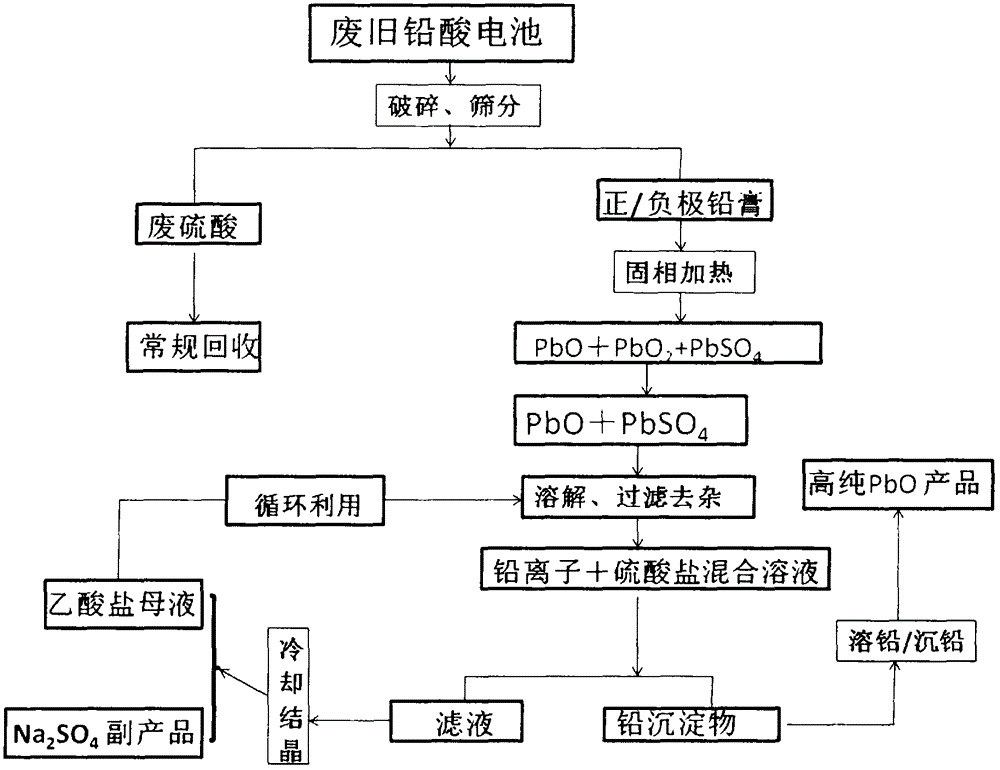

Method for preparing high-purity PbO by cycle wet method

A cyclic, high-purity technology, applied in the field of recycling and regenerating lead from waste lead-acid batteries and lead-containing materials, can solve the problems of difficult process control, raw material consumption, long cycle, etc., and achieve high product purity and fewer process steps. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Use mechanical dismantling to separate and sort waste lead-acid batteries to obtain lead paste, grids, waste sulfuric acid, separators and shells. The separated positive / negative lead paste is crushed and screened with a 100-mesh stainless steel screen, and the larger lead paste particles are continuously transferred to the pulverizer for crushing until all the lead paste can pass through the screen. The crushed and sieved positive / negative lead paste is fully mixed in solid phase.

[0018] (2) Take 1kg of lead paste powder mixture, slowly heat up to 280°C under normal pressure, and keep it for 3 hours so that the lead dioxide and lead in it undergo redox reaction under heating conditions and convert into lead oxide to generate lead oxide and sulfuric acid Lead-based solid mixture; then add 3mL of 80% hydrazine hydrate solution and react at 20°C for 10 minutes to make the unreacted PbO 2 The solid compound is completely converted to PbO.

[0019] (3) The PbO obtai...

Embodiment 2

[0023] (1) Use mechanical dismantling to separate and sort waste lead-acid batteries to obtain lead paste, grids, waste sulfuric acid, separators and shells. The separated positive / negative lead paste is crushed and screened with a 100-mesh stainless steel screen, and the larger lead paste particles are continuously transferred to the pulverizer for crushing until all the lead paste can pass through the screen. The crushed and sieved positive / negative lead paste is fully mixed in solid phase.

[0024] (2) Take 2kg of lead plaster powder mixture, slowly heat up to 320°C under normal pressure, and keep it for 4 hours so that the lead dioxide and lead in it undergo oxidation-reduction reaction under heating conditions and convert into lead oxide to generate lead oxide and sulfuric acid Lead-based solid mixture; then add 6mL of 80% hydrazine hydrate solution and react at 25°C for 20 minutes to make the unreacted PbO 2 The solid compound is completely converted to PbO.

[0025](3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com