Cathode electrode composite material and preparation method thereof and electrochemical device applying same

A negative electrode and composite material technology, which is applied in the direction of alkaline battery electrodes, nickel batteries, alkaline batteries, etc., can solve the problems that the battery energy density and power density cannot meet the power supply requirements for power, and the electric capacity of iron electrodes is not high. The effect of improving charge and discharge characteristics, low production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

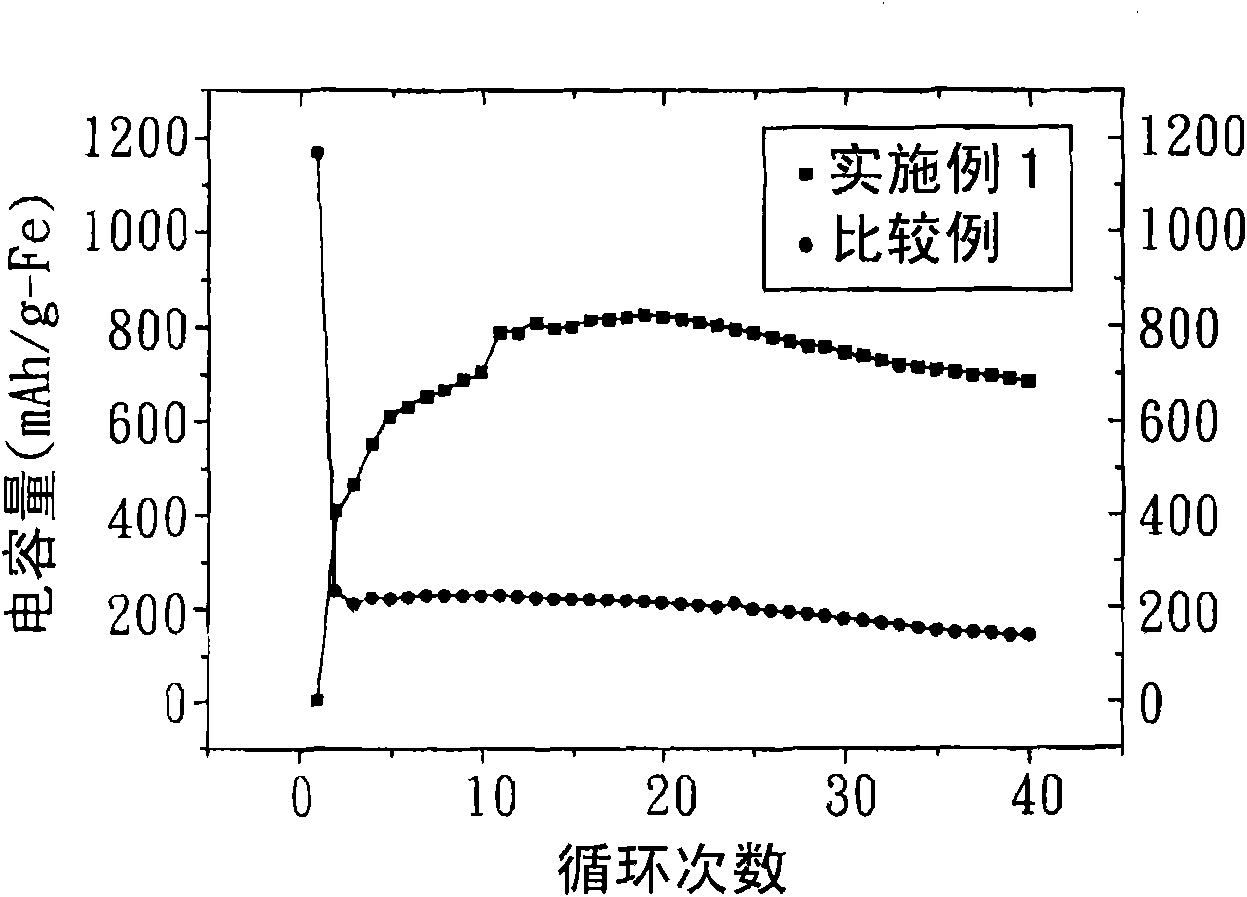

Embodiment 1

[0032] Formulated with FeSO 4 ·7H 2 O(2.3352g) and Fe 2 (SO 4 ) 3 ·7H 2 O (8.94 g) in water and bubbled with nitrogen for 5 minutes. Then, add sodium hydroxide, the pH value of aqueous solution is adjusted to 11-12, and keep stirring for 30 minutes, to generate about 2g of ferric oxide (Fe 3 o 4 ). Then, using a magnet to separate the ferric oxide (Fe 3 o 4 ), and wash several times, then add CuSO 4 ·5H 2 O (1.834g, as a conductive additive), Na 2 S·9H 2 O (0.09g) and polytetrafluoroethylene (PTFE, 0.22g, as a binder) to make a slurry (ie negative electrode composite material). Finally, the slurry is coated on the collector grid (ie, the negative electrode substrate) to form a negative electrode coating, and then a negative electrode is produced.

[0033] After the negative electrode prepared in this embodiment is charged, the copper sulfate (as a conductive aid) in the negative electrode will be reduced to nano-copper, which will be dispersed in the reduced iron...

Embodiment 2

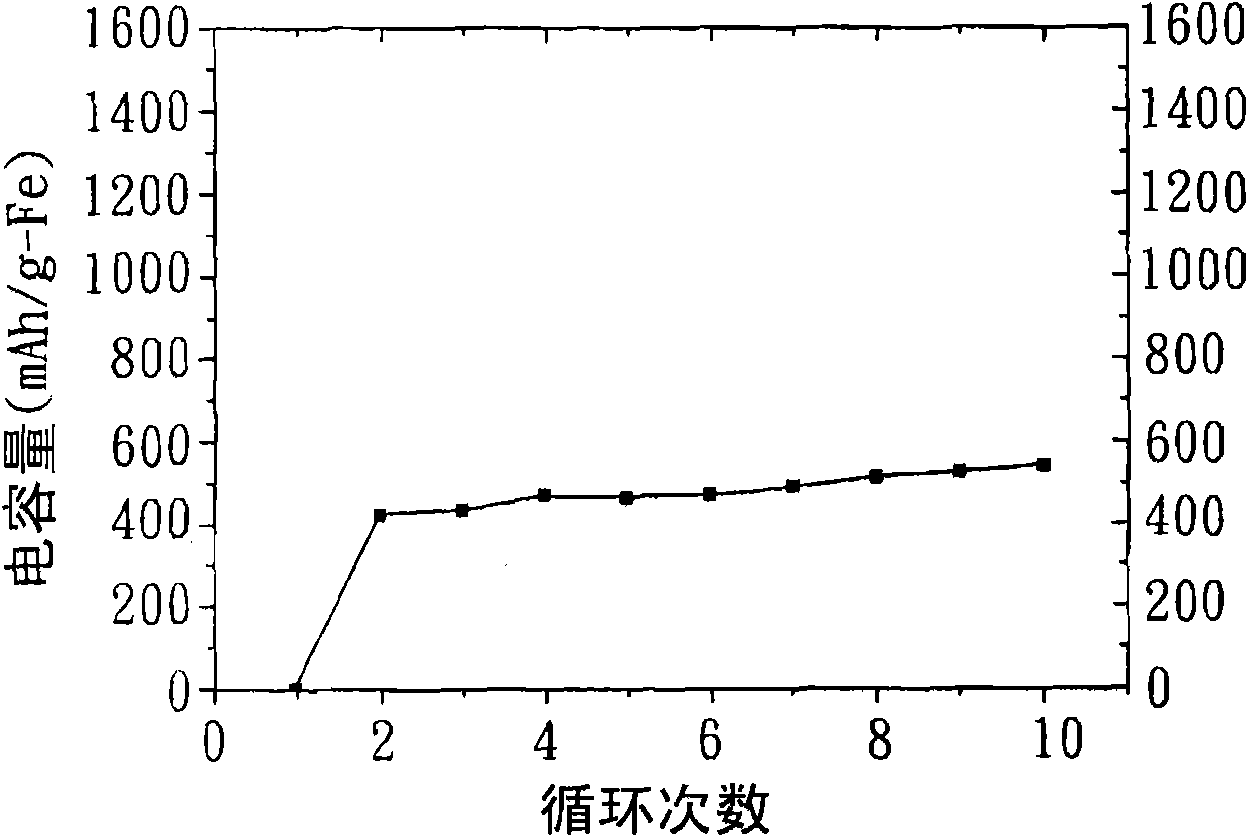

[0036] Formulated with FeSO 4 ·7H 2 O(2.3352g) and Fe 2 (SO 4 ) 3 ·7H 2 O (8.94 g) in water and bubbled with nitrogen for 5 minutes. Then, add sodium hydroxide, adjust the pH value of the aqueous solution to about 12, and continue to stir for 30 minutes, to generate about 2g of ferric oxide (Fe 3 o 4 ). Then, using a magnet to separate the ferric oxide (Fe 3 o 4 ), and cleaned several times, then added nano-Cu (0.467g, as a conductive additive), Na 2 S·9H 2 O (0.09g) and polytetrafluoroethylene (PTFE, 0.22g, as a binder) to make a slurry (ie negative electrode composite material). Finally, the slurry is coated on the collector grid (ie, the negative electrode substrate) to form a negative electrode coating, and then a negative electrode is produced.

[0037] In this embodiment, iron oxide particles (Fe 3 o 4 Particles) have a diameter of about 20nm to 100nm; while iron oxide particles (ie Fe 3 o 4 Particles) to the weight ratio of the conductive additive (ie na...

Embodiment 3

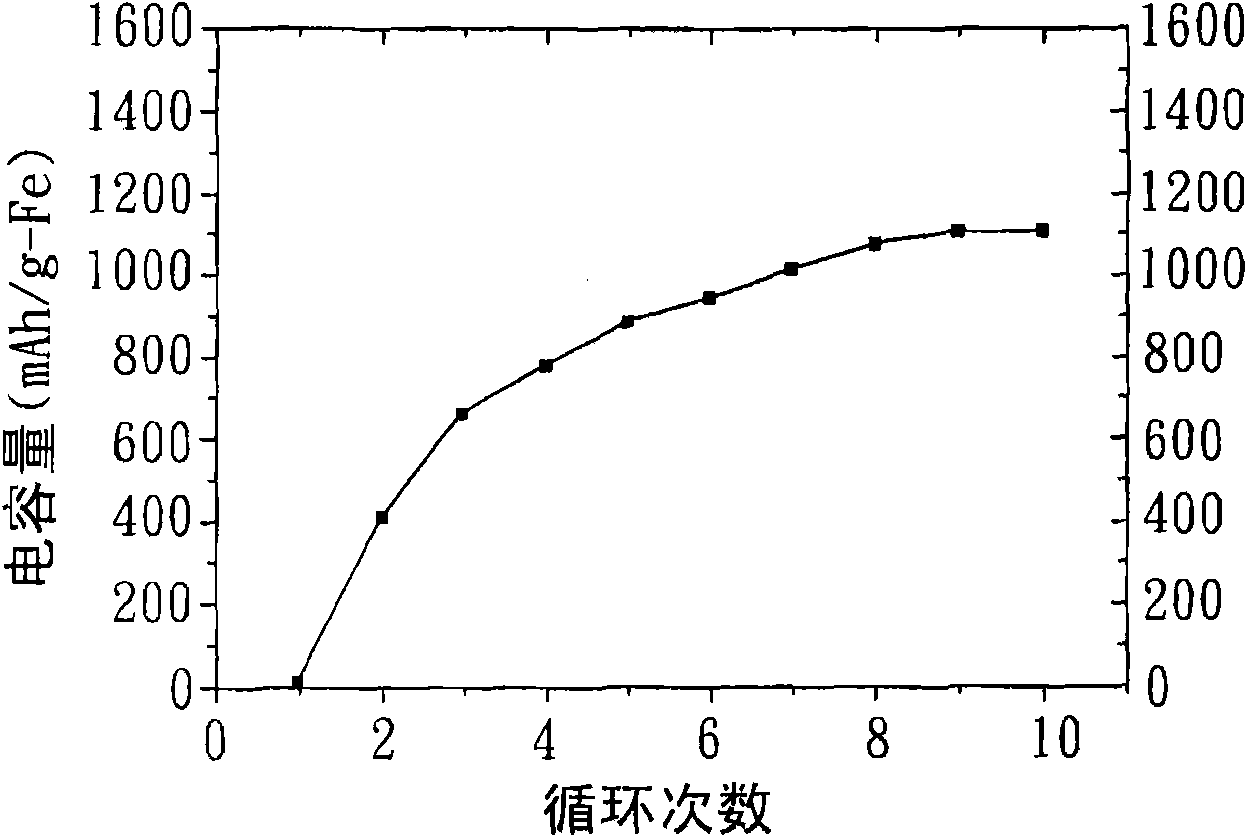

[0039] Formulated with FeSO 4 ·7H 2 O(2.3352g) and Fe 2 (SO 4 ) 3 ·7H 2 O (8.94 g) in water and bubbled with nitrogen for 5 minutes. Then, add sodium hydroxide, adjust the pH value of the aqueous solution to about 12, and continue to stir for 30 minutes, to generate about 2g of ferric oxide (Fe 3 o 4 ). Then, add CuSO 4 ·5H 2 O (1.834g), and adjust the pH value of the aqueous solution to about 12 (CuSO 4 ·5H 2 O is formed as Cu(OH) 2 ), and then suction and filter to collect the powder (Cu(OH) 2 with Fe 3 o 4 homogeneous mixture), and dry. Subsequently, the dried powder was mixed with Na 2 S·9H 2 O (0.09g) and polytetrafluoroethylene (PTFE, 0.22g, used as a binder) were evenly mixed to make a slurry (ie negative electrode composite material). Finally, the slurry is coated on the collector grid (ie, the negative electrode substrate) to form a negative electrode coating, and then a negative electrode is produced.

[0040] After the negative electrode prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com