Hot-rolled structural steel ST52 medium-thick plate with thickness of 15-60mm and production method thereof

A production method and technology for structural steel, applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of poor steel quality and cumbersome production of thick plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, and stack cooling processes, a 15-60mm thick hot-rolled structural steel ST52 medium plate is obtained. Contains the following chemical composition in mass percent (unit, wt%): C: 0.11, Si: 0.44, Mn: 1.22, P: 0.015, S: 0.001, Als: 0.050, Nb: 0.020, Ti: 0.019, others are Fe and residual elements.

Embodiment 2

[0024]Through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, and stack cooling processes, a 15-60mm thick hot-rolled structural steel ST52 medium plate is obtained. Contains the following chemical composition (unit, wt%) in mass percentage: C: 0.15, Si: 0.26, Mn: 1.50, P: 0.002, S: 0.003, Als: 0.017, Nb: 0.038, Ti: 0.010, others are Fe and residual elements.

[0025] Analysis of mechanical properties

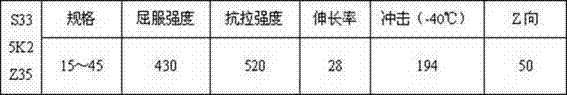

[0026] Composition and mechanical properties are implemented according to ASTM A370, and the mechanical properties are shown in the following table 1

[0027] Table 1 Mechanical and mechanical properties of hot-rolled structural steel ST52 plate with a thickness of 15-60mm

[0028]

[0029] The trial production of 15-60mm thick hot-rolled structural steel ST52 medium and heavy plates totaled 40 batches, of which: the yield strength was controlled at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com