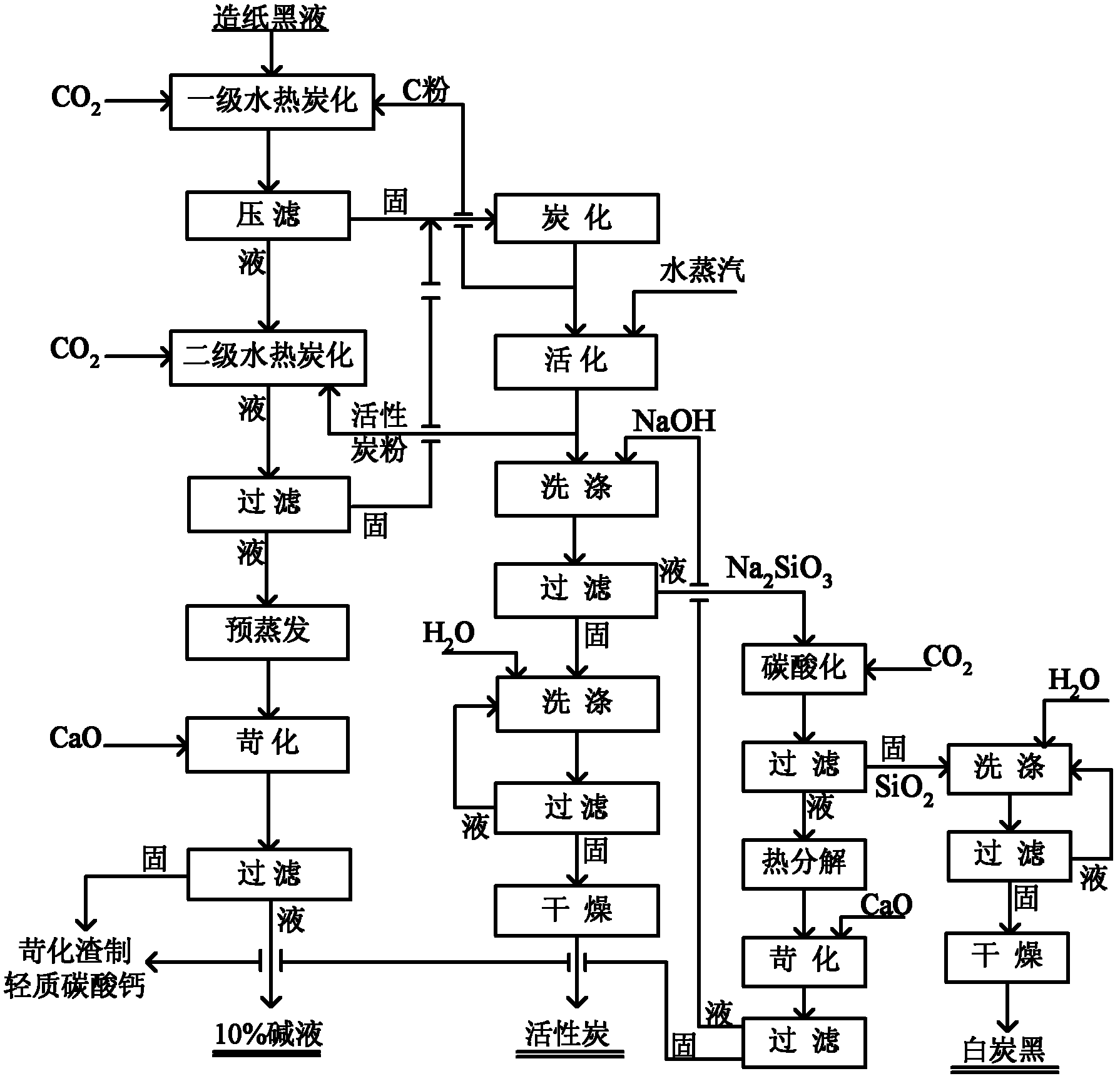

Alkali recovery method for by-producing activated carbon and white carbon black by using paper making black liquid

A technology of papermaking black liquor and recycling method, which is applied in chemical instruments and methods, regeneration of sulfite waste liquor, silica, etc., and can solve the problem of no space to be used, high energy consumption, and secondary acidity of the acid precipitation lignin process Wastewater pollution and other issues, to achieve the effect of reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

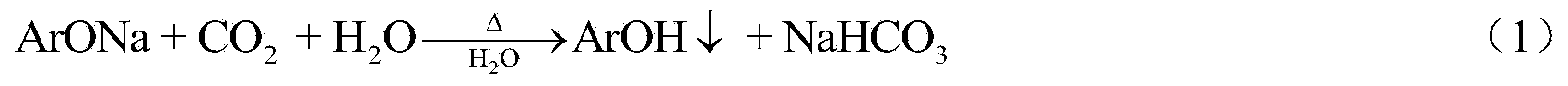

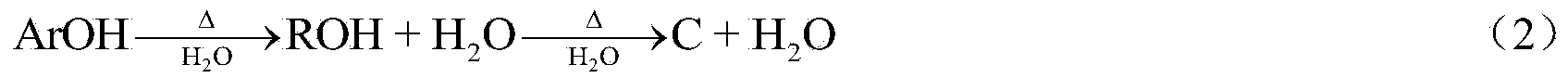

Embodiment 1

[0042] Take 3L of straw pulp papermaking black liquor and 660g of carbon powder and mix it in a 5L pressure reaction kettle, seal it, start stirring, program the temperature, and when the temperature reaches 100 °C, introduce 1.7MPa CO 2 Gas, continue to heat up to the set temperature of 200 °C, after hydrothermal reaction for 3 hours, cool down and discharge, filter, and send the solid phase (first-stage hydrothermal carbonized material) to the tube furnace reactor (protected by nitrogen atmosphere) and carbonize at 400 °C 1h, take 500g of carbon powder and return it to the first-level hydrothermal carbonization step for use. The remaining carbon powder is continuously heated to 850 °C in the tubular furnace reactor for physical activation by steam for 80min to obtain 260g of crude activated carbon, and 120g is used for the second-level hydrothermal treatment. In the carbonization process, the remaining crude activated carbon was washed with 500 mL of 5% dilute alkaline soluti...

Embodiment 2

[0044] Take 4L of straw pulp papermaking black liquor and 900g of carbon powder and mix it in a 5L pressure reaction kettle, seal it, start stirring, and program the temperature. When the temperature reaches 100 °C, 1.6MPa CO is introduced. 2 Gas, continue to heat up to the set temperature of 200 ℃, after the hydrothermal reaction for 3.5 hours, cool down and discharge, filter, and send the solid phase (first-level hydrothermal carbonization material) to the tube furnace reactor (protected by nitrogen atmosphere) at 400 ℃ After carbonization for 1.2 hours, 680 g of carbon powder was returned to the first-level hydrothermal carbonization step for use. The remaining carbon powder was continuously heated to 870 °C in the tubular furnace reactor and was physically activated by steam for 70 minutes to obtain 350 g of coarse activated carbon, and 160 g of it was used for the second stage. In the hydrothermal carbonization process, the remaining crude activated carbon was washed with ...

Embodiment 3

[0046] Take 3.5L of straw pulp papermaking black liquor and 780g of carbon powder and mix it in a 5L pressure reaction kettle, seal it, start stirring, program the temperature, and when the temperature reaches 100 °C, introduce 1.8MPa CO 2 Gas, continue to heat up to the set temperature of 200 °C, after hydrothermal reaction for 3 hours, cool down and discharge, filter, and send the solid phase (first-stage hydrothermal carbonized material) to the tube furnace reactor (protected by nitrogen atmosphere) and carbonize at 410 °C 1.3h, take 590g of carbon powder and return it to the first-level hydrothermal carbonization step for use. The remaining carbon powder is continuously heated to 830 °C in the tubular furnace reactor for physical activation by steam for 90min to obtain 310g of crude activated carbon, and 140g is used for secondary water. In the thermal carbonization process, the remaining crude activated carbon was washed with 580 mL of 5% dilute alkali solution, washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com