Treatment method of secondary wastewater of kitchen waste

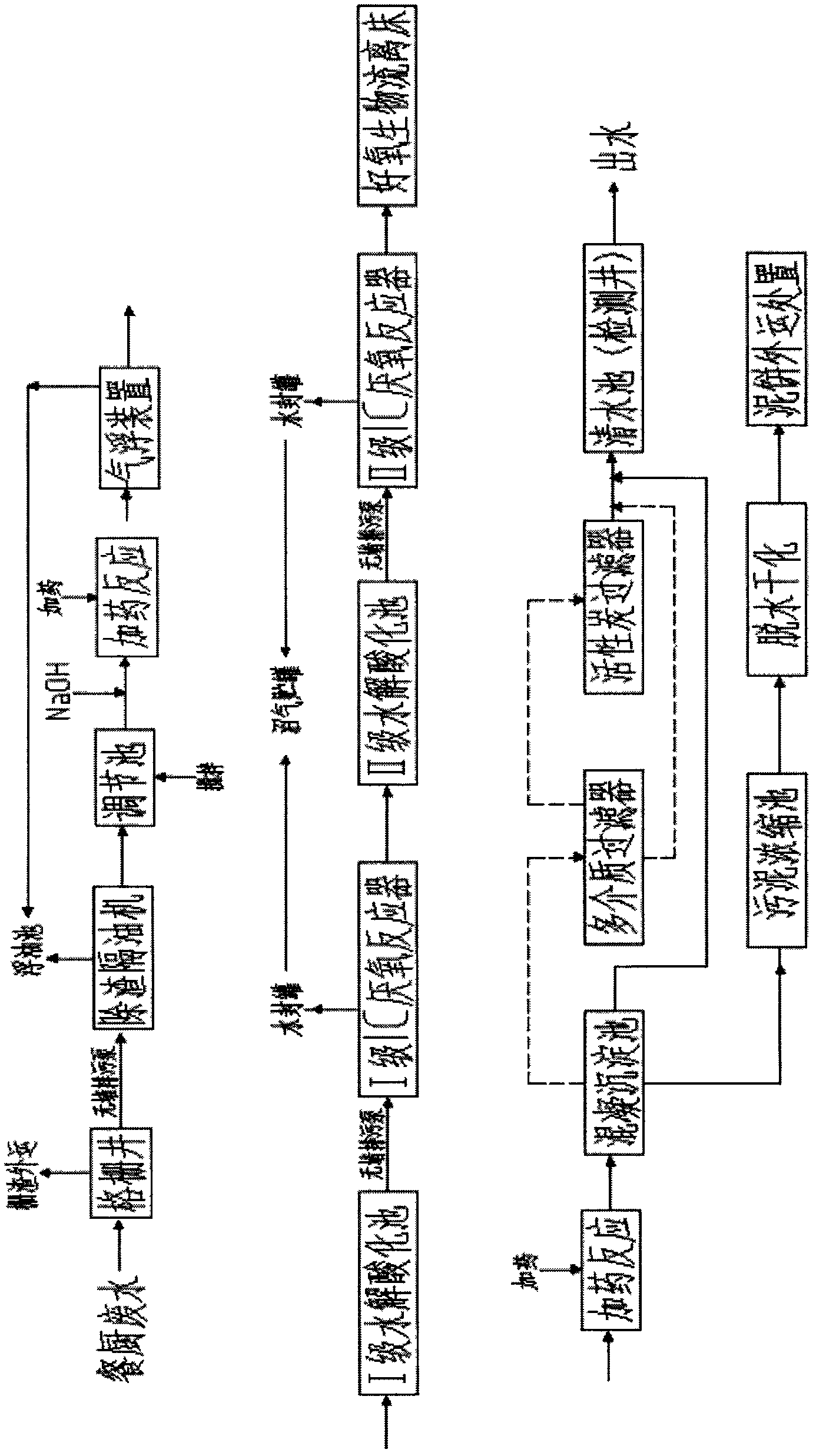

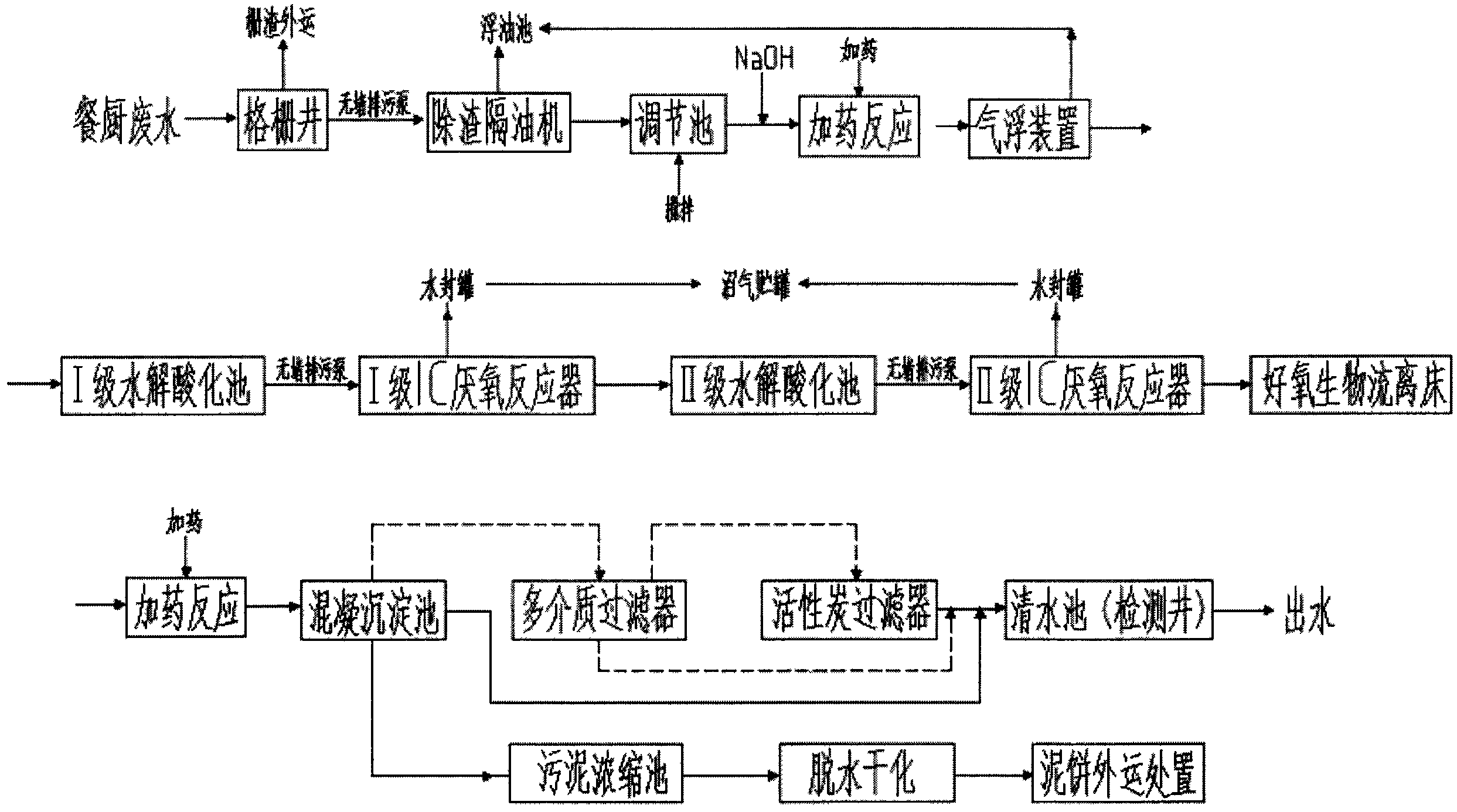

A food waste and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of affecting the lower-level anaerobic digestion reaction and the mass transfer effect is not very good , Separation effect is not increased, etc., to achieve the effect of reducing daily operation and management costs, reducing daily maintenance, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Take food waste wastewater: CODcr: 80000mg / L, ammonia nitrogen: 350mg / L, total nitrogen TN: 900mg / L, total phosphorus TP: 150mg / L, suspended solids SS: 10000mg / L, animal and vegetable oil: 2000mg / L, pH for 3.

[0035] (1) After the secondary waste water from the above-mentioned catering waste treatment is collected, it enters the grid set in the grid well to remove the larger floating objects in the wastewater, and the color of the water body becomes lighter; the wastewater after removing the larger floating objects is passed into the slag removal and oil separator Remove the grease in the waste water, the grease is passed into the floating oil pool, and exported to the system;

[0036](2) The waste water after removing grease enters the adjustment tank to homogenize the water quality at room temperature, stir, and then add lye, usually sodium hydroxide, to adjust the pH of the water quality, and the pH reaches 7.2 to 7.5. Dosing reaction zone and air flotation device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com