Method for comprehensively using pulping waste water by sulfite method

A technology of sulfite method and pulping wastewater, which is applied in the regeneration of sulfite waste liquid, etc., can solve the problem of membrane fouling and rapid decline of separation effect, low comprehensive utilization rate of bamboo and wood pulp resources, frequent membrane cleaning and other problems. Short service life and other problems, to solve the pollution and separation efficiency decline, improve comprehensive utilization, save equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

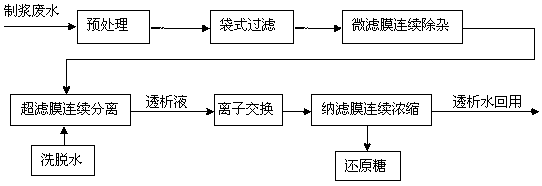

[0044] [Example 1] such as figure 1 Shown, a kind of sulfite method comprehensively utilizes the method for pulping waste water, and it comprises the following steps:

[0045] S1: Pretreatment: adding coagulant AlCl to pulping wastewater 3 Carry out pretreatment to remove suspended solids, fine fibers, some organic matter, tannin and silicate dissolved solids in pulping wastewater, avoid fouling of membrane pores, and greatly extend the service life of membrane modules;

[0046] S2: Bag filter: The clarified liquid after coagulation and sedimentation to remove impurities is further filtered out fine particles and suspended solids through a 5 μm bag filter;

[0047] S3: Continuous impurity removal by microfiltration membrane: remove particles, suspended solids, colloidal substances and high-molecular organic matter (relative molecular weight greater than 100,000) in wastewater, reducing the load of subsequent treatment processes. The microfiltration membrane adopts a microfil...

Embodiment 2

[0053] [Example 2] such as figure 1 Shown, a kind of sulfite method comprehensively utilizes the method for pulping waste water, and it comprises the following steps:

[0054] S1: Pretreatment: adding coagulant to polymerize AlCl in pulping wastewater 3 Carry out pretreatment to remove suspended solids, fine fibers, some organic matter, tannin and silicate dissolved solids in pulping wastewater, avoid fouling of membrane pores, and greatly extend the service life of membrane modules;

[0055] S2: Bag filter: The clarified liquid after coagulation and sedimentation to remove impurities is further filtered out fine particles and suspended solids through a 5 μm bag filter;

[0056] S3: Continuous impurity removal by microfiltration membrane: remove particles, suspended solids, colloidal substances and high-molecular organic matter (relative molecular weight greater than 100,000) in wastewater, reducing the load of subsequent treatment processes. The microfiltration membrane ado...

Embodiment 3

[0062] [Example 3] such as figure 1 Shown, a kind of sulfite method comprehensively utilizes the method for pulping waste water, and it comprises the following steps:

[0063] S1: Pretreatment: adding coagulant FeCl to pulping wastewater 3 Carry out pretreatment to remove suspended solids, fine fibers, some organic matter, tannins and silicate soluble solids in pulping wastewater, avoid fouling of membrane pores, and greatly extend the service life of membrane modules;

[0064] S2: Bag filter: The clarified liquid after coagulation and sedimentation to remove impurities is further filtered out fine particles and suspended solids through a 5 μm bag filter;

[0065]S3: Continuous impurity removal by microfiltration membrane: remove particles, suspended solids, colloidal substances and high-molecular organic matter (relative molecular weight greater than 100,000) in wastewater, reducing the load of subsequent treatment processes. The microfiltration membrane adopts a microfiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com