Treatment process and treatment system of pharmaceutical wastewater

A pharmaceutical wastewater and treatment process technology, applied in water/sewage treatment, natural water treatment, degassed water/sewage treatment, etc., can solve problems such as poor adaptability of harmful substances, low survival rate of anaerobic bacteria, unstable water quality, etc. , to achieve the effect of reducing the impact and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

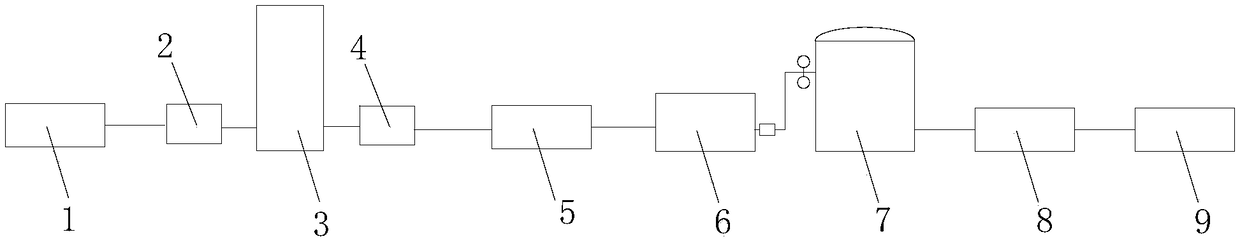

Image

Examples

Embodiment 1

[0034] The waste water from the chemical and pharmaceutical production field has a COD of 20000-25000 mg / L, a SS of 1000-1500 mg / L, a B / C<0.1, and a pH of 6.8. The waste water is treated by the following process;

[0035]Choose a simple primary sedimentation tank according to different wastewater quality, remove the large particle pollutants in the wastewater, and then carry out the following treatment procedures in sequence:

[0036] a. Oxidation of Fenton's reagent: first use a sulfuric acid solution with a concentration of 30% to adjust the pH of the pharmaceutical wastewater to be treated to 2.5, and then add Fenton's reagent H 2 o 2 with FeSO 4 , oxidized for 40 minutes after stirring evenly with the long-rod stirring paddle; among them, the dosage of Fenton’s reagent is H 2 o 2 =3g / L, FeSO 4 =1.6g / L;

[0037] b. Sedimentation: the waste water treated in step a is treated with Ca(OH) 2 Adjust the suspension to neutral, then add the coagulant PAM2.5mg / L, stir well an...

Embodiment 2

[0042] Wastewater from the field of biopharmaceutical production, its COD is 8400mg / L, SS is 240mg / L, BOD is 4300mg / L, pH is 8.6, adopt the following process to treat the wastewater;

[0043] Choose simple primary sedimentation according to different wastewater quality, remove the large particle pollutants in the wastewater, and then carry out the following treatment procedures in sequence:

[0044] a. Oxidation of Fenton's reagent: first use a sulfuric acid solution with a concentration of 25% to adjust the pH of the pharmaceutical wastewater to be treated to 3, and then add Fenton's reagent H 2 o 2 with FeSO 4 , after stirring evenly with the long-rod stirring blade, the oxidation treatment was carried out for 30 minutes, wherein the dosage of Fenton’s reagent was H 2 o 2 =2g / L, FeSO 4 =1.2g / L;

[0045] b. Sedimentation: After the wastewater NaOH solution treated in step a is adjusted to neutral, then add coagulant PAM2.5mg / L, stir well and then enter the sedimentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com