Electroplastic equal-diameter rolling mill

An electroplastic and equal-diameter technology, applied in the field of radial rolling mills, can solve the problems of sheet metal grain growth, large deformation resistance, and low processing efficiency, and achieve the effects of improving microstructure, improving mechanical properties, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

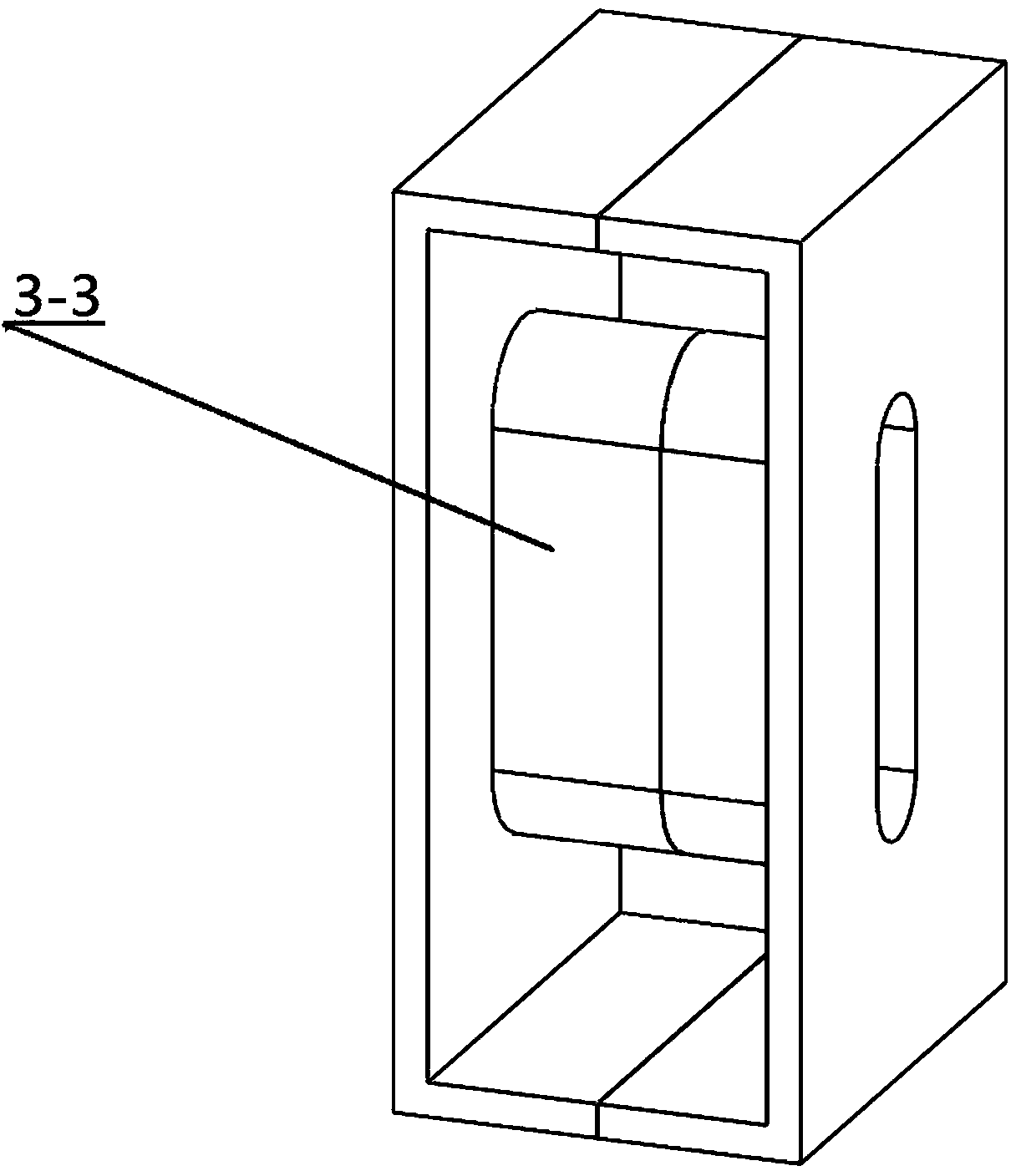

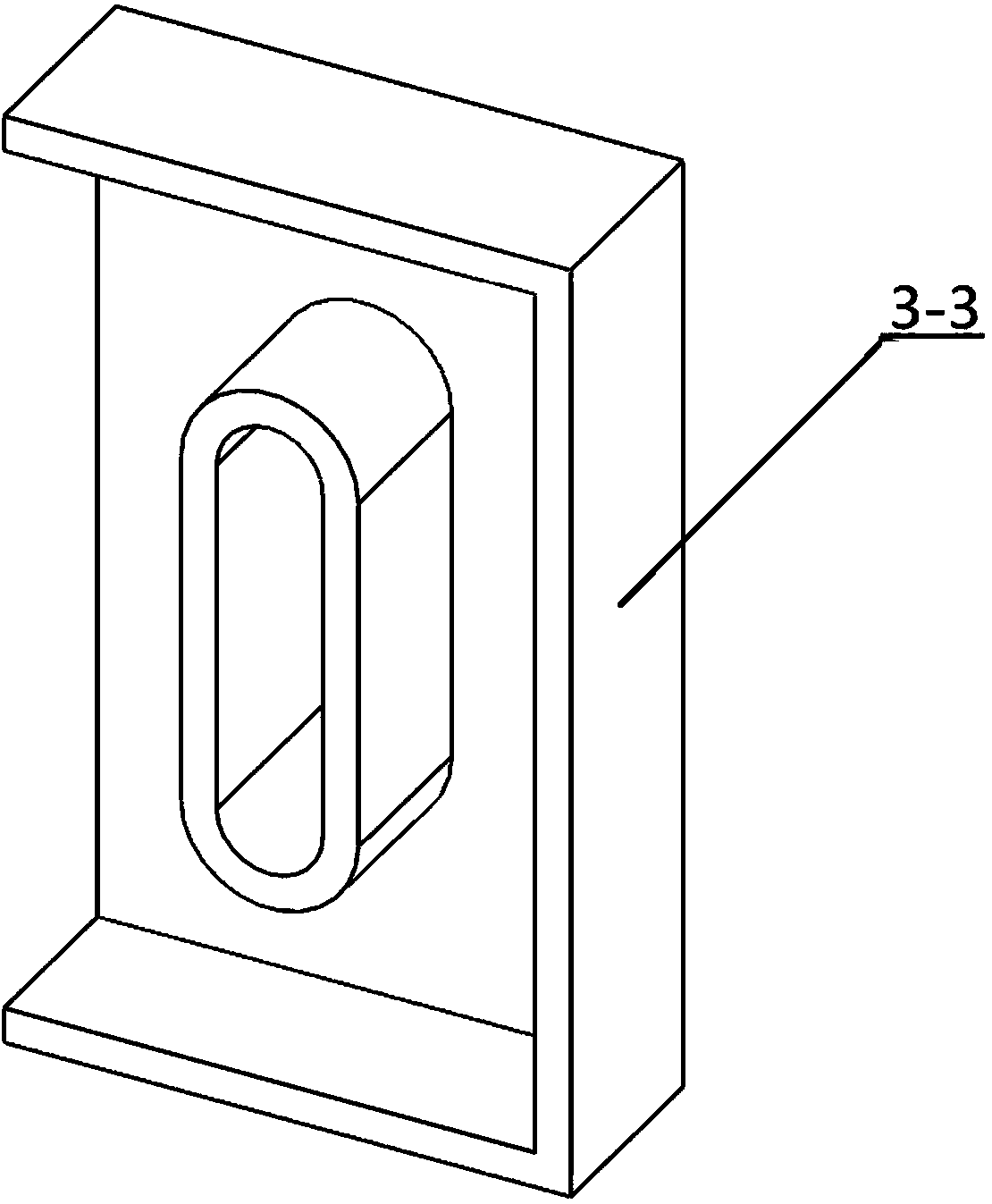

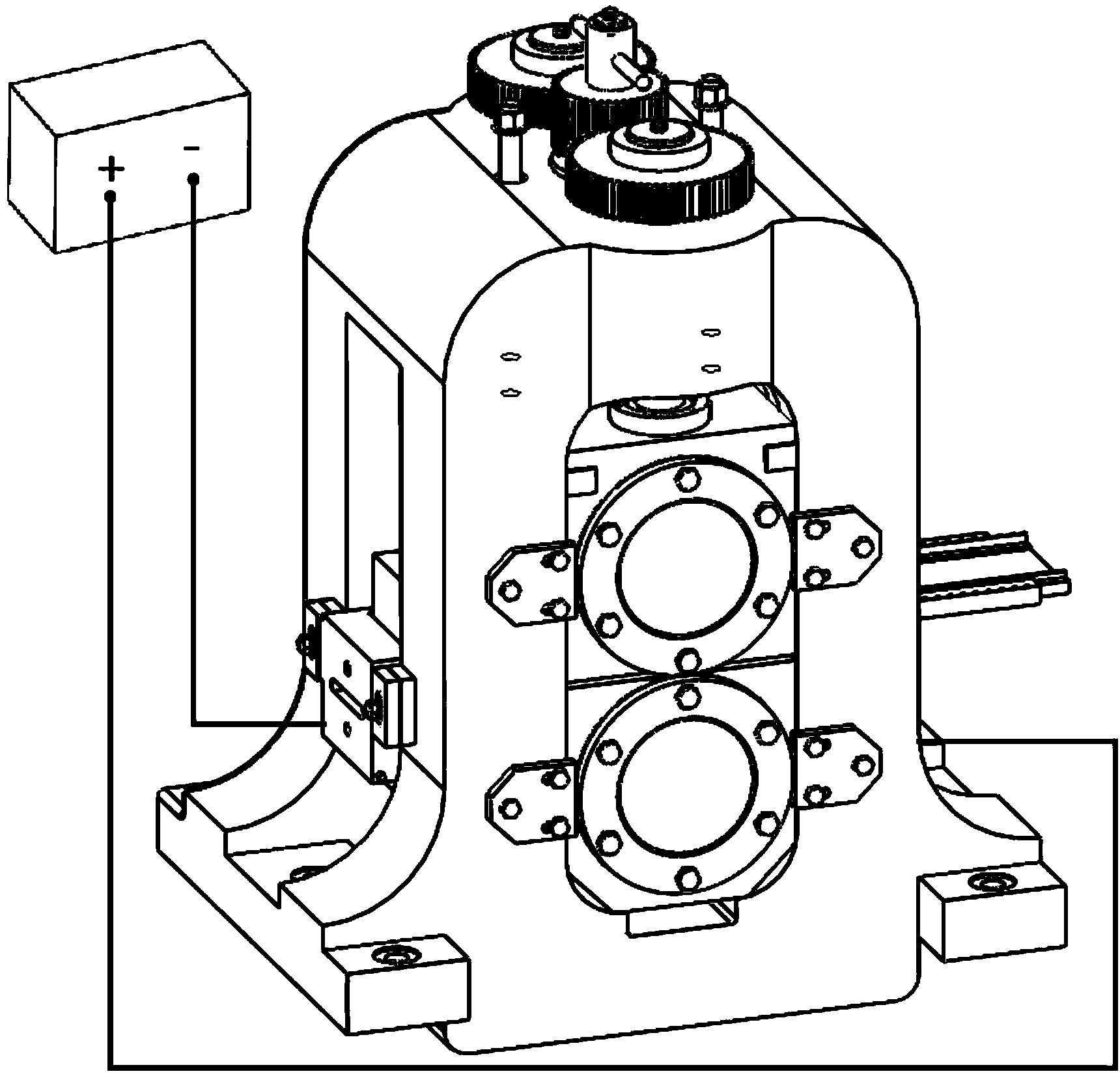

[0029] exist figure 1 and figure 2 In the schematic diagram of the electroplastic equal-diameter rolling mill shown, the main body of the two-roll mill is a closed four-column stand 1, and there is a roller 6 with a nominal diameter of 180 mm between the two columns on each side. , the upper part of the upper roller bearing seat 6-5 is provided with a threaded pressing mechanism 8, which can manually adjust the roller spacing. The manual adjustment mechanism is located on the top of the frame, passing through the vertical hole on the top of the frame and the upper roller bearing 6-5 connected. There is a balance mechanism 7 on the left and right sides of the pressing mechanism, the lower end of which is connected to the bearing seat of the upper roller, and the upper end of the pressing mechanism is connected to the gear set through the vertical through hole on the top of the frame, and the gear can be rotated by turning the adjusting lever. The group drives the pressing me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com