Process for performing ammonium sulfite pulping by using sulfur-containing flue gas absorber

An ammonium method and absorbent technology, applied in the field of recycling process, can solve the problems of low economic added value, waste pollutants, material loss, etc., and achieve the effects of reducing heat preservation time, reducing degradation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

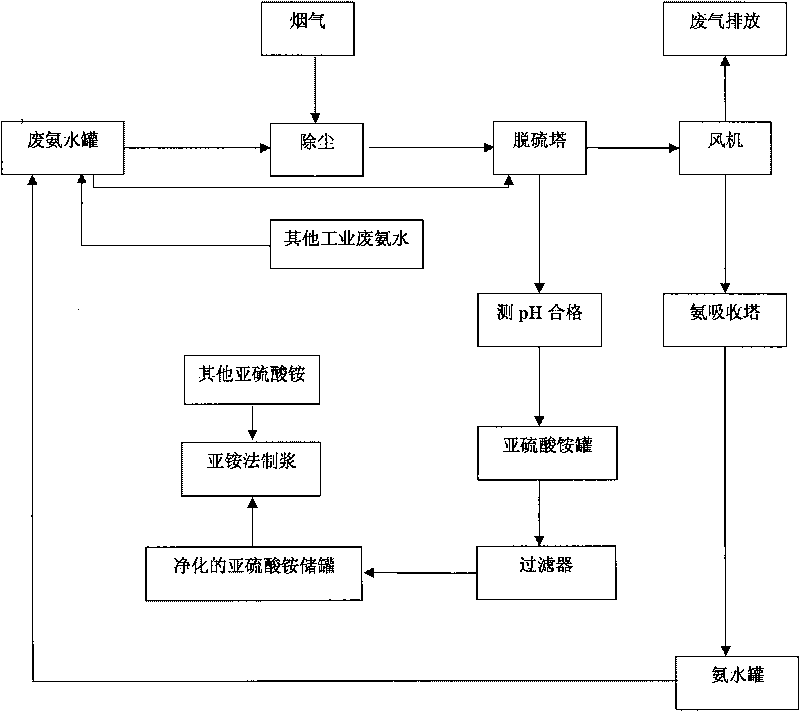

Image

Examples

Embodiment 1

[0048] The flue gas is firstly dedusted by the electrostatic precipitator, and after the dedusted flue gas is pressurized by the induced draft fan, the amount of flue gas entering the induced draft fan is 310800m 3 / h, the flue gas enters the liquid collection tank at the bottom of the desulfurization tower, sprays excess ammonia water and reacts with sulfur dioxide to form ammonium sulfite and ammonium bisulfite. A mixture of ammonium bisulfite and ammonium sulfite ammonia is formed in the liquid collection tank. The mixture is pumped to the height of the tower and sprayed downward through the three-layer spray device in the middle of the tower. The gas is evenly mixed to absorb the residual sulfur dioxide in the flue gas. Ammonium bisulfite in the mixture reacts with sulfur dioxide to obtain ammonium sulfite and returns to the liquid collection tank. Such repeated cycles will completely absorb the sulfur dioxide in the flue gas. The temperature in the desulfurization tower...

Embodiment 2

[0062] The flue gas first passes through the filter and dust removal equipment for dust removal. After the dust removal flue gas is pressurized by the induced draft fan, the amount of flue gas entering the induced draft fan is 200,000~400,000m 3 / h, into the liquid collection tank at the bottom of the desulfurization tower, spraying excess ammonia water with a concentration of 0.8-11% to react with ammonium bisulfite to generate ammonium sulfite. A mixture of ammonium bisulfite and ammonium sulfite ammonia is formed in the liquid collection tank, and the mixture is pumped to the height of the tower, and sprayed downward through the second-layer spray device in the middle of the tower, and the upward smoke The gas is evenly mixed to absorb the residual sulfur dioxide in the flue gas. Ammonium bisulfite in the mixture reacts with sulfur dioxide to obtain ammonium sulfite and returns to the liquid collection tank. The temperature in the desulfurization tower is 90-120°C; the pre...

Embodiment 3

[0076] The flue gas is firstly dedusted by the electrostatic precipitator, and after the dedusted flue gas is pressurized by the induced draft fan, the intake volume of the induced draft fan is 305,000-400,000m 3 / h, the flue gas enters the liquid collection tank at the bottom of the desulfurization tower, sprays excess ammonia water and reacts with sulfur dioxide to form ammonium sulfite and ammonium bisulfite. A mixture of ammonium bisulfite and ammonium sulfite ammonia is formed in the liquid collection tank. The mixture is pumped to the height of the tower and sprayed downward through the three-layer spray device in the middle of the tower. The gas is evenly mixed to absorb the residual sulfur dioxide in the flue gas. Ammonium bisulfite in the mixture reacts with sulfur dioxide to obtain ammonium sulfite and returns to the liquid collection tank. Such repeated cycles will completely absorb the sulfur dioxide in the flue gas. The temperature in the desulfurization tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com