Closed treatment method of paper-making waste water with sulfite

A pulping wastewater and sulfite technology, applied in the regeneration of sulfite waste liquid, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of lack of treatment methods for papermaking red liquor, and achieve operating costs Low, reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

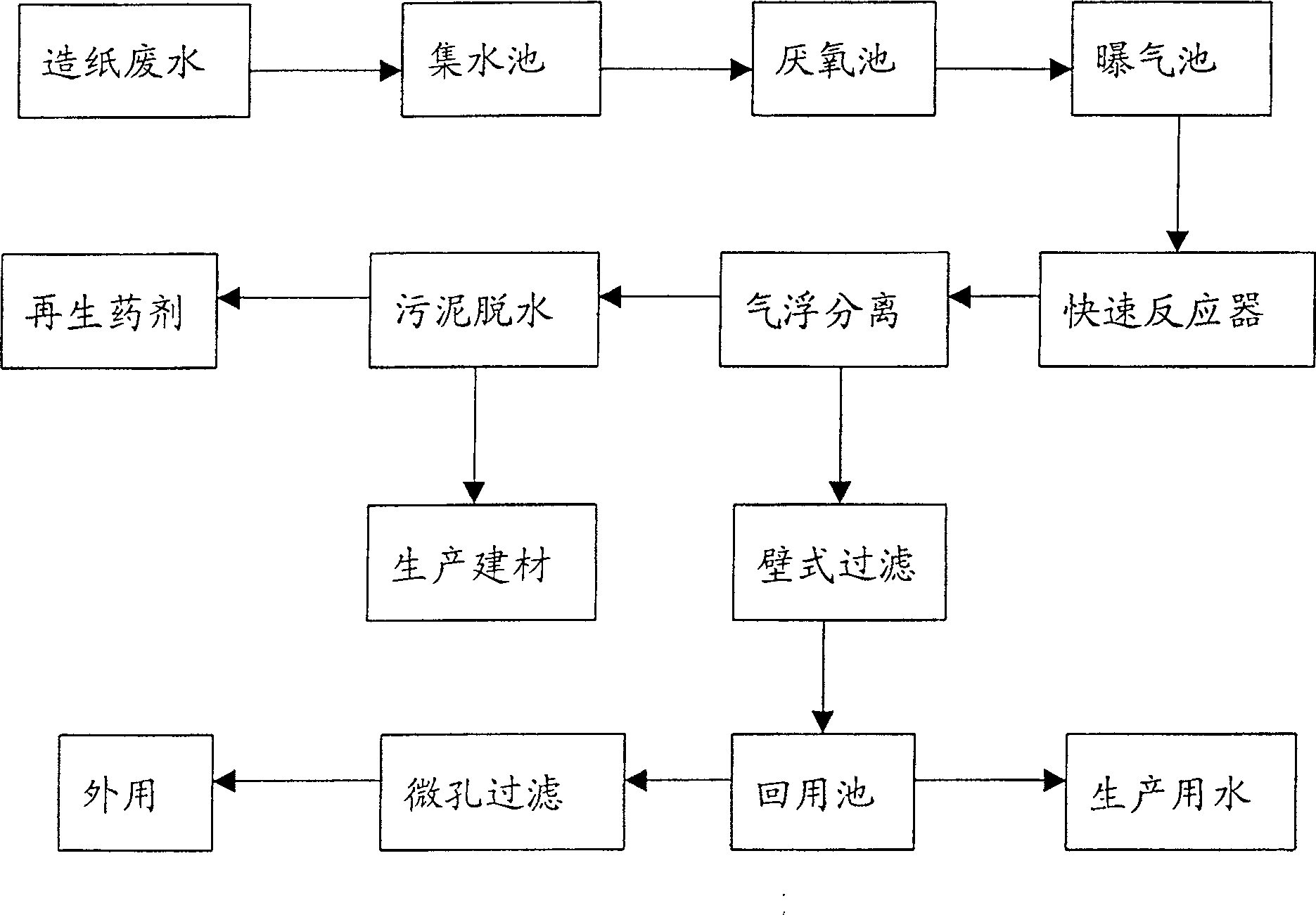

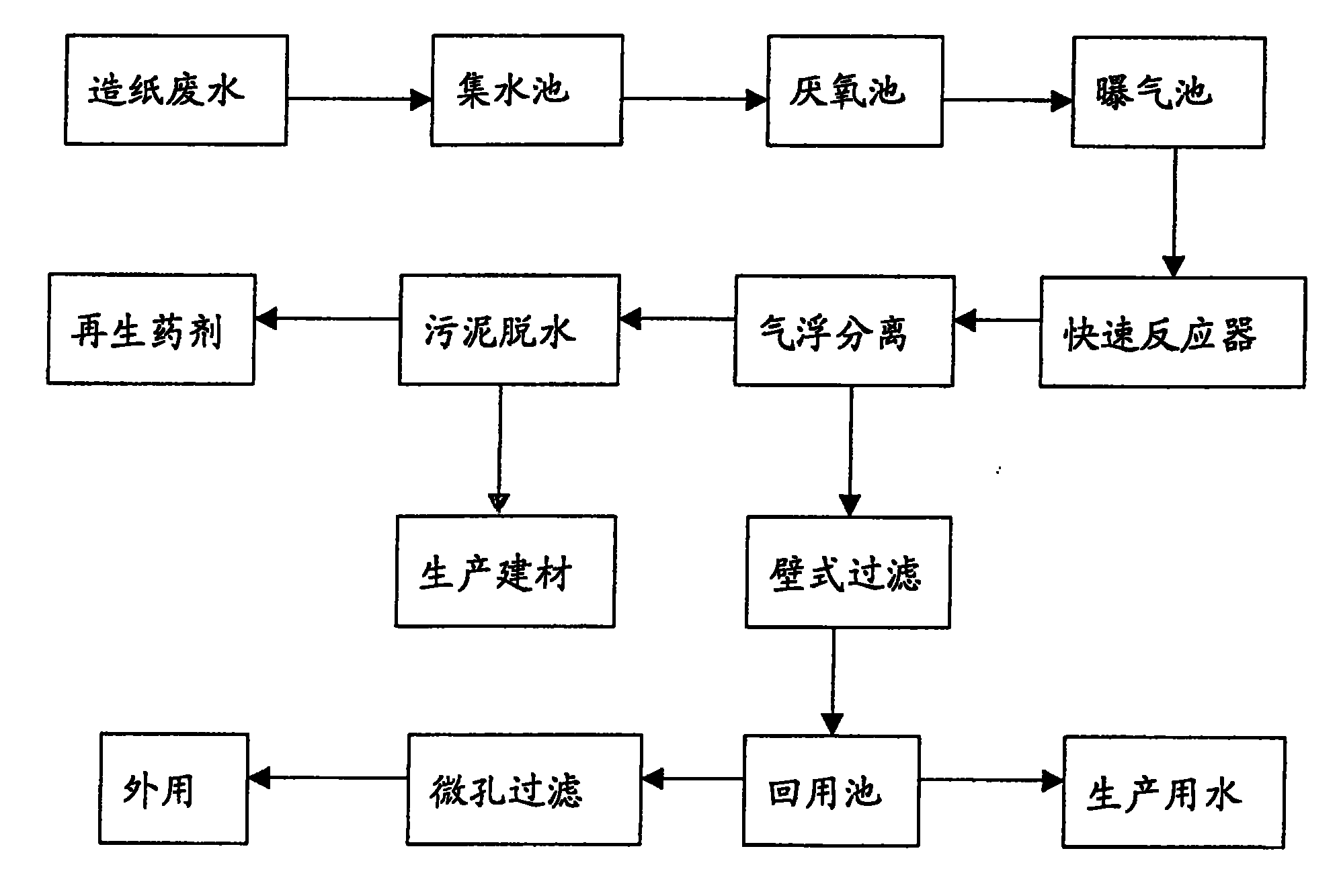

Method used

Image

Examples

Embodiment

[0020] A paper company uses amorpha as raw material to produce ammonium sulfite pulp, with an annual output of 25,000 tons of paper, located in a saline-alkali area short of water. Most of the sewage is reused after being stored in the big pond.

[0021] The method of the present invention is used for treatment, and the sewage enters the anaerobic tank, and then the bacterial seed liquid cultivated with old red liquid is added. Temperature T=30-45°C, residence time: HRT=5h, then enter the aeration tank, T=20-30°C, HRT=5h.

[0022] The effluent from the aeration tank enters the fast reactor (1) to react with 2wt% lime, 0.1wt% ferrous sulfate and 0.005wt% polyacrylamide. The separated scum is added to the sludge tank. The water phase then enters the fast reactor (2) and reacts in neutral with 0.5wt% lime, 0.06wt% aluminum salt and 0.004wt% polyacrylamide. The scum enters the sludge tank, and the water can be reused after passing through the pH controller and the wall filter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com