Method and system for reducing phosphorus in effluent or filtrate

A filter and effluent technology, applied in the field of phosphorus systems, can solve problems such as complex operations, high investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

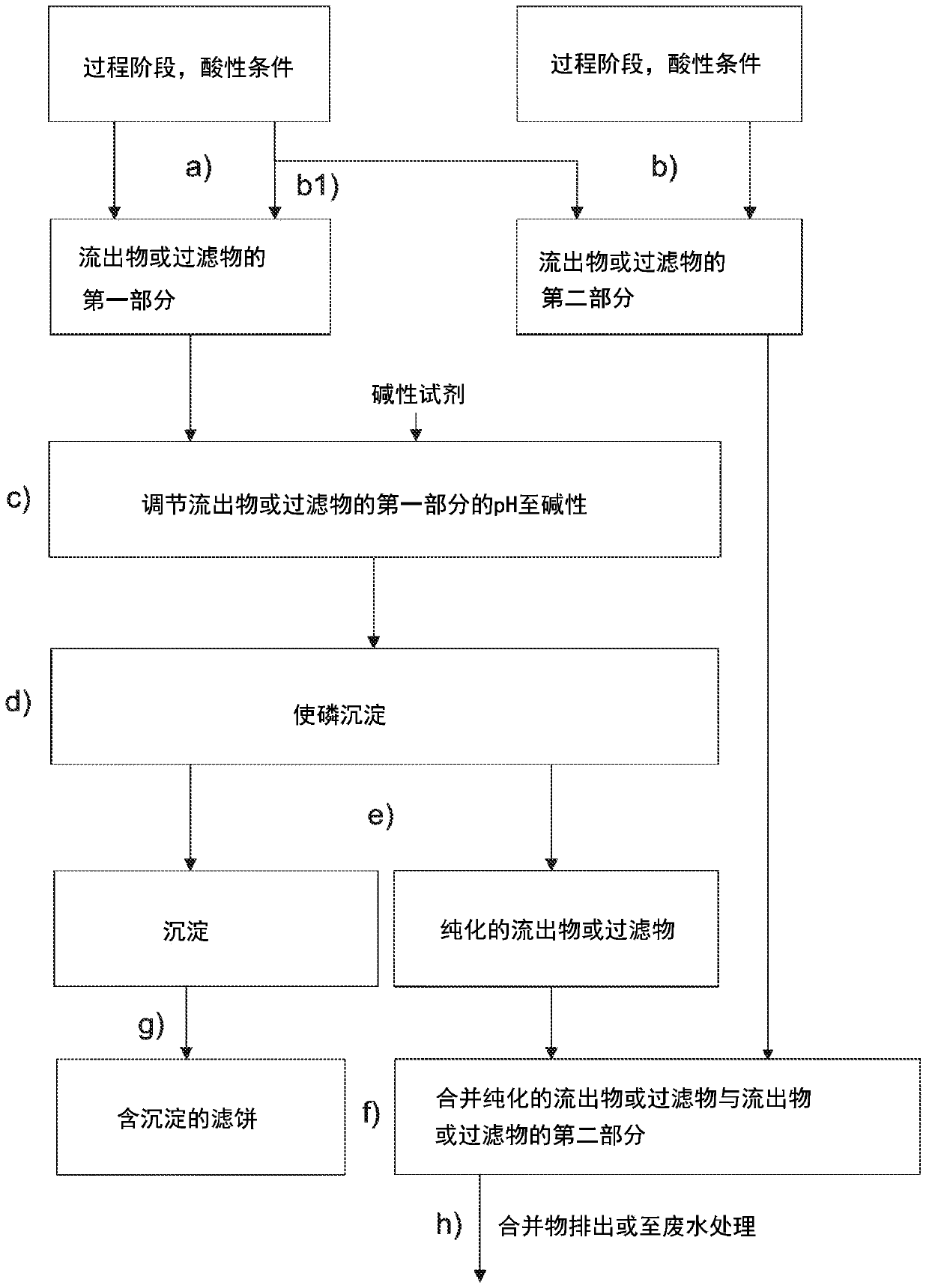

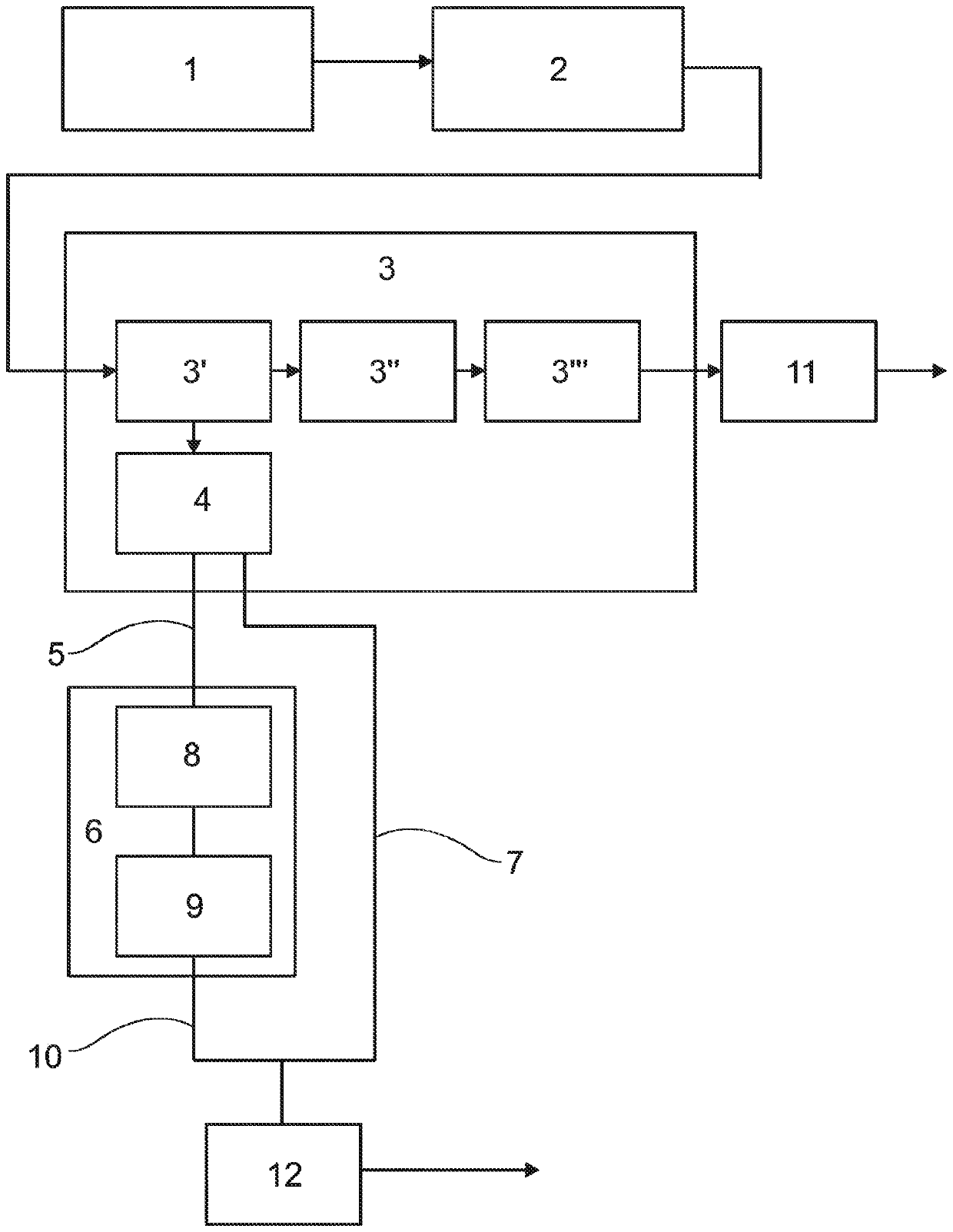

Method used

Image

Examples

Embodiment 1

[0161] Example 1 - Phosphorus removal from acid bleached filtrate

[0162] Acid bleached filtrate (A / D1 filtrate) was obtained from a kraft pulp mill. 9m 3 / ADt Filtration flow is divided into two parts, the first part is 2m 3 / ADt and the second part 7m 3 / ADt.

[0163] The first part uses calcium hydroxide (Ca(OH) 2 ) aqueous solution treatment. Calcium hydroxide was used at a concentration of 1.84 g / l or 20 g / l. The pH of the first portion was adjusted to 9.0, 9.2, 9.5, 9.8 or 10.0 by adding aqueous calcium hydroxide solution. The precipitate was removed by decantation 2 hours after adjusting the pH to basic, or by filtration through a fiberglass filter 2 minutes after adjusting the pH to basic. After removing the precipitate, the purified filtrate obtained from the first part is combined with the second part and sent to the wastewater treatment plant.

[0164] Samples were taken from the first portion of the filtrate before adding the calcium hydroxide solution and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com