Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

A technology of high-strength steel plates and hot-rolled steel plates, which is applied in the manufacture of tools, metal rolling, temperature control, etc., can solve the problem of easy cracking, low cold-bending performance and impact energy of thick specifications, and cannot meet the requirements of cold-formed steel sheet pile production To achieve the effect of increasing the nucleation position, increasing the grain boundary area and deformation zone area, and improving the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

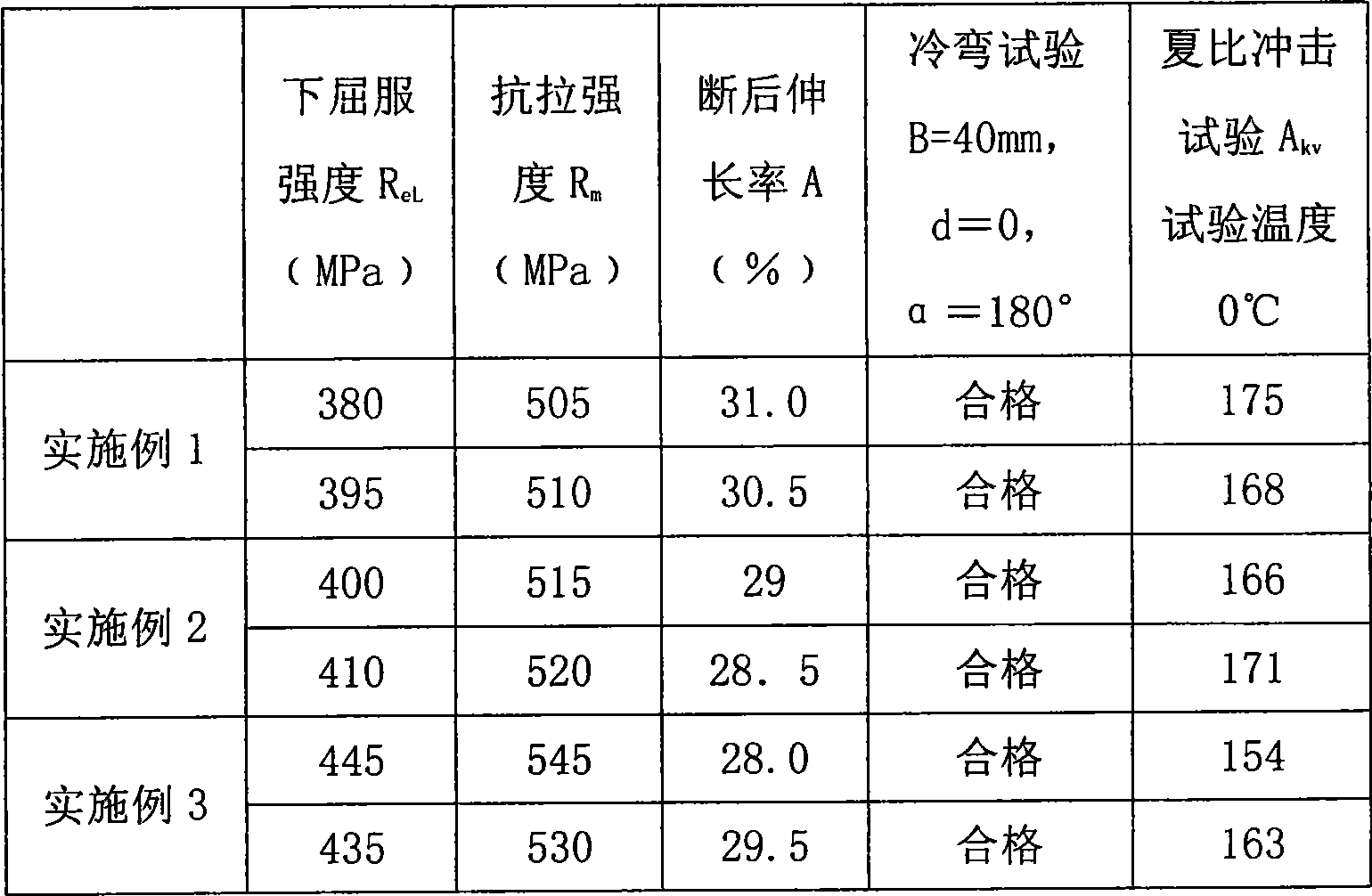

[0013] The specific embodiment: the present invention will be further described in conjunction with embodiment 1-3, see table 1 below,

[0014] Table 1 Component distribution ratio of the present invention, component is % by weight, balance is Fe.

[0015] C Si mn Nb Ti P S this invention 0.08~

0.15 0.10~

0.40 0.30~0.90 0.010~

0.040 0.010~

0.030 ≤0.025 ≤0.015 Example 1 0.08 0.15 0.40 0.020 0.015 ≤0.025 ≤0.015 Example 2 0.11 0.22 0.6 0.025 0.020 ≤0.025 ≤0.015 Example 3 0.14 0.35 0.80 0.035 0.030 ≤0.025 ≤0.015

[0016] Continuous casting slabs meeting the required chemical composition are obtained through converter smelting, with a thickness of 210-240 mm, a width of 800-1300 mm, and a length of 5000-10000 mm. Manufactured by rolling on a fully continuous hot rolling mill. The process control is shown in Table 2 below: the rough rolling is 5-pass rolling, and the finish rolling is 5-pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com