Electroplating pretreatment waste water online reuse technology

A pre-plating treatment and waste water technology, which is applied in metallurgical waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of wasting water resources and chemicals, and save fresh water, Promote the effect of high value and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

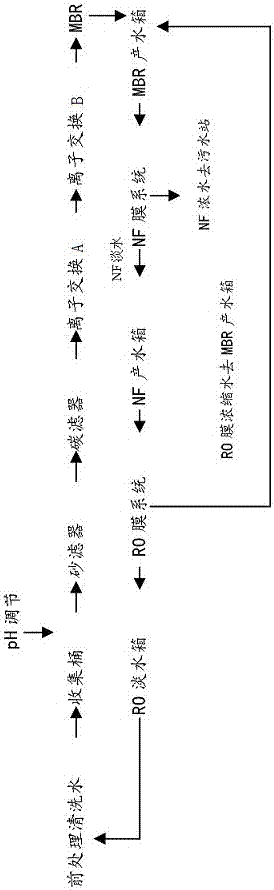

[0025] see figure 1 , an on-line recycling process for electroplating pretreatment wastewater, comprising the following steps:

[0026] 1. Collect the cleaning wastewater in the workshop, that is, the pre-treatment cleaning water, through the collection bucket;

[0027] 2. Adjust the pH of the wastewater to 8-9, preferably about 8.5, and complete the pH adjustment in the cleaning bucket; preferably, the pH can be adjusted by an automatic pH adjustment system;

[0028] 3. Then pump the wastewater quantitatively into the sand filter through the pump, filter out the trace suspended matter in the water through the sand filter, and then enter the carbon filter, and further filter out the suspended matter in the water through the carbon filter;

[0029] 4. Then pump the waste water into the ion exchange resin tank A, absorb the metal ions in the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com