Method for preparing lead hydroxide nano-rod based on liquid-phase chemical reaction

A liquid-phase chemical reaction, lead hydroxide technology, applied in directions such as lead hydroxide, can solve problems such as no literature report on the preparation method of lead hydroxide nanorods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

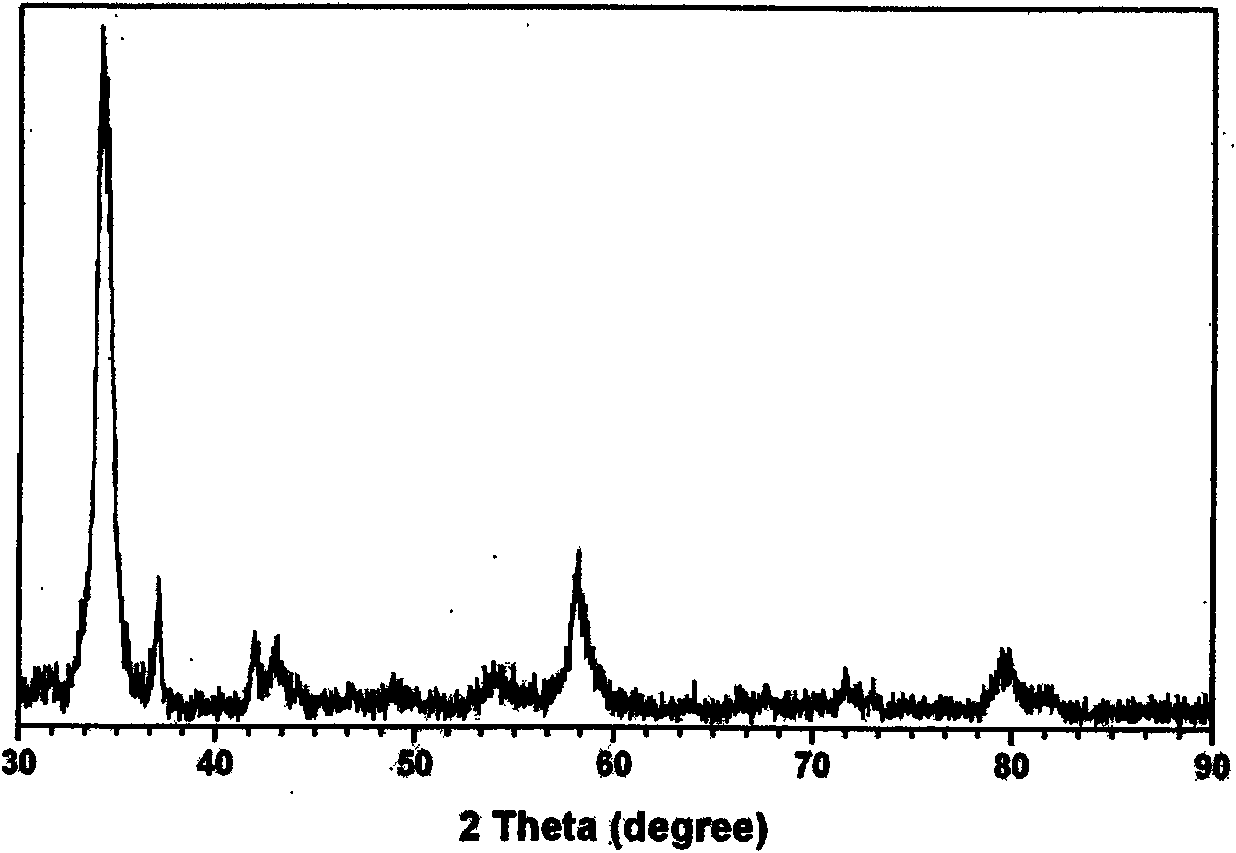

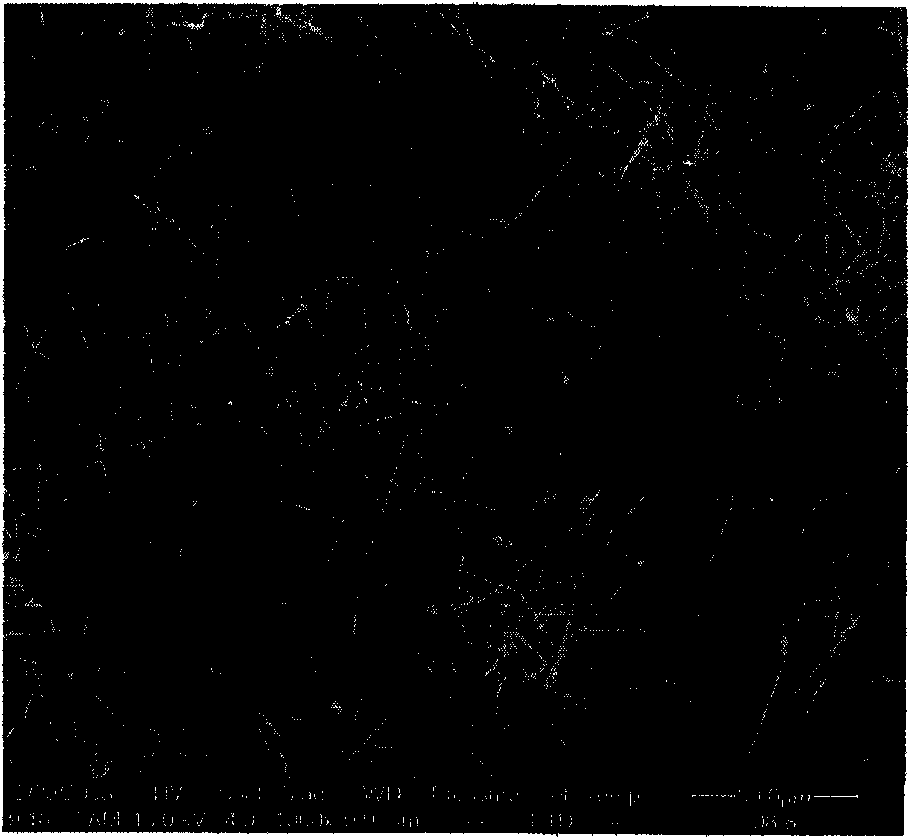

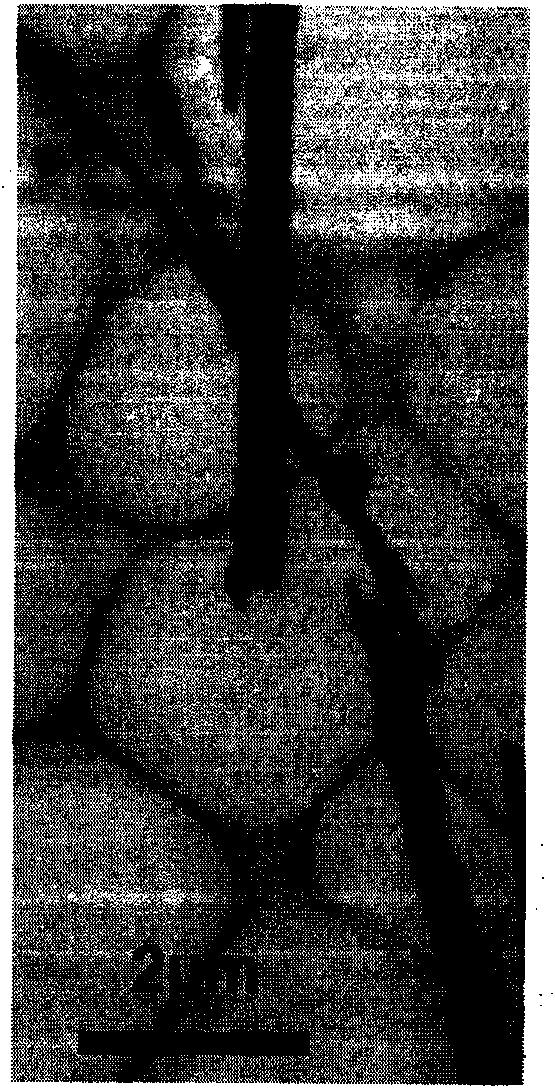

[0013] Get 0.166g of lead nitrate and 0.06g of sodium chloride and dissolve in 50ml of deionized water, heat the solution to 80 degrees Celsius, then add 0.084g of potassium hydroxide solid into the solution, stir to obtain a white precipitate, filter, wash, After drying, lead hydroxide nanorods are obtained. Such as figure 1 Shown, the product is identified as lead hydroxide through X-ray powder diffraction; Carry out morphology analysis to product with scanning electron microscope, from figure 2 It can be seen from the figure that its shape is a rod, the length of the rod is about 50 microns, the diameter of the rod is between 100-500 nanometers, and the aspect ratio is as high as 100 or more; image 3 It shows that the morphology seen under the transmission electron microscope is also rod-shaped; Figure 4 It shows the lattice fringes of the (002) crystal plane that can be seen clearly under the high-resolution transmission electron microscope, and the interplanar spacin...

Embodiment 2

[0015] Take 0.662g lead nitrate and 0.117g sodium chloride and dissolve in 200ml deionized water, heat the solution to 90 degrees Celsius, then add 0.336g potassium hydroxide solid to the solution, stir to obtain a white precipitate, filter, wash, After drying, lead hydroxide nanorods are obtained.

Embodiment 3

[0017] Take 0.662g lead nitrate and 0.234g sodium chloride and dissolve in 200ml deionized water, heat the solution to 90 degrees Celsius, then add 0.084g potassium hydroxide solid to the solution, stir to obtain a white precipitate, filter, wash, After drying, lead hydroxide nanorods are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com