Method for comprehensive recovery of lead and tin from alkaline refining slag of lead

A refining slag and alkaline technology, applied in the field of tin and lead comprehensive recovery, can solve the problems of waste of resources, difficult to recycle, increase the difficulty of tin removal, etc., and achieve the effect of reducing the difficulty and improving the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

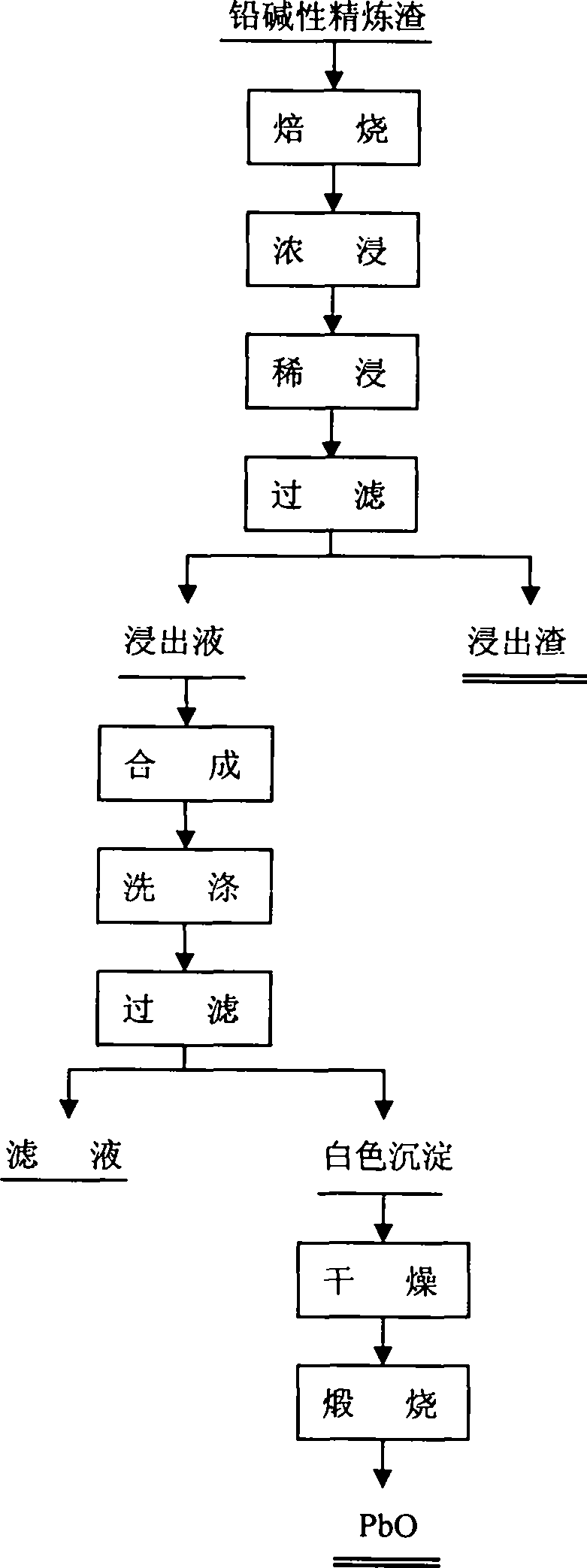

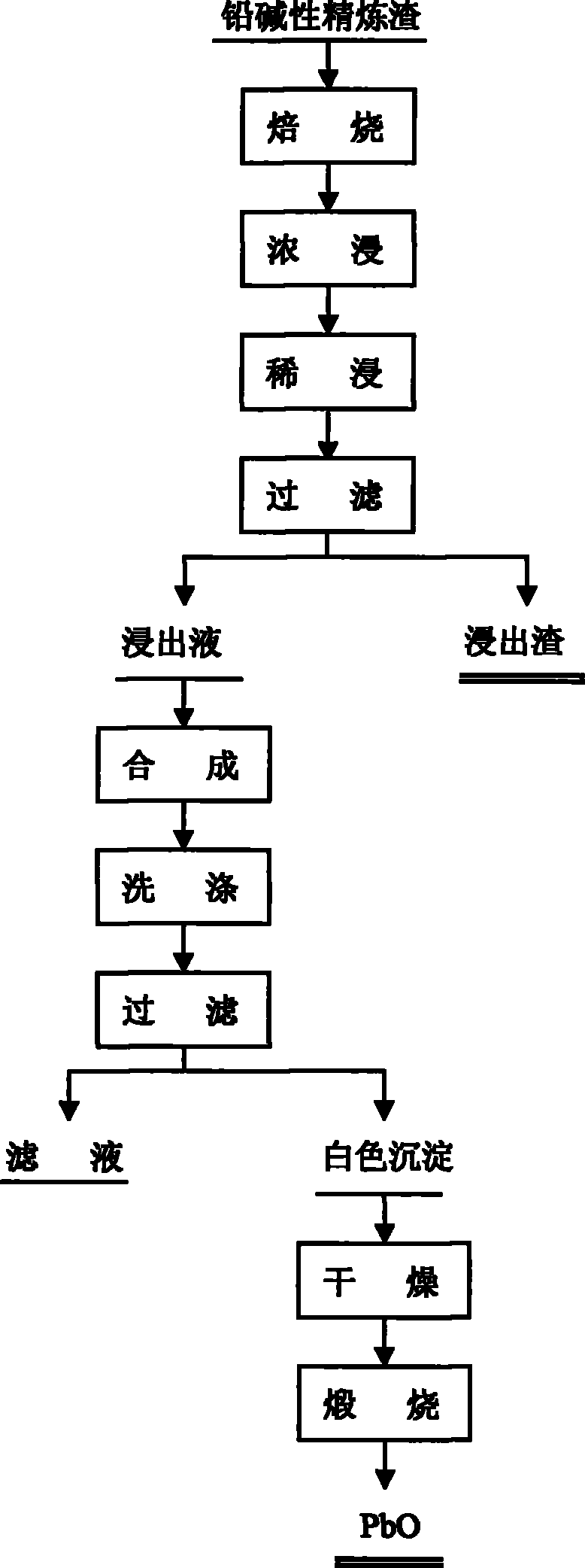

[0024] Adopt the present invention to composition be following weight percentage Pb81.06, the lead alkaline refining slag of Sn6.79 carries out comprehensive recovery lead, tin, carries out by following steps successively:

[0025] Step 1: oxidative roasting step, the lead alkaline refining slag is oxidatively roasted according to the conventional method, the oxidation roasting temperature of the lead alkaline refining slag is 300-500° C., and the roasting time is 2-6 hours to obtain the roasting slag;

[0026] Step 2: the leaching step, leaching the roasted slag obtained in step 1 with nitric acid, first leaching with 25% nitric acid solution for 2 hours; then replenishing water to dilute the leaching solution and then leaching for 2 hours, the liquid-solid weight ratio after dilution is 6:1 , the temperature is 40-80°C, and then filtered and separated to obtain lead nitrate solution and tin slag; the leaching solution is used for the synthesis of the next process, the tin sla...

Embodiment 2

[0031] Adopt the present invention to composition be following weight percentage Pb81.06, the lead alkaline refining slag of Sn6.79 carries out comprehensive recovery lead, tin, carries out by following steps successively:

[0032] Step 1: oxidative roasting step, the lead alkaline refining slag is oxidatively roasted according to the conventional method, the oxidation roasting temperature of the lead alkaline refining slag is 300-500° C., and the roasting time is 2-6 hours to obtain the roasting slag;

[0033] Step 2: namely the leaching step, leaching the calcined slag obtained in step 1 with nitric acid, first leaching with 30% nitric acid solution for 1.5h; then replenishing water to dilute the leaching solution and then leaching for 2h, the liquid-solid weight ratio after dilution is 7: 1. The temperature is 60°C, and then filtered to obtain the leaching slag, which is tin slag and leaching solution. The leaching solution is used for the synthesis of the next process. The ...

Embodiment 3

[0038] Adopt the present invention to composition be following weight percentage Pb81.06, the lead alkaline refining slag of Sn6.79 carries out comprehensive recovery lead, tin, carries out by following steps successively:

[0039] Step 1: oxidative roasting step, the lead alkaline refining slag is oxidatively roasted according to the conventional method, the oxidation roasting temperature of the lead alkaline refining slag is 300-500° C., and the roasting time is 2-6 hours to obtain the roasting slag;

[0040] Step 2: the leaching step, leaching the roasted slag obtained in step 1 with nitric acid, first leaching with 35% nitric acid solution for 1.5 hours; then replenishing water to dilute the leaching solution and then leaching for 1.5 hours, the liquid-solid weight ratio after dilution is 8 : 1, the temperature is 70°C, then filter to obtain the leaching slag, namely tin slag and leaching solution, the leaching solution is used for synthesis in the next stage of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com