Lead-carbon composite particle and preparation method thereof

A technology of composite particles and lead carbon, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy precipitation and peeling of activated carbon, poor affinity of lead powder, and large amount of activated carbon added, so as to improve stability and use safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned lead-carbon composite particle comprises the following steps:

[0035] 1) sodium hydroxide solution and lead acetate solution are mixed homogeneously, fully reacted, the precipitate that generates is separated, obtains lead hydroxide;

[0036] 2) Dispersing lead hydroxide in the PVP solution, fully reacting, separating the resulting PVP modified lead hydroxide precipitate, adding it to absolute ethanol, adding water, and dispersing evenly to obtain a dispersion;

[0037] 3) Add the tetramethylammonium hydroxide solution to the dispersion in step 2), and react fully, then add the ethanol solution of ethyl orthosilicate, react fully, separate the formed precipitate, and obtain a silica coating lead hydroxide;

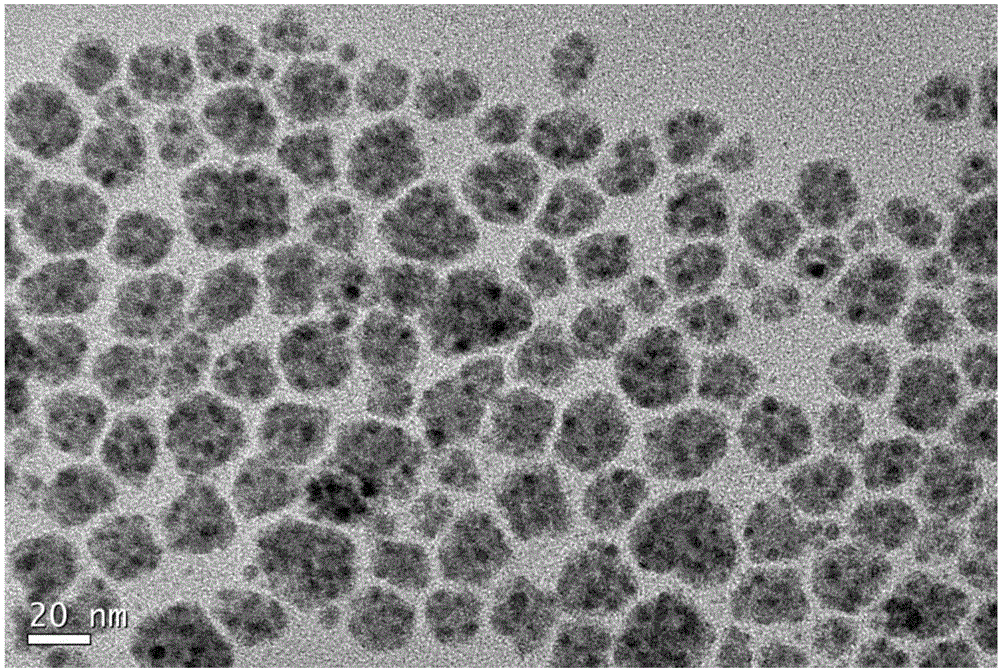

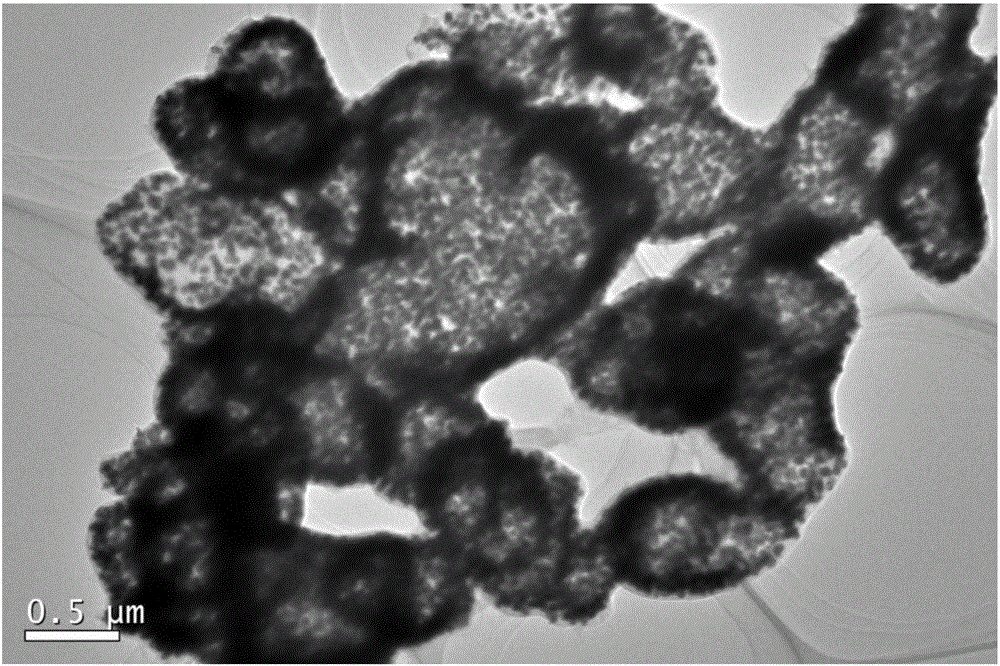

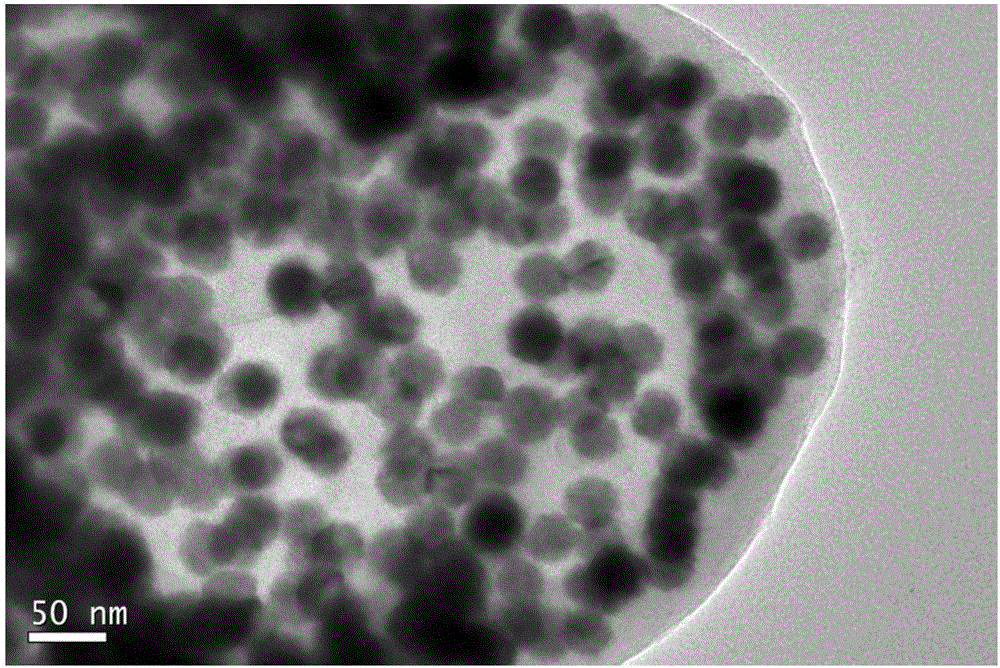

[0038] 4) Disperse the silica-coated lead hydroxide in the glucose solution and react fully to obtain C@[SiO 2 @Pb(OH) 2 ];

[0039] 5) The C@[SiO 2 @Pb(OH) 2 ] into zinc chloride solution for impregnation, fully drie...

Embodiment 1

[0056] 1) Mix 80mL of 20g / L sodium hydroxide solution and 40mL of 400g / L lead acetate solution evenly, react for 2 hours, separate the formed white precipitate, wash it with deionized water, and obtain lead hydroxide;

[0057] 2) Disperse lead hydroxide in 150mL of 30g / L PVP solution, stir and react for 10 hours, separate the resulting pale yellow PVP-modified lead hydroxide precipitate, add it to 130mL absolute ethanol, and add 8mL Deionized water, ultrasonic dispersion for 10 minutes to obtain a dispersion;

[0058] 3) While stirring, add 100 μL of tetramethylammonium hydroxide solution with a mass fraction of 10% dropwise to the dispersion in step 2), fully react, and then add 20 mL of tetramethylammonium hydroxide solution with a volume fraction of 0.05% dropwise The ethanol solution was dropped within 2 hours, and the stirring reaction was kept for 10 hours, and the white precipitate generated was separated to obtain silica-coated lead hydroxide;

[0059] 4) Disperse sil...

Embodiment 2

[0062] 1) Mix 160mL of 10g / L sodium hydroxide solution and 40mL of 20g / L lead acetate solution evenly, react for 2 hours, separate the formed white precipitate, wash it with deionized water, and obtain lead hydroxide;

[0063] 2) Disperse lead hydroxide in 150mL of 10g / L PVP solution, stir and react for 10 hours, separate the resulting pale yellow PVP-modified lead hydroxide precipitate, add it to 130mL absolute ethanol, and add 8mL Deionized water, ultrasonic dispersion for 10 minutes to obtain a dispersion;

[0064] 3) While stirring, add 100 μL of tetramethylammonium hydroxide solution with a mass fraction of 30% dropwise to the dispersion in step 2), fully react, and then add dropwise 20 mL of tetramethylammonium hydroxide solution with a volume fraction of 0.05% The ethanol solution was dropped within 2 hours, and the stirring reaction was kept for 10 hours, and the white precipitate generated was separated to obtain silica-coated lead hydroxide;

[0065] 4) Disperse sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com