Preparation method for modified actived carbons

A technology of activated carbon and modification, applied in the field of preparation of modified activated carbon, can solve the problems of low working voltage, low hydrogen evolution potential, accelerated water, etc., and achieve the effects of short production cycle, simple preparation process and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

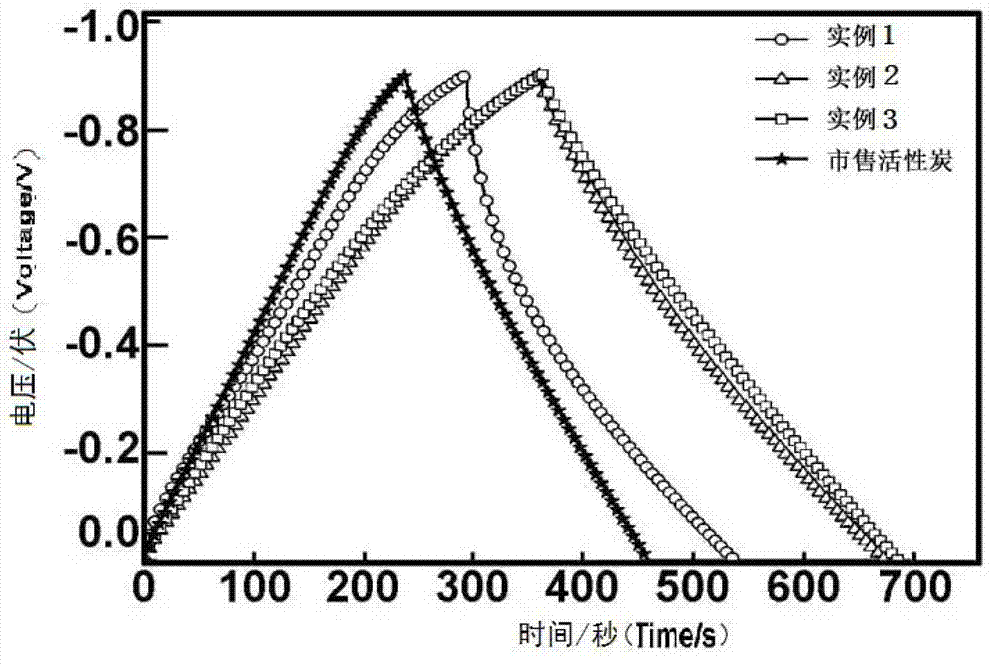

[0026] Example 1: Step 1: Weigh 100 grams of activated carbon, put 5 grams of lead nitrate into a ball milling tank, control the ball-material ratio to 25:1, ball mill the above mixture for 20 minutes, and break the raw materials.

[0027] The second step: get 1.9 grams of potassium hydroxide and put it into the ball mill jar described in the first step, and add 0.1 gram of deionized water, and ball mill the above mixture for 20 minutes to obtain a black powder of activated carbon loaded with lead.

[0028] The third step: drying the powder obtained in the second step, the drying temperature is controlled at 85° C., and the drying time is 0.5 hour.

[0029] Step 4: Put the powder obtained in the third step into a tube furnace for protection with argon gas. The flow rate of argon gas is 70ml / min. Heat treatment at a rate of 5°C / min. The heat treatment temperature is 650°C and kept for 1.5 h, the tube furnace is naturally cooled to room temperature to obtain the modified activat...

Embodiment 2

[0030] Example 2: Step 1: Weigh 500 grams of activated carbon and 50 grams of lead nitrate into a ball mill tank, control the ball-material ratio to 10:1, ball mill the above mixture for 25 minutes, and break the raw materials.

[0031] The second step: get 20 grams of potassium hydroxide and put it into the ball mill jar described in the first step, and add 1.5 grams of deionized water, and ball mill the above mixture for 30 minutes to obtain a black powder of activated carbon loaded with lead.

[0032] The third step: drying the powder obtained in the second step, the drying temperature is controlled at 90° C., and the drying time is 0.5 hour.

[0033] Step 4: Put the powder obtained in the third step into a tube furnace with argon protection, the flow rate of argon gas is 75ml / min, heat treatment at a rate of 5°C / min, the heat treatment temperature is 750°C, and keep it warm for 2h , the tube is naturally cooled to room temperature to obtain the modified activated carbon pr...

Embodiment 3

[0034] Example 3: Step 1: Weigh 1000 grams of activated carbon, put 50 grams of lead acetate into a ball mill tank, control the ball-material ratio to 20:1, ball mill the above mixture for 28 minutes, and break the raw materials.

[0035] The second step: get 19 grams of potassium hydroxide and put it into the ball mill jar described in the first step, and add 2 grams of deionized water, and ball mill the above mixture for 30 minutes to obtain a black powder of activated carbon loaded with lead.

[0036] The third step: drying the powder obtained in the second step, the drying temperature is controlled at 80° C., and the drying time is 1 hour.

[0037] Step 4: Put the powder obtained in the third step into a tube furnace for protection with argon gas. The argon gas flow rate is 80ml / min. Heat treatment at a rate of 5°C / min. The heat treatment temperature is 850°C and kept for 2 hours. , the tube is naturally cooled to room temperature to obtain the modified activated carbon pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com