Process and device for processing and recycling leaded wastewater

A waste water treatment and equipment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of large pollution hidden dangers, unstable lead ion discharge water quality, etc., to avoid pollution Hidden dangers, guaranteed water quality and stability, compact and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

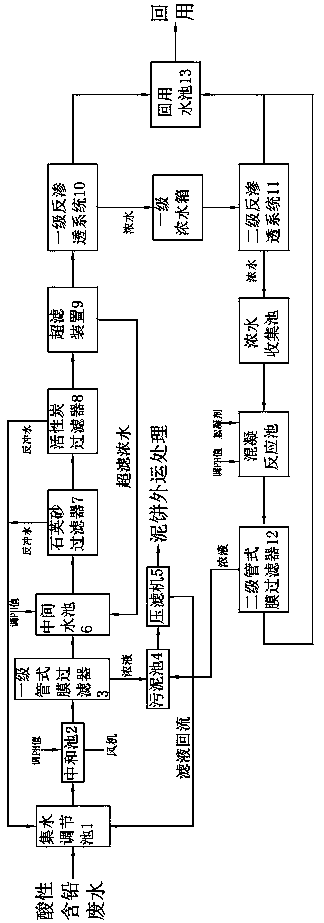

[0015] like figure 1 As shown, the lead-containing wastewater treatment and recycling process of the present invention is divided into two parts: primary treatment and advanced treatment. The first-stage reverse osmosis concentration and desalination process uses two-stage tubular membrane filtration for the concentrated water of the two-stage reverse osmosis.

[0016] 1. Primary processing equipment:

[0017] Water collection adjustment pool 1: The water collection adjustment pool 1 serves the purpose of collecting waste water and homogenizing the waste water.

[0018] Neutralization pool 2: The function of neutralization pool 2 is to adjust the pH value of 9.2 to 9.5, make lead ions react to form lead hydroxide, and add a coagulant appropriately according to the actual situation.

[0019] One-stage tubular membrane filter 3: the tubular membrane fully intercepts the flocs containing lead hydroxide.

[0020] Sludge pool 4: The sludge pool 4 is used to store the sludge conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com