Method for treating and recycling heavy metal wastewater by double-membrane process

A heavy metal and double-membrane technology, applied in chemical instruments and methods, reduced water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low recycling rate, ensure the quality of reused water, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

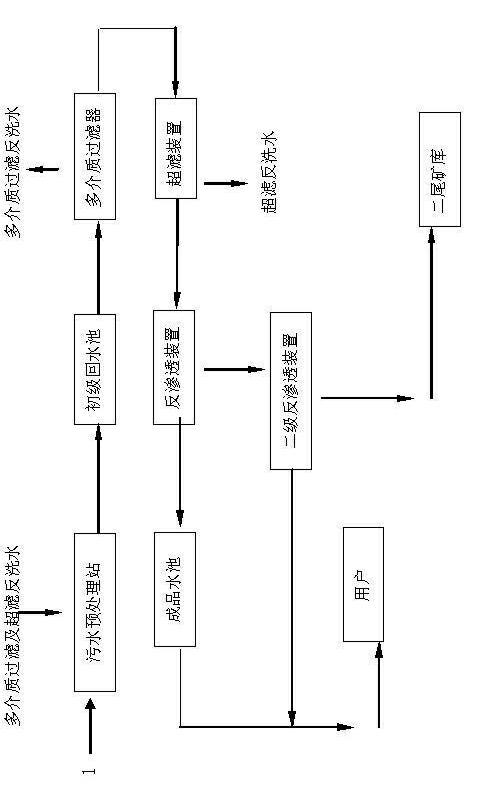

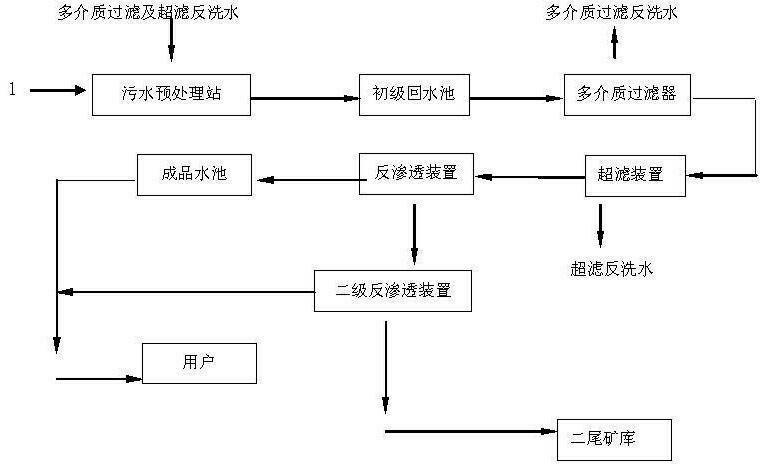

[0027] Such as figure 1 Shown, the basic flow process of double-membrane process process heavy metal waste water and recycling method among the present invention is as follows:

[0028] 1. Pretreatment

[0029] 1-1. Precipitation pretreatment: heavy metal wastewater 1 is input to the pretreatment station, and then enters the primary backwater tank and adds sodium hypochlorite and flocculant to precipitate the heavy metals in the wastewater;

[0030] 1-2. The wastewater treated in step 1-1 is input into the multi-media filtration system through the lifting pump, and most of the suspended solids, colloids and part of COD in the wastewater are removed in the media filtration system; part of the effluent is input Ultrafiltration treatment in the ultrafiltration system, and the other part is used as multimedia filter backwash water. The ratio between the two can be determined according to the water recovery rate of the multimedia filter; in addition, the multimedia filter backwash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com