Process for controlling sodium and sulfur balance in pulp mill

A pulp mill, level technology, applied in the regeneration of pulping chemicals, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of increasing NaOH, sulfur and increasing operating costs, so as to reduce the amount of alkali and improve sodium / Sulfur balance, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

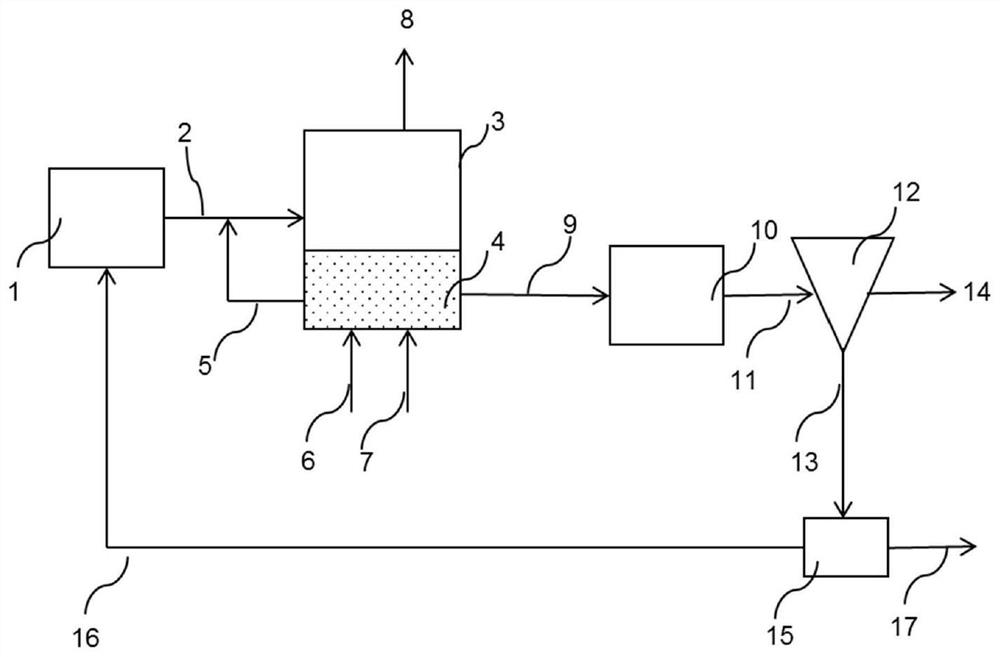

Method used

Image

Examples

Embodiment 1

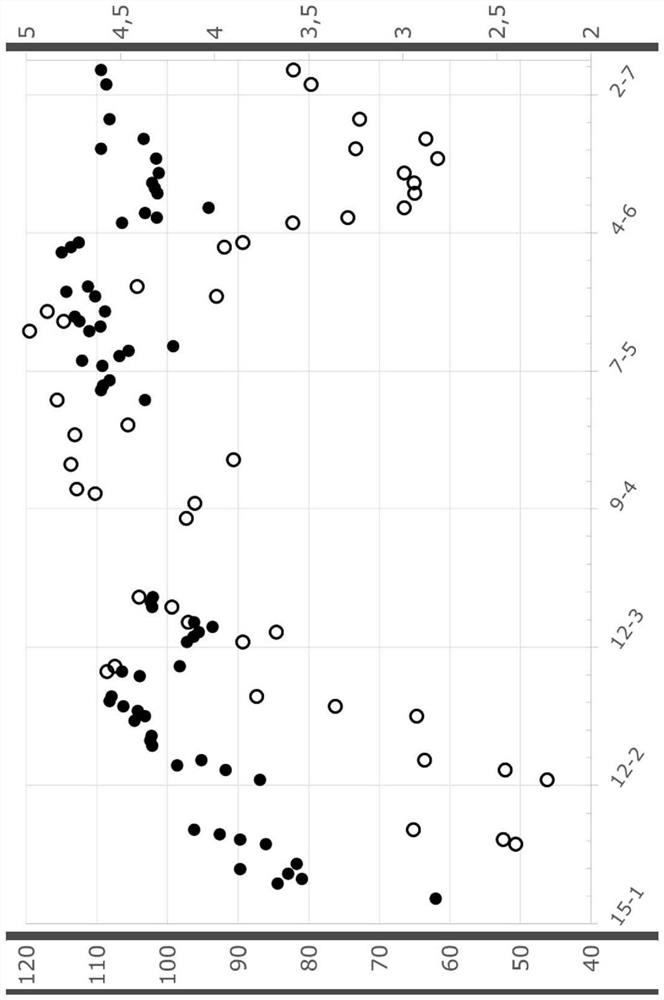

[0079] A continuous feed system consisting of a series of bioreactors is used. Using autotrophic sulfide-oxidizing bacteria from Soda lake, under sulfide-oxidizing conditions (pH 9.5; Na + >4M) to operate the system. The maximum wet volume of the reactor is 5L The temperature was maintained at 30°C by using a water jacket and a constant temperature bath (Shinko, Japan). The influent was fed to the bioreactor using a peristaltic pump (Watson-Marlow) and the effluent from the reactor was controlled by overflow. The sulfide-rich stream (influent) was mixed with a portion of the bioreactor contents prior to addition to the bioreactor. pH was monitored using a pH sensor (Endress+Hauser, The Netherlands). Oxygen supply was performed with an air feed controlled with an ORP-sensor (Endress+Hauser, The Netherlands).

[0080] The sulfide oxidizing bacteria present in the bioreactor are species adapted to elevated salt concentrations but not to the high salt concentrations of green...

Embodiment 2

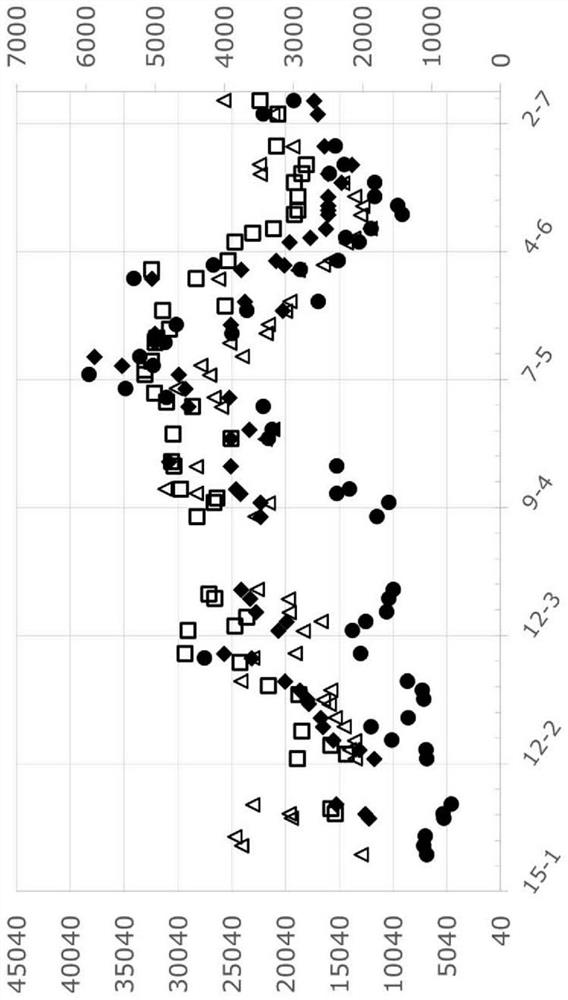

[0087] Table 2

[0088] Savings in caustic consumption 3

2-A: No premix 2

Negligible <0.6kg NaOH / kg S removed

2-1 with premix 2

2.6kg NaOH / kg removed S

[0089] 2 Influent pulp mill stream – green liquor

[0090] 3 Separated from effluent

[0091] Example 2-1 shows that premixing the pulp mill stream with bioreactor contents increases sulfur production and caustic (NaOH) regeneration compared to Example 2-A where no premixing occurs (comparative).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com