Gasification of sulphite thick liquor

A sulfite thick liquid and sulfite technology, which is applied in the regeneration of sulfite waste liquid, the regeneration of pulping liquid, pulping with acid salt/acid anhydride, etc., can solve the problem of poor performance and accumulation of melting layer , accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

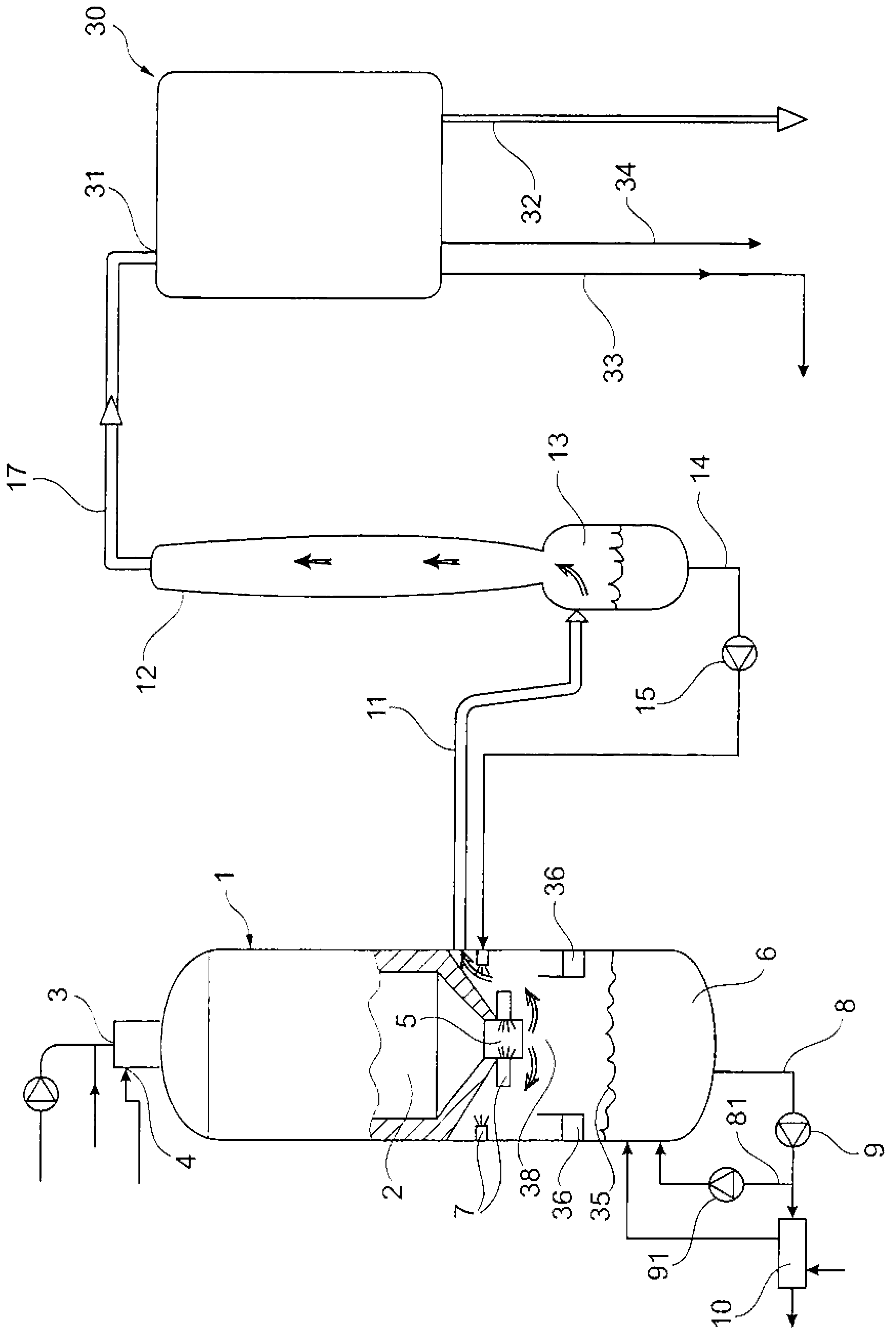

[0032] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0033] The following detailed description, and the examples contained herein are for the purpose of illustration and merely illustrate certain embodiments of the invention and are not intended to limit the scope of the invention in any way.

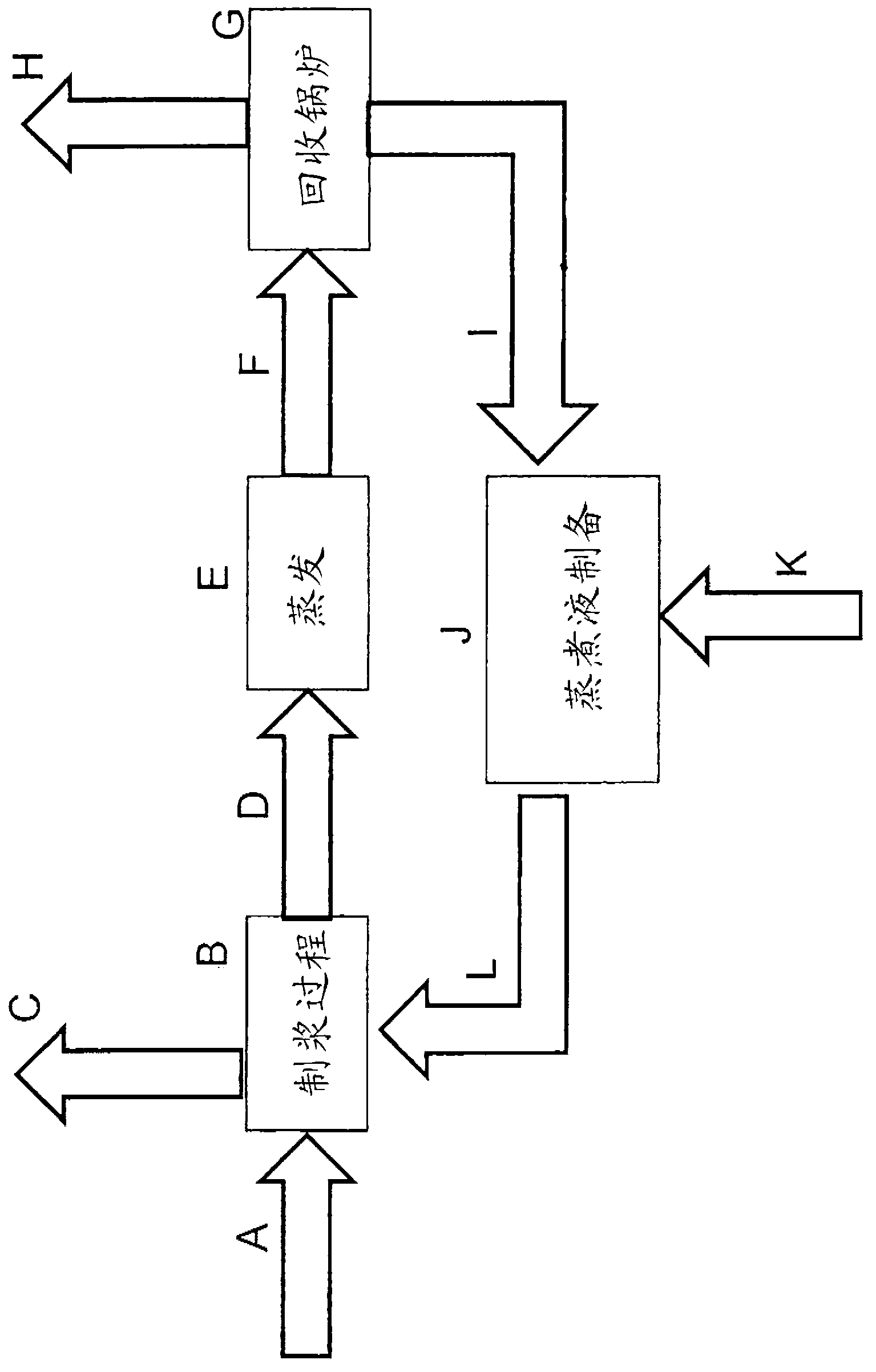

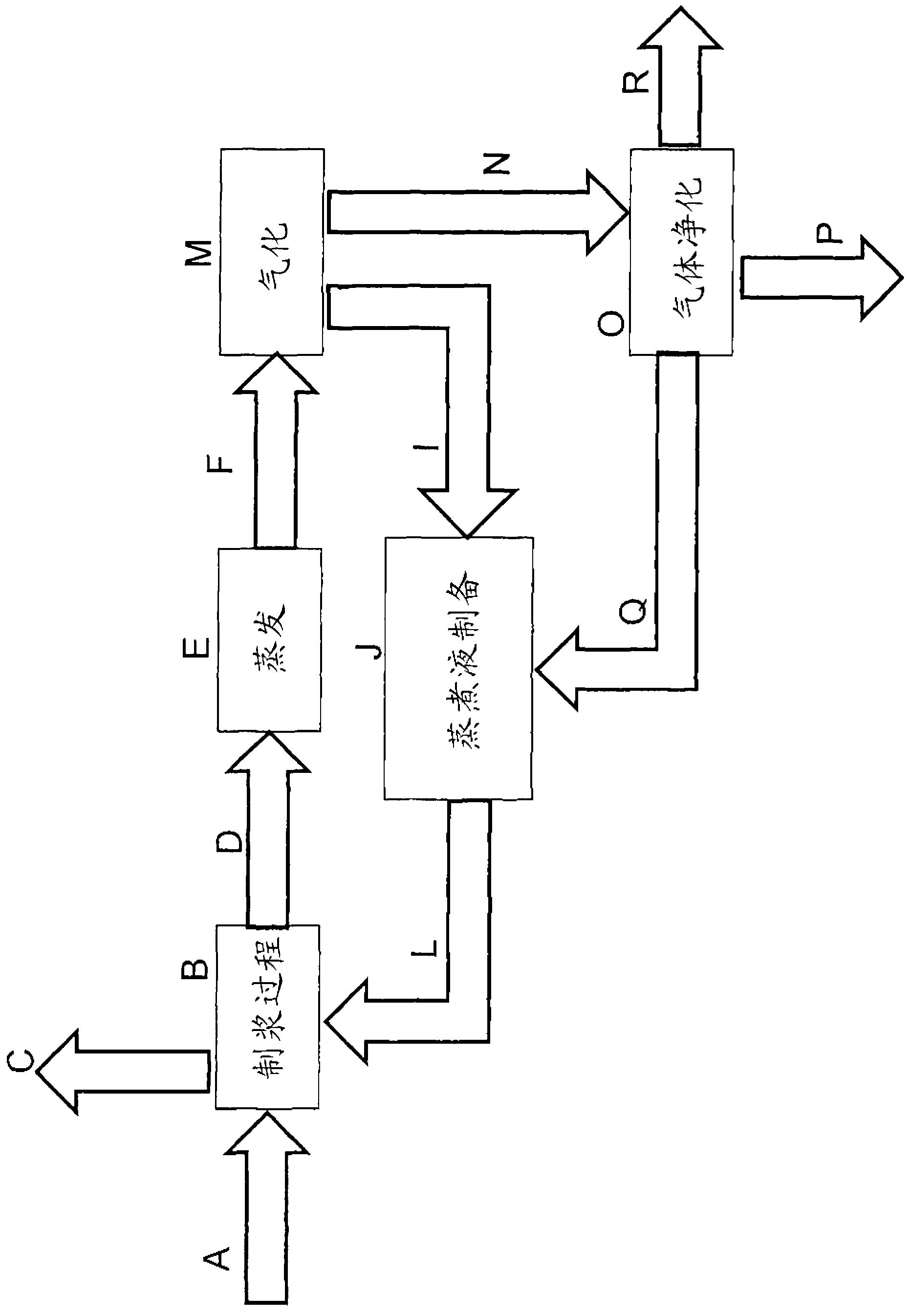

[0034] figure 1 A flow diagram of a typical chemical recovery cycle for sodium sulfite pulping is shown. The chemical recovery cycle described will only be briefly explained here, since it is common knowledge to those skilled in the art. Chips A are pumped into a digester where delignification / pulping process B is carried out in a suitable sulfite cooking liquor at elevated temperature to release cellulose fibers, pulp C. Pulp is separated from spent cooking liquor, also known as dilute sulfite thick liquor D, where spent cooking liquor is a mixture of spent cooking compounds and wood residues such as lignin. Raw pulp C is then ready but can usually be further processed in a bleac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com