbonization materials, evaporating the secondary hydrothermal carbonization liquid, regulating the pH (Potential Of Hydrogen), and carrying out causticization treatment to obtain alkali liquid. The method provided by the invention has the advantages that because the alkali recovery work procedure is a bottle neck of most alkali process pulp making paper making plants in prior art, after the efficiency of the process is improved, the pulp making capability of the paper making plants can be greatly improved, meanwhile, the by-production of high-added-value activated carbon and white carbon black can be realized, and further, the scale benefits of the paper making enterprises can be integrally improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

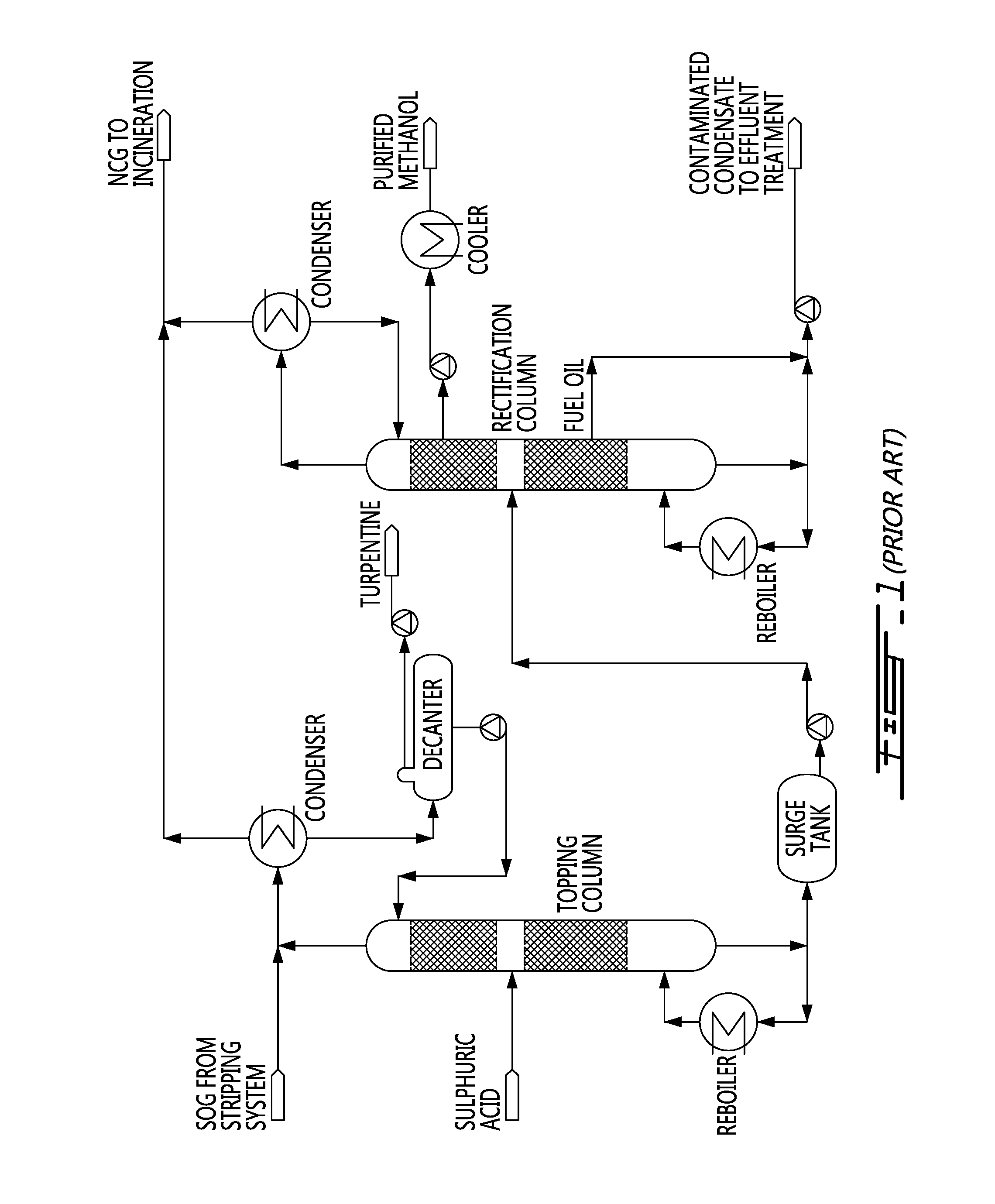

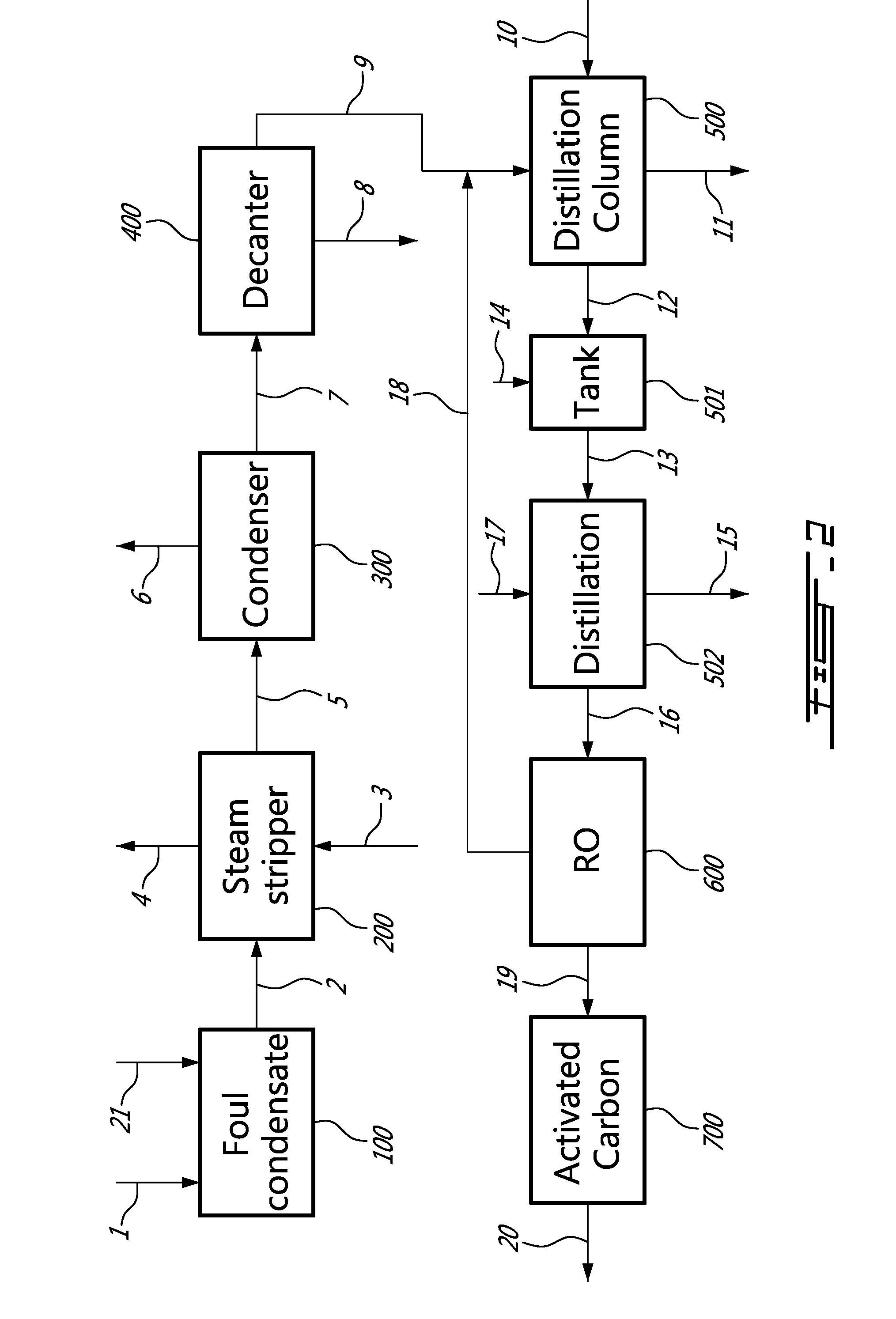

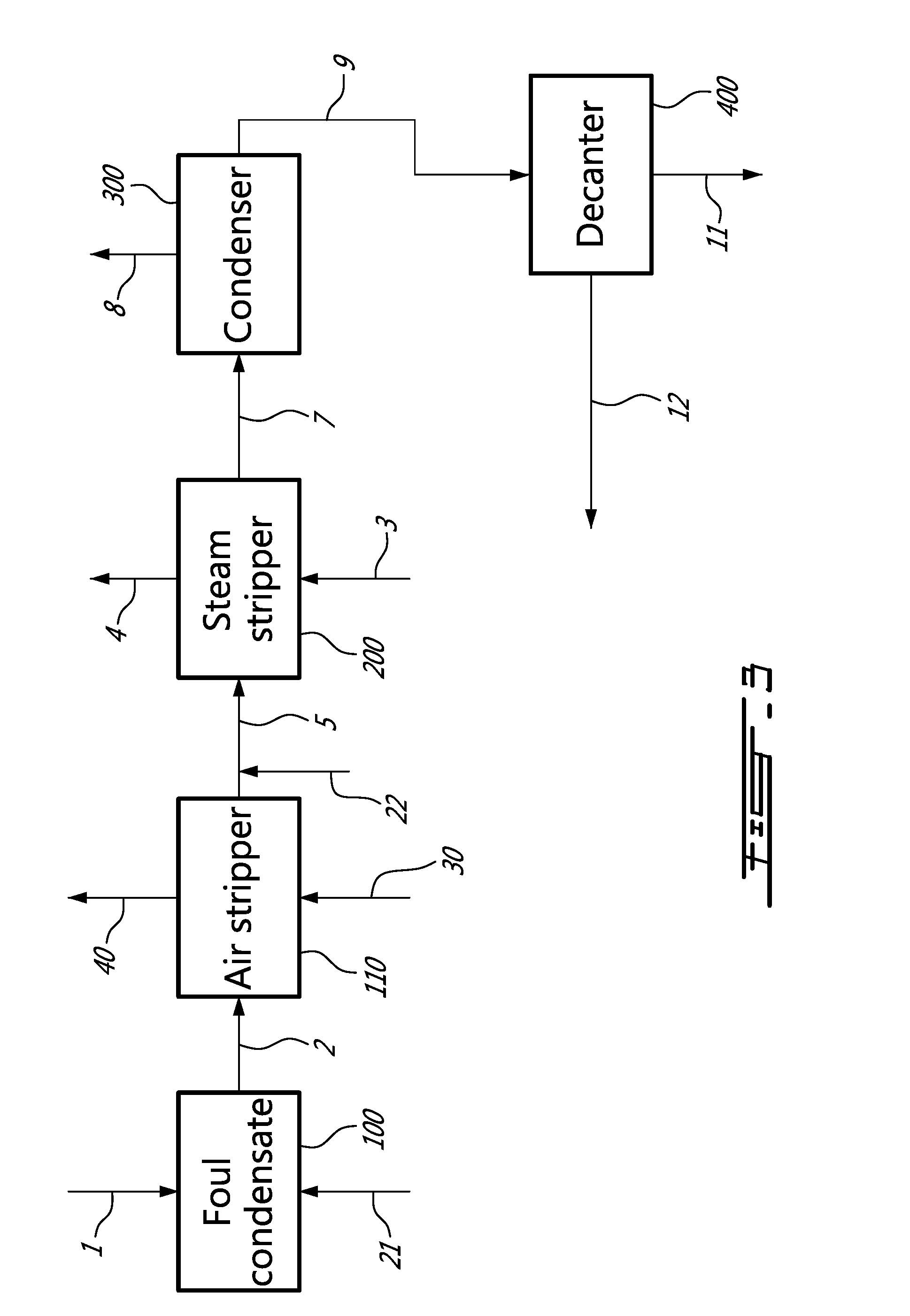

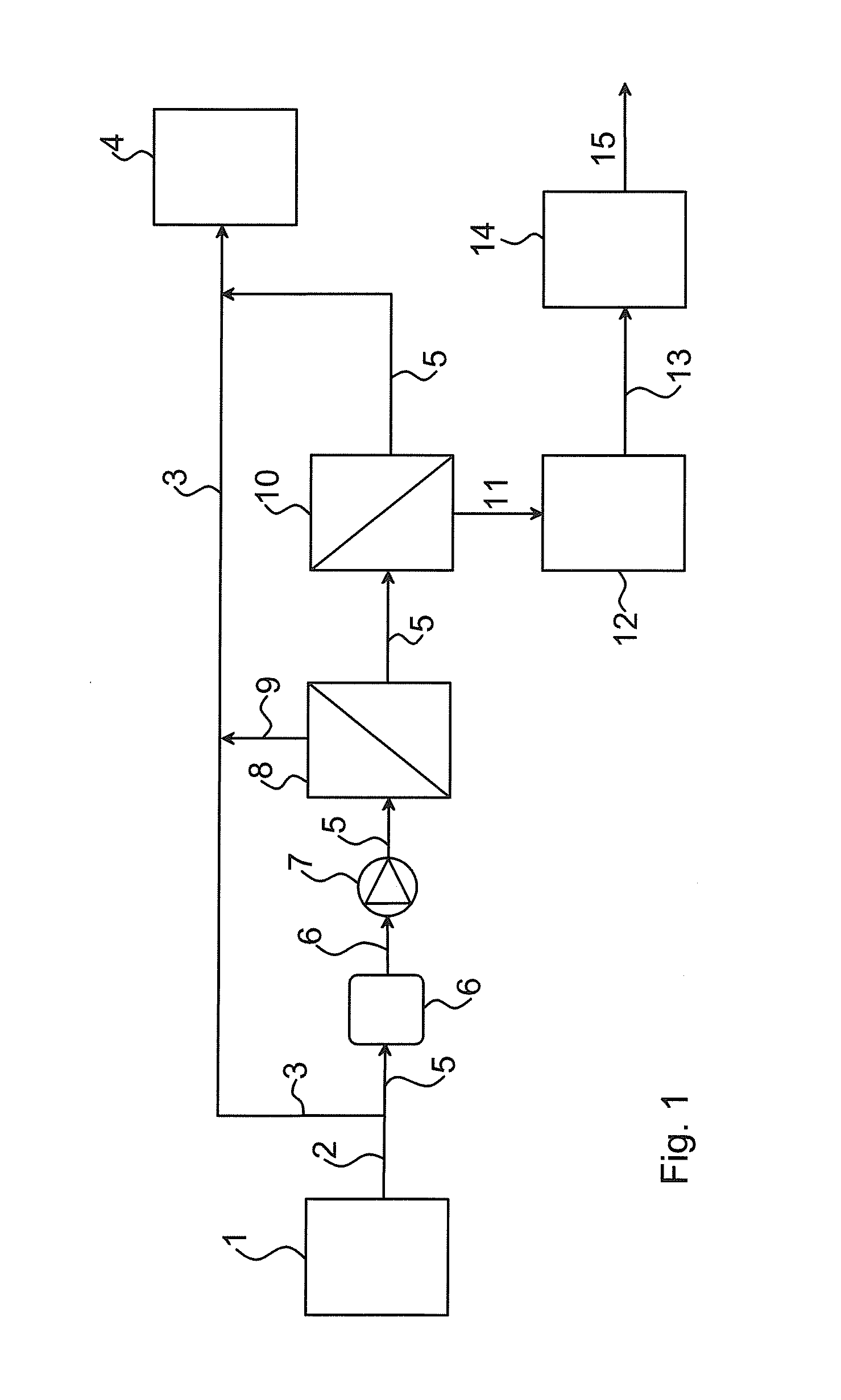

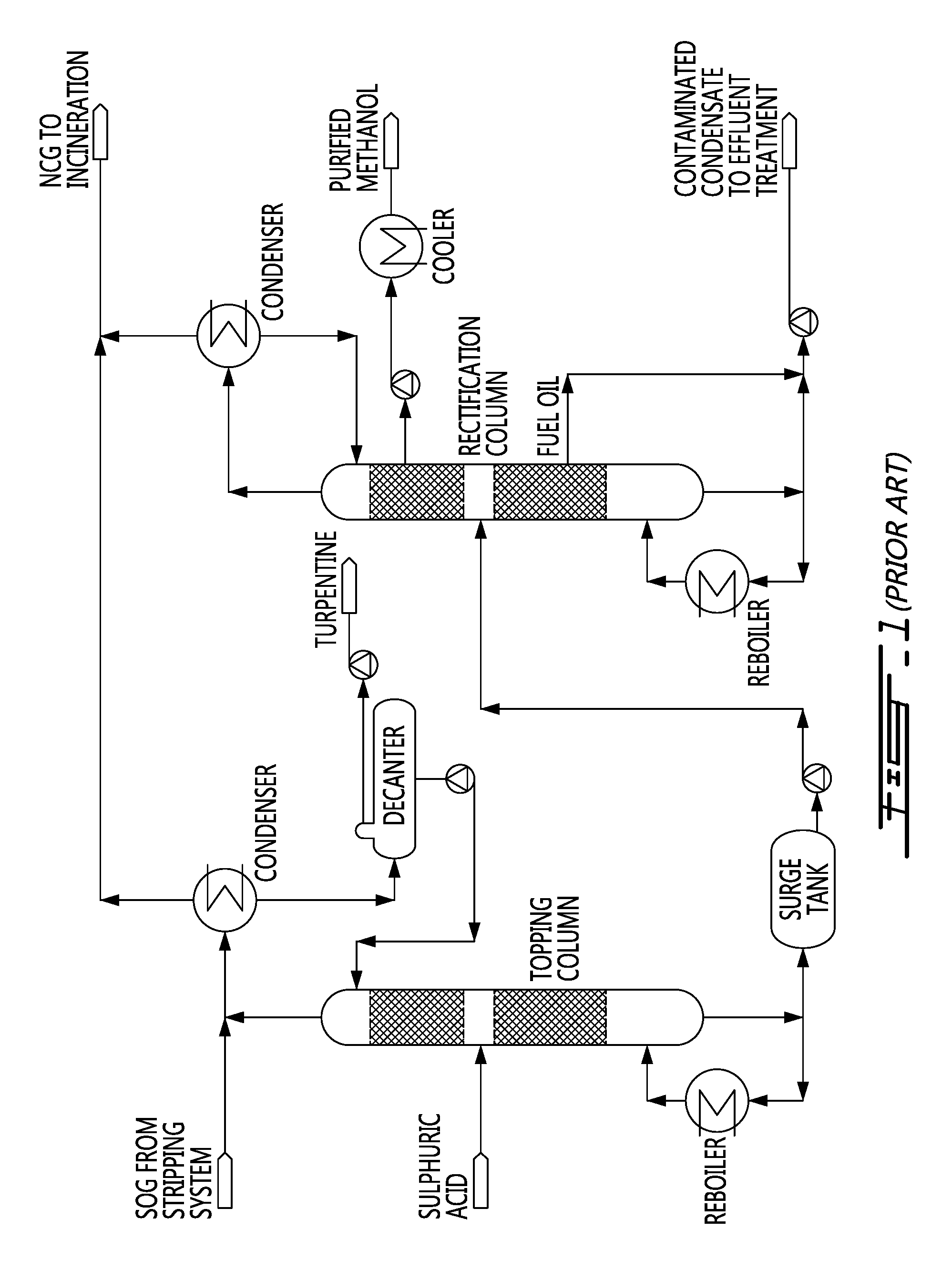

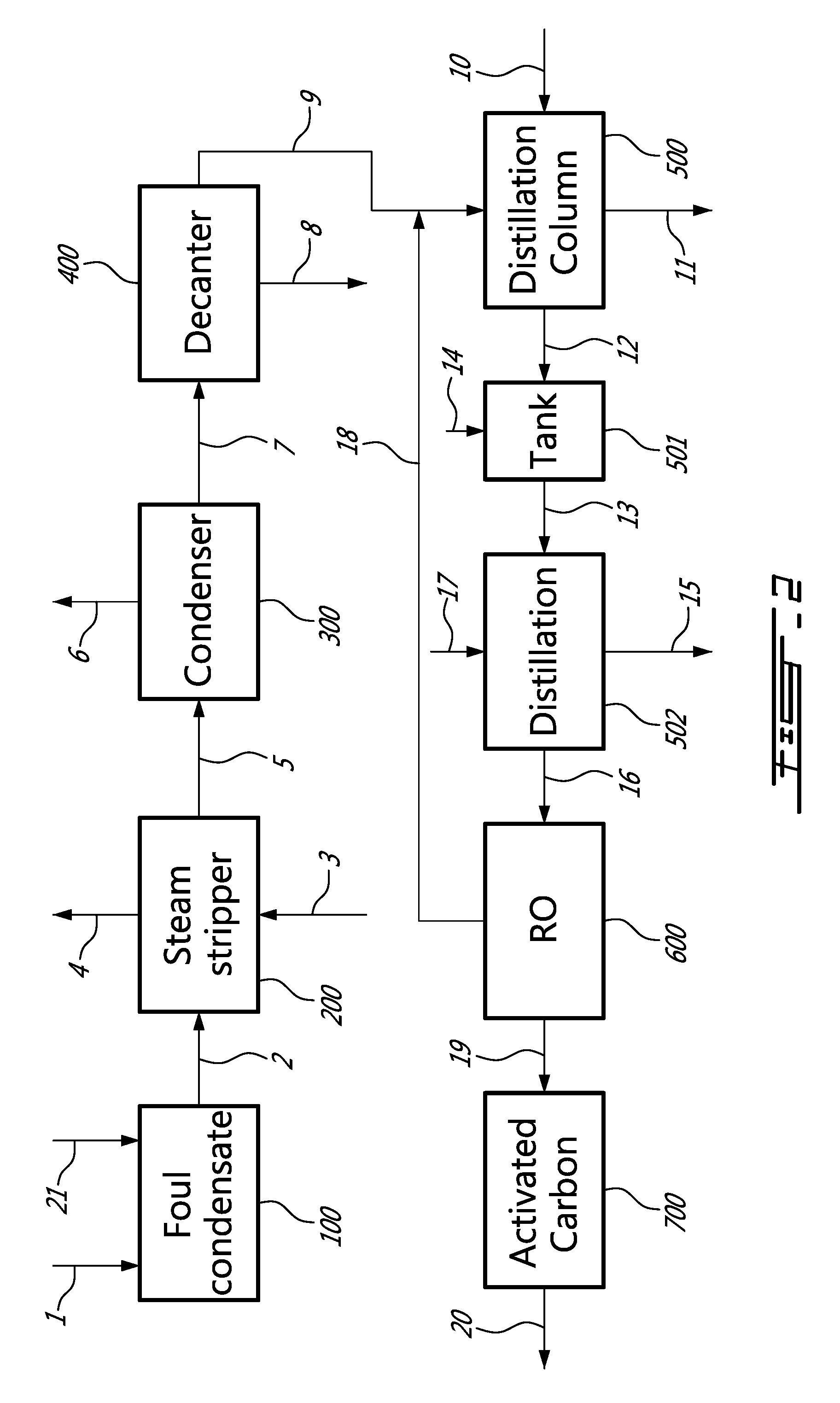

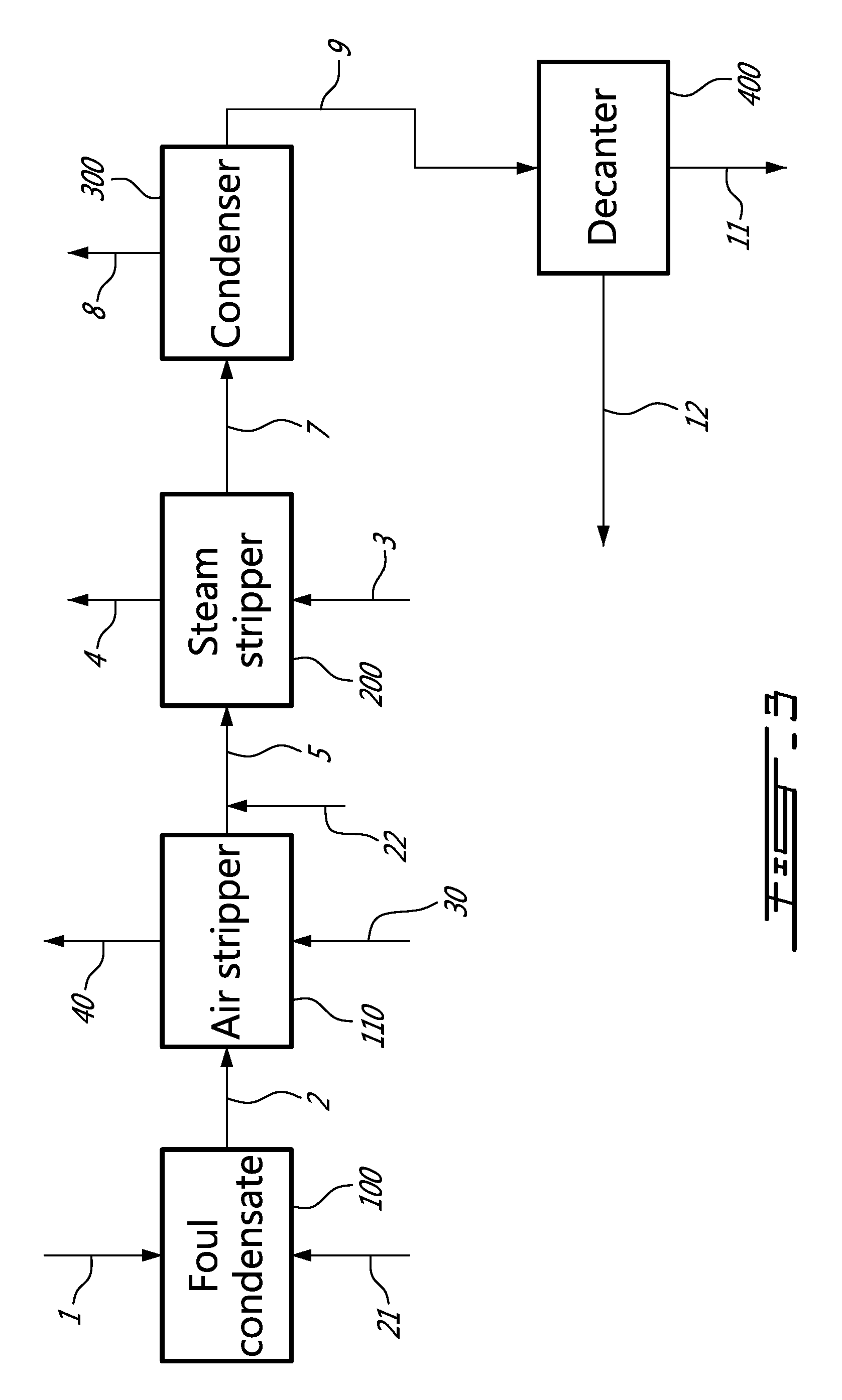

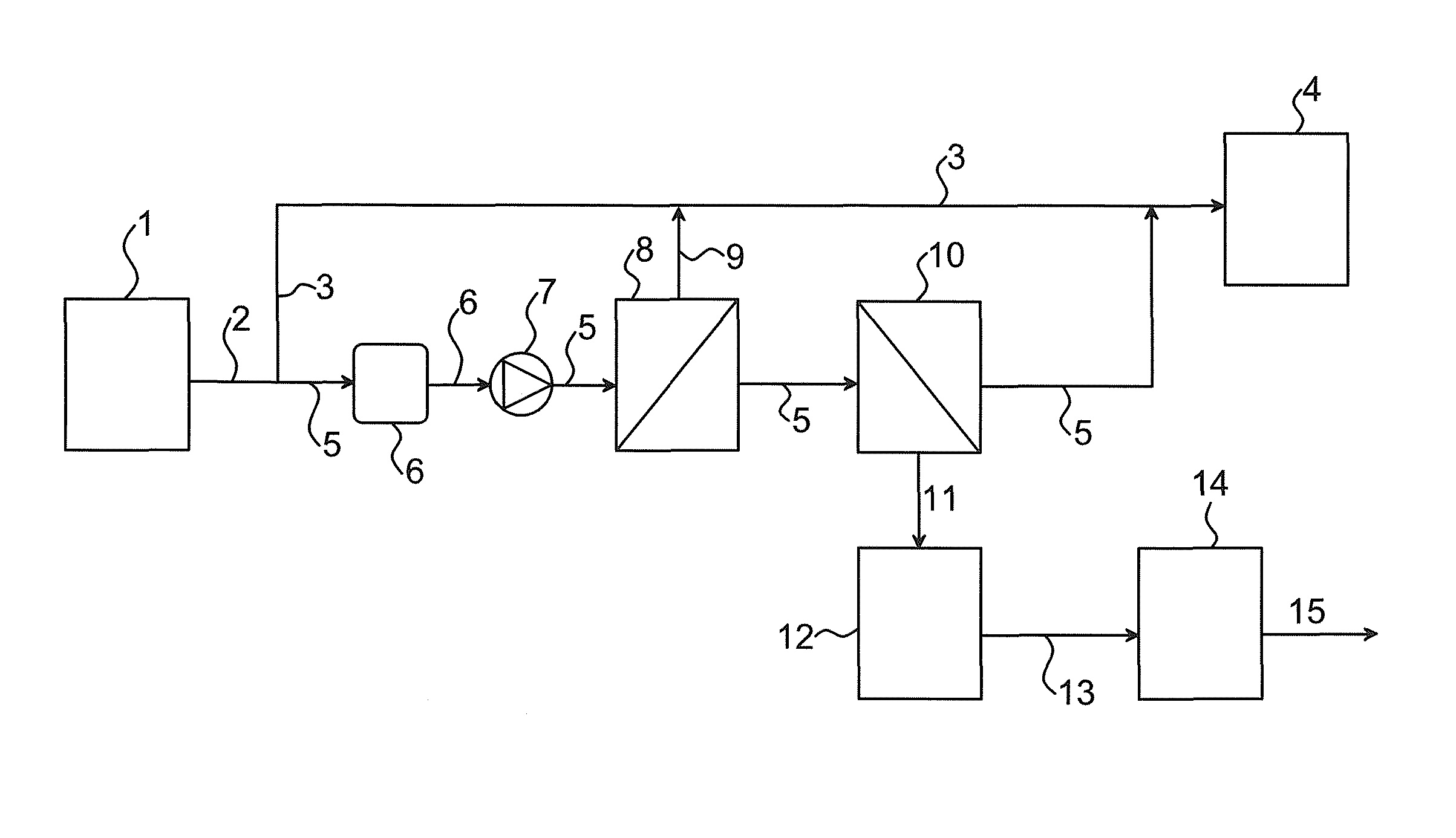

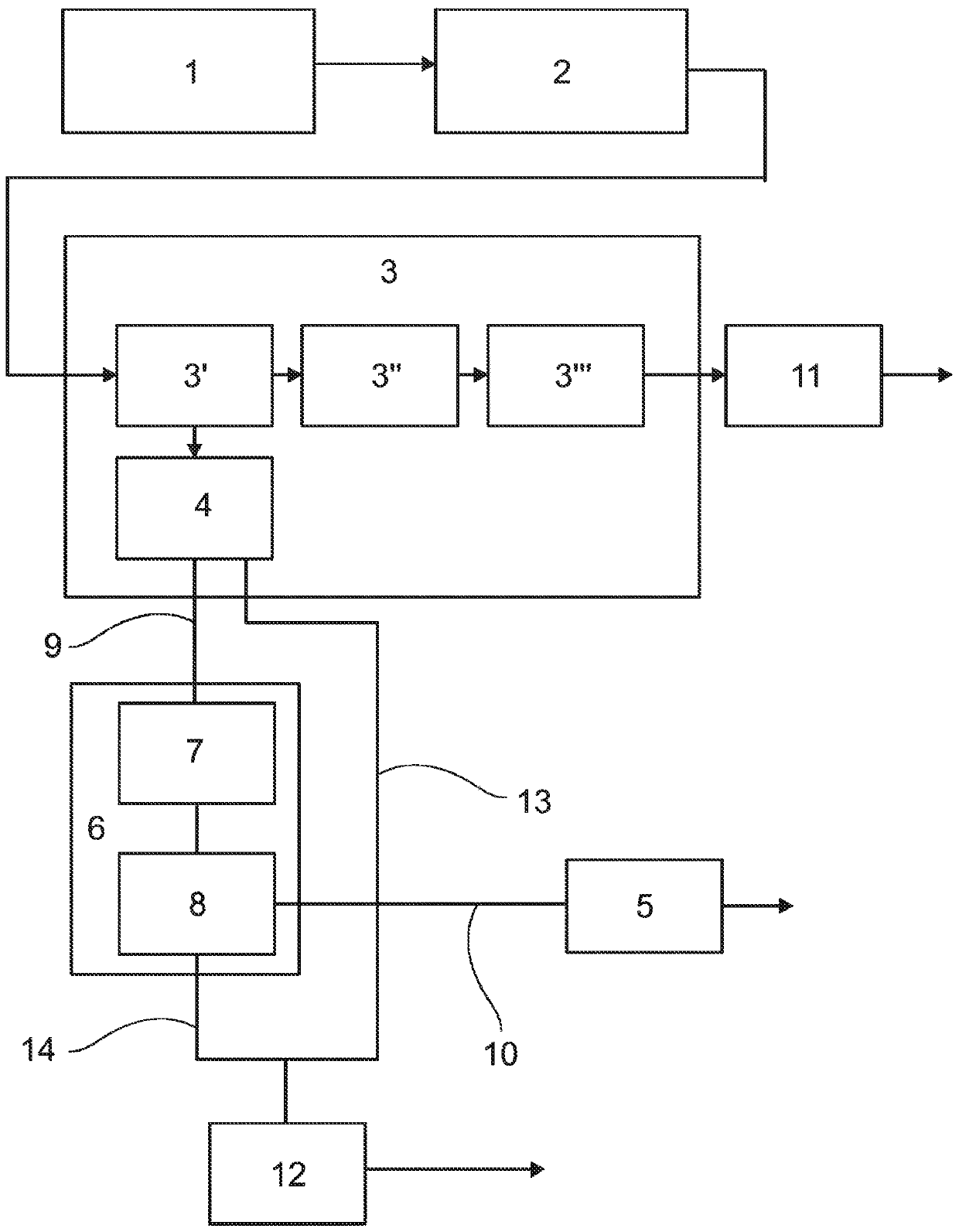

Method for producing bio-methanol at pulp mills

ActiveUS20160122267A1Reduce sulfur contentIon-exchanger regenerationReverse osmosisDistillationReverse osmosis

The present invention describes a process and system of producing methanol from methanol condensates. In a preferred embodiment the condensates are biomethanol condensates from chemical pulp mills and various waste sources used to produce a purified biomethanol. Pulp condensates are rich in methanol and contain many other contaminants. Presently, most chemical pulp mills, such as Kraft pulp mills use steam stripping to remove and concentrate the methanol and burn the methanol onsite along with the contaminants. A combination of treatments that include air stripping, steam stripping, distillation and reverse osmosis is described to obtain purified biomethanol suitable for sale or use on site.

Owner:FPINNOVATIONS INC

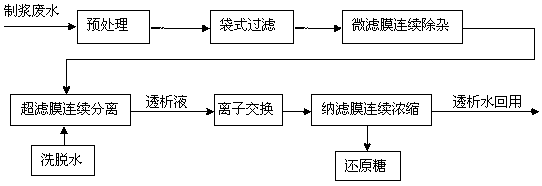

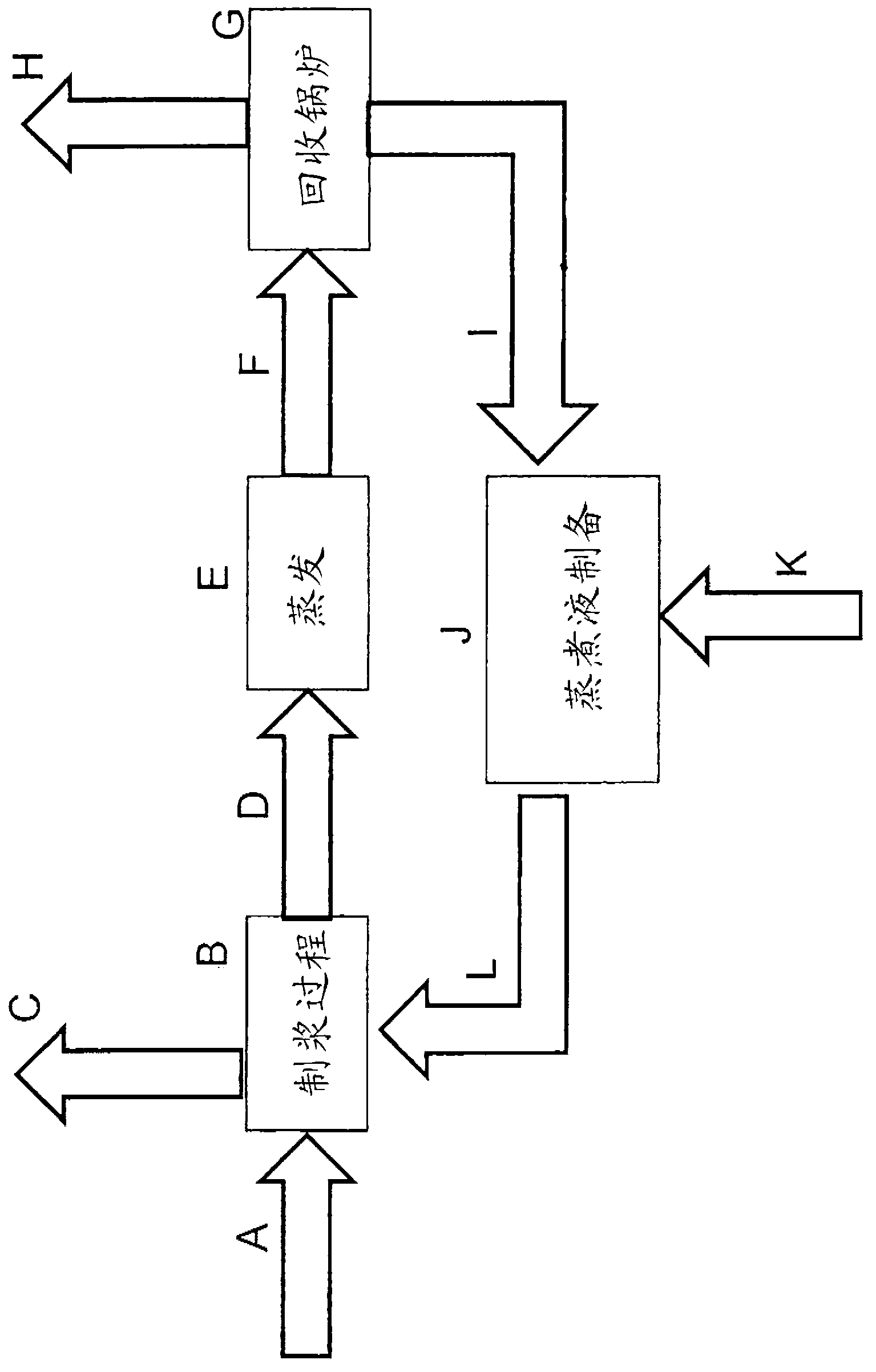

Method for comprehensively using pulping waste water by sulfite method

InactiveCN103015246ASmall footprintLow infrastructure costRegeneration of sulfite lyeDialysis membranesFiltration membrane

The invention discloses a method for comprehensively using pulping waste water by a sulfite method. The method comprises the steps of pretreatment, bag type filtration, continuous impurity removal of micro-filtration membranes, continuous separation of ultra-filtration membranes, ion exchange, continuous concentration of nano-filtration membranes, and treatment of nano-filtration concentration dialysis water by using reverse osmosis membranes. The method can effectively separate and recover valuable substances, such as lignosulfonate, oligosaccharide and the like in the pulping waste water so as to improve the comprehensive utilization rate of bamboo pulp resources, can strength the pretreatment of papermaking waste water before membrane entrance so as to avoid the dirt blockage problem of membrane holes due to effective removal of easy fouling substances which pollute the membranes and to largely prolong the service life of membrane modules, and can separate and extract the lignosulfonate and revertose by adopting the continuous dialysis membrane ultra-filtration separation and washing method to effectively solve the difficulties of membrane pollution and separation efficiency decrement and to be applied in the treatment of the papermaking waste water in large scale; and the membrane materials are preferentially hydrophilic materials, so that high water passing quantity and reduced membrane pollution are guaranteed.

Owner:CHENGDU LIANJIE MEMBRANE TECH

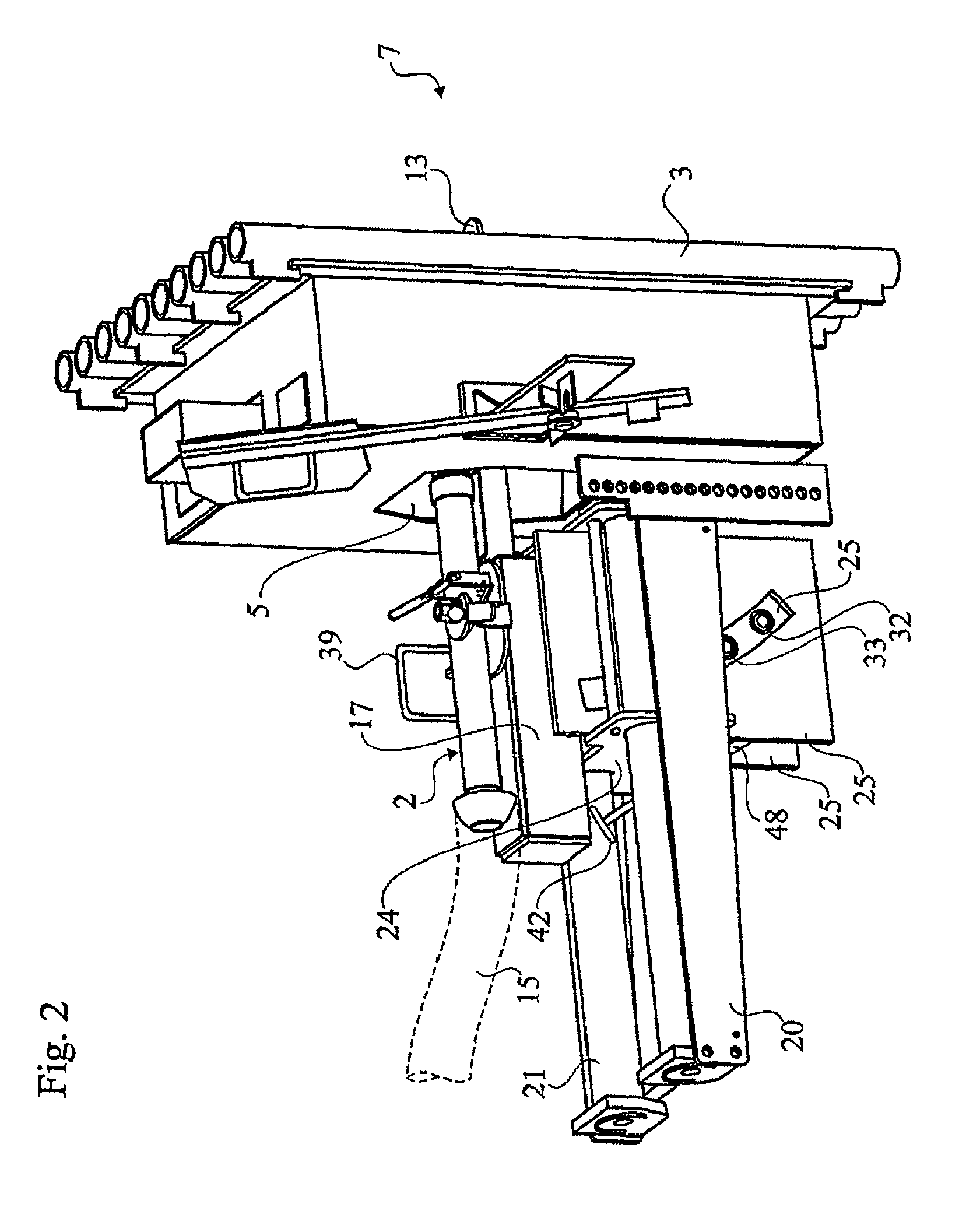

Arrangement for the adjustment of equipment for a boiler

Owner:METSO POWER AB

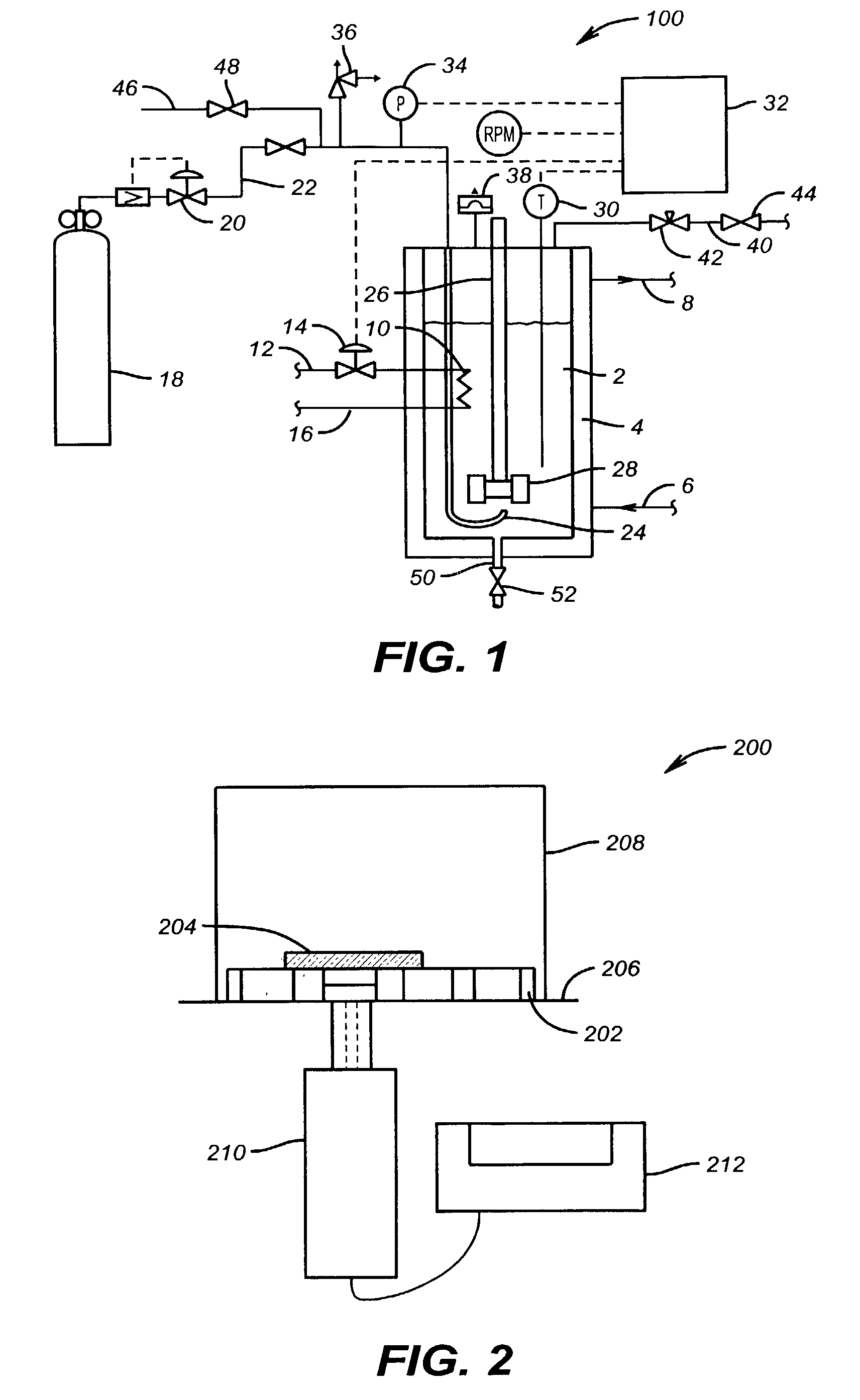

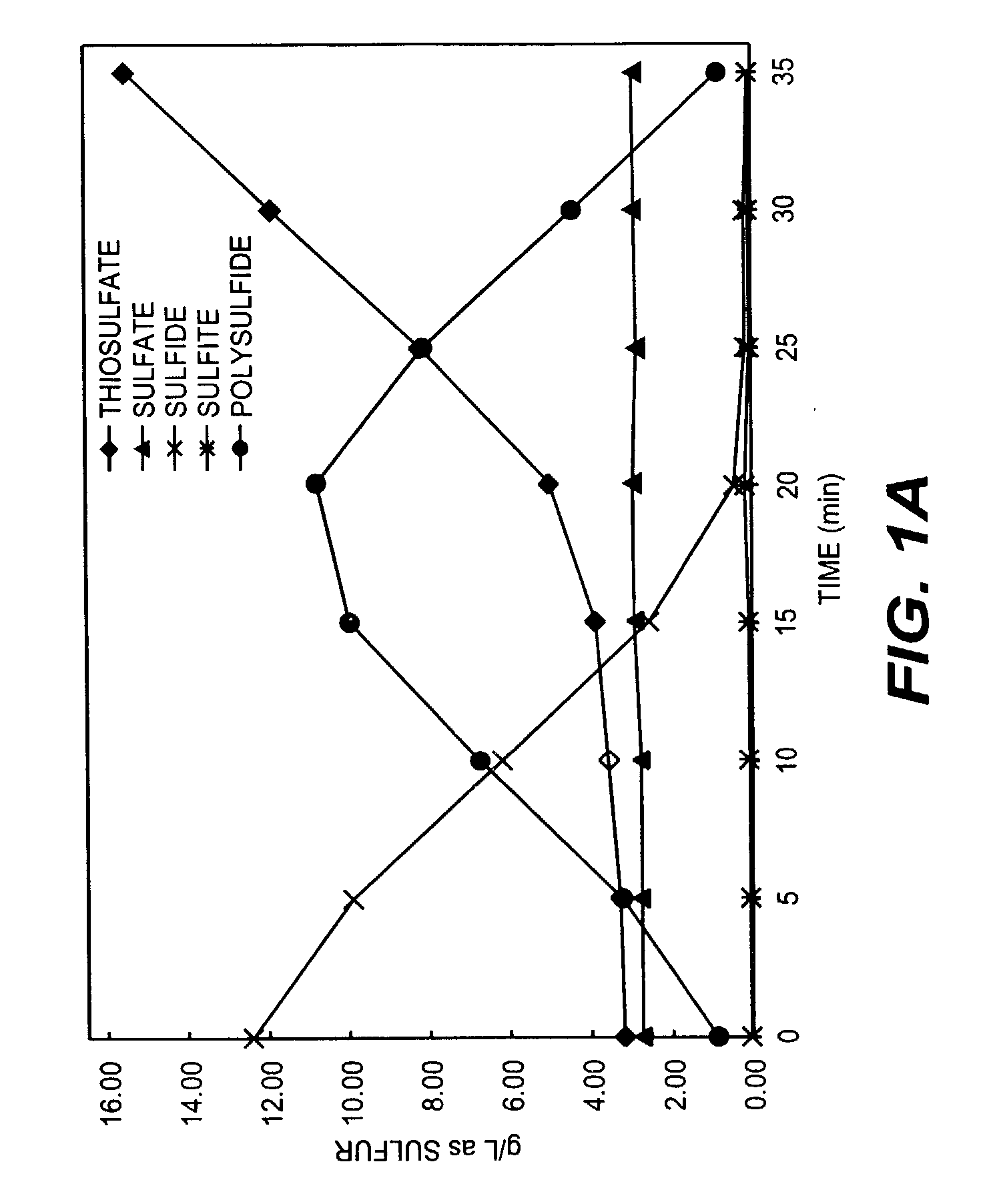

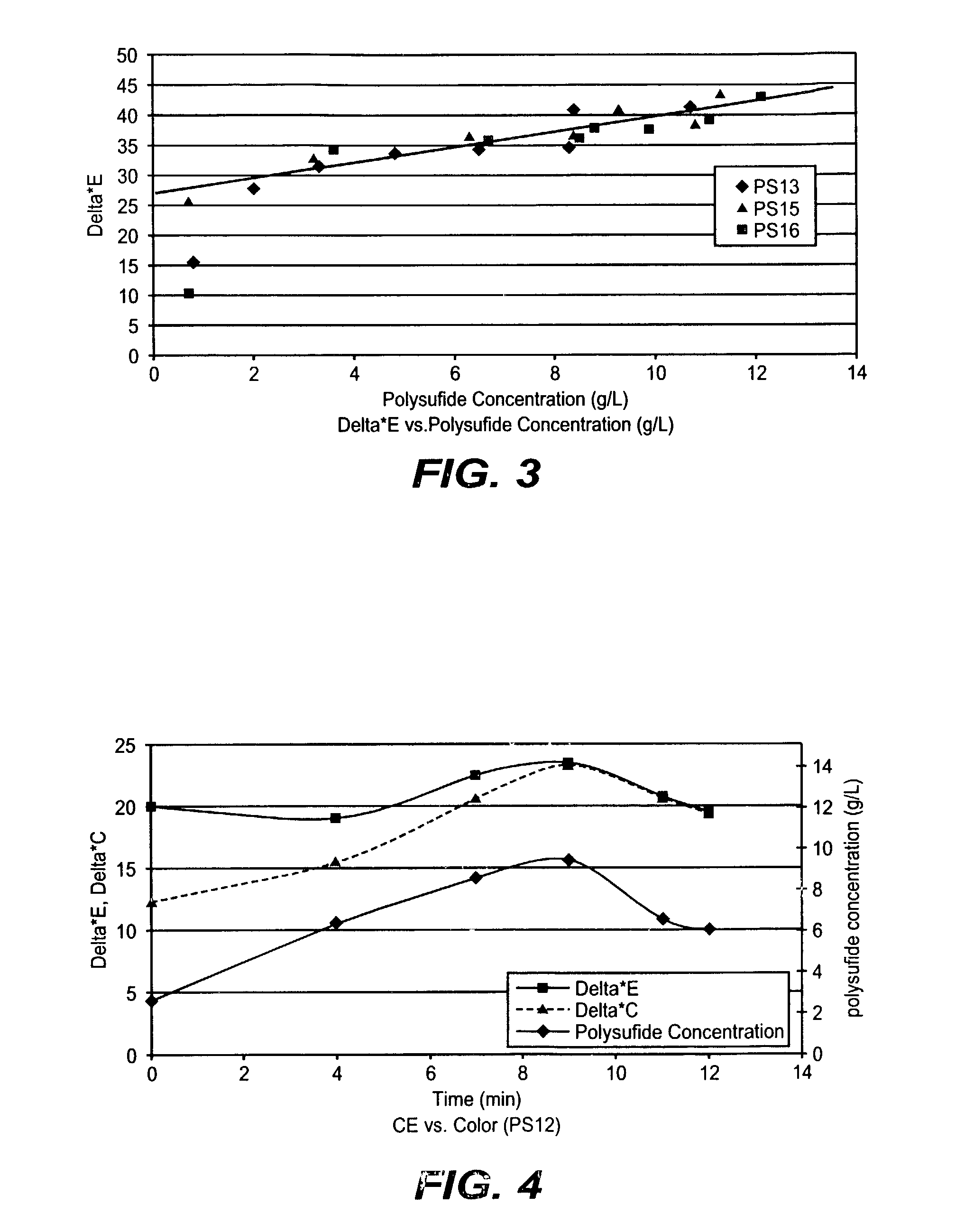

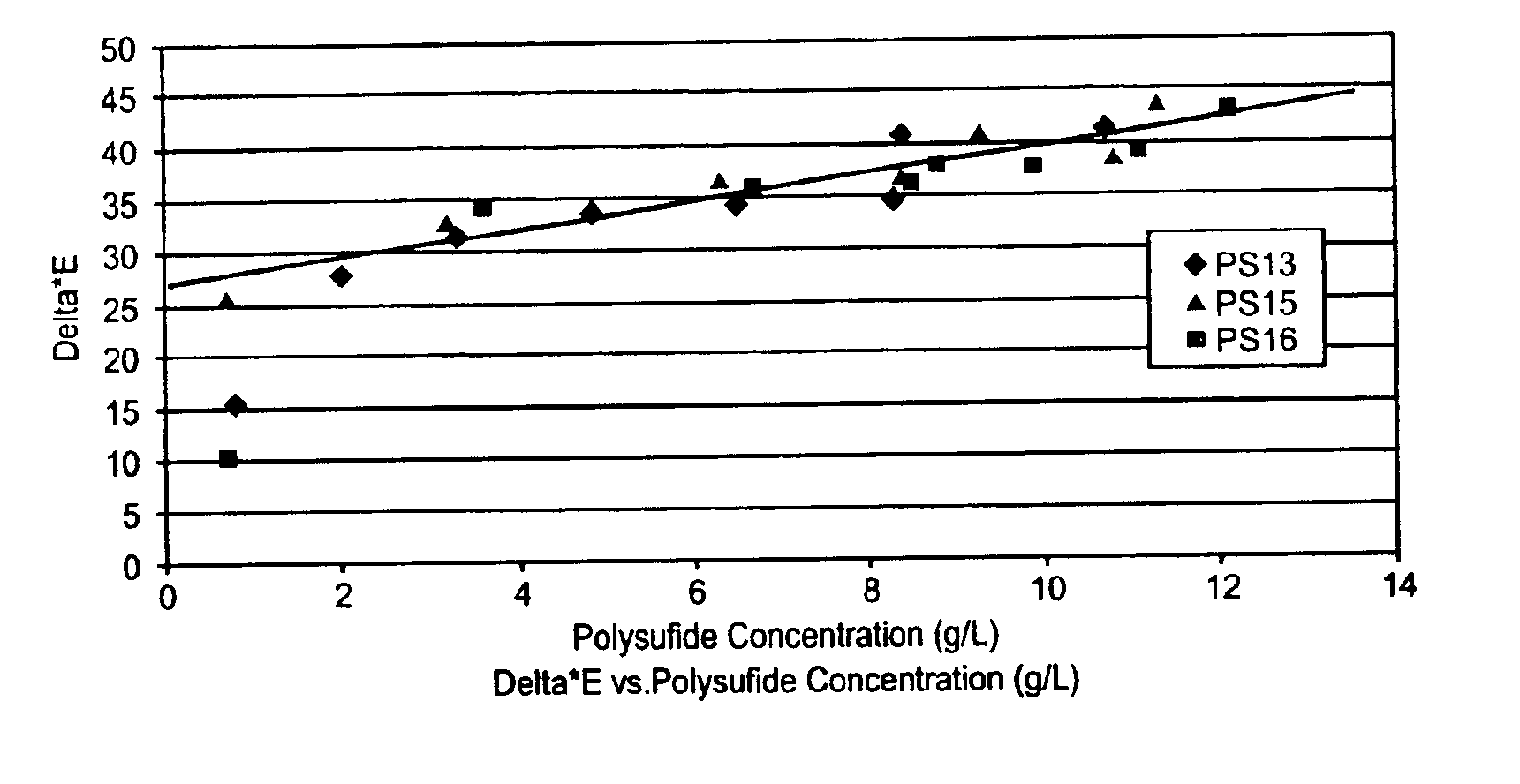

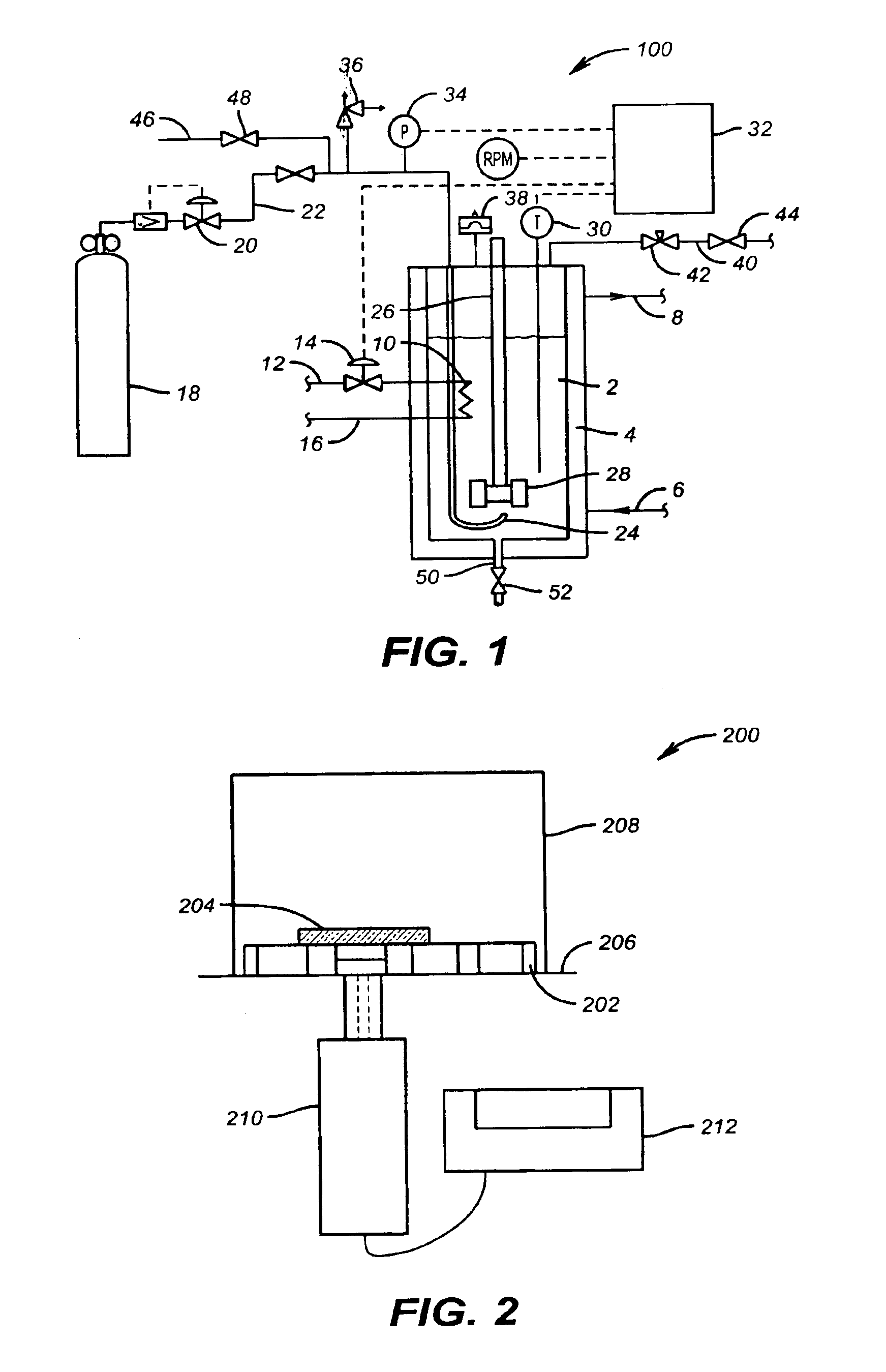

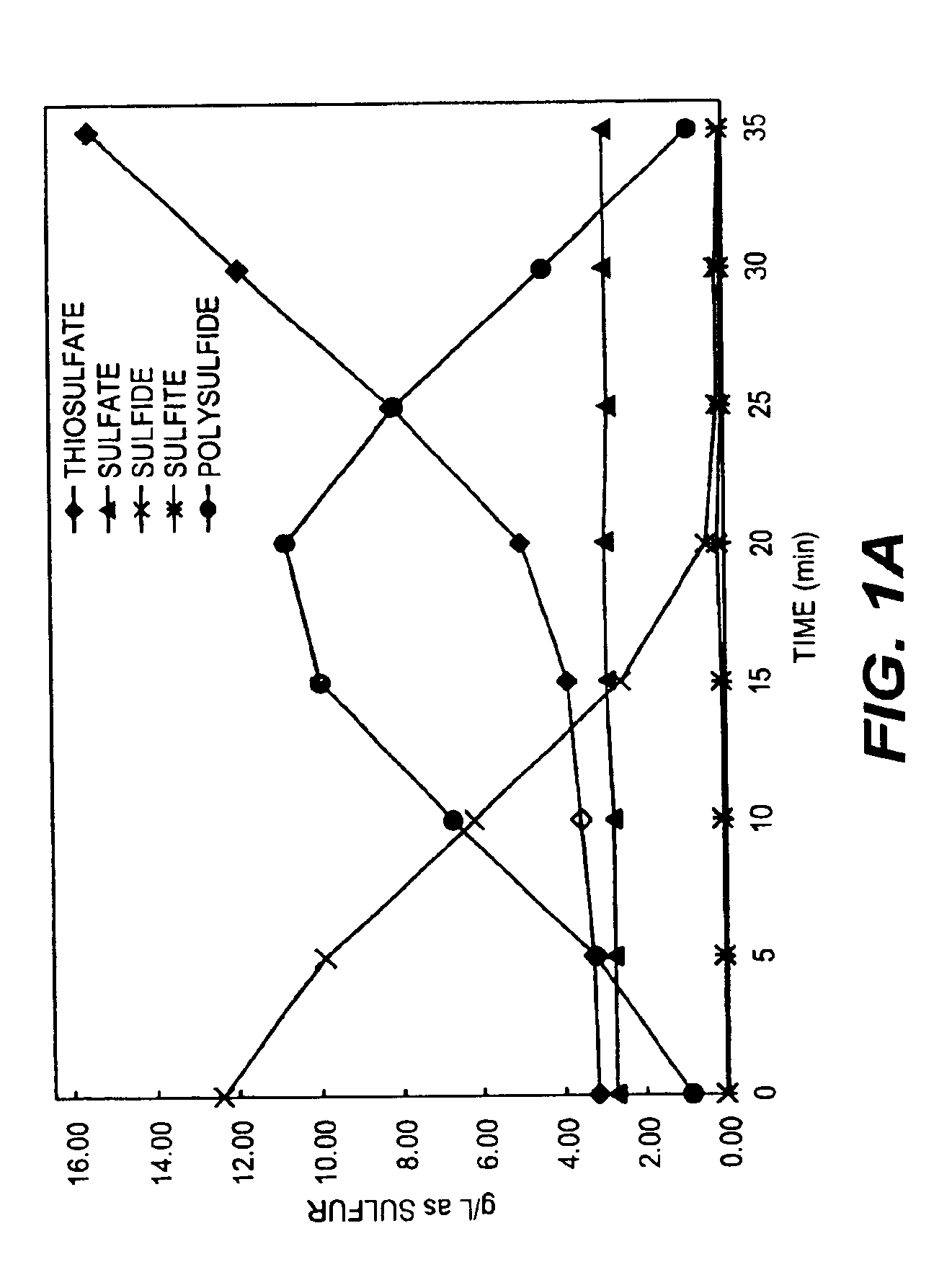

Polysulfide measurement methods using colormetric techniques

InactiveUS20030157017A1Pulp liquors combustionMaterial analysis by observing effect on chemical indicatorPhysical chemistryPolysulfide

Methods of converting a sulfide in a composition to polysulfide are described, one method comprising the steps of exposing the composition to conditions and for a time sufficient to cause conversion of at least a portion of the sulfide, to polysulfide to form a modified composition; and controlling the conversion to polysulfide by measuring a color parameter of the modified composition.

Owner:AIR LIQUIDE AMERICA INC +1

Combined producing process for realizing zero discharge and comprehensively utilizing in pulp production by using filter film technology

InactiveCN101050600ARealize comprehensive utilizationIncrease profitSemi-permeable membranesWater/sewage treatmentWater useLiquid waste

The present invention relates to a combined production process capable of utilizing filter membrane technique to implement zero discharge of pulp production and comprehensive utilization. It is characterized by that said production process can utilize filter membrane technique to make waste liquor produced in every independent water-using work section in the course of pulp production undergo the process of purification treatment, and make the purified water obtain circular utilization so as to implement zero discharge of waste liquor.

Owner:葛文宇

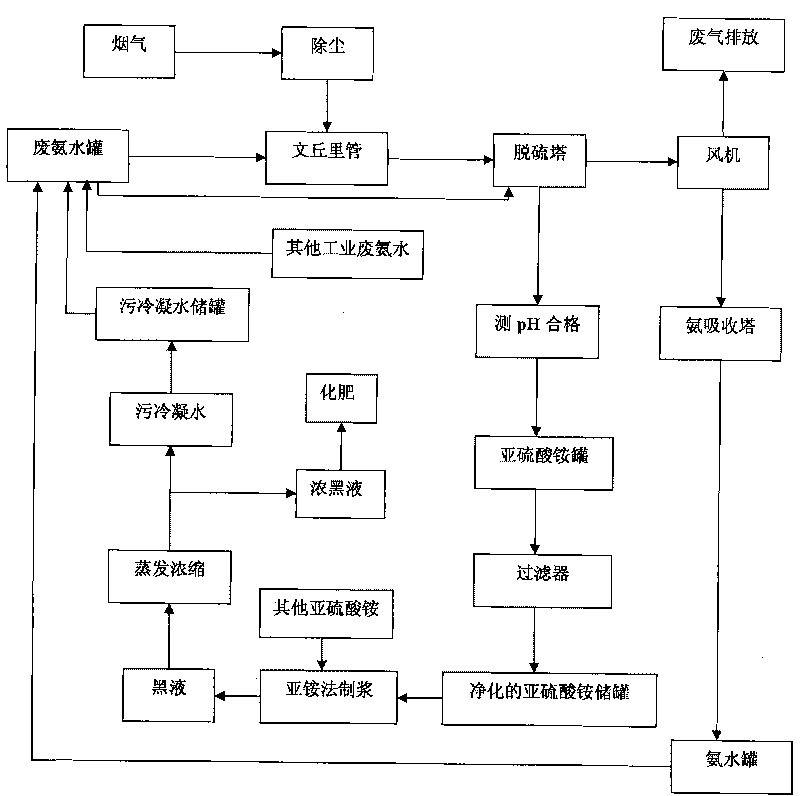

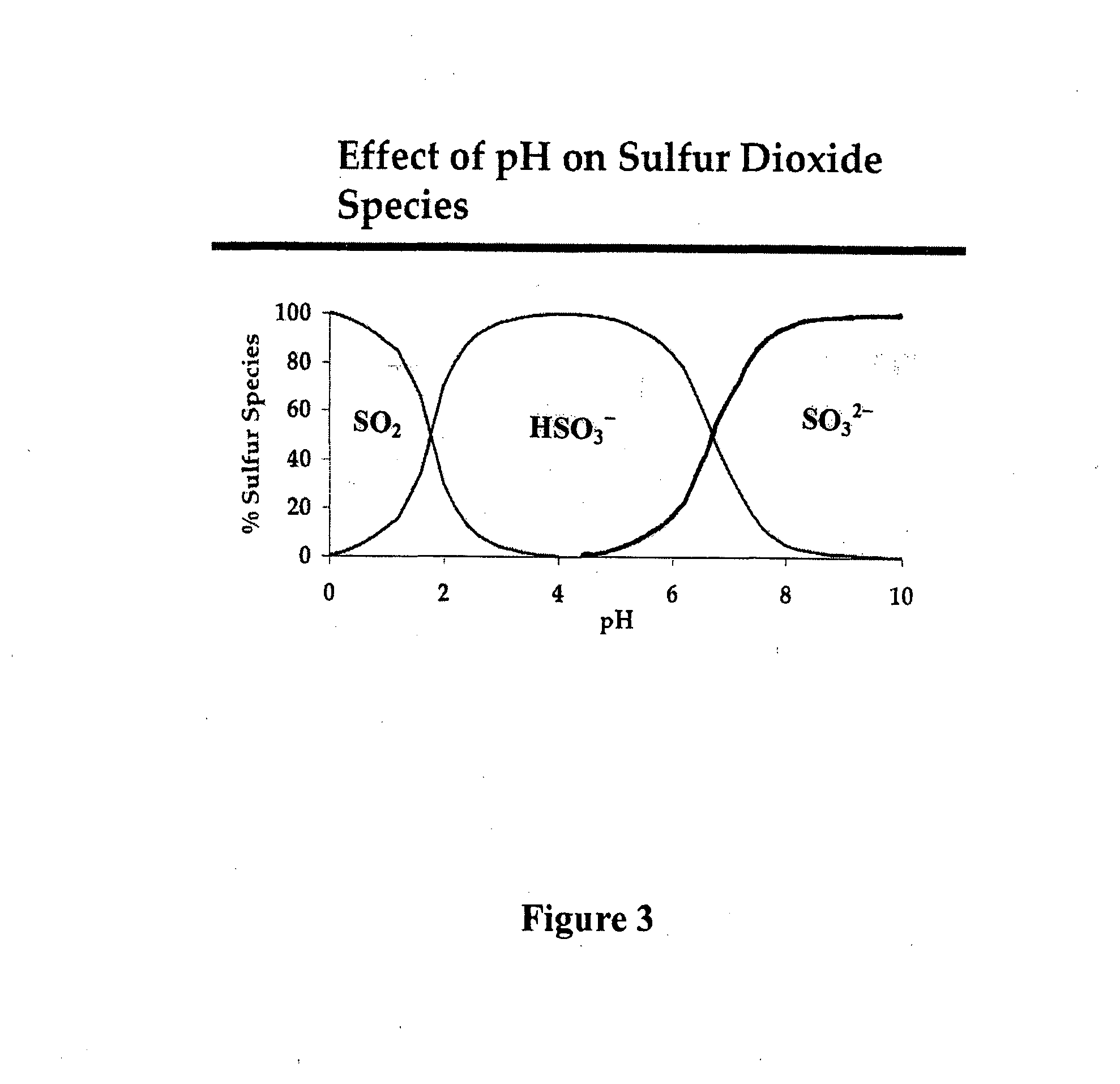

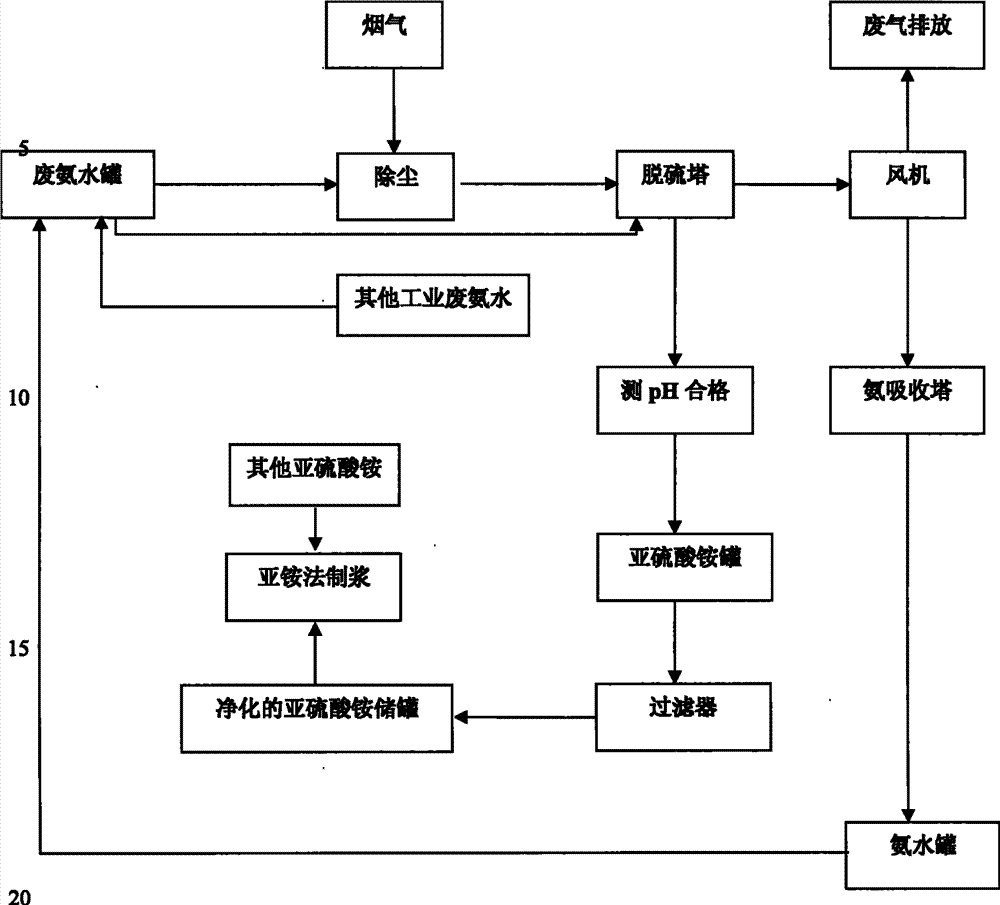

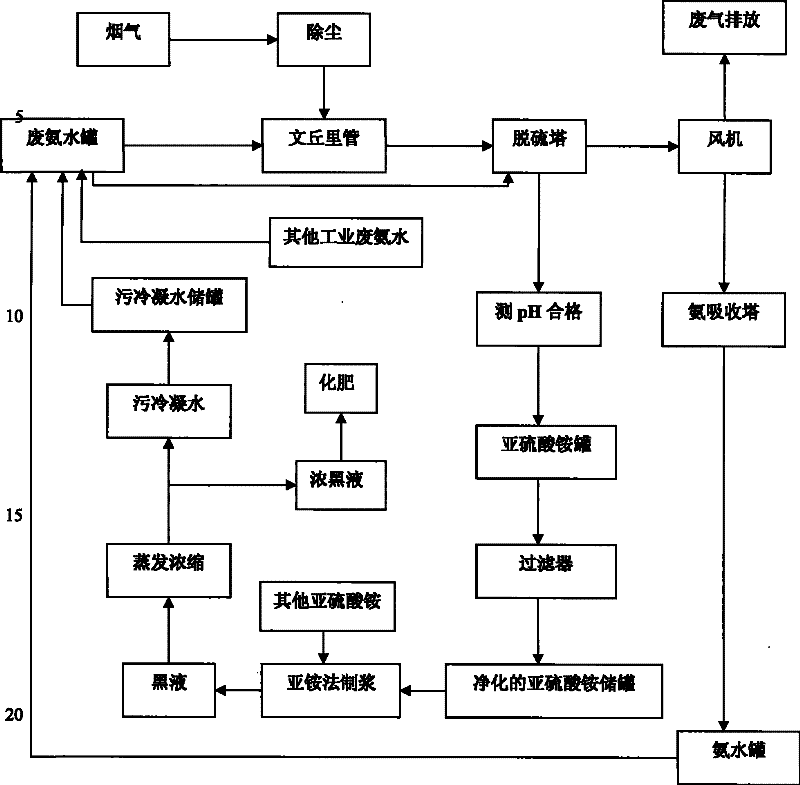

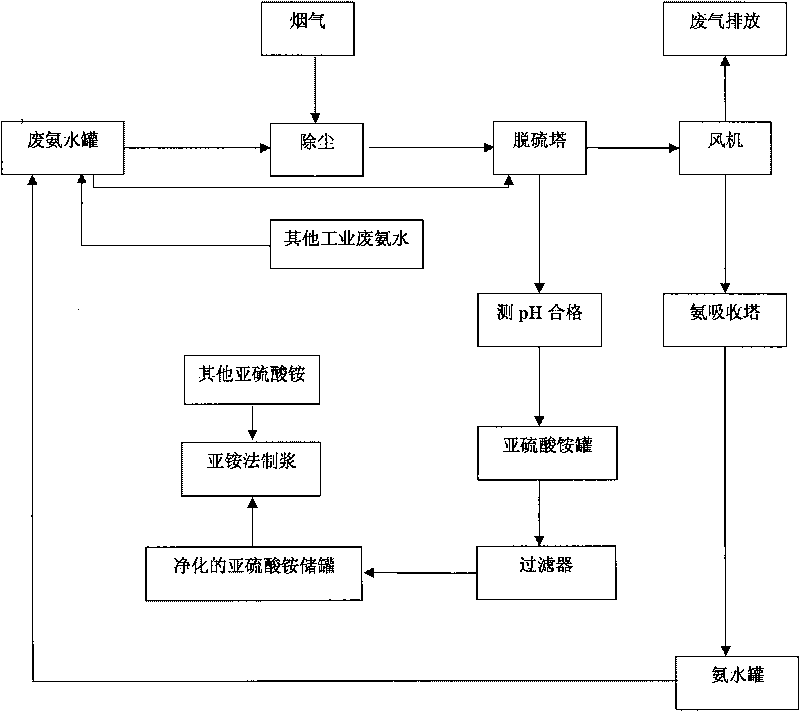

Circulation process for performing ammonium sulfite pulping by using sulfur-containing flue gas absorber

ActiveCN101760975AEmission reductionAchieve recyclingDigestersDispersed particle separationSodium sulfiteSulfur containing

The invention relates to a circulation process for performing ammonium sulfite pulping by using a sulfur-containing flue gas absorber, which comprises the following steps: (1) performing desulphurization on flue gas by using ammonia water, wherein the flue gas is sulfur-containing flue gas; (2) performing ammonium sulfite pulping during papermaking by using sulfurous acid mixed solution obtained after the desulphurization; and (3) performing desulphurization on the flue gas in the step (1) by recycling ammonia-containing contaminated condensate produced during the ammonium sulfite pulping. In the circulation process, a high-efficiency flue gas absorption system is adopted; the obtained ammonium sulfite is used for ammonium sulfite pulping in papermaking industry; and the contaminated condensate produced by pulping can also be used for absorbing sulfur dioxide in the flue gas. The scheme of the invention not only minimally reduces the environmental pollution, but also recycles the resources. The circulation process is particularly suitable to be used in a paper mill with a self-owned power plant.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Treatment and recycle process for sulfite pulping waste liquid

ActiveCN103669069ATurn waste into treasureTo achieve the purpose of reducing pollution and increasing efficiencyRegeneration of sulfite lyeLiquid wasteSeparation technology

The invention discloses a treatment and recycle process for sulfite pulping waste liquid. The treatment and recycle process mainly comprises pretreatment, lignin purification, replacement and modification, nanofiltration and concentration. According to the process, purified lignin sulfonate is obtained by adopting a membrane separation technology; through modification, the sulfonate can be used as a dye dispersant, can be used for preparing a high-efficiency cement dispersant, can also be used for preparing drilling mud diluent and the like, can serve as a raw material of vanillin, and can be used for preparing high-quality food spices and the like; high-value utilization of waste is realized. After the sulfite is treated by the process, over 80 percent of lignin sulfonate, 70 to 90 percent of reducing sugar and 60 to 80 percent of water can be recycled; the production cost can be reduced for production enterprises; waste water emission amount can be greatly reduced; waste solid emission amount can be greatly reduced; the requirement on environment friendliness of the enterprises can be met more easily; the aims of saving energy and reducing emission can be fulfilled for the enterprises.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Conditioning of so2-ethanol-water spent liquor for fermentation by clostridia

The present invention relates to producing chemicals and biofuels from wood material, e.g. mixed forest biomass. Specifically, the invention concerns a process for conditioning spent liquor produced by SO2-ethanol-water (SEW) fractionation of wood chips for fermentation to butanol, ethanol and acetone / isopropanol (so called ABE process) by Clostridia bacteria.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

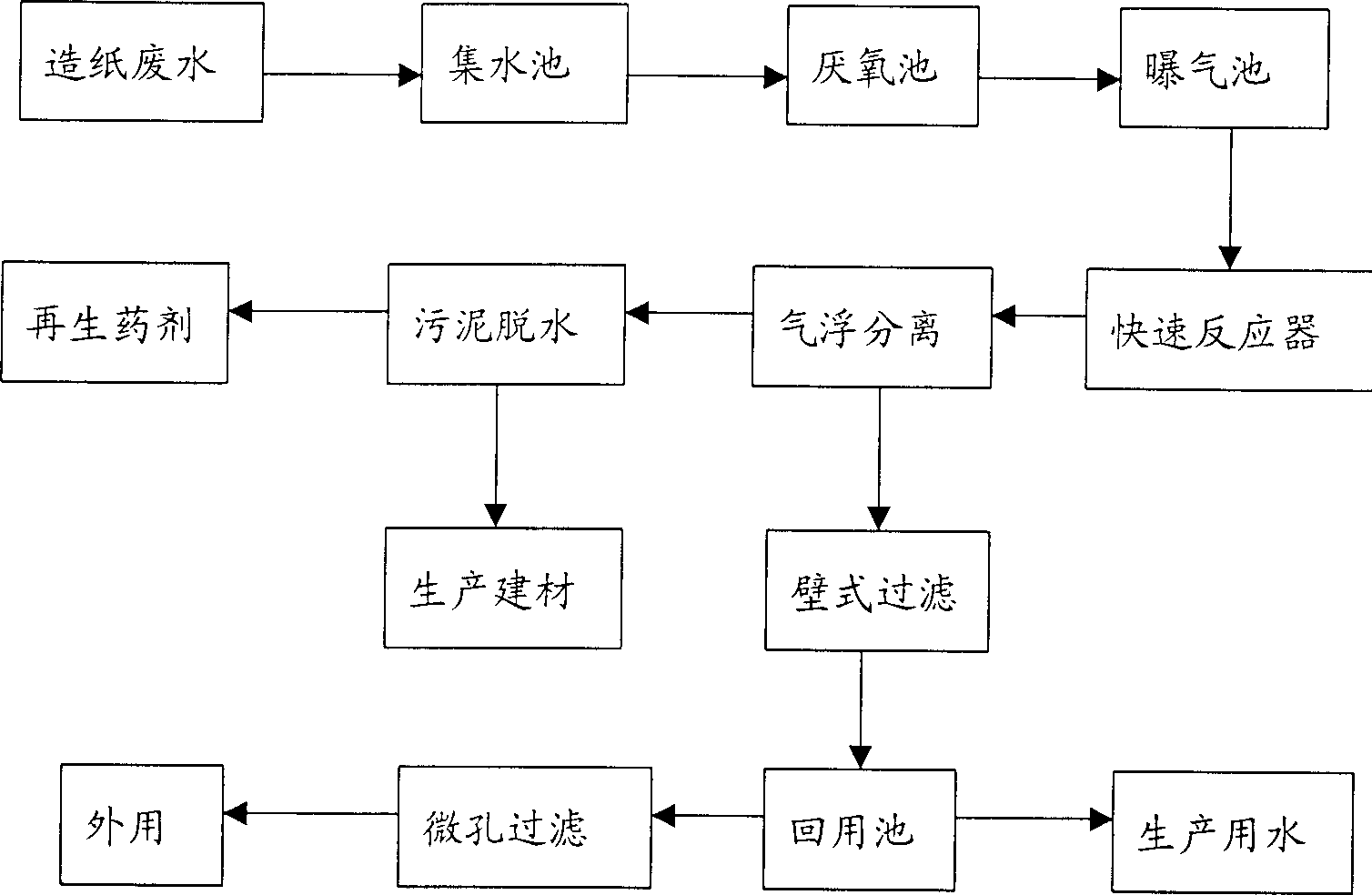

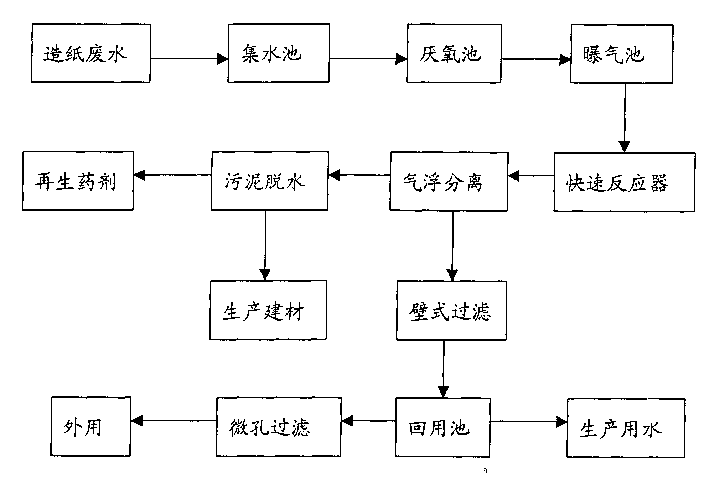

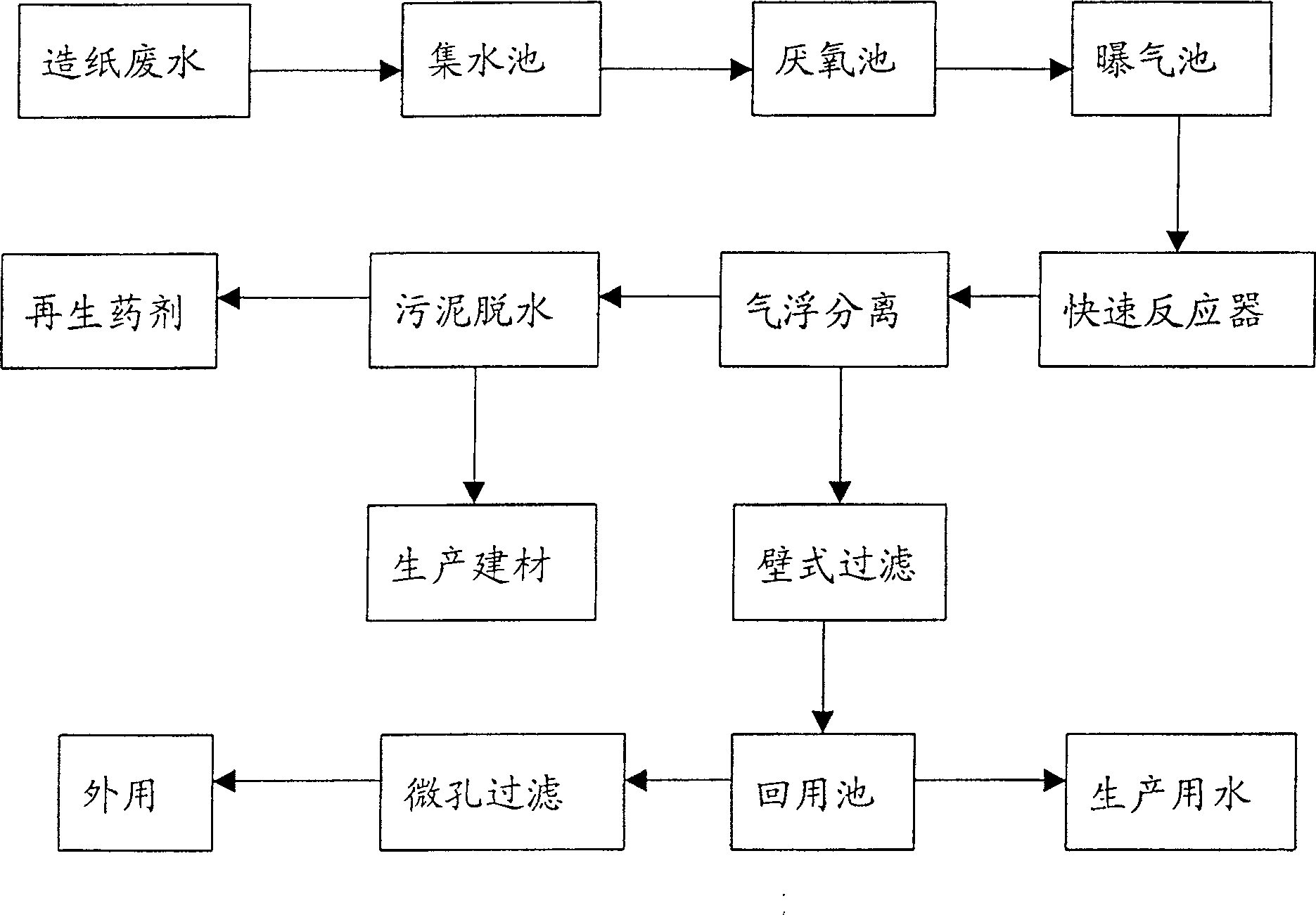

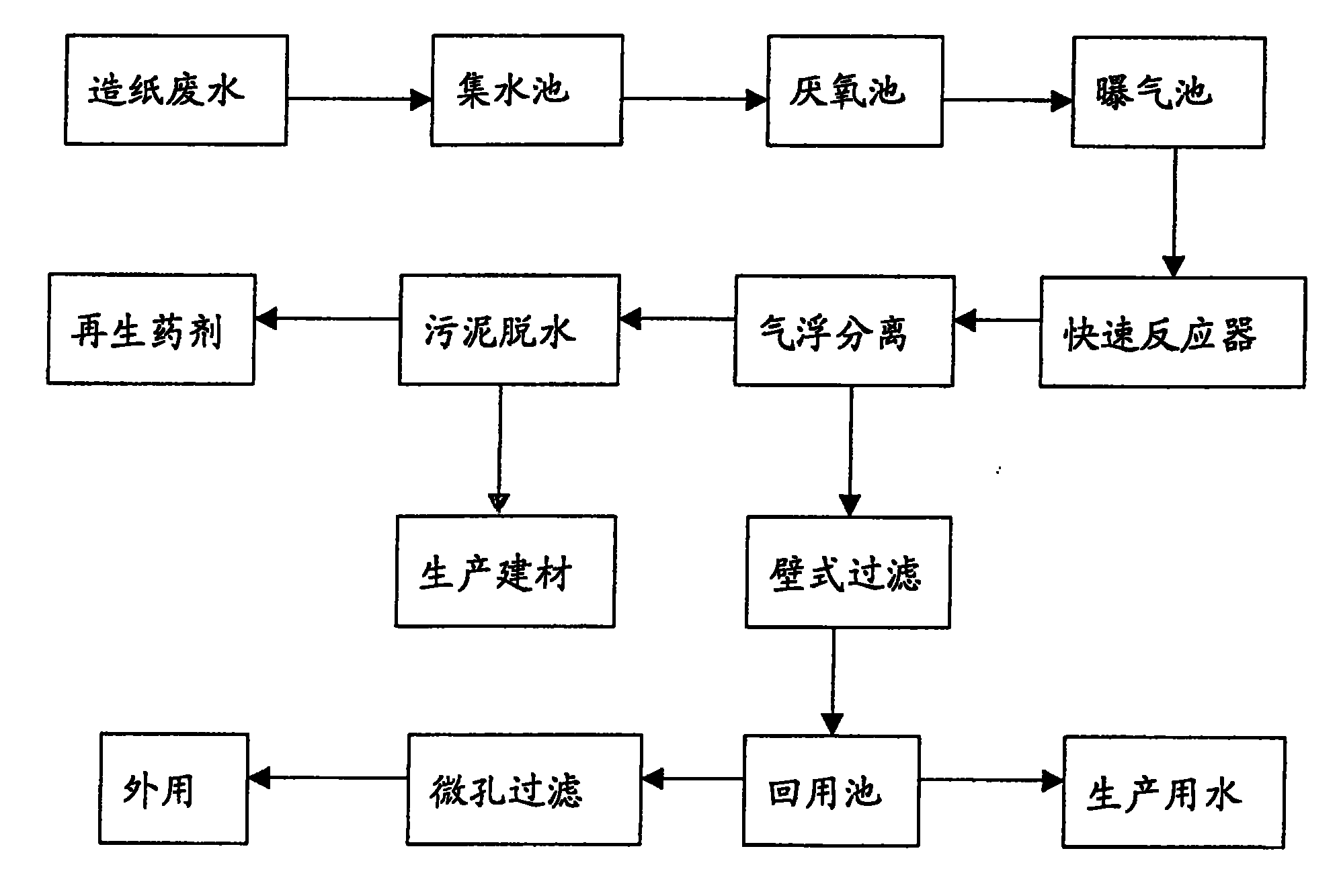

Closed treatment method of paper-making waste water with sulfite

InactiveCN1374423ALess investmentLow running costMultistage water/sewage treatmentRegeneration of sulfite lyeSulfite saltWastewater

The closed treatment of papermaking waste water with sulfites, including ammonium sulfite and sodium sulfite, consists of bacteria strain culture, biochemical treatment, separation of lignin and other matters in alkali or neutral condition, gas floating, filtering, and returning filtrate for reuse in digestion and pulp making. The present invention has the advantages of complete treatment, recovery of all water and reduced investment and running cost.

Owner:尤丹丹

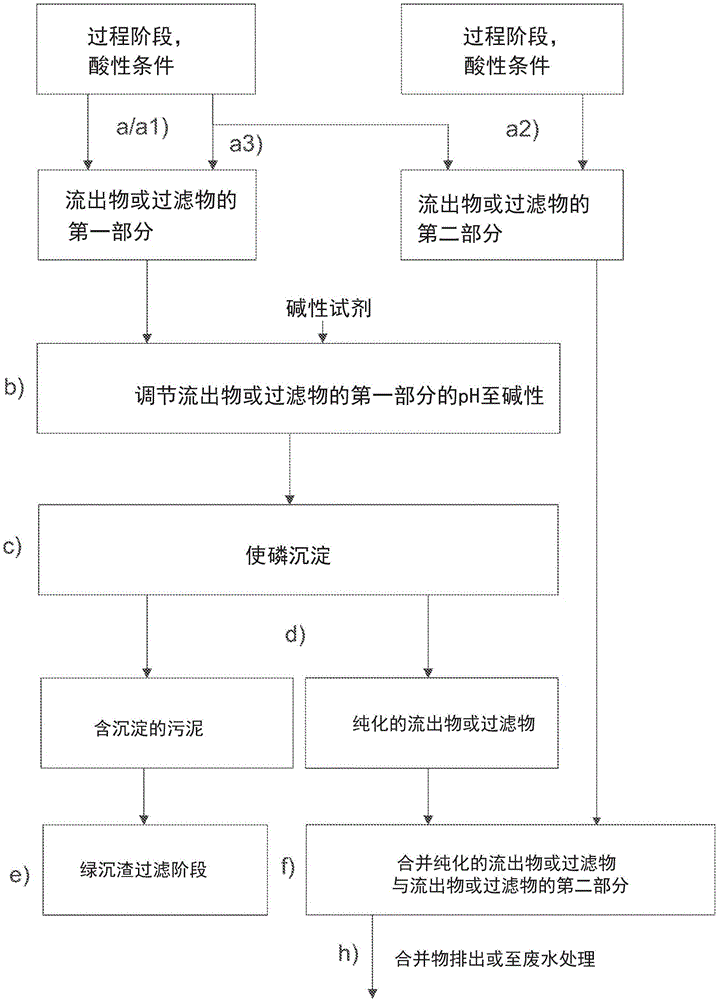

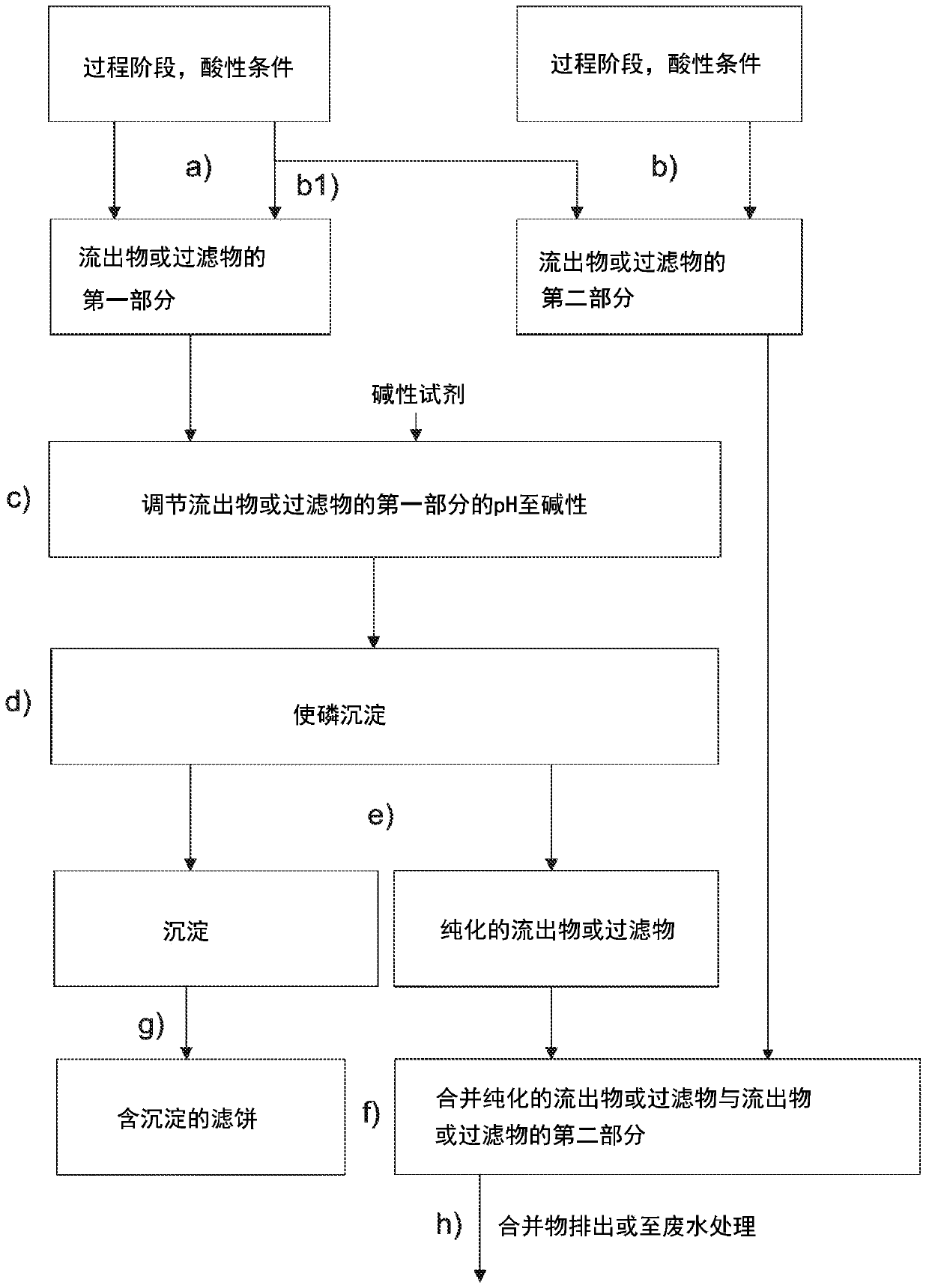

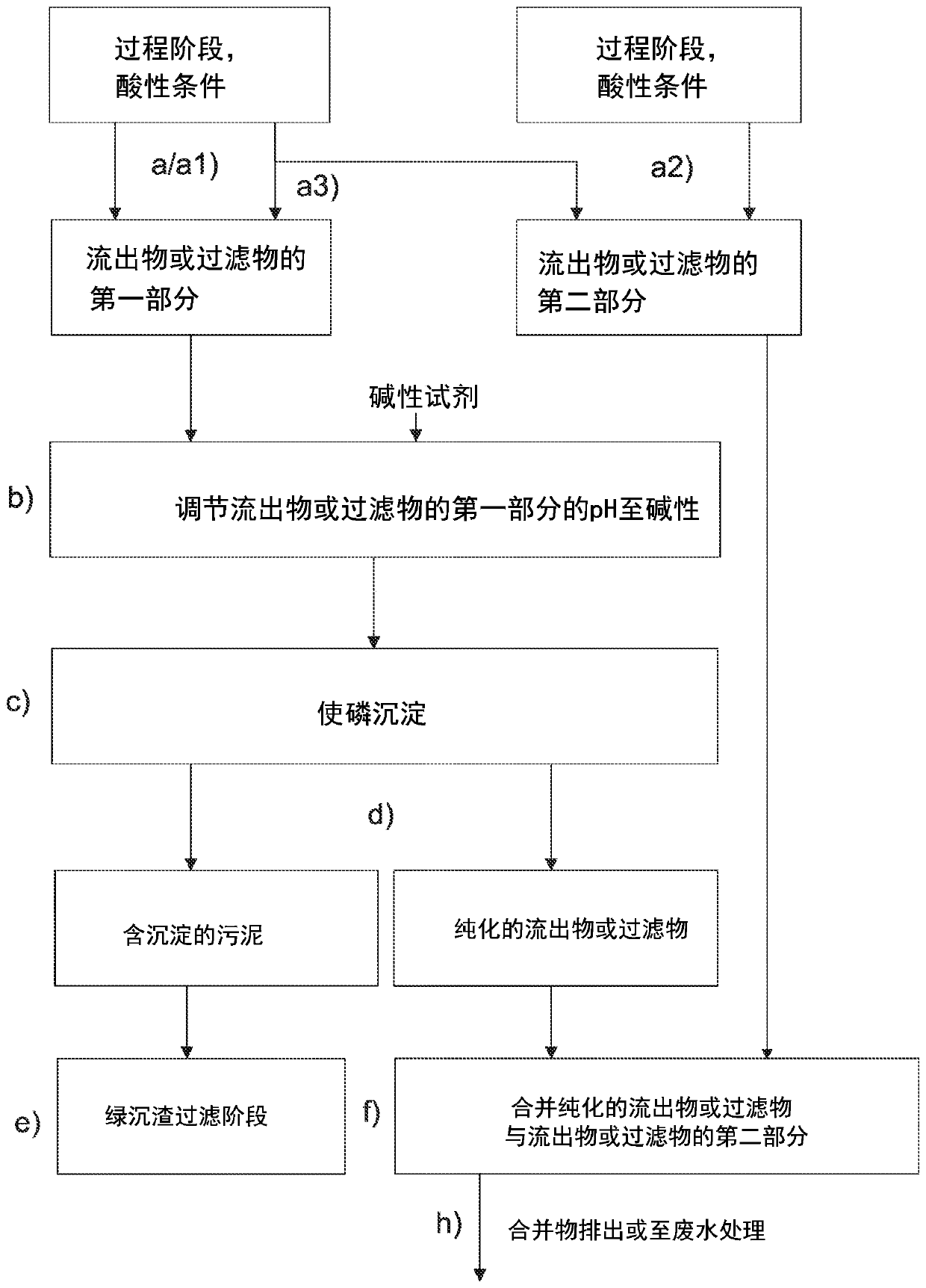

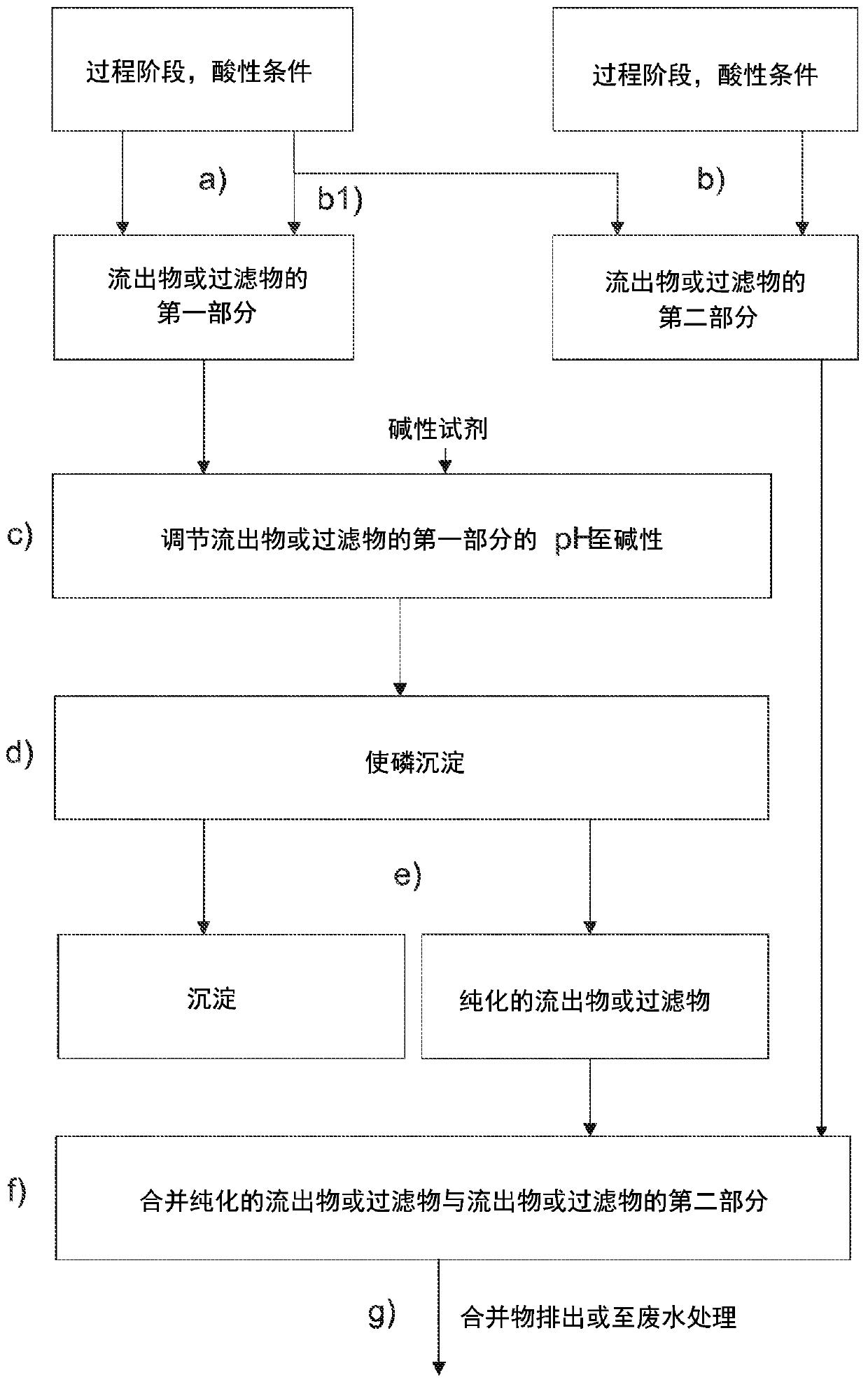

Method and system for reducing phosphorus in effluent or filtrate

ActiveCN106414347AReduce phosphorus contentTreatment using aerobic processesTreatment involving filtrationSludgePhosphate

The invention relates to a method for reducing phosphorus in effluent or filtrate from a process which comprises a stage in which green liquor dregs are filtered using a green liquor dregs filter and at least one stage in which conditions are acidic, wherein the method comprises the steps of: a) obtaining an effluent or filtrate from a stage in which conditions are acidic; b) adjusting pH of at least a portion of the effluent or filtrate to alkaline with an alkaline agent; c) allowing phosphorus to be precipitated in form of a phosphate salt; d) separating the precipitate to produce purified effluent or filtrate and a sludge comprising the precipitate; and e) filtering the sludge comprising the precipitate obtainable from step d) using the green liquor dregs filter.

Owner:UPM-KYMMENE OYJ

Polysulfide measurement methods using colormetric techniques

InactiveUS6875414B2Pulp liquors combustionMaterial analysis by observing effect on chemical indicatorPolysulfideInorganic sulfide

Methods of converting a sulfide in a composition to polysulfide are described, one method comprising the steps of exposing the composition to conditions and for a time sufficient to cause conversion of at least a portion of the sulfide, to polysulfide to form a modified composition; and controlling the conversion to polysulfide by measuring a color parameter of the modified composition.

Owner:AIR LIQUIDE AMERICA INC +1

Alkali recovery method for by-producing activated carbon and white carbon black by using paper making black liquid

InactiveCN102587187BImprove evaporation efficiencyReduce energy consumptionSilicaCarbon compoundsRecovery methodActivated carbon

The invention relates to paper making industry clean production, in particular to an alkali recovery method based on paper making black liquid. The method comprises the following steps of: 1) adding carbon powder in paper making black liquid, introducing CO2 gas for carrying out primary hydrothermal carbonization, and carrying out filtering to obtain primary hydrothermal carbonization liquid and primary hydrothermal carbonization materials; 2) adding crude activated carbon into the primary hydrothermal carbonization liquid obtained in the first step, carrying out secondary hydrothermal carbonization under the CO2 gas introduction condition, carrying out filtering to obtain secondary hydrothermal carbonization liquid and secondary hydrothermal carbonization materials, evaporating the secondary hydrothermal carbonization liquid, regulating the pH (Potential Of Hydrogen), and carrying out causticization treatment to obtain alkali liquid. The method provided by the invention has the advantages that because the alkali recovery work procedure is a bottle neck of most alkali process pulp making paper making plants in prior art, after the efficiency of the process is improved, the pulp making capability of the paper making plants can be greatly improved, meanwhile, the by-production of high-added-value activated carbon and white carbon black can be realized, and further, the scale benefits of the paper making enterprises can be integrally improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for performing ammonium sulfite pulping by using sulfur-containing flue gas absorber

ActiveCN101760974BEmission reductionAchieve recyclingDigestersDispersed particle separationSodium sulfiteSulfur containing

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

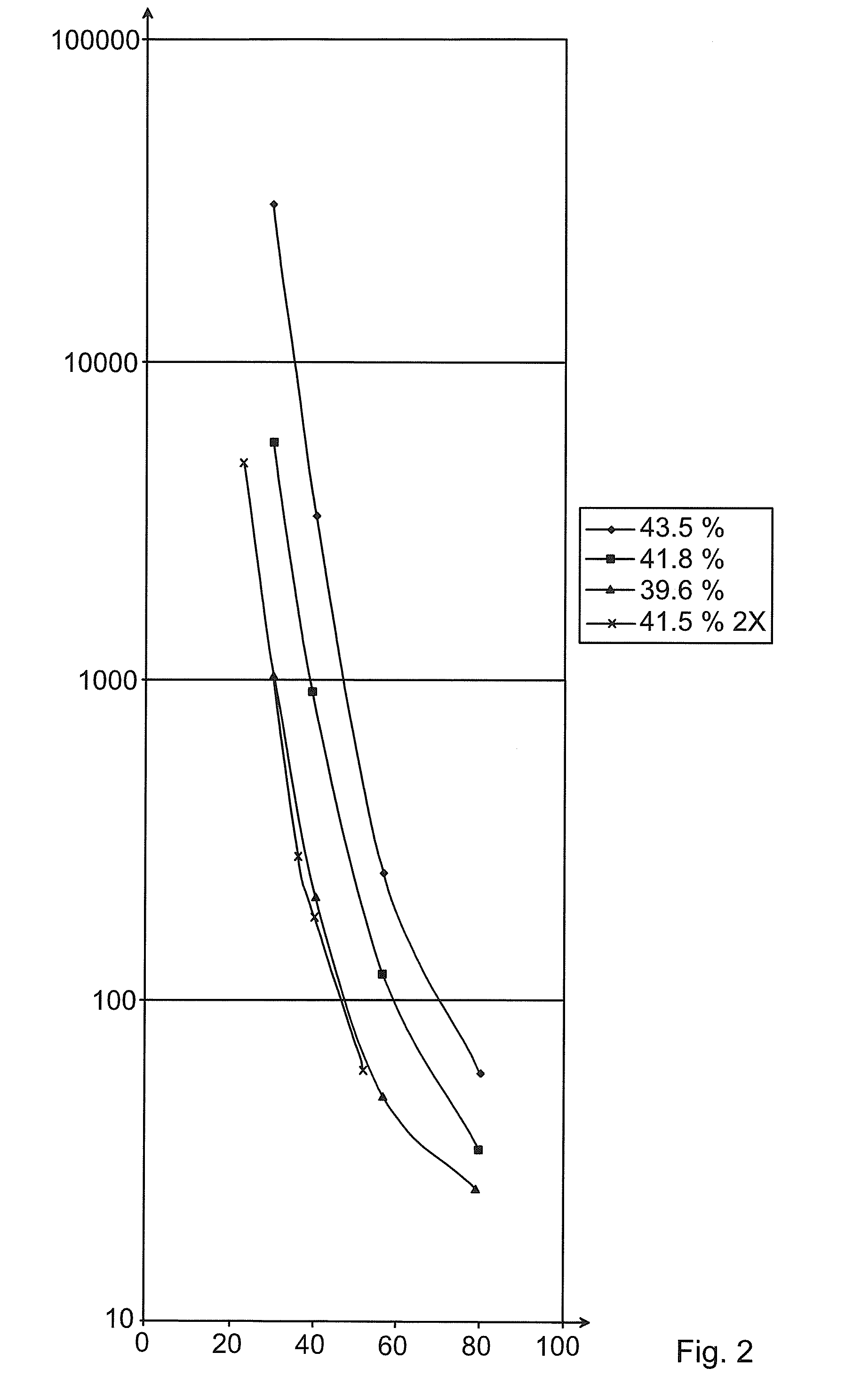

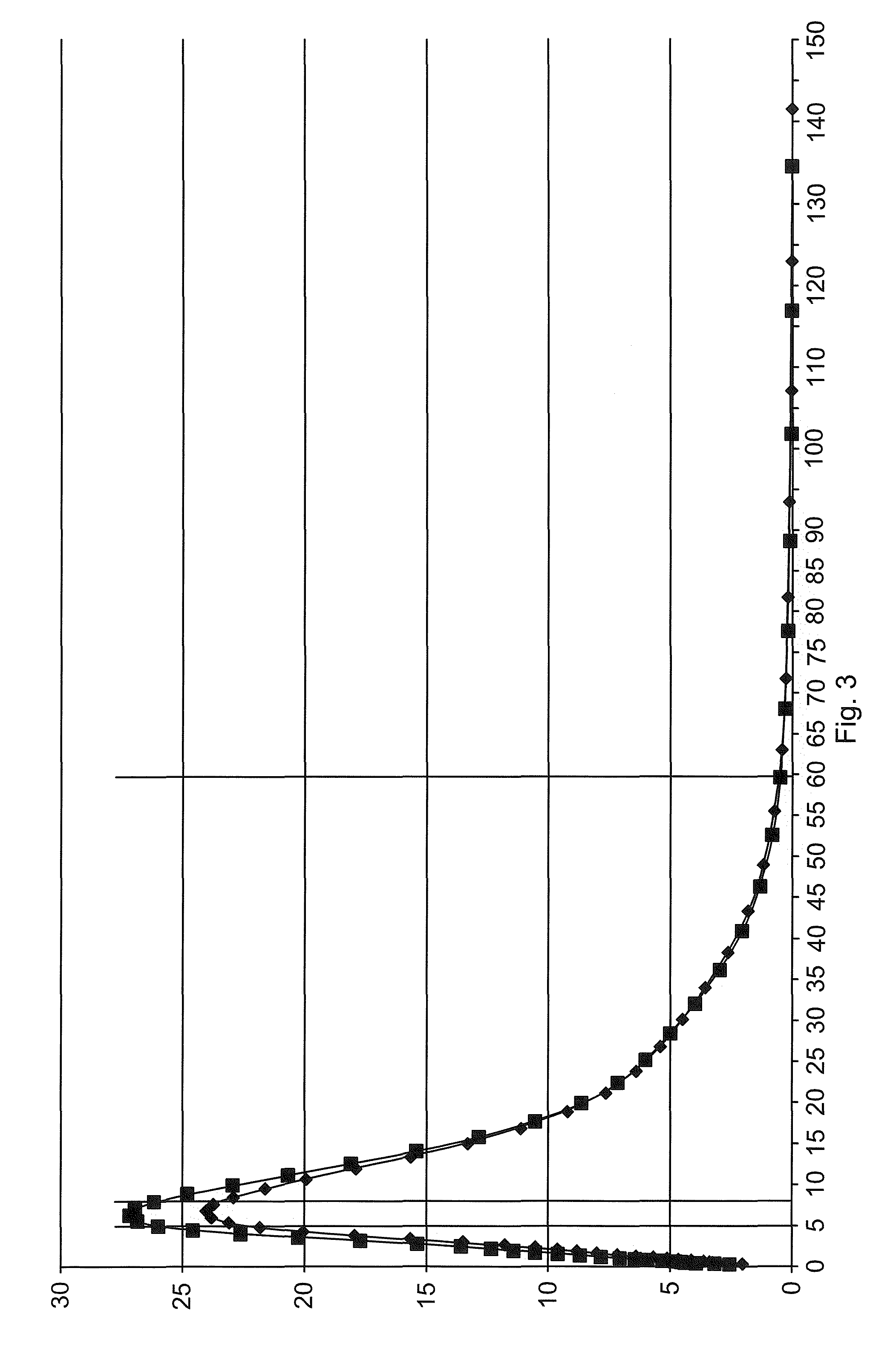

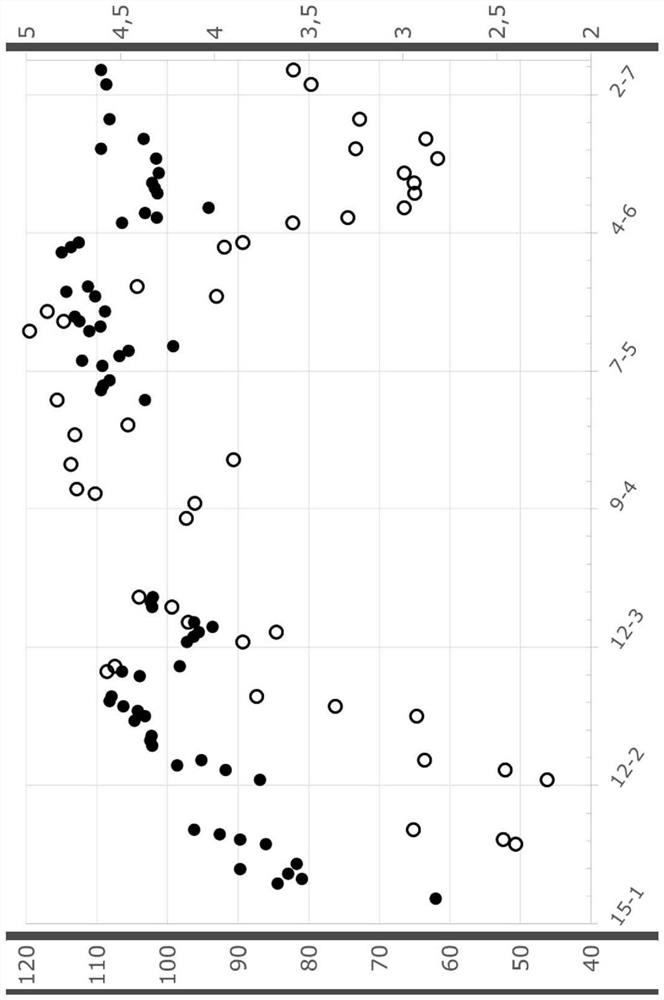

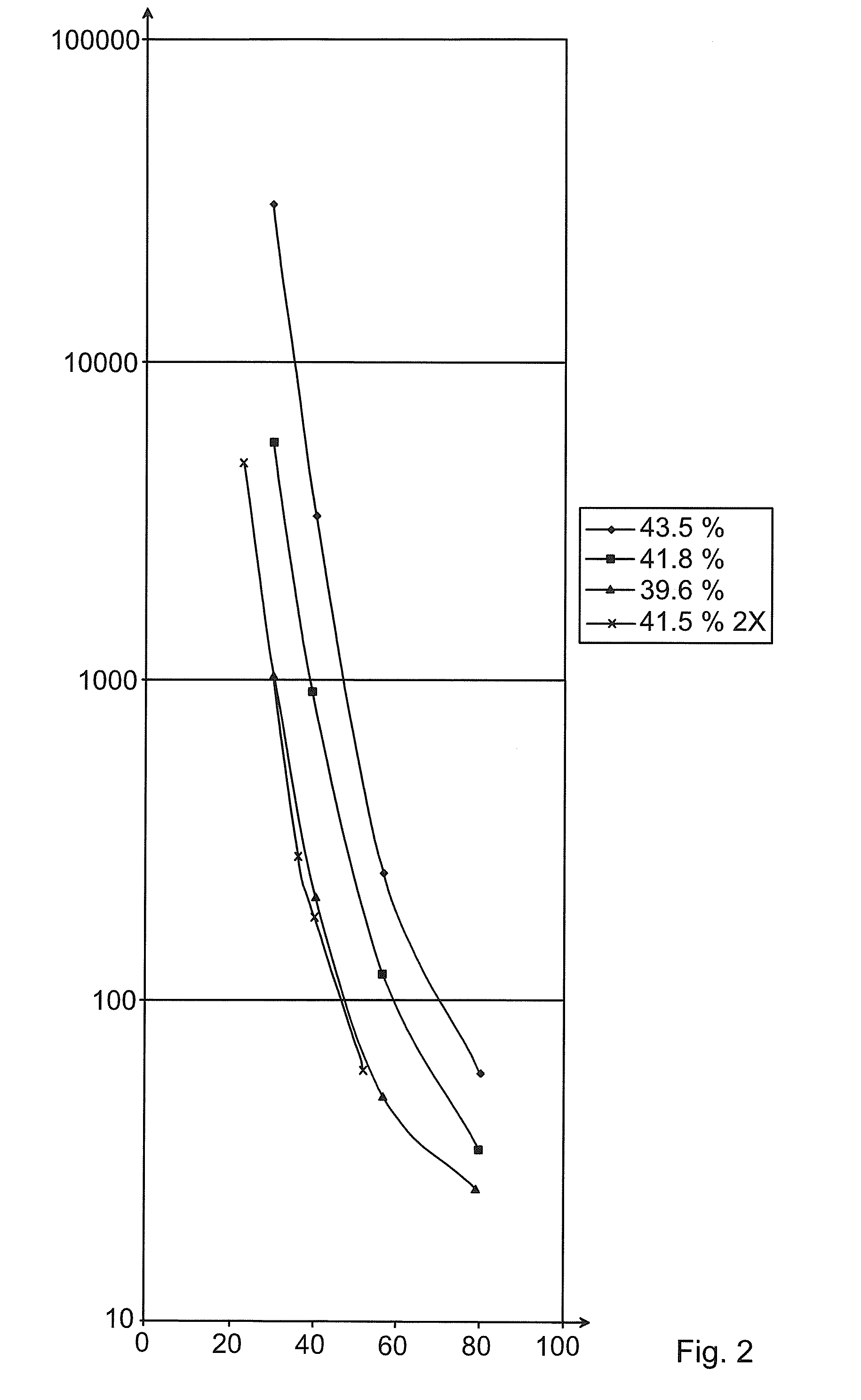

Lignosulfonate of a certain quality and method of preparation of lignosulfonate of a certain quality

ActiveUS20120267064A1Increase productionIncrease capacitySemi-permeable membranesSolid waste managementFiltrationLignosulfonates

There is provided a process for improving the quality of lignosulfonate at least partly derived form a spent sulfite cooking liquor in at least two steps, comprising: one step in which a lignosulfonate-containing fraction at least partly derived from the spent sulfite cooking liquor is subjected to filtration using a membrane having a cut-off of 40-150 kD (high cut-off) at the pressure, flow rate and temperature of the step and the permeate is recovered; and another step in which a lignosulfonate-containing fraction at least partly derived from the spent sulfite cooking liquor is subjected to filtration using a membrane having a cut-off of 1-20 kD (low cut-off) at the pressure, flow rate and temperature of the step and the retentate is recovered. Products, uses thereof as well as a system are also provided.

Owner:DOMSJO FAB

Circulation process for performing ammonium sulfite pulping by using sulfur-containing flue gas absorber

ActiveCN101760975BEmission reductionAchieve recyclingDigestersDispersed particle separationSulfite saltWater circulation

The invention relates to a circulation process for performing ammonium sulfite pulping by using a sulfur-containing flue gas absorber, which comprises the following steps: (1) performing desulphurization on flue gas by using ammonia water, wherein the flue gas is sulfur-containing flue gas; (2) performing ammonium sulfite pulping during papermaking by using sulfurous acid mixed solution obtained after the desulphurization; and (3) performing desulphurization on the flue gas in the step (1) by recycling ammonia-containing contaminated condensate produced during the ammonium sulfite pulping. Inthe circulation process, a high-efficiency flue gas absorption system is adopted; the obtained ammonium sulfite is used for ammonium sulfite pulping in papermaking industry; and the contaminated condensate produced by pulping can also be used for absorbing sulfur dioxide in the flue gas. The scheme of the invention not only minimally reduces the environmental pollution, but also recycles the resources. The circulation process is particularly suitable to be used in a paper mill with a self-owned power plant.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for producing bio-methanol at pulp mills

ActiveUS9394220B2Reduce sulfur contentIon-exchange process apparatusFermented solutions distillation/rectificationDistillationReverse osmosis

The present invention describes a process and system of producing methanol from methanol condensates. In a preferred embodiment the condensates are biomethanol condensates from chemical pulp mills and various waste sources used to produce a purified biomethanol. Pulp condensates are rich in methanol and contain many other contaminants. Presently, most chemical pulp mills, such as Kraft pulp mills use steam stripping to remove and concentrate the methanol and burn the methanol onsite along with the contaminants. A combination of treatments that include air stripping, steam stripping, distillation and reverse osmosis is described to obtain purified biomethanol suitable for sale or use on site.

Owner:FPINNOVATIONS INC

Process for controlling sodium and sulfur balance in pulp mill

ActiveCN112534094AImproves sodium/sulfur balanceLess quantityWater treatment parameter controlWater contaminantsPulp millEngineering

Owner:STORA ENSO OYJ +1

Method and system for reducing phosphorus in effluent or filtrate

The present invention relates to a method for reducing phosphorus in an effluent or filtrate from a process comprising at least one stage in which conditions are acidic, wherein said method comprises the step of: a) taking an effluent from a stage in which conditions are acidic or a first part of the filtrate; b) taking an effluent or a second part of the filtrate from the same or a different stage where the conditions are acidic; c) adjusting the pH of said first part of the effluent or filtrate with an alkaline reagent adjusting to alkaline; d) allowing the phosphorus to precipitate in the form of phosphate; e) isolating said precipitate by filtration to produce a purified effluent or filtrate; and f) combining the purified effluent or filtrate with said effluent or the second portion of the filtrate is combined.

Owner:UPM-KYMMENE OYJ

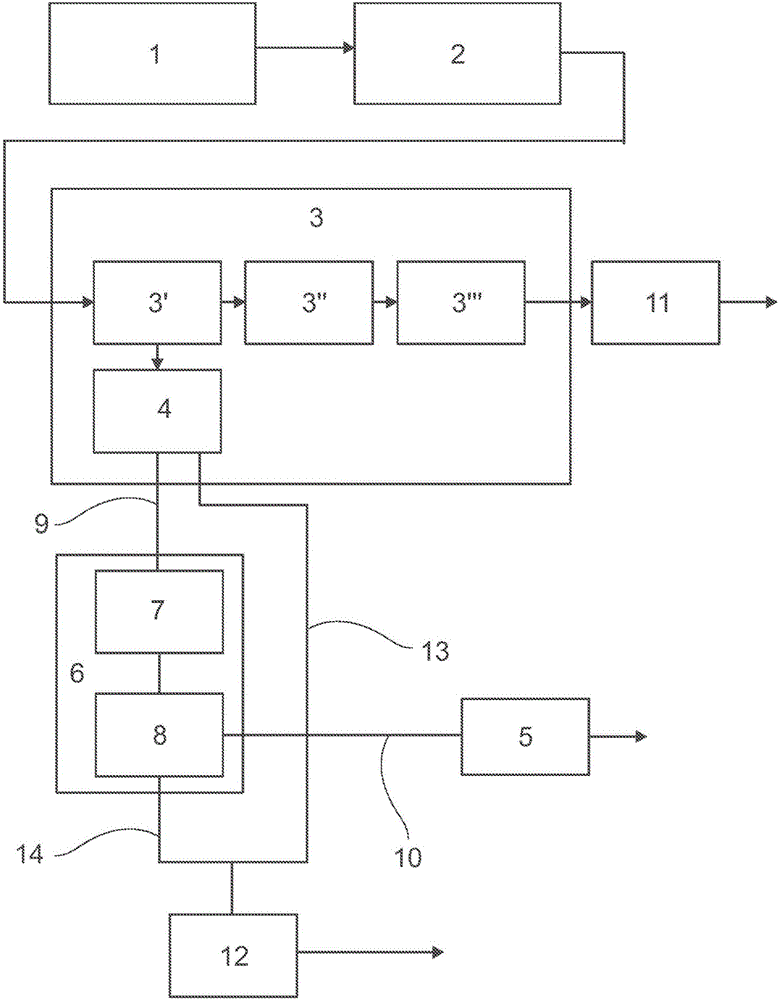

Lignosulfonate of a certain quality and method of preparation of lignosulfonate of a certain quality

ActiveUS9447131B2Increase productionIncrease capacitySolid waste managementTransportation and packagingFiltrationLignosulfonates

There is provided a process for improving the quality of lignosulfonate at least partly derived form a spent sulfite cooking liquor in at least two steps, comprising: one step in which a lignosulfonate-containing fraction at least partly derived from the spent sulfite cooking liquor is subjected to filtration using a membrane having a cut-off of 40-150 kD (high cut-off) at the pressure, flow rate and temperature of the step and the permeate is recovered; and another step in which a lignosulfonate-containing fraction at least partly derived from the spent sulfite cooking liquor is subjected to filtration using a membrane having a cut-off of 1-20 kD (low cut-off) at the pressure, flow rate and temperature of the step and the retentate is recovered. Products, uses thereof as well as a system are also provided.

Owner:DOMSJO FAB

Method and system for reducing phosphorus in effluent or filtrate

ActiveCN106414347BTreatment using aerobic processesTreatment involving filtrationSludgeSediment Filter

Owner:UPM-KYMMENE OYJ

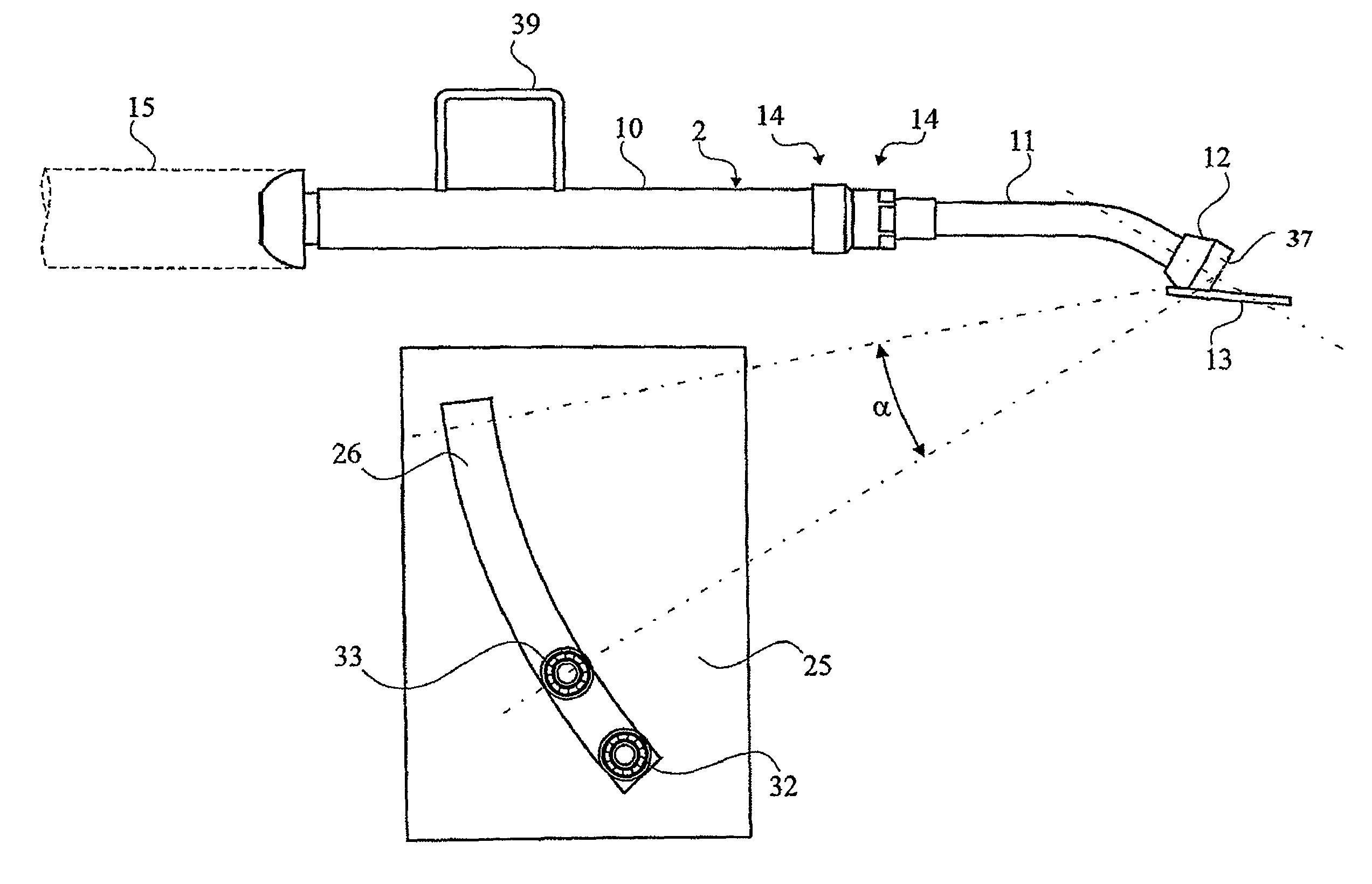

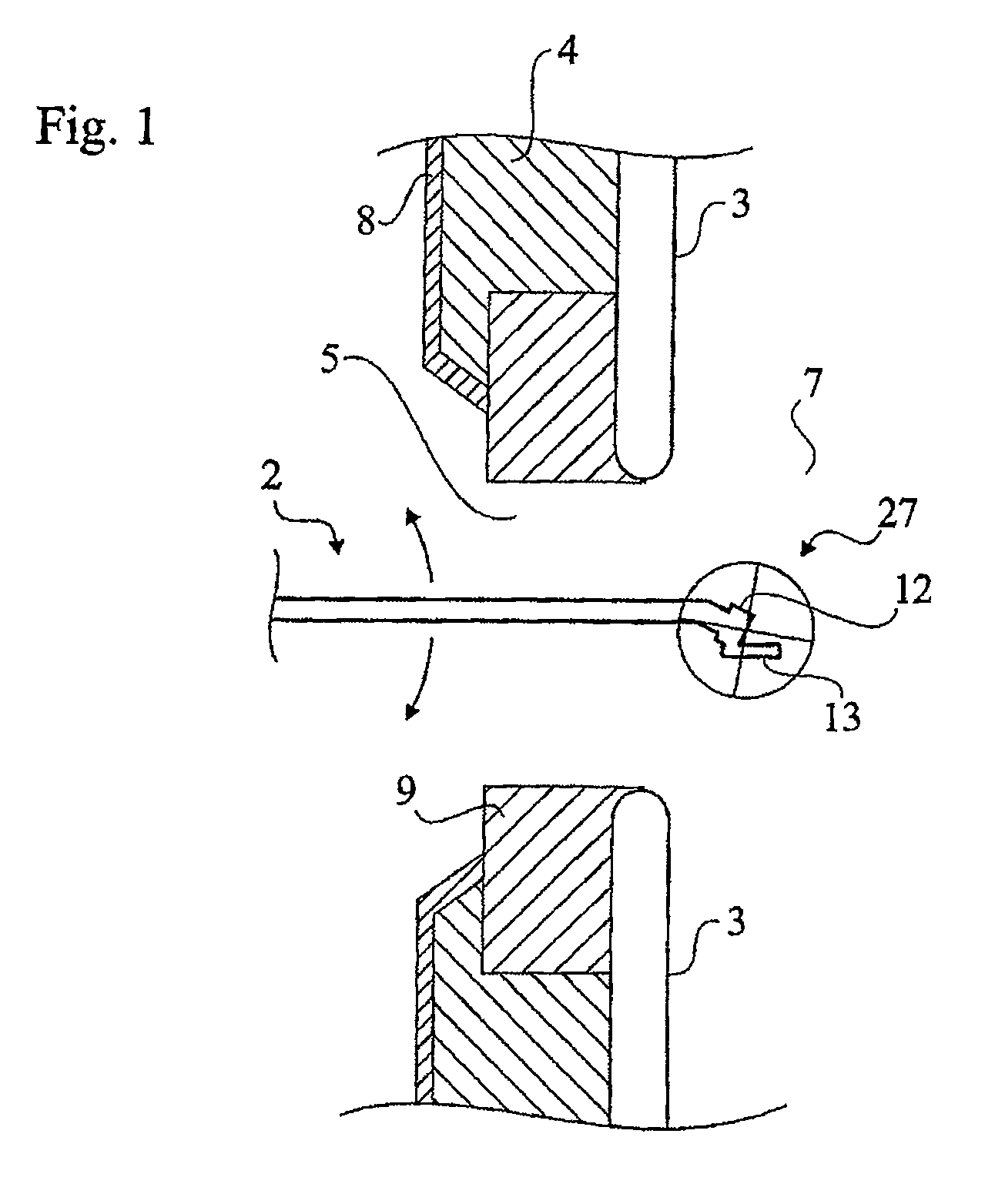

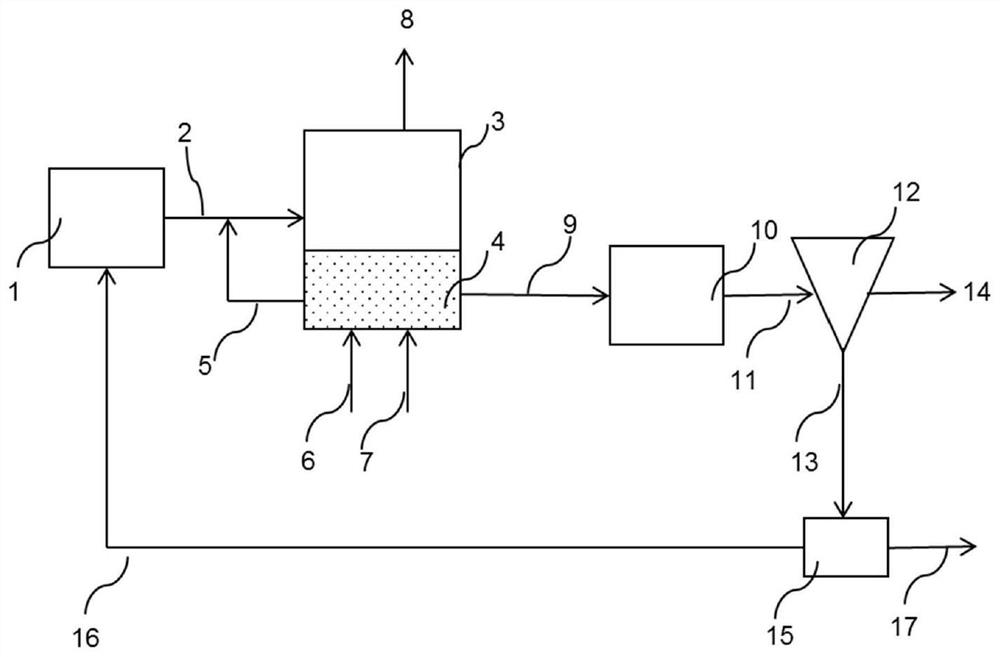

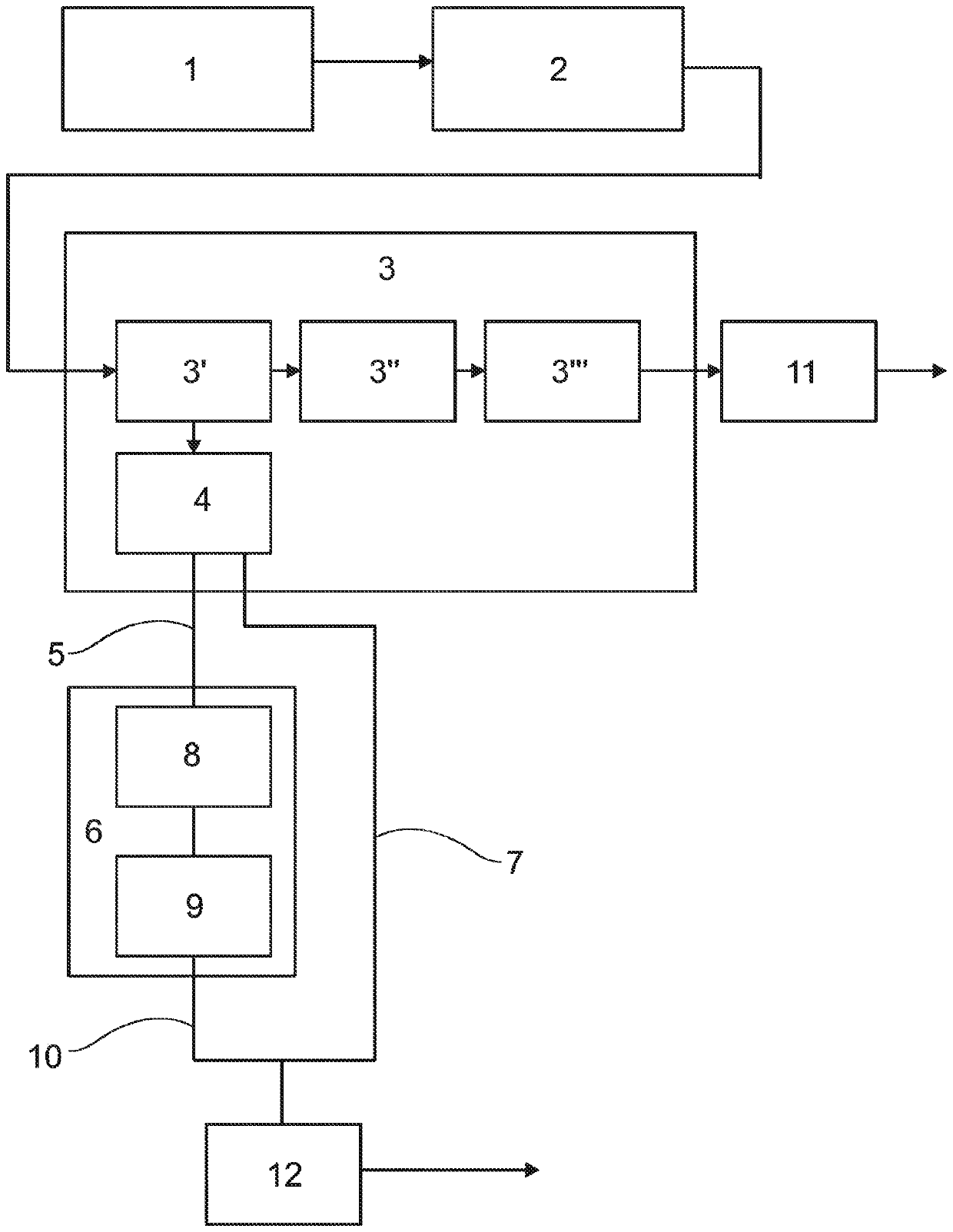

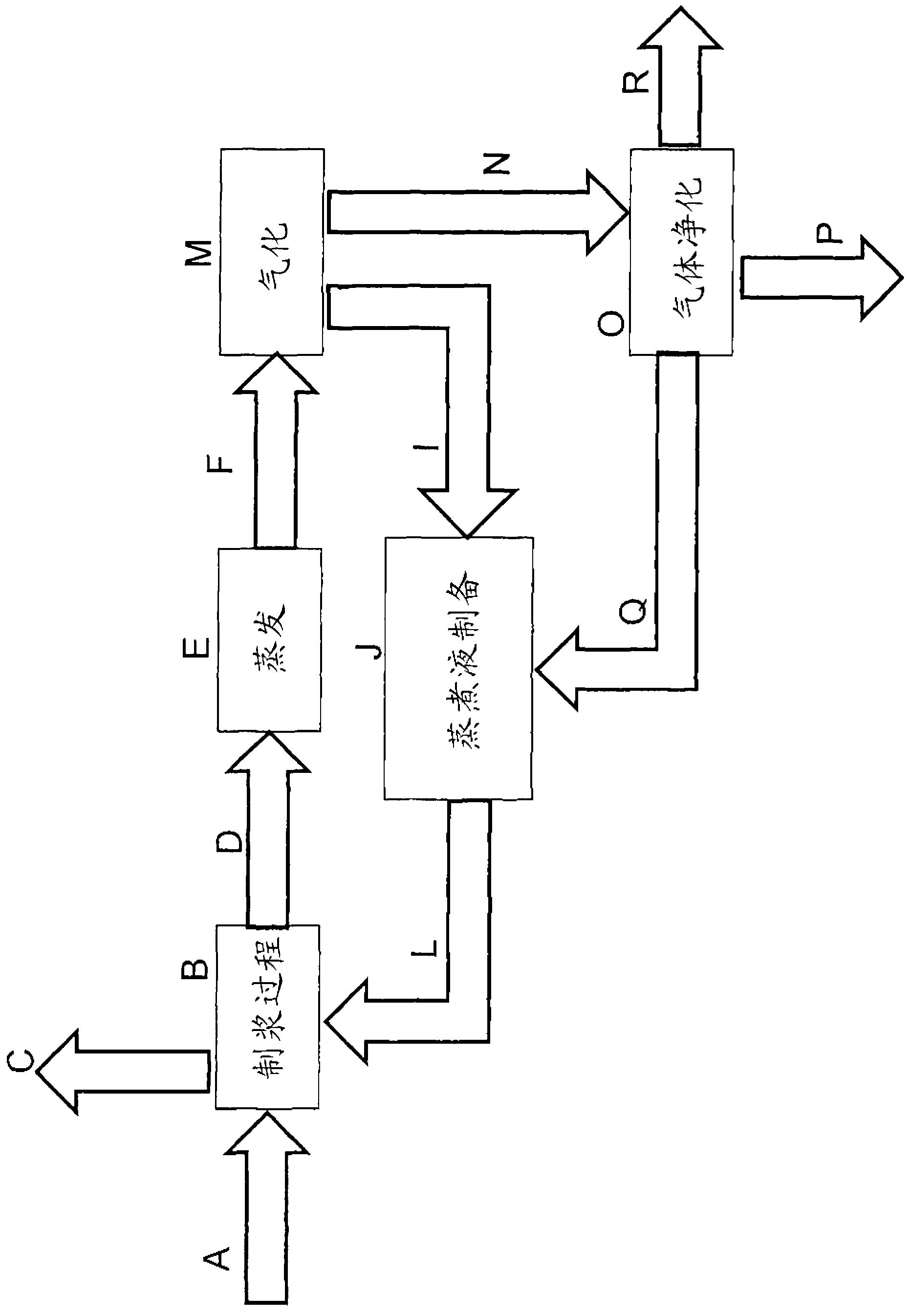

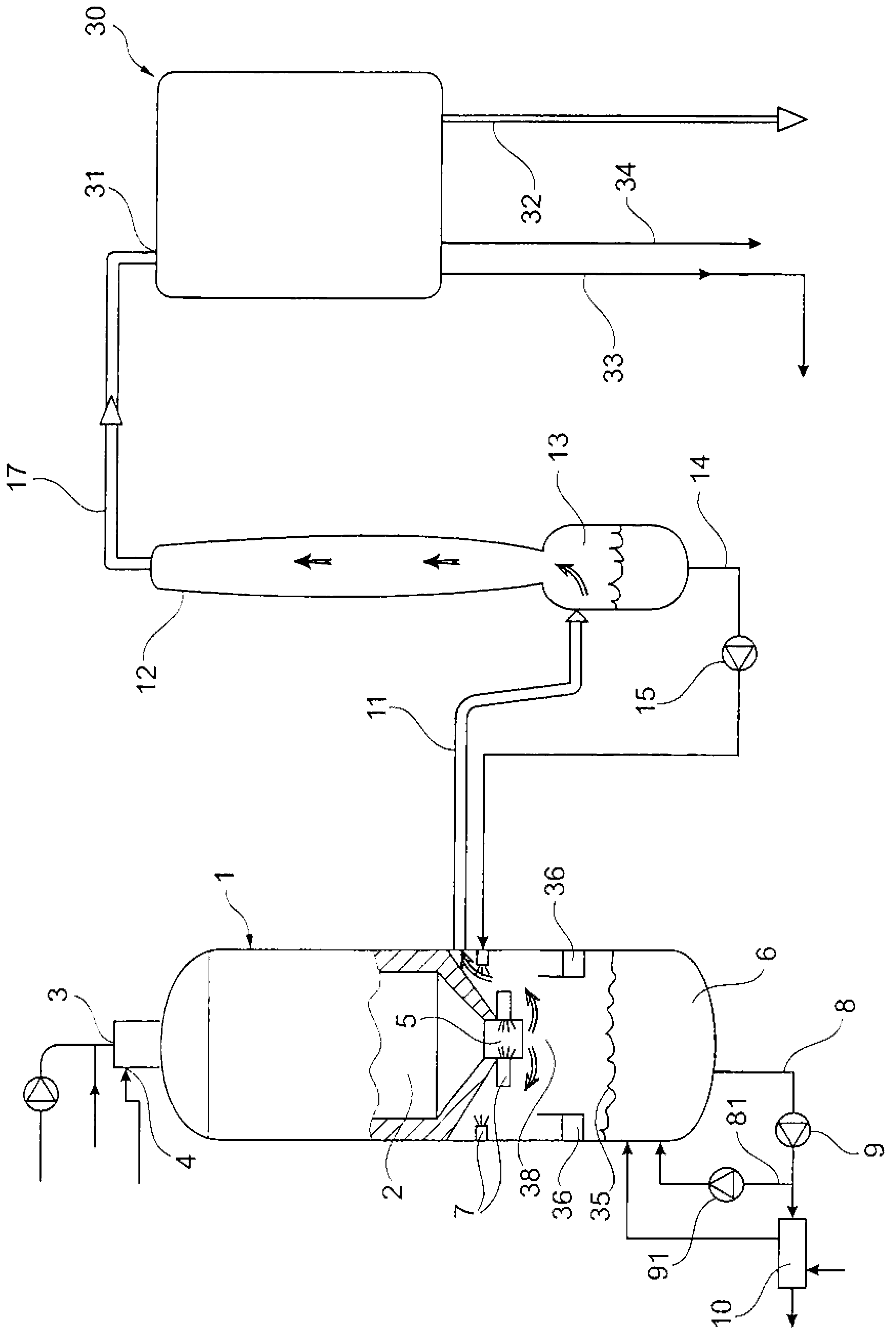

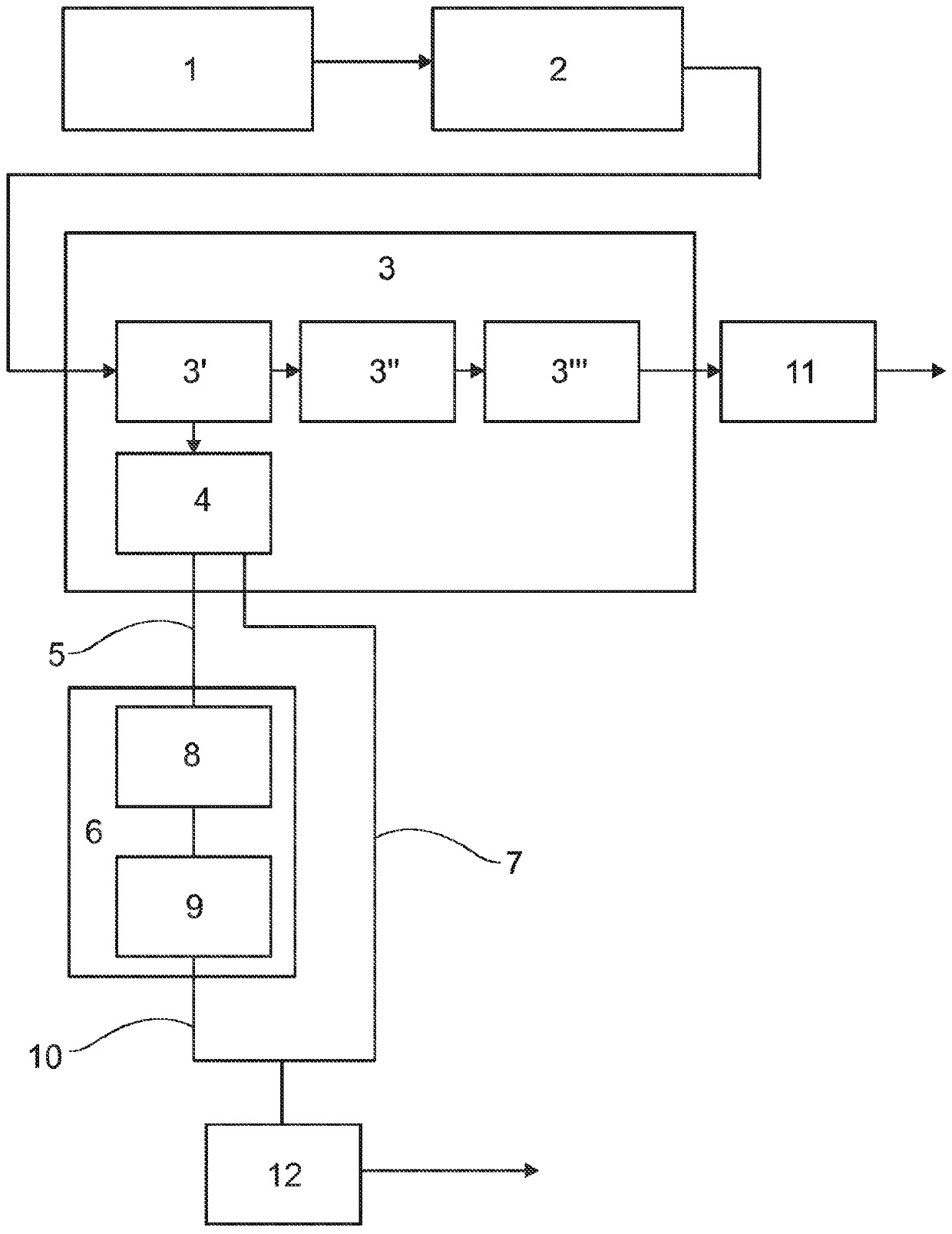

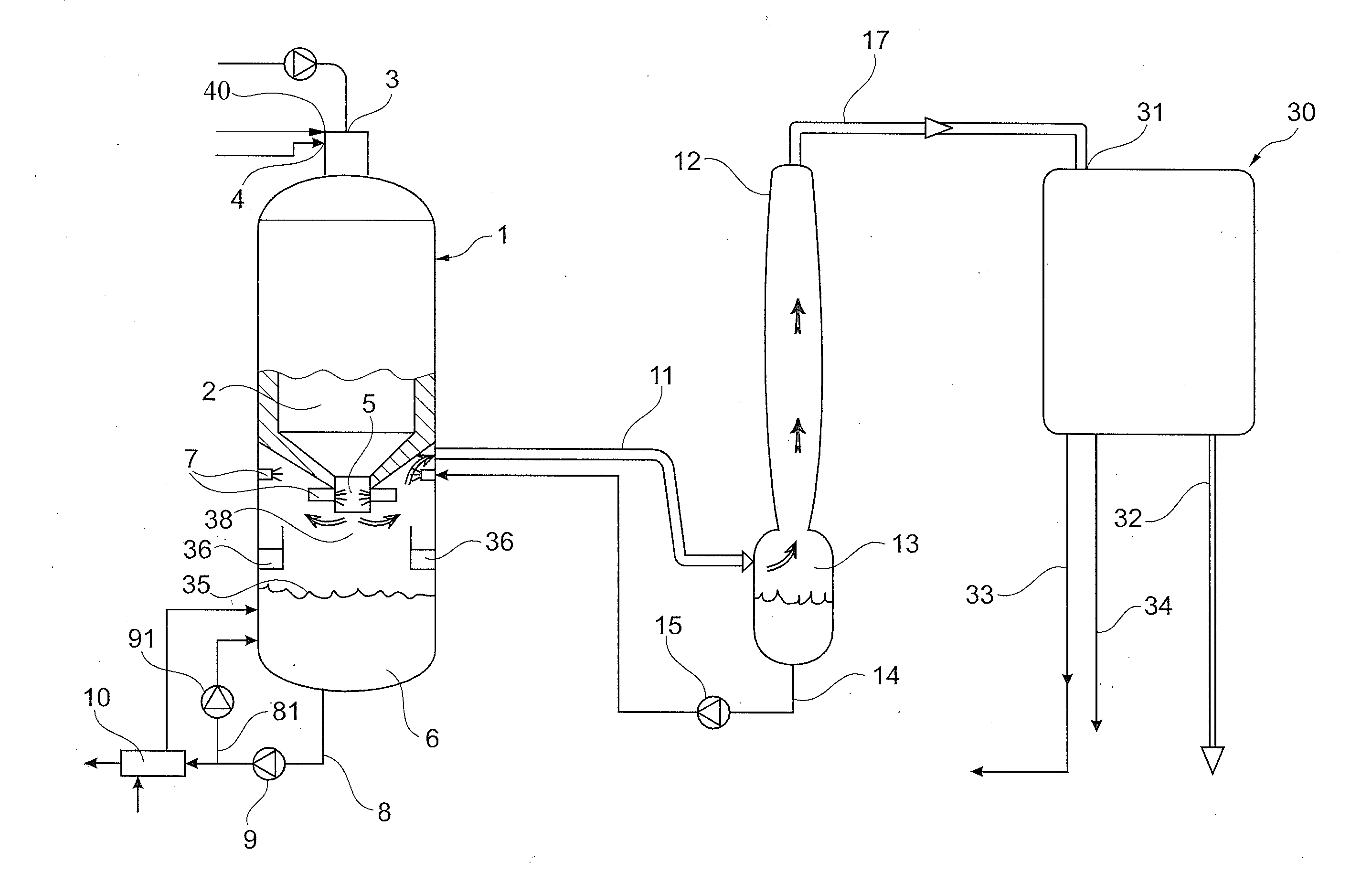

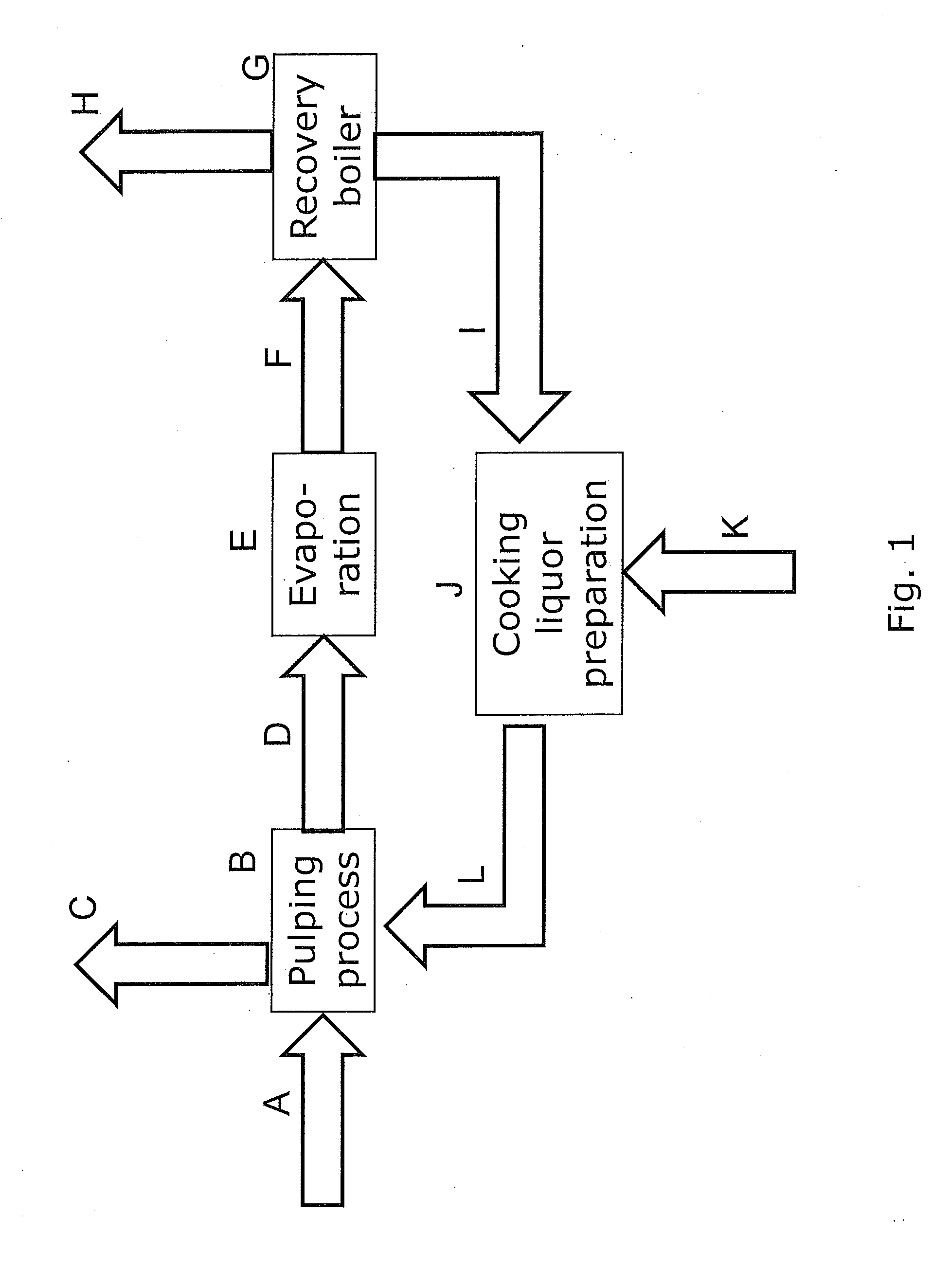

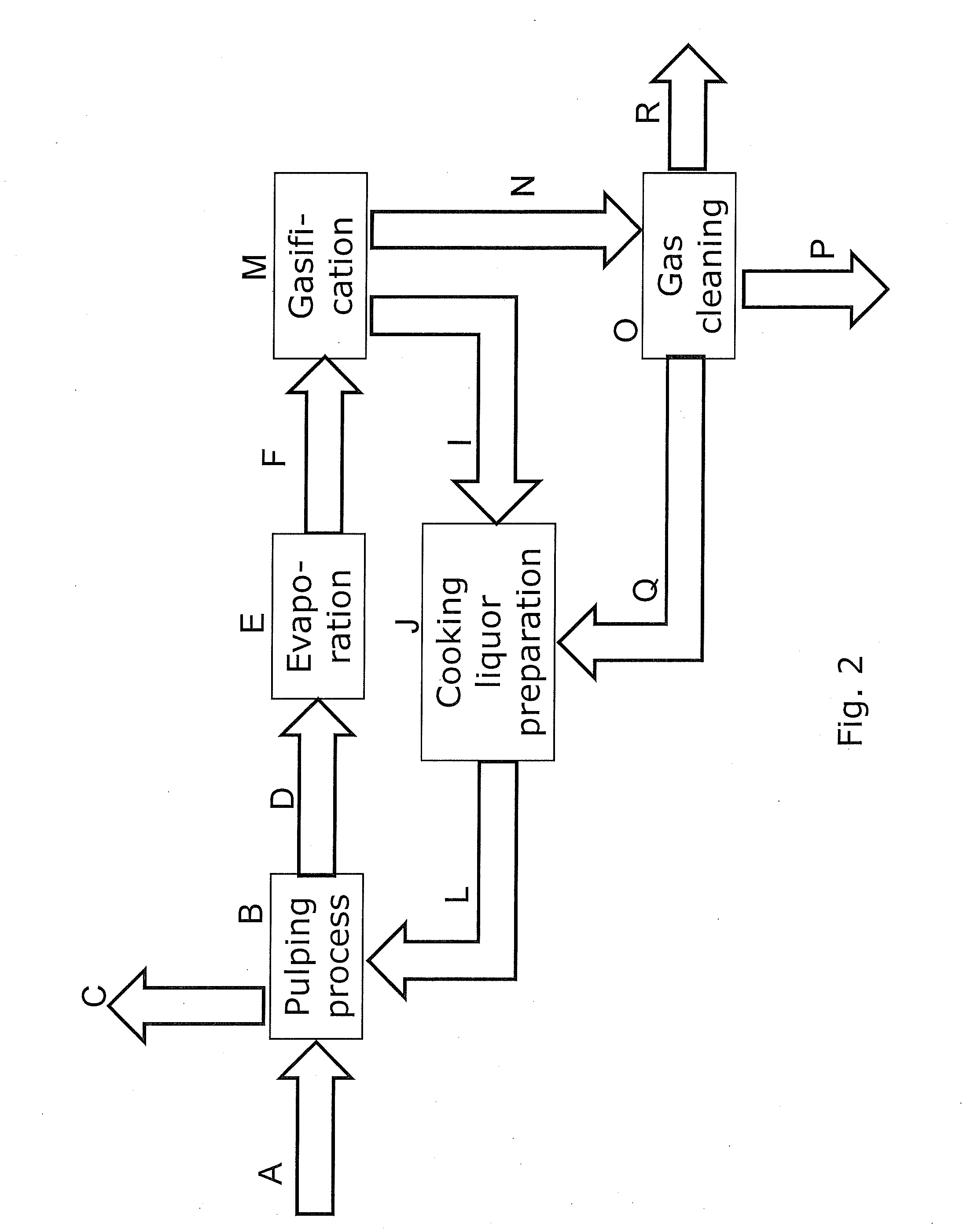

Gasification of sulphite thick liquor

InactiveCN102884248APulp liquors combustionPulping with acid salts/anhydridesFiberInorganic compound

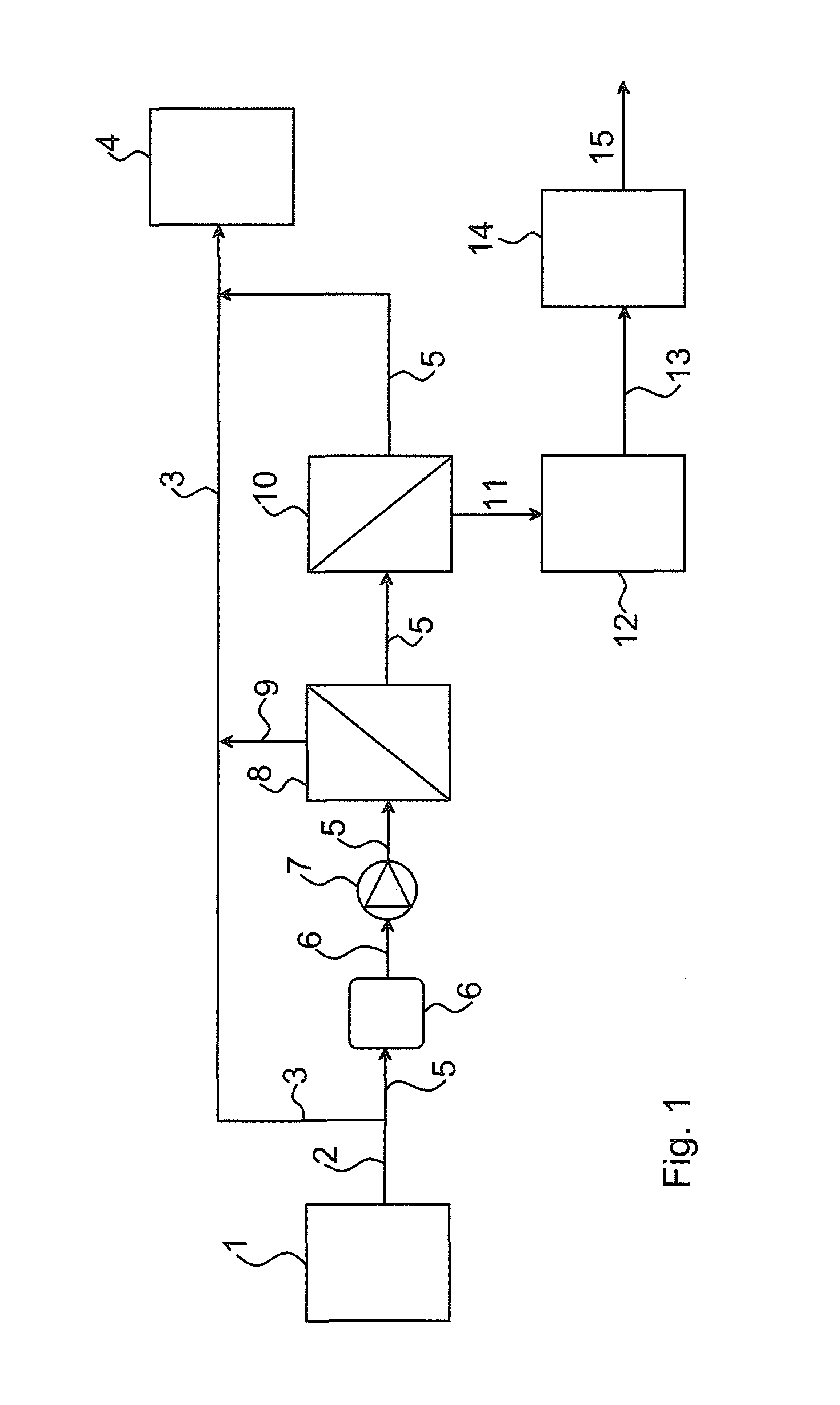

Method for recovering chemicals and energy from sulphite thick liquor, said sulphite thick liquor being obtained when producing pulp by chemical delignification of fibrous raw material using a sulphite pulping process, said sulphite thick liquor comprising organic and inorganic compounds; the method comprising processing of said organic and inorganic compounds at a temperature above 800 DEG C whereby producing partly at least one phase of a liquid material and partly at least one phase of a gaseous material, wherein said processing is carried out by gasification of said sulphite thick liquor in a gasification reactor (2) at sub-stoichiometric conditions and in the presence of an oxidizing medium; said reactor (2) having an opening in its bottom in the form of a chute (5), which opens directly into a quench compartment (38).

Owner:坎雷克股份公司

Process for performing ammonium sulfite pulping by using sulfur-containing flue gas absorber

ActiveCN101760974AReduce pollutionReduce degradationDigestersDispersed particle separationSodium sulfiteSulfur containing

The invention relates to a process for performing ammonium sulfite pulping by using a sulfur-containing flue gas absorber, which comprises the following steps: (1) performing desulphurization on flue gas by using ammonia water, wherein the flue gas is sulfur-containing flue gas; and (2) performing ammonium sulfite pulping during papermaking by using sulfurous acid mixed solution obtained after the desulphurization. In the process, a high-efficiency flue gas absorption system is adopted; the obtained ammonium sulfite is used for ammonium sulfite pulping in papermaking industry; and heavy contaminated condensate produced by pulping can also be used for absorbing sulfur dioxide in the flue gas. The scheme of the invention not only minimally reduces the environmental pollution, but also recycles the resources. The process is particularly suitable to be used in a paper mill with a self-owned power plant.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Sulphite pulping wastewater treatment and recovery process

ActiveCN103669069BTurn waste into treasureTo achieve the purpose of reducing pollution and increasing efficiencyRegeneration of sulfite lyeLiquid wasteSeparation technology

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Closed treatment method of paper-making waste water with sulfite

InactiveCN100482887CThorough governanceLess investmentMultistage water/sewage treatmentRegeneration of sulfite lyeSulfite saltWastewater

The closed treatment of papermaking waste water with sulfites, including ammonium sulfite and sodium sulfite, consists of bacteria strain culture, biochemical treatment, separation of lignin and other matters in alkali or neutral condition, gas floating, filtering, and returning filtrate for reuse in digestion and pulp making. The present invention has the advantages of complete treatment, recovery of all water and reduced investment and running cost.

Owner:尤丹丹

Method and system for reducing phosphorus in effluent or filtrate

ActiveCN106458657BReduce phosphorus contentTreatment using aerobic processesWater contaminantsPhosphatePulp and paper industry

The present invention relates to a method for reducing phosphorus in an effluent or filtrate from a process comprising at least one stage in which conditions are acidic, wherein the method comprises the step of: a) taking an effluent from a stage in which conditions are acidic or a first part of the filtrate; b) taking an effluent or a second part of the filtrate from the same or a different stage where the conditions are acidic; c) adjusting the pH of said first part of the effluent or filtrate with an alkaline reagent adjusting to alkaline; d) allowing phosphorus to precipitate in the form of phosphate; e) separating said precipitate to produce a purified effluent or filtrate; and f) combining the purified effluent or filtrate with said effluent or filtrate The second part of the object is combined.

Owner:UPM-KYMMENE OYJ

Gasification of sulphite thick liquor

InactiveUS20120073772A1Improve energy efficiencyEfficient chemical recoveryPulping with acid salts/anhydridesGreen and white liquor treatmentFiberGlobal temperature

Method for recovering chemicals and energy from sulphite thick liquor containing organic and inorganic compounds obtained when producing pulp by chemical delignification of fibrous raw material using a sulphite pulping process, the method including processing of the organic and inorganic compounds at a global temperature above 800° C. whereby producing partly at least one phase of a liquid material and partly at least one phase of a gaseous material. The processing is carried out by gasification of the sulphite thick liquor in a gasification reactor at sub-stoichiometric conditions and in the presence of an oxidizing medium. The reactor has an opening in its bottom in the form of a chute which opens directly into a quench compartment.

Owner:CHEMREC AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com