Method of synthesizing nano grade calcium titanium ceramic powder

A technology of ceramic powder and perovskite, which is applied in the field of ultra-fine nano-powder preparation, can solve the problems that it is difficult to break away from the limitations of hydrothermal synthesis, increase the difficulty of process and operation, and the difficulty of guaranteeing the purity of powder. The effect of narrow distribution range, avoiding grain growth and agglomeration, and stable ratio of barium to titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

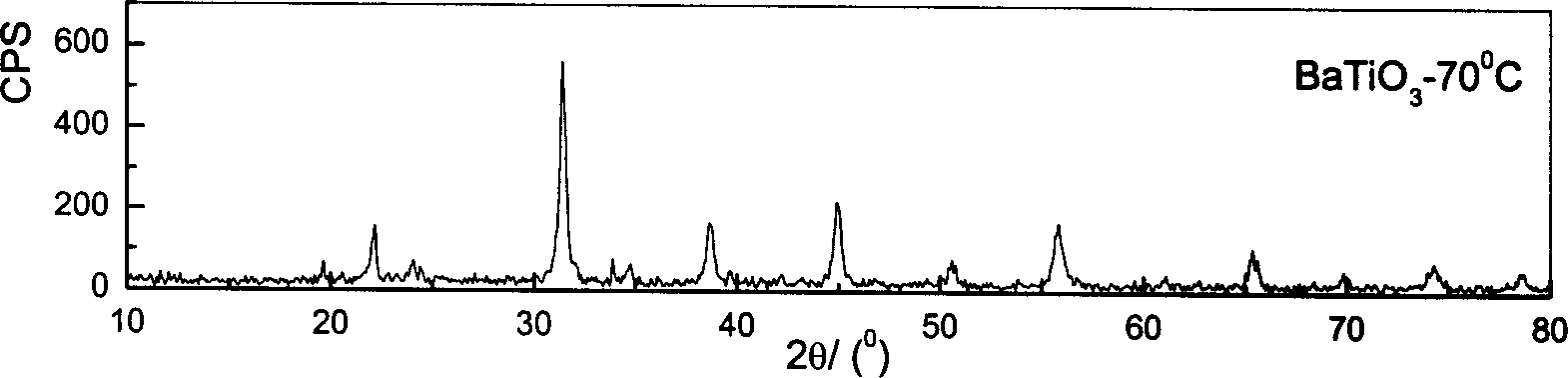

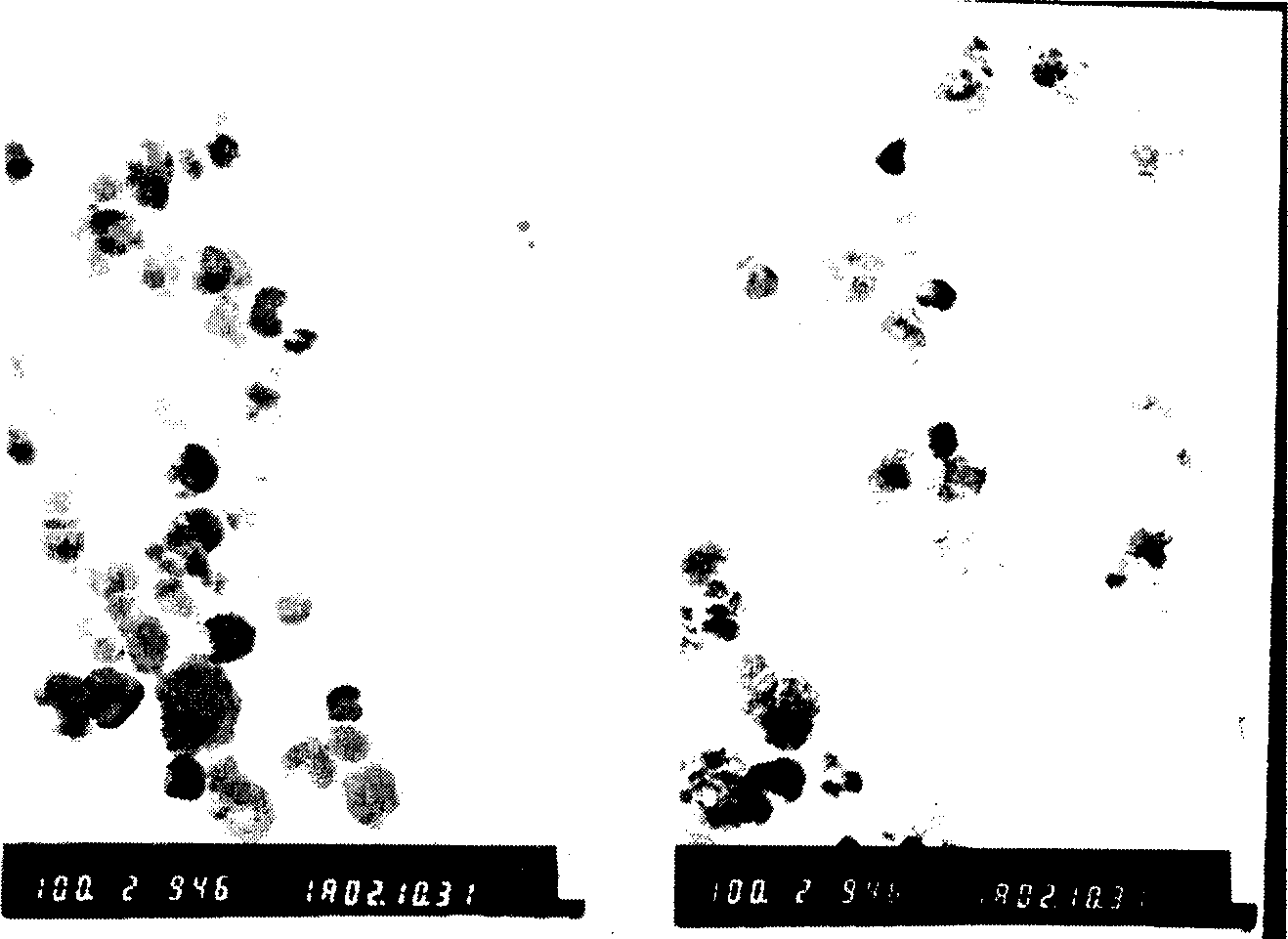

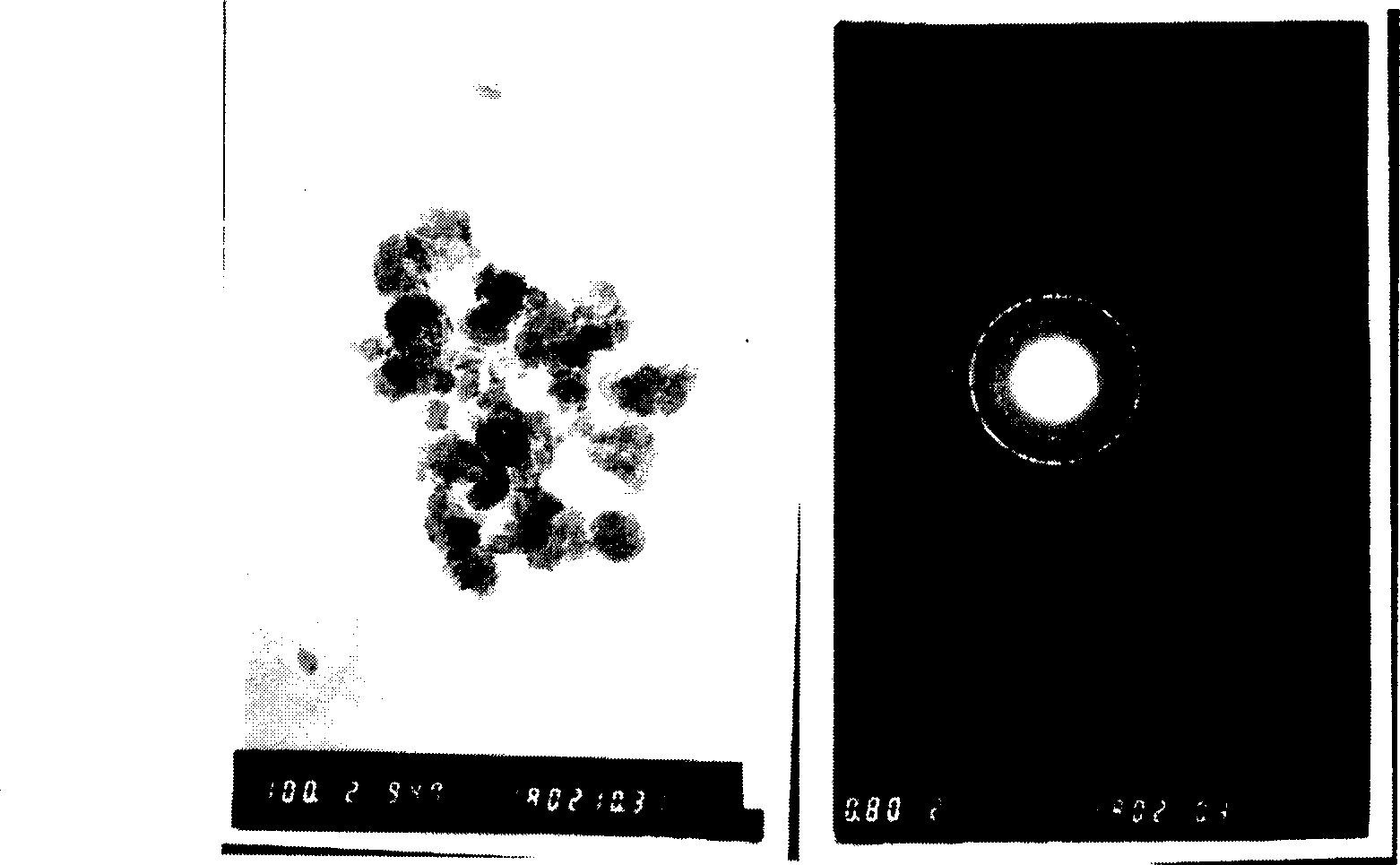

Embodiment 1

[0022] 631 g of Ba(OH) 2 ·8H 2 O was dissolved in 5 liters of water and heated to 70°C as bottom solution A. Dissolve 680 g of tetrabutyl titanate in 5 liters of absolute ethanol as solution B. Slowly add liquid B to bottom liquid A. During this period, when there is 1 / 5 of liquid B left, add 100 ml of concentrated ammonia water to bottom liquid A, and continue to add the remaining liquid B. During the whole process, the temperature of the bottom liquid must be kept roughly constant, and at the same time, vigorously stirred to facilitate the control of powder properties. After the reaction was finished, filter with suction. Dry the solid part at 60-100 ° C to obtain BaTiO with a particle size of ~ 30 nanometers 3 Powder. The XRD results show that the obtained powder is a fine powder of perovskite structure. From the TEM photos, the finished product belongs to nearly spherical crystalline particles.

Embodiment 2

[0024] Change the temperature of the bottom liquid in Example 1 to 60°C, and keep the other conditions constant, to obtain BaTiO with a particle size of ~30 nanometers. 3 Powder.

Embodiment 3

[0026]Change the temperature of the bottom liquid in Example 1 to 45°C, and keep the other conditions constant, to obtain BaTiO with a particle size of ~100 nanometers 3 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com