Patents

Literature

63results about How to "Little daily maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

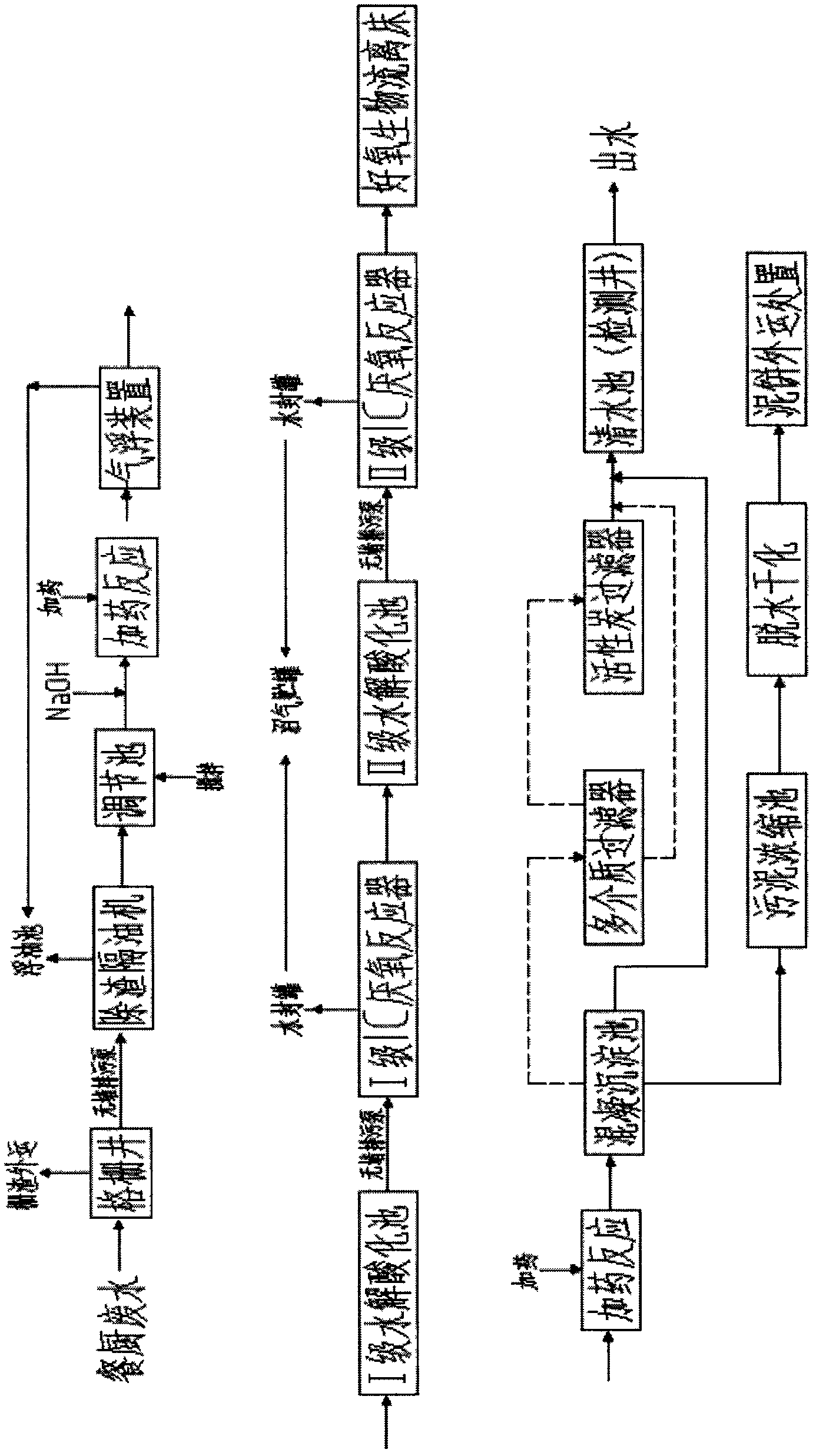

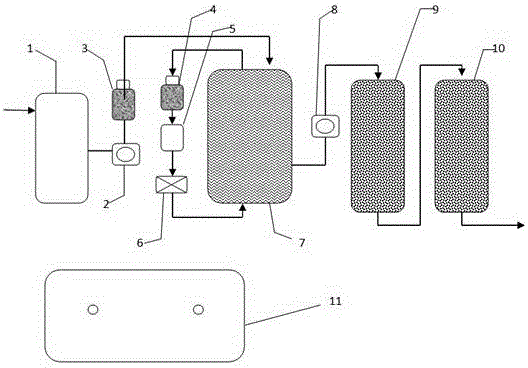

Treatment method of secondary wastewater of kitchen waste

ActiveCN102603117AReduce productionReduced processing system difficultyMultistage water/sewage treatmentFlocculationChemical oxygen demand

The invention discloses a treatment method of secondary wastewater of kitchen waste. The treatment method comprises the following steps of: (1) carrying out materialization pretreatment on kitchen wastewater to remove floater, animal or vegetable butter, oil and SS (suspended matter) in the wastewater; (2) carrying out the two-stage hydrolysis acidification-IC (internal circulation) anaerobic reaction treatment and biochemical treatment of an aerobiont separation bed on the wastewater; and (3) carrying out flocculation and precipitation on the biochemically-treated wastewater to discharge, and concentrating, dewatering and drying precipitate. The wastewater discharged by using the method reaches The people's Republic of China national standard of sewage comprehensive discharge standard (third-level discharge standard); through two-stage hydrolysis acidification-IC anaerobic reaction treatment, the gross removing rate of CODcr (chemical oxygen demand) can reach more than 92%, and carbon source does not needed to be supplied in the midway of the reaction, so that the normal running of equipment can be guaranteed.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

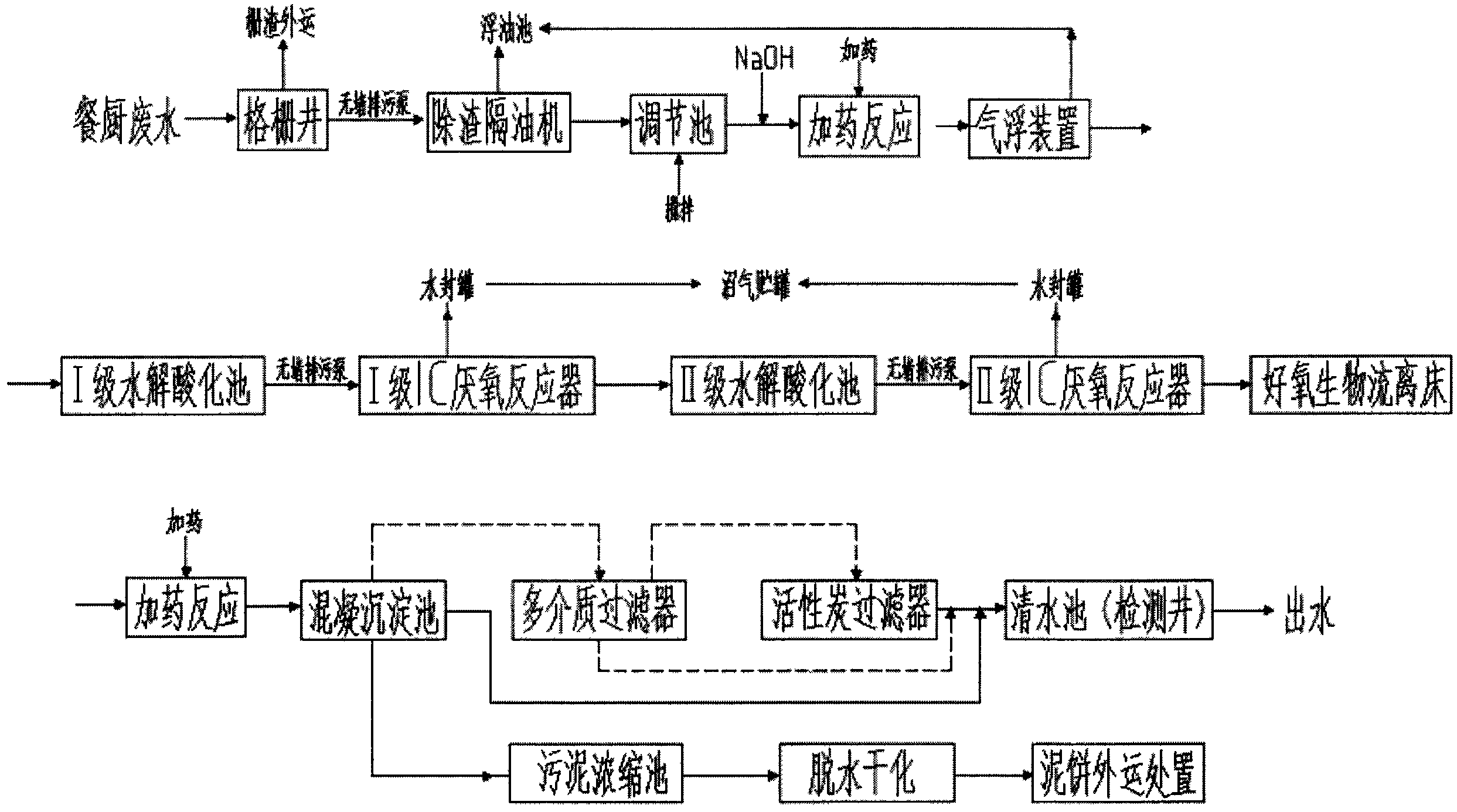

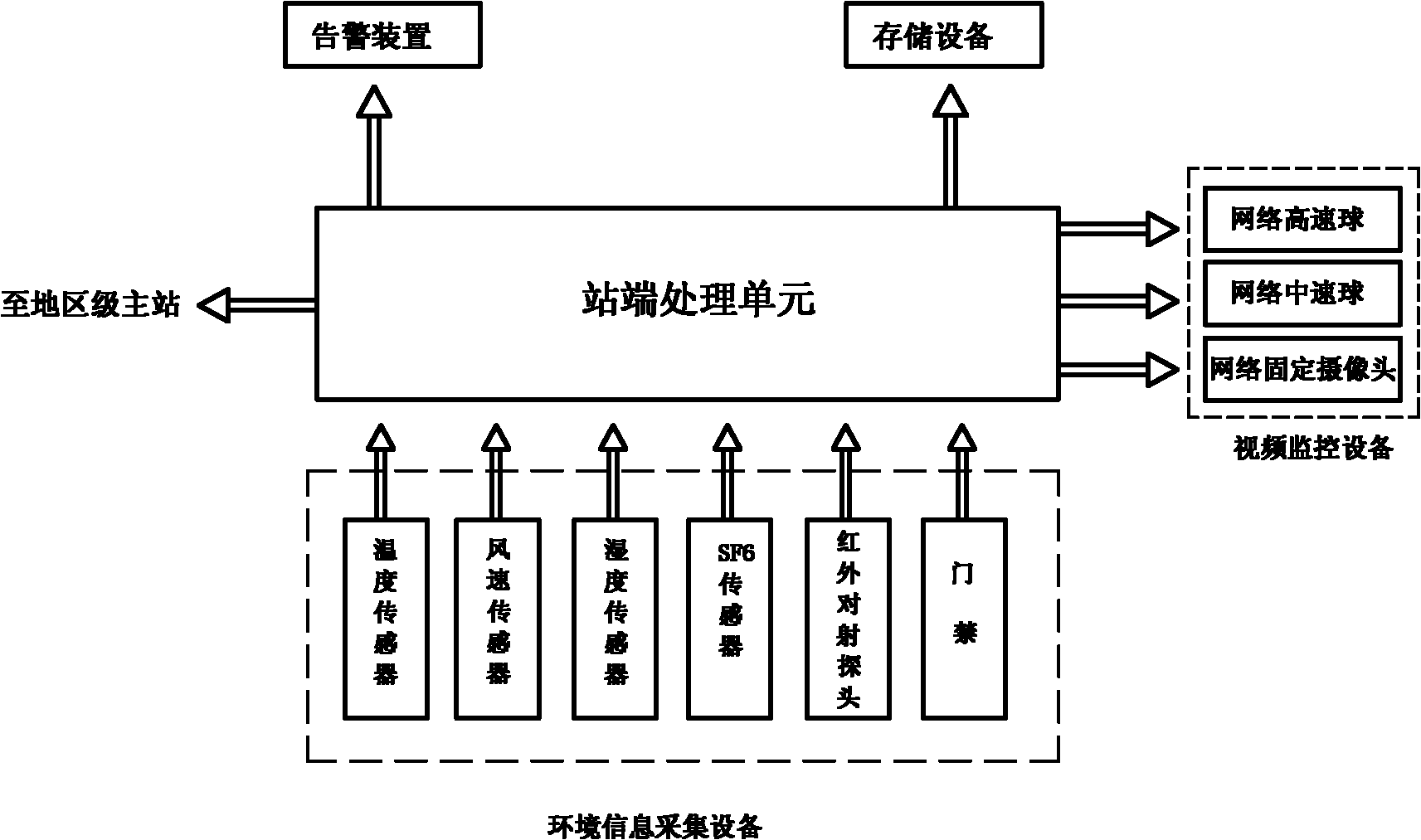

Substation video and environment monitoring terminal system

InactiveCN101976889AImprove securityReduce riskCircuit arrangementsClosed circuit television systemsPrimary stationInformation sharing

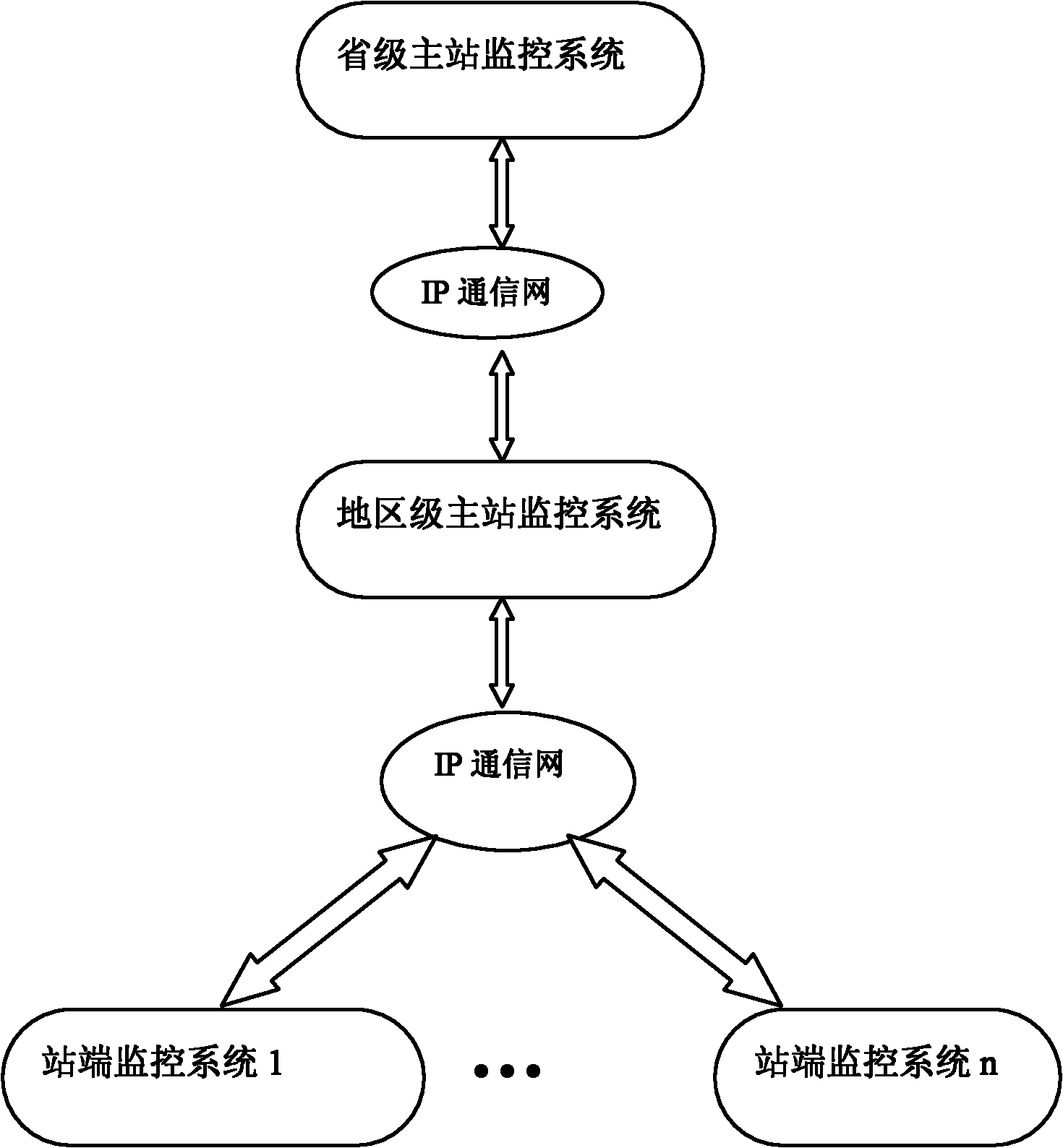

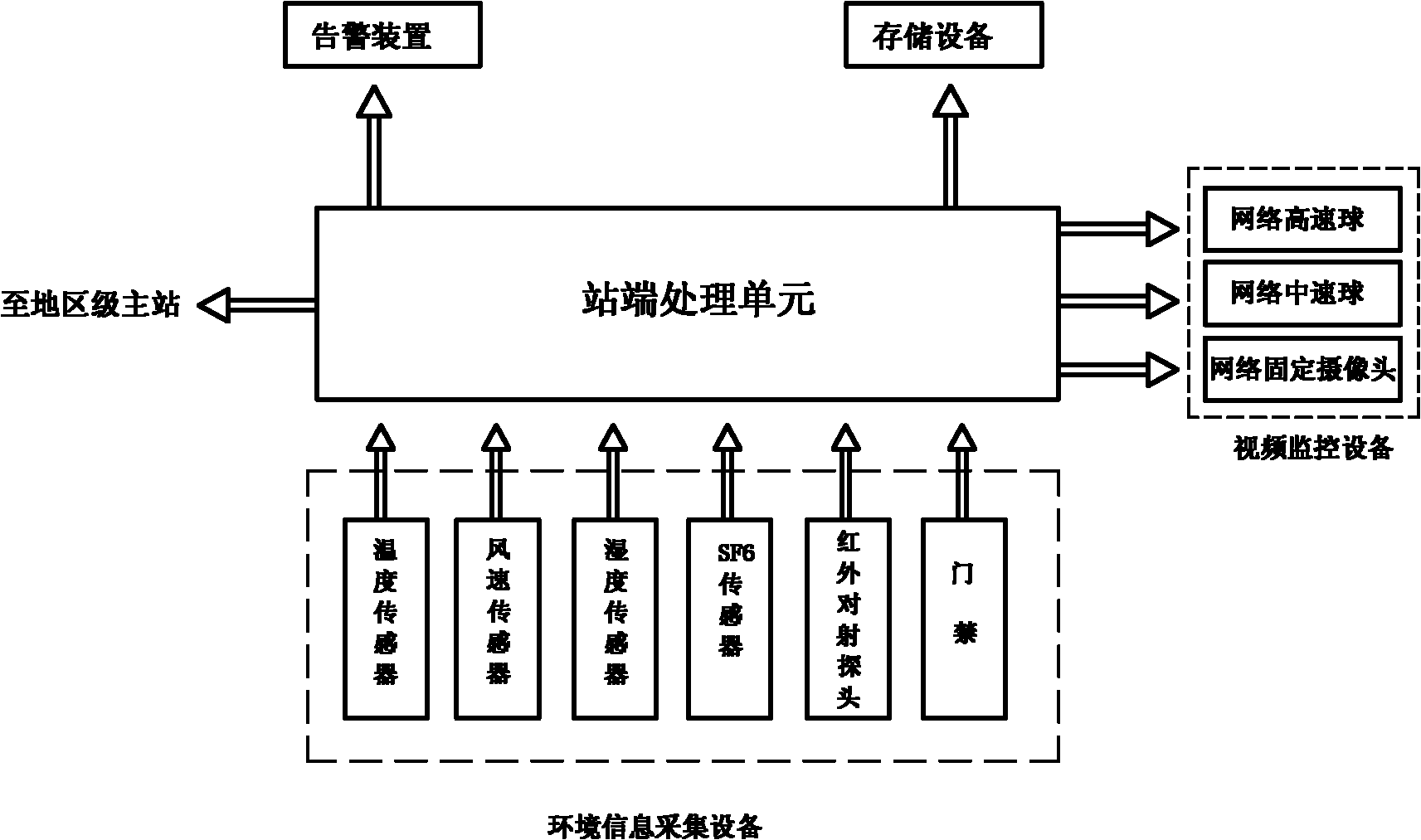

The invention discloses a substation video and environment monitoring terminal system. The system is used for collecting the real-time monitoring information of a substation. The system is connected with a regional main station monitoring system through an IP communication network and used for uploading the real-time monitoring information to the regional main station monitoring system. The system can be used for timely and omnidirectionally monitoring the video information, the environment information and the like of a terminal substation site, and the acquired information can be exchanged and shared with the superior or the exterior through network equipment. The system reduces the working intensity of inspection personnel, overcomes the defect of poor intuitionism of the inspection personnel, enhances the safety check of the substation and increases the operating level of the substation.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

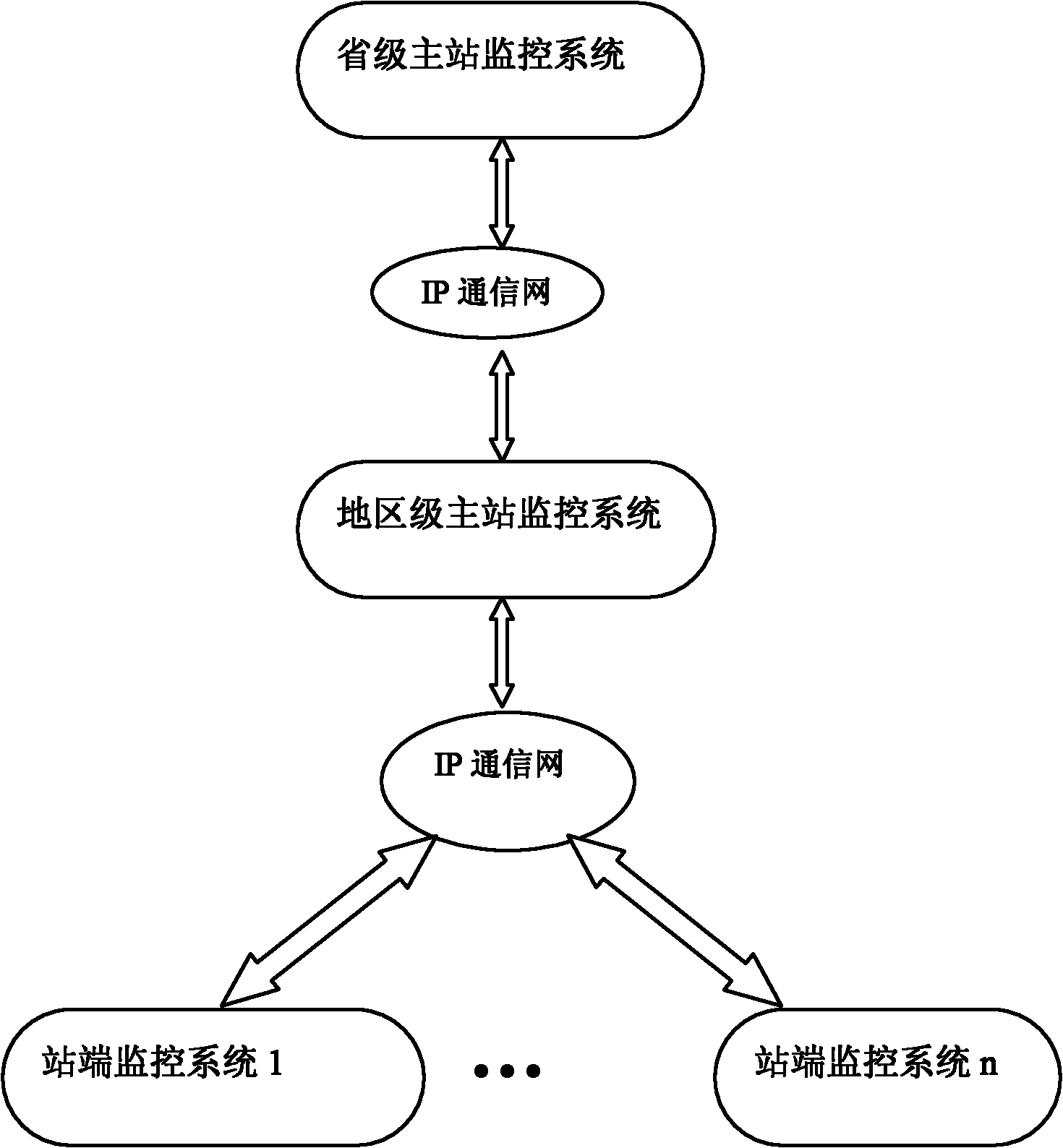

Main station system for transformer substation videos and environment monitoring

InactiveCN101976888ARealize unified monitoringRealize unified storageCircuit arrangementsClosed circuit television systemsPrimary stationInformation sharing

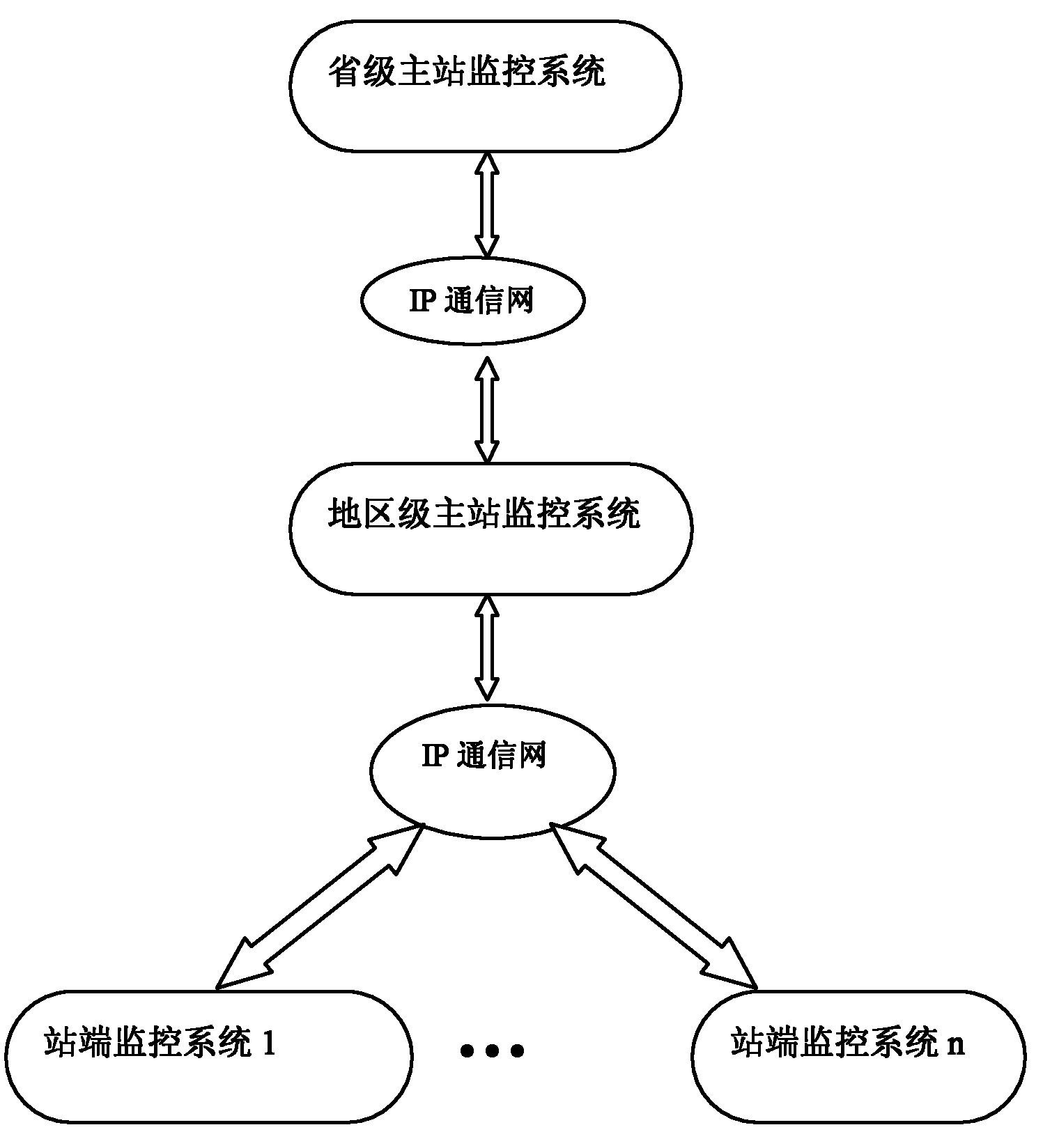

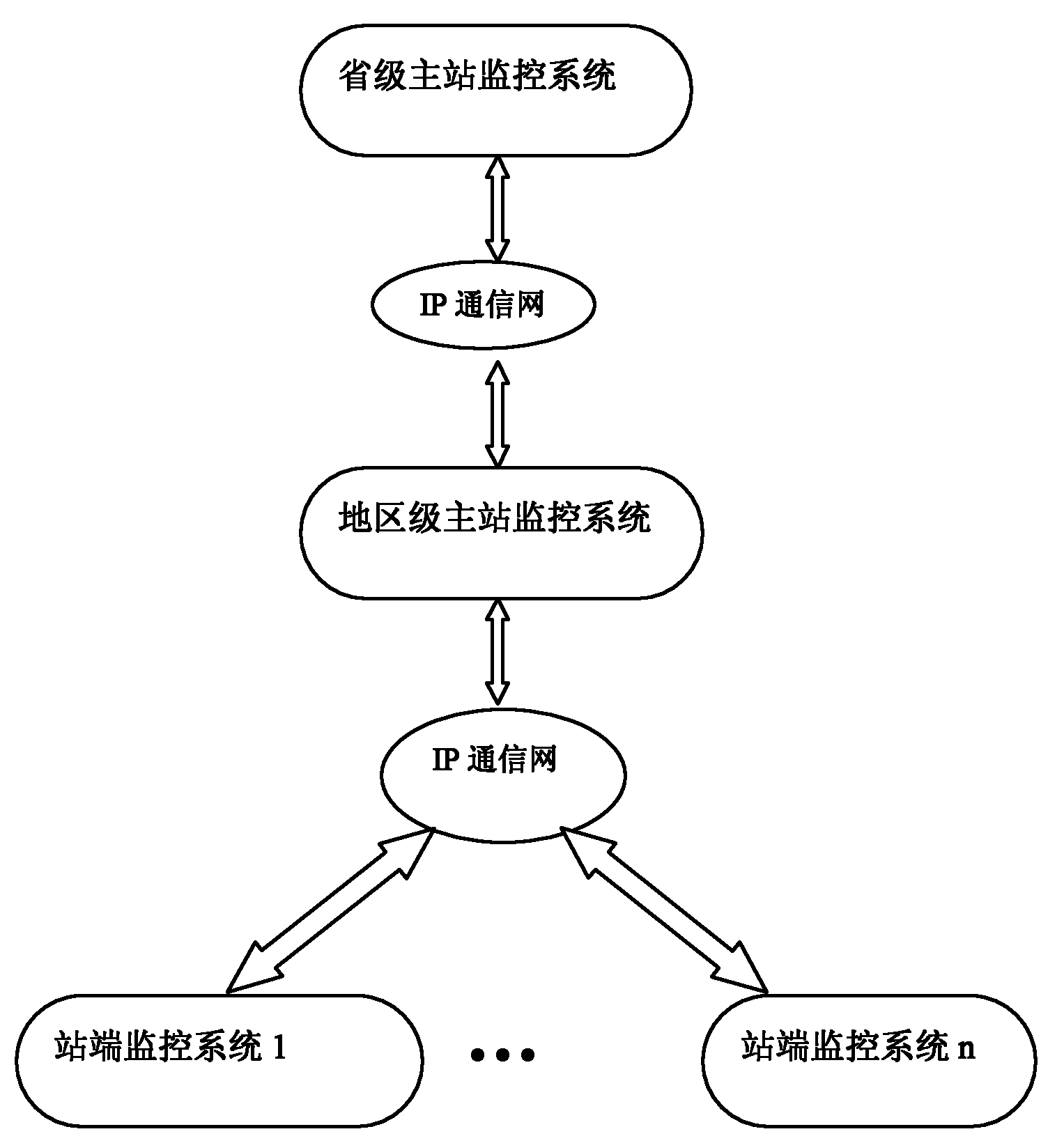

The invention discloses a main station system for transformer substation videos and environment monitoring. The system comprises a provincial main station monitoring system which is connected with a regional main station monitoring system through an IP (Internet Protocol) communication network, and the regional main station monitoring system is connected with a station terminal monitoring system through the IP communication network. The invention intensively manages monitoring resources of a power grid, establishes the interconnection and the communication of monitoring information, reasonably and effectively assigns the resources and shares the information to the maximum extend. Meanwhile, the invention lightens the working intensity of inspectors, overcomes the defects of poor intuition of operators, enhances the safe detection of the transformer substation and improves the operation level of the transformer substation.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

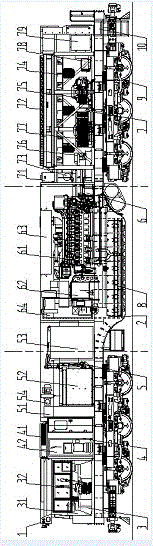

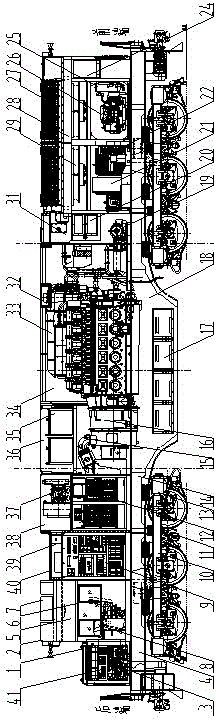

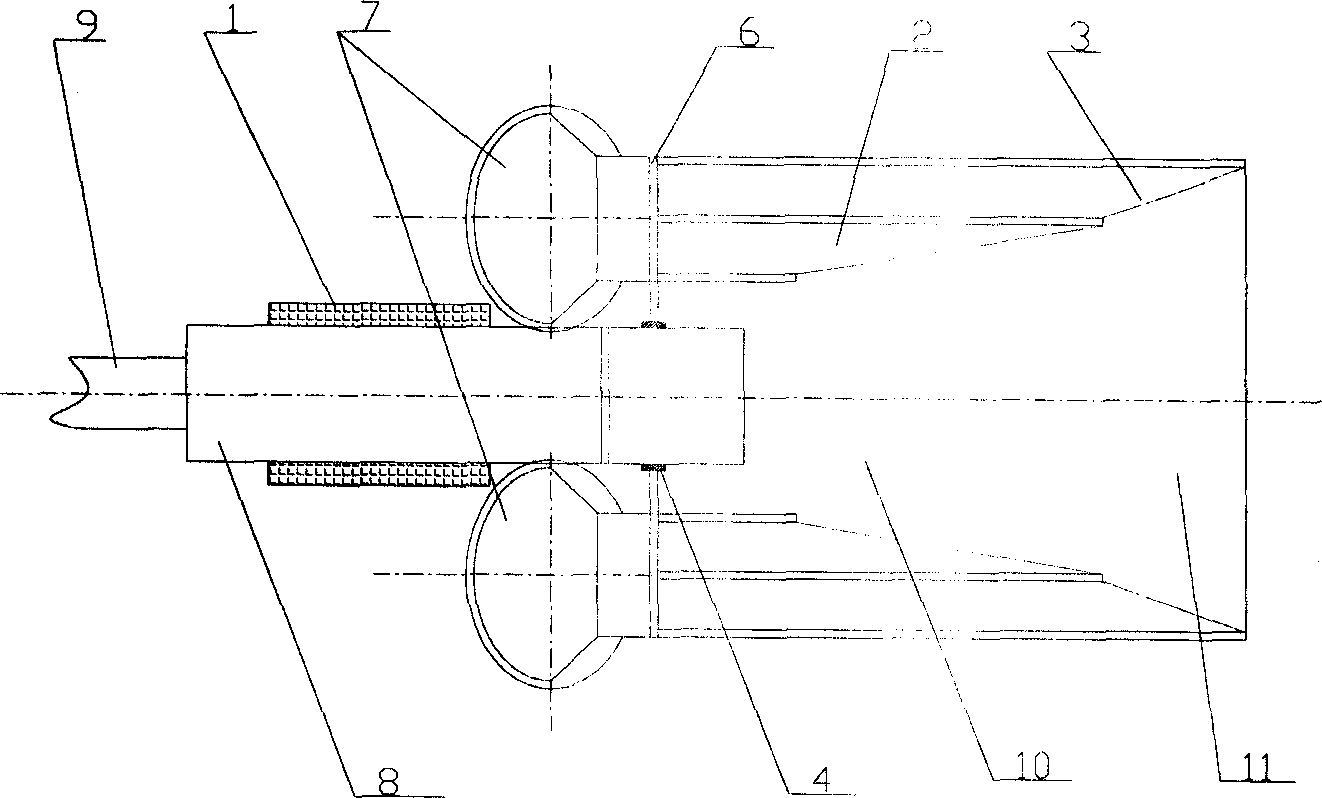

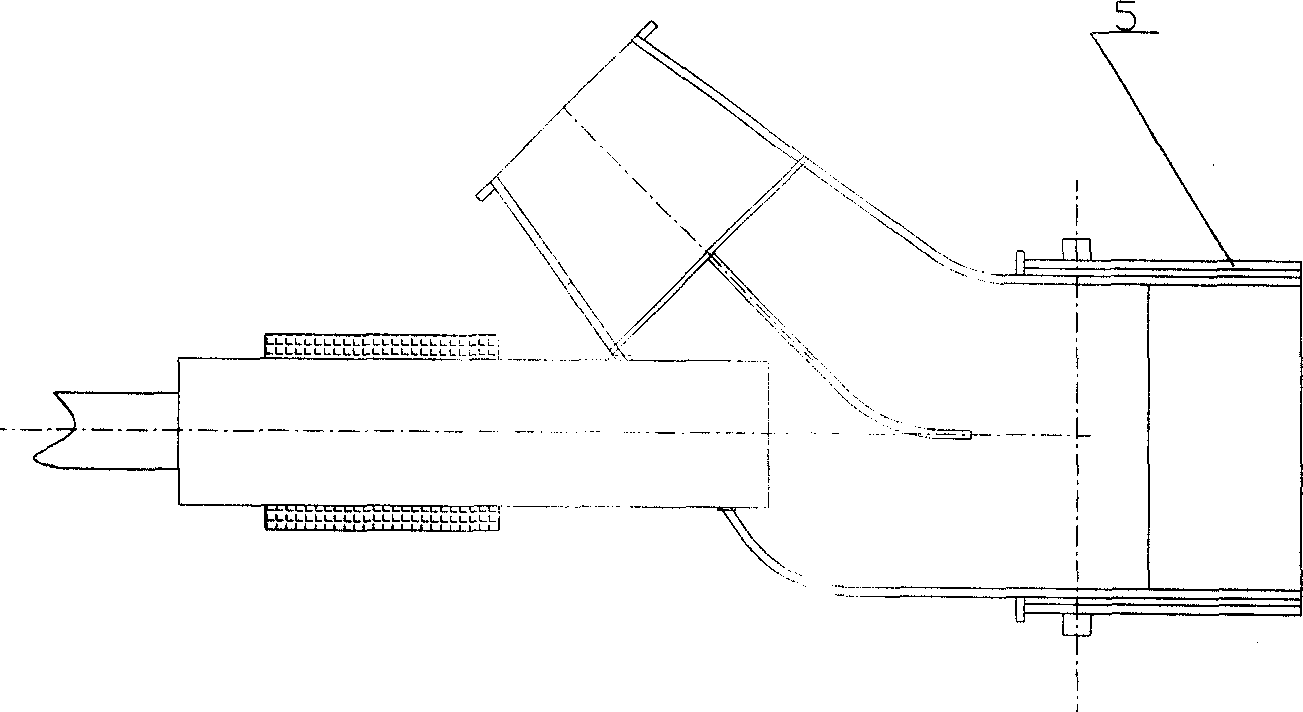

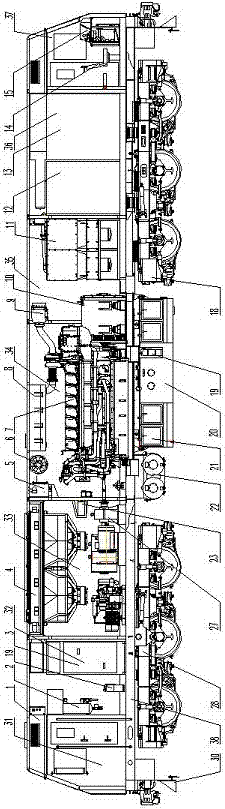

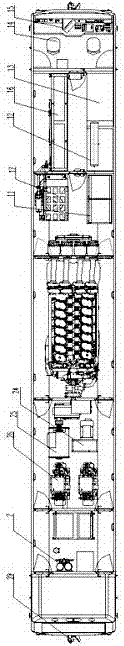

Narrow-gauge alternating-current transmission diesel locomotive

InactiveCN102910180ACompact and reasonableEasy and fast assemblyIC engine locomotivesGas turbine locomotivesBogieVehicle frame

The invention relates to the technical field of diesel locomotives, in particular to a narrow-gauge alternating-current transmission diesel locomotive. The narrow-gauge alternating-current transmission diesel locomotive comprises an upper locomotive body, a lower locomotive body, a cab, an auxiliary chamber, an electric chamber, a power house, a cooling chamber, a load bearing type fuel tank, a bogie and a locomotive frame. The upper locomotive body is composed of the cab, the auxiliary chamber, the electric chamber, the power house and the cooling chamber. The lower locomotive body is formed by the load bearing type fuel tank and the bogie. The cab is arranged on one side of the auxiliary chamber, the electric chamber is arranged on the other side of the auxiliary chamber, and the power house is arranged between the electric chamber and the cooling chamber. Partition walls are respectively arranged among cavities except the auxiliary chamber and the electric chamber. The bogie is arranged on two sides of the load bearing type fuel tank. The locomotive frame is arranged between the upper locomotive body and the lower locomotive body. The narrow-gauge alternating-current transmission diesel locomotive is compact and reasonable in structure, convenient and fast to assemble, reliable in connection, applicable to a narrow-gauge line, capable of adapting to various severe climatic environments, simultaneously small in daily maintenance and easy to use and popularize.

Owner:CRRC QISHUYAN CO LTD

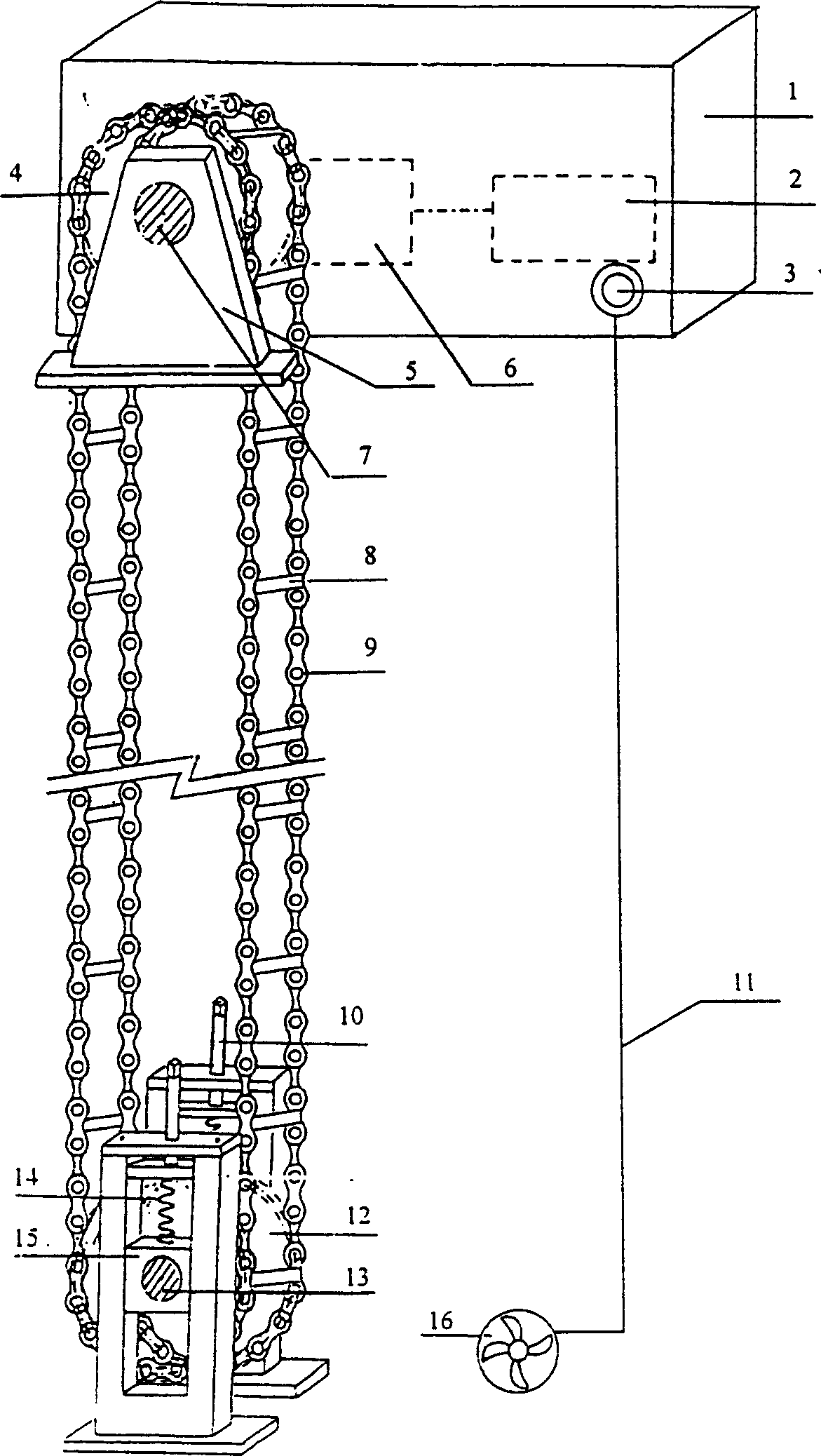

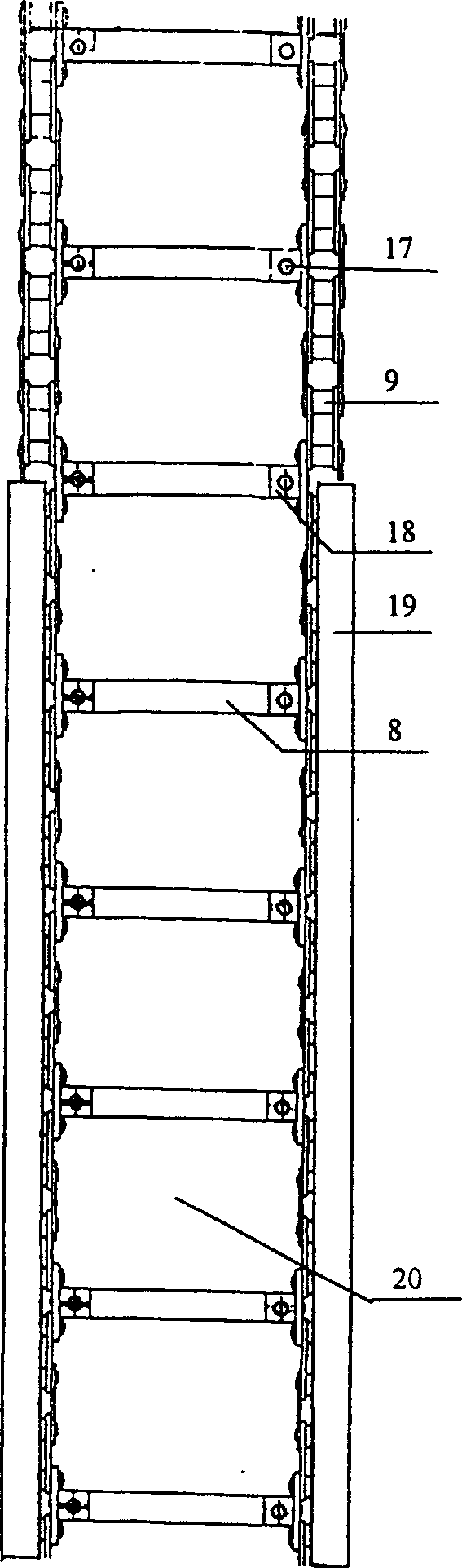

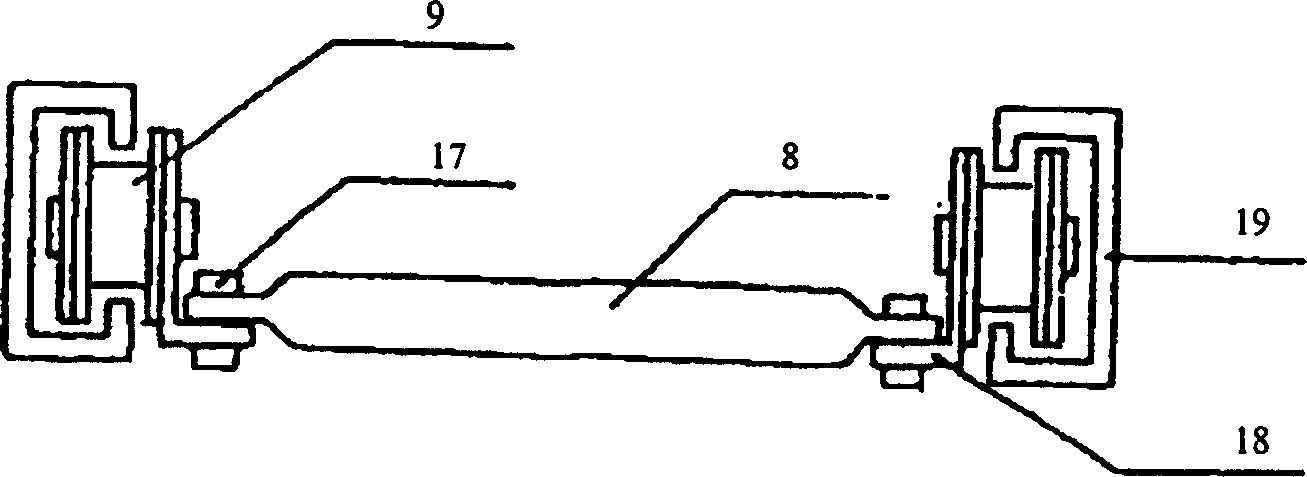

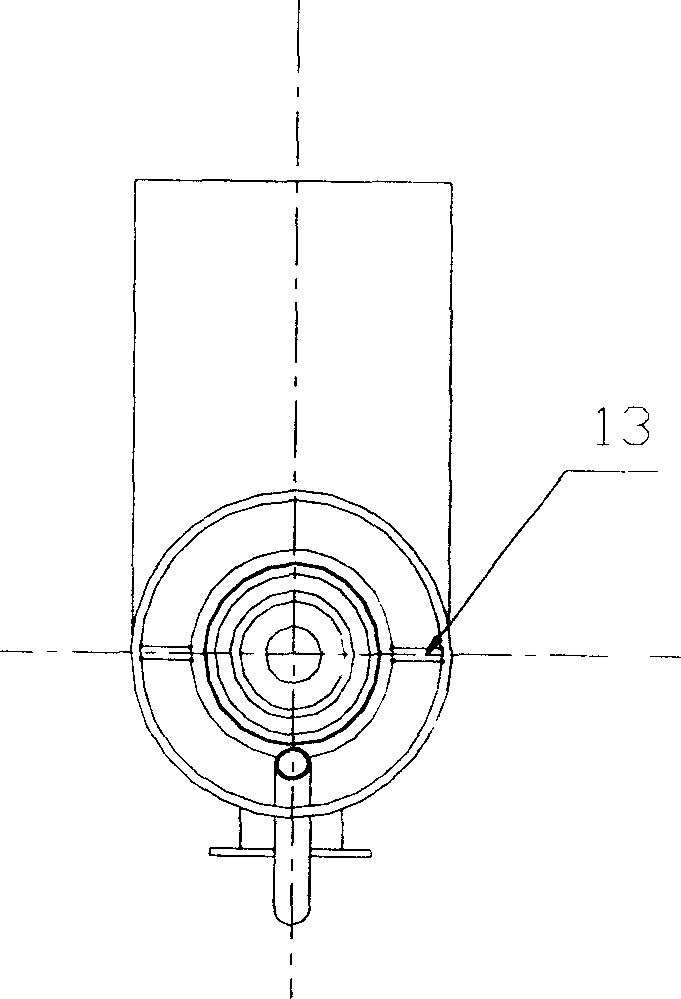

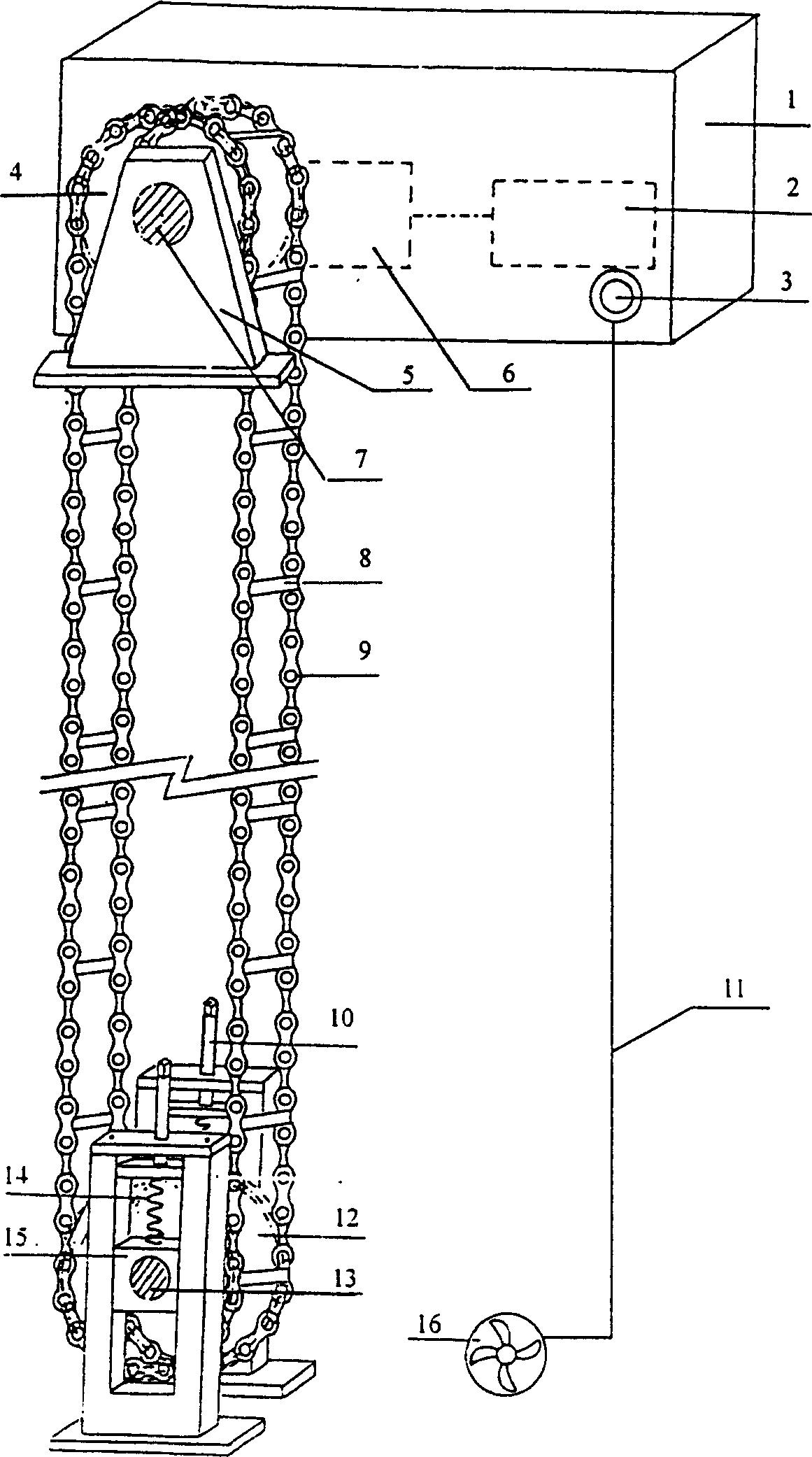

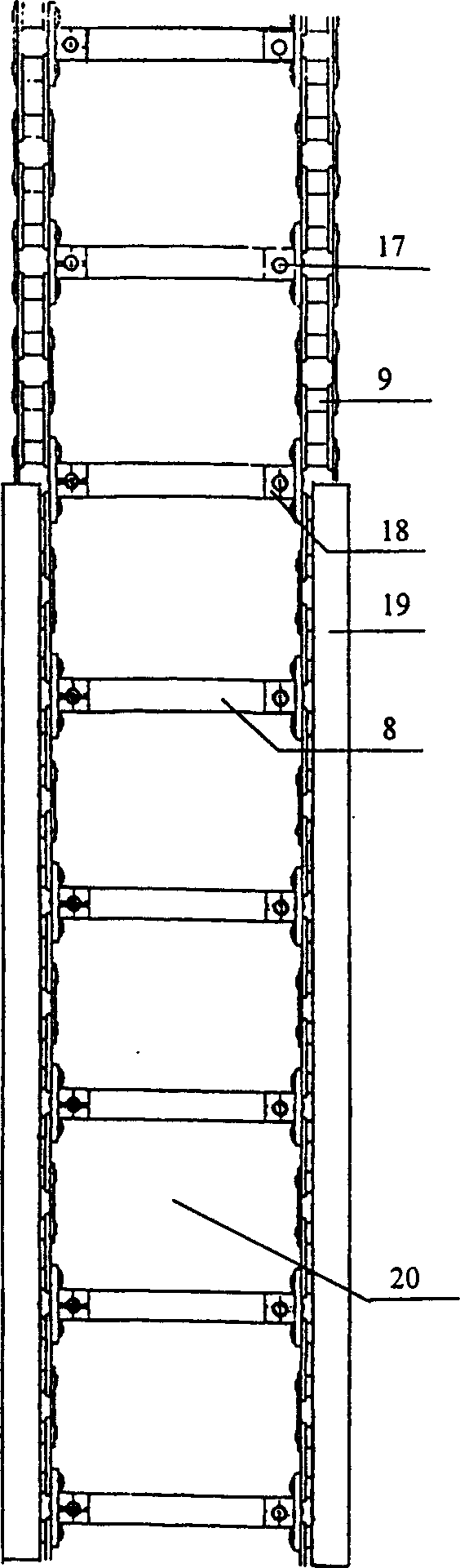

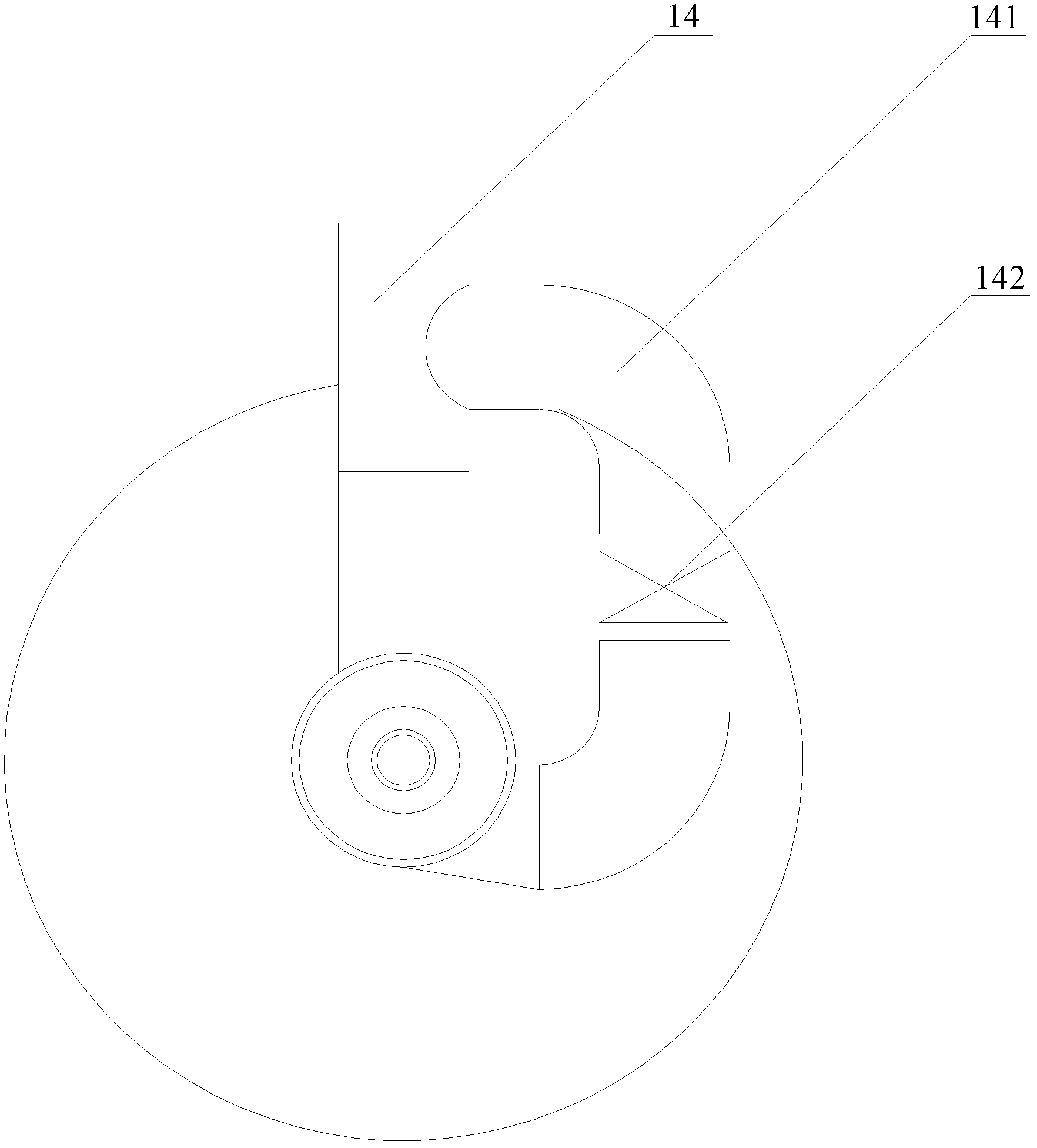

Hydaulic speed regulating type slow landing jack ladder escape device

InactiveCN1554458AKeep the speed of descent constantSolve the imbalanceBuilding rescueHigh riseControl theory

The emergency escape device for high rise building consists of jack ladder, guide track, chain wheel, speed varying mechanism, hydraulic speed regulating controller, etc. It is used for person in high rise building to escape in emergency. The present invention has the advantages of no need of outer driving force, relatively smooth lowering speed and no floating motion.

Owner:JIANGSU UNIV

Device for measuring settling ratio and optimal settling ratio of sludge

PendingCN110702569ASolve the control index problem that is difficult to quantify the sedimentation ratioImprove measurement rateParticle suspension analysisAutomatic controlSludge

The invention discloses a device for measuring a settling ratio and an optimal settling ratio of sludge in a mechanical acceleration settling pond and a method for measuring the settling ratio and theoptimal settling ratio of sludge by using the device, wherein the device comprises a shell, a settling assembly, an interface observation assembly and a control assembly, and a cavity is arranged inthe shell; the settling assembly and the interface observation assembly are arranged in the cavity in the shell; the settling assembly comprises two settling pipes which are connected in series, the volume of a first settling pipe is larger than or equal to the volume of a second settling pipe, the first settling pipe communicates with the second settling pipe through a connecting pipe, and the settled and concentrated sludge liquid in the first settling pipe is injected into the second settling pipe. The device of the invention is a portable device with simple structure, small size and compactness, is automatically controlled, is capable of obtaining the settling ratio and the optimal settling ratio of the sludge in the sludge liquid, overcomes artificial subjective factors, has accuratedata measurement, can automatically sample and analyze settling characteristics of the sludge, and provides guidance parameters for tap water treatment operation.

Owner:北京市自来水集团有限责任公司技术研究院

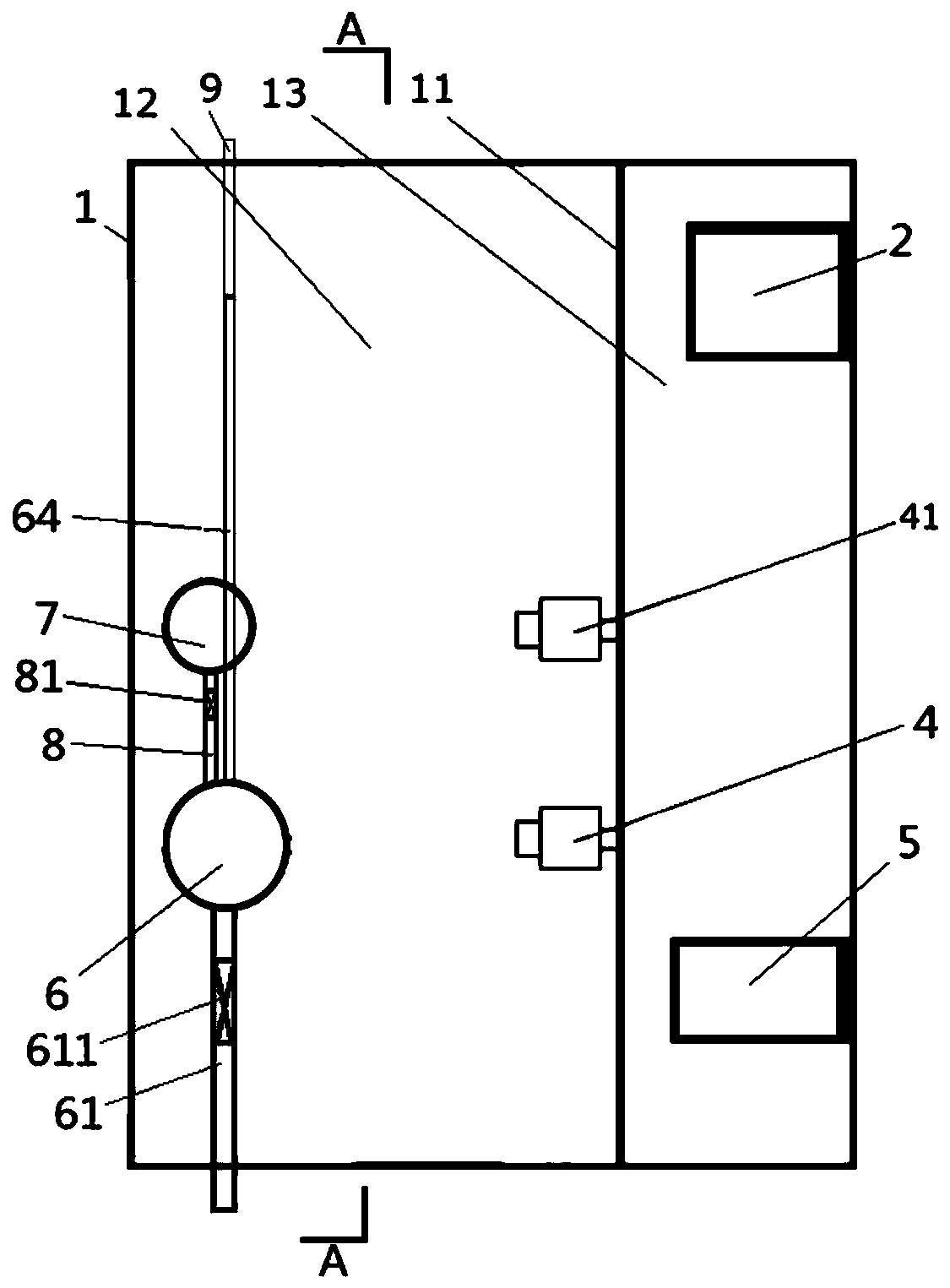

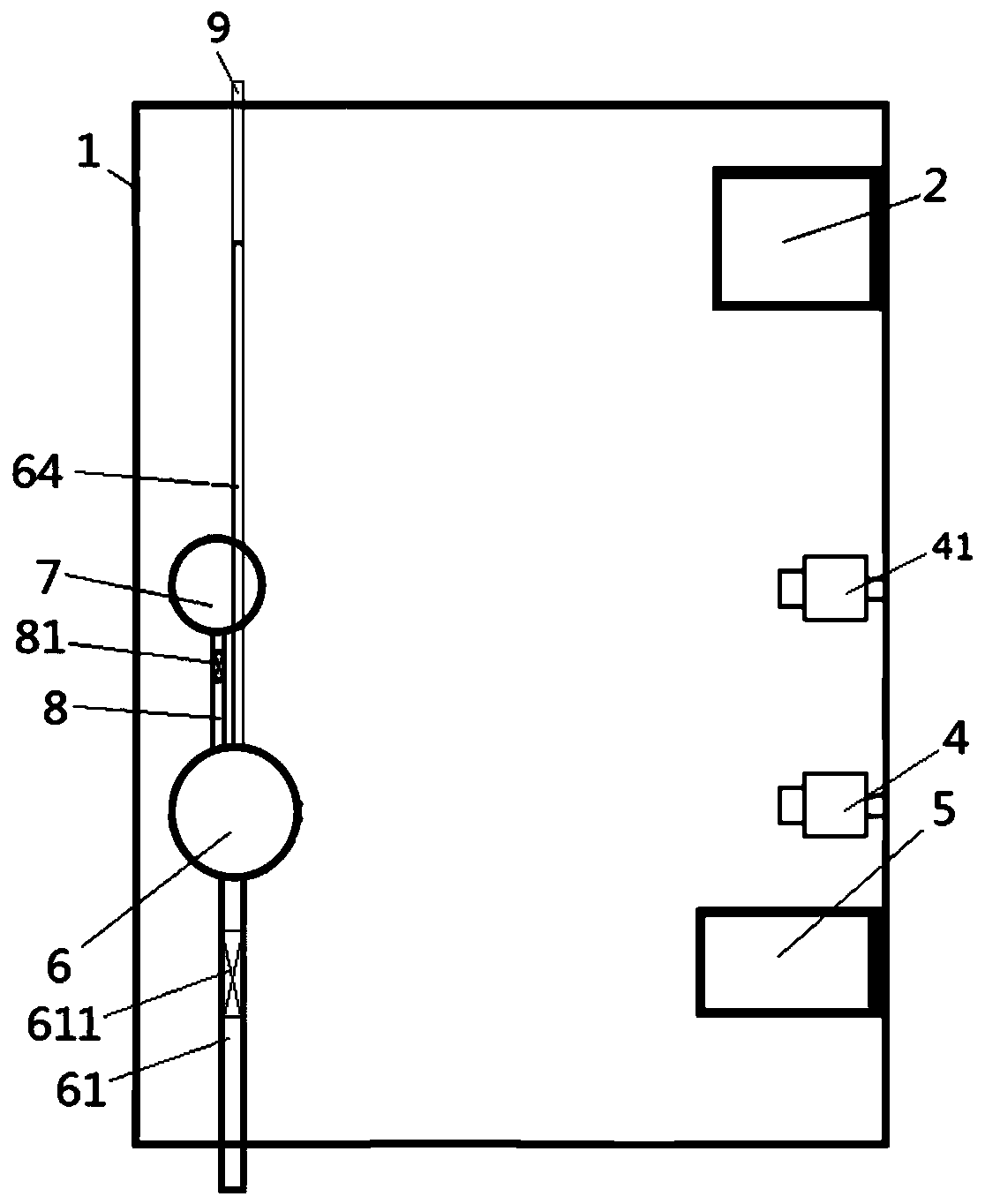

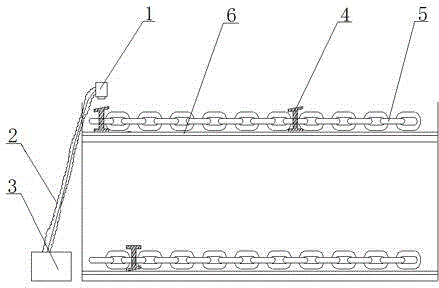

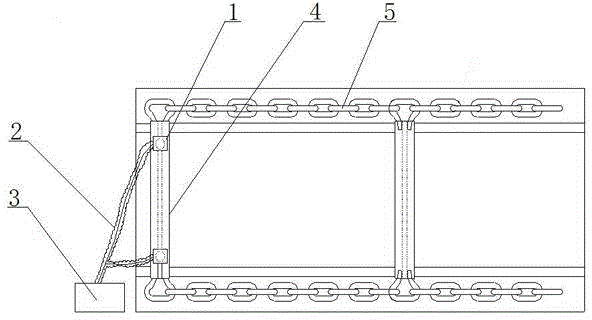

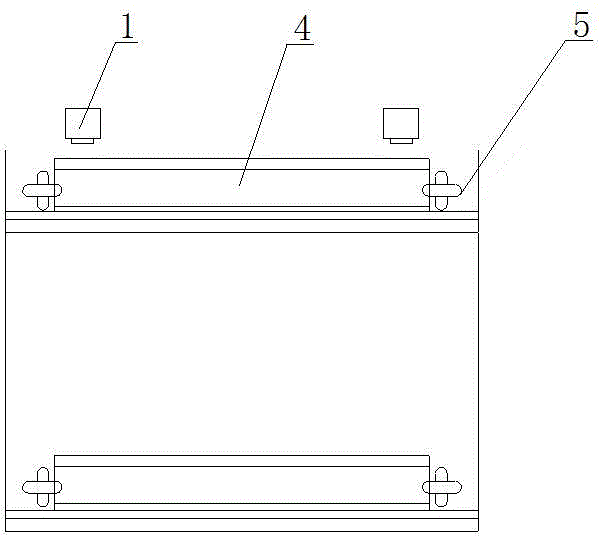

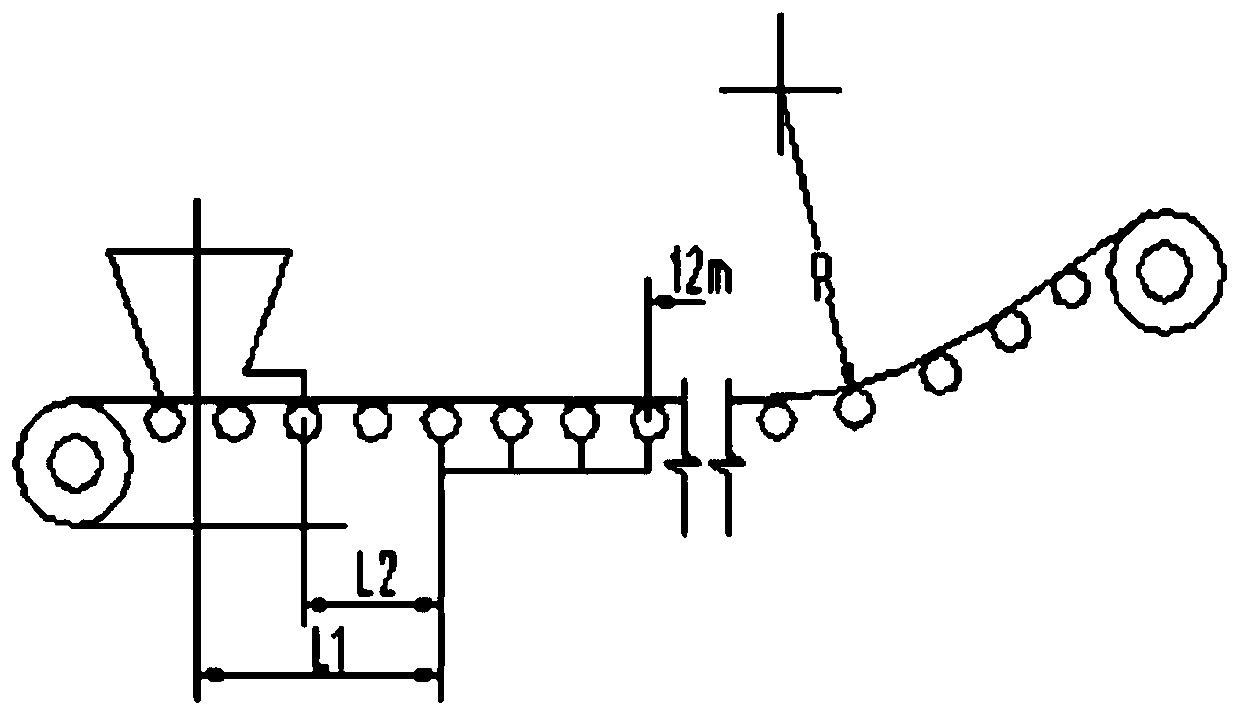

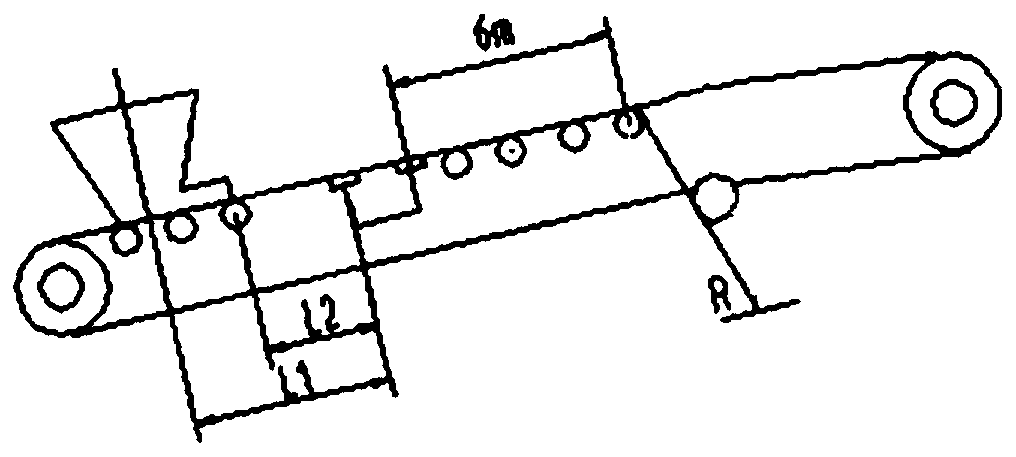

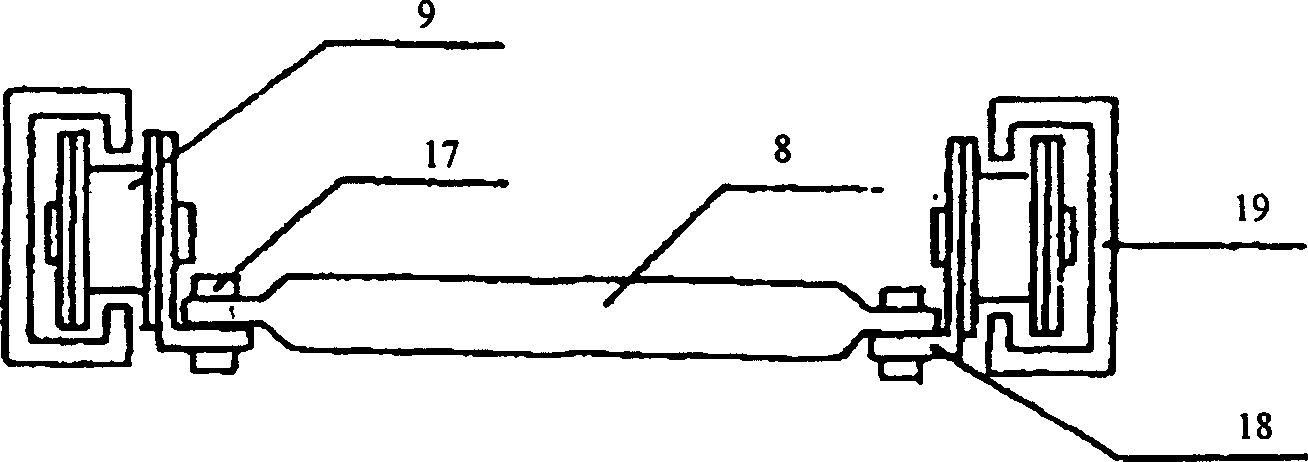

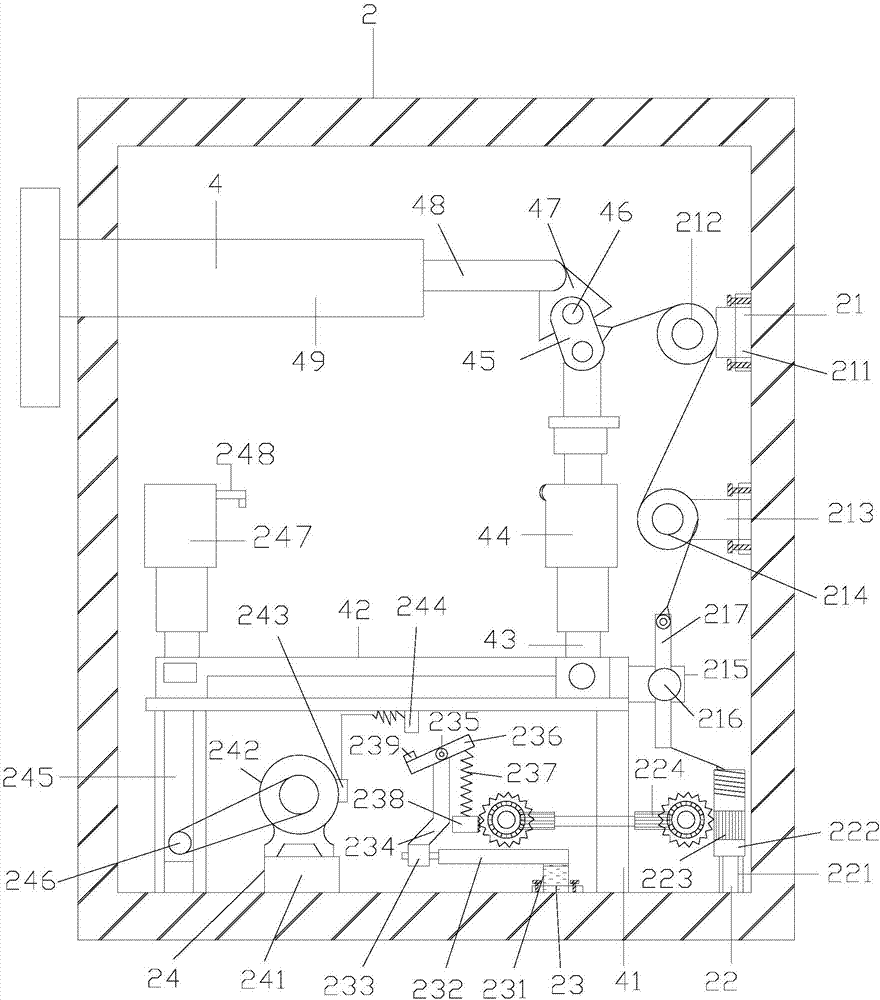

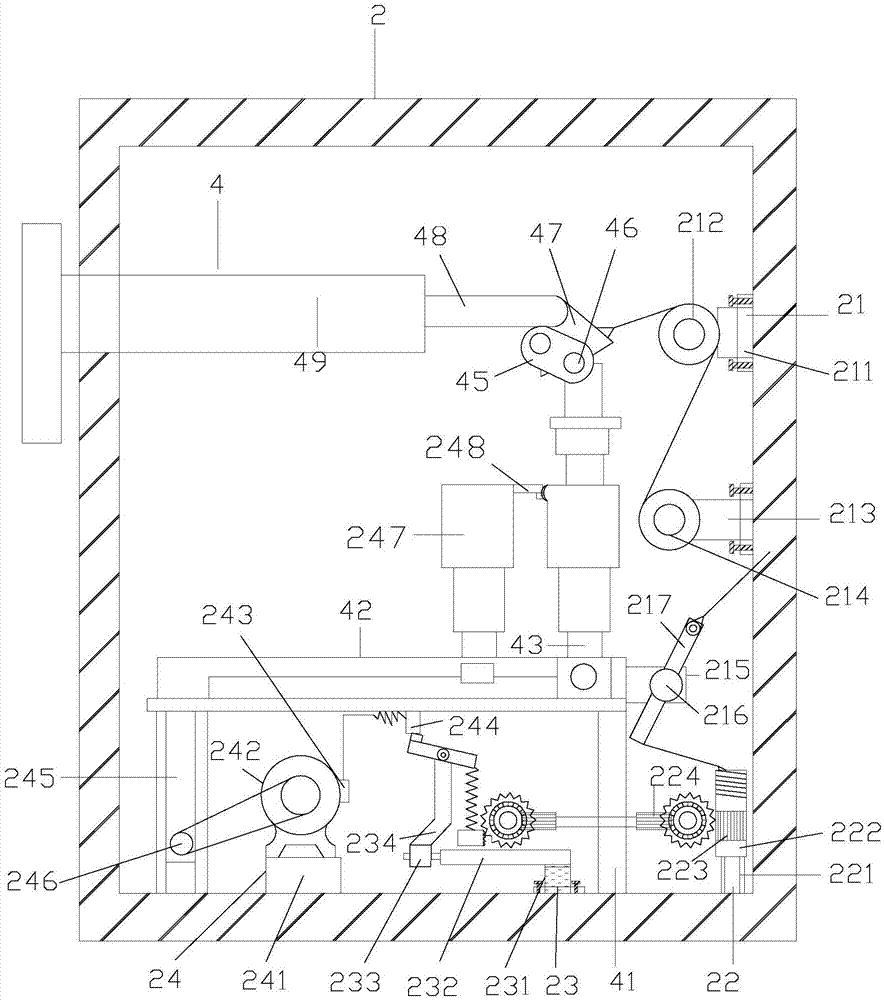

Chain breaking, dislocation and chain falling comprehensive protection device of scraper conveyor

InactiveCN104555341AAvoid bumpingReduce lossesConveyorsControl devices for conveyorsEngineeringDislocation

The invention relates to an automatic monitoring comprehensive protection device of a scraper conveyor, in particular to a chain breaking, dislocation and chain falling comprehensive protection device of a scraper conveyor, which is applied to the field of coal mine machinery. Parallel chains are arranged on both sides of the scraper conveyor placed in parallel; scraping plates are uniformly and vertically arranged on each chain along the length direction of the chain; the chains are operated to a tail pulley from a head pulley of the scraper conveyor; a first proximity switch and a second proximity switch are arranged above the scraping plates; the first proximity switch and the second proximity switch are respectively connected with a monitoring device in parallel through signal wires in a heat shrinkage pipe. The comprehensive protection device disclosed by the invention has the advantages of high automation degree, little influence to the scraper conveyor and relatively wide application range and is simple and reliable.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

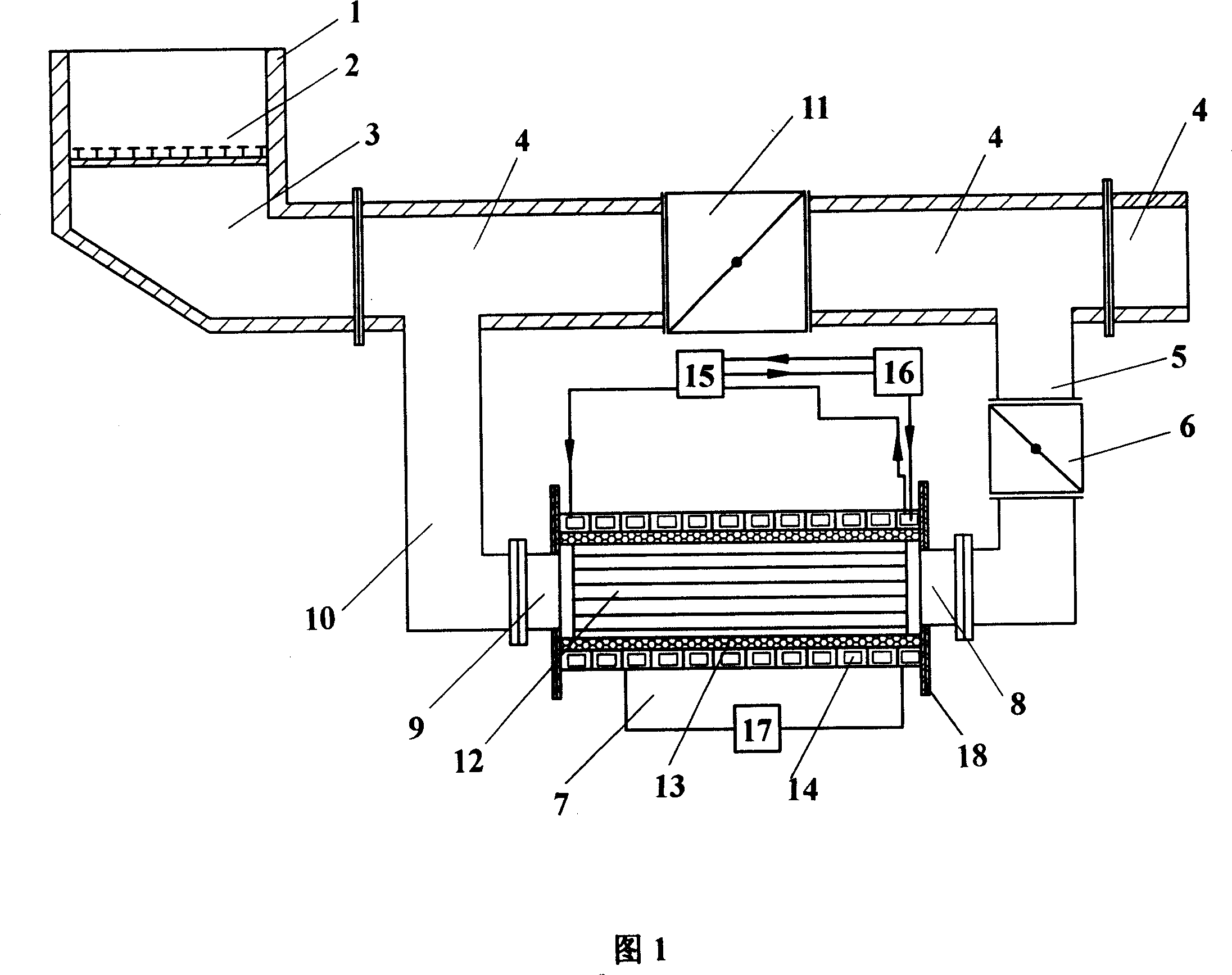

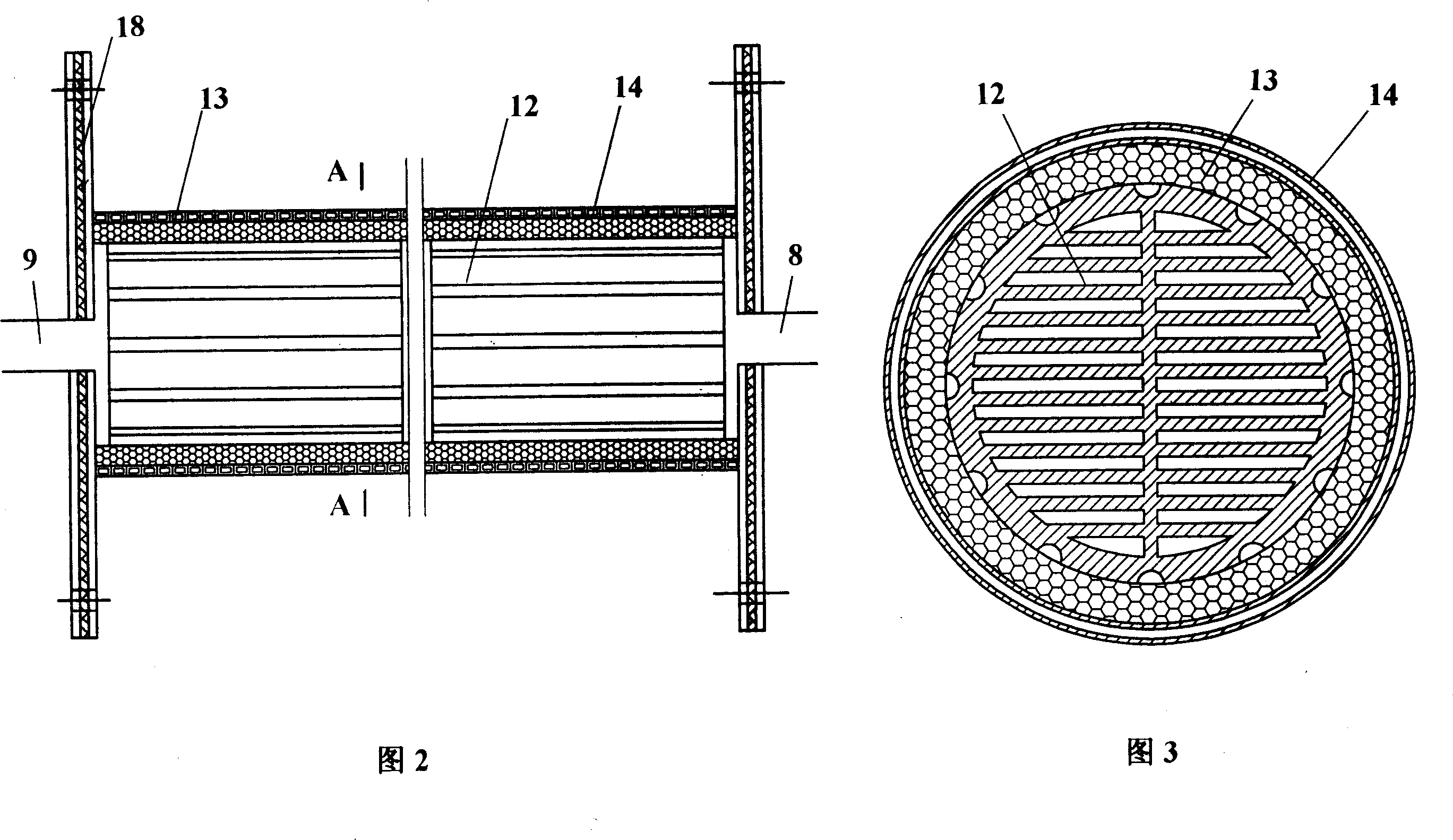

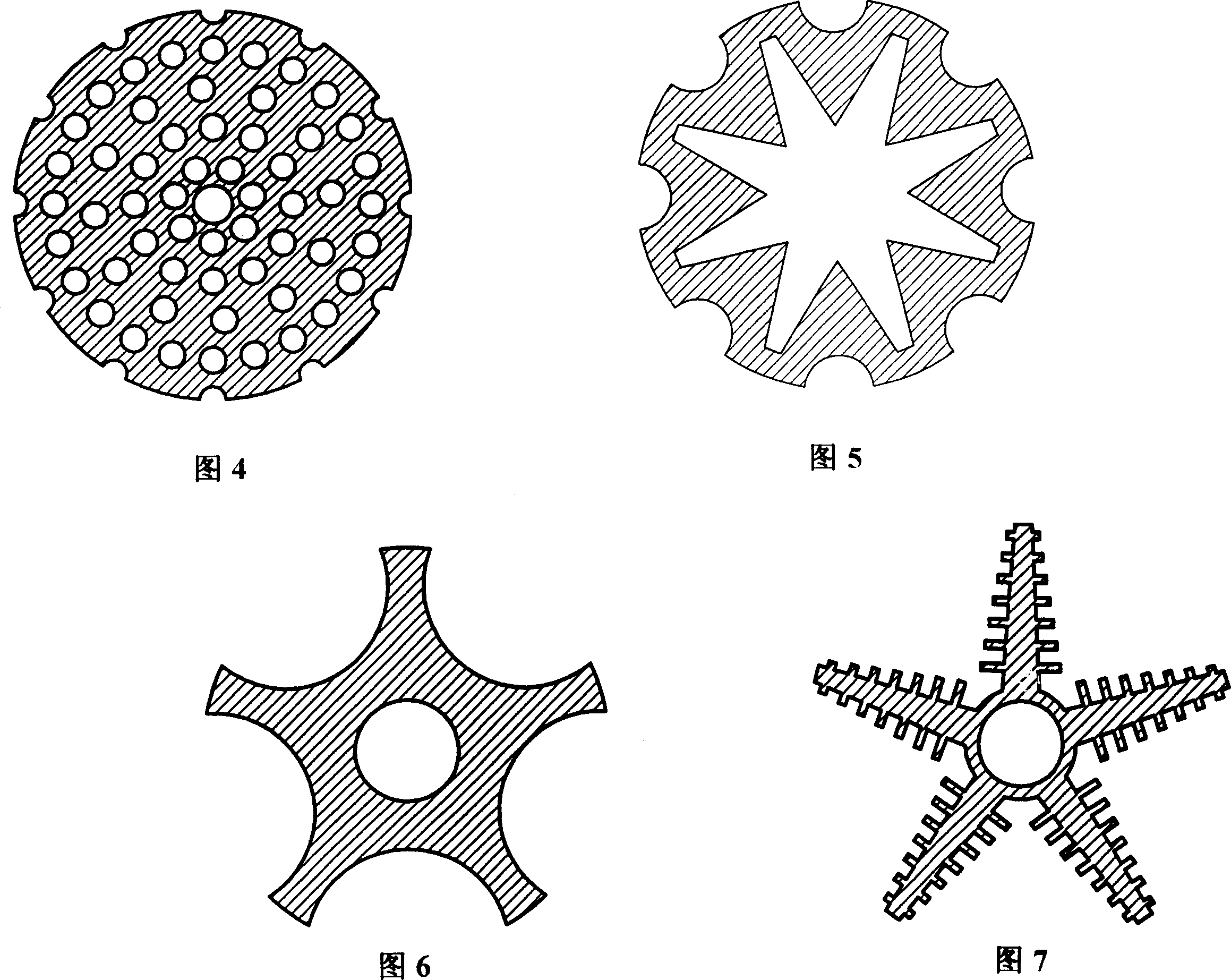

High-temperature air lighting system under bed for fluidized bed and circulating fluidized bed boiler

InactiveCN1952478AReduce ignition costsEasy to controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEconomic benefits

The invention relates to an igniting system for flowing bed and circulating fluid bed boiler in the high temperature air, comprising furnace body, air distribution plate, wind room and wind channel for a first wind, characterized in that electromagnetic induction heater is connected with the wind channel for a first wind in parallel. The first wind is heated by electromagnetic induction heater and is formed high temperature igniting air with more than 900DEG C. Then it enters into furnace to fluidize the igniting material on the air distribution plate and ignite is gradually. The invention is provided with simple technology and structure, no assistant fuel such as oil and gas, low igniting cost, good economic benefit; conveniently adjusting, simple operation, safety and stability, high successful ratio during igniting process; little maintenance in daily and no circumstance pollution so on. It has an influence of energy-saving, oil-saving and circumstance protection and so on. It can be widely applied in the igniting of flowing bed and circulating fluid bed boiler in electrical factory or heat supply system and have huge application value. After it brings into effect social, environmental and economical benefits can be produced notably.

Owner:NORTHEAST DIANLI UNIVERSITY

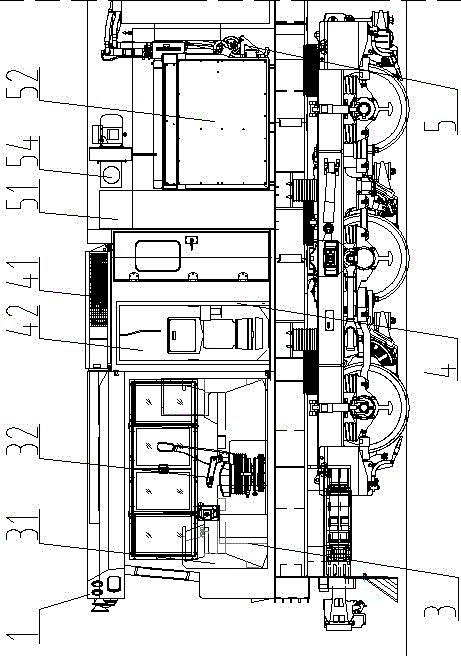

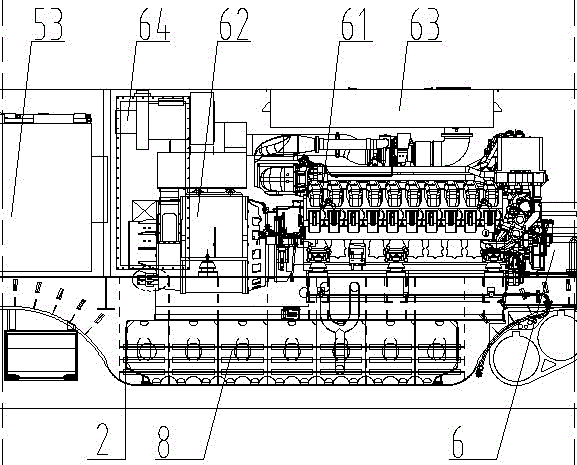

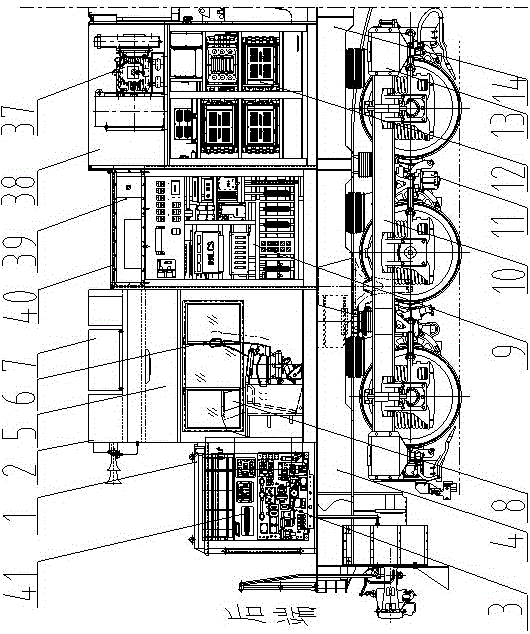

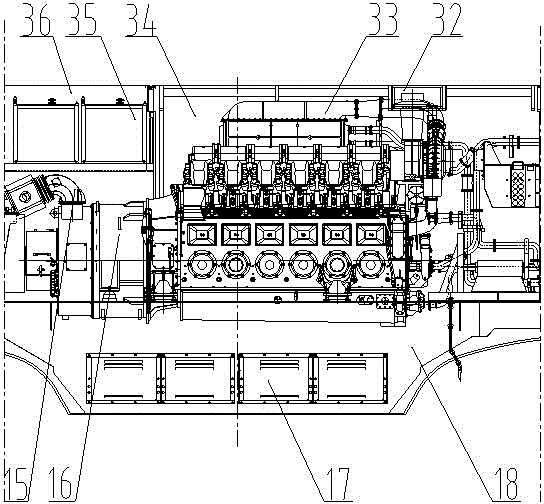

High-power alternating-current transmission shunting diesel locomotive

InactiveCN104691560ACompact and reasonableEasy and fast assemblyIC engine locomotivesIC reciprocating piston engine transmissionBogieVehicle frame

The invention relates to the technical field of diesel locomotives, in particular to a high-power alternating-current transmission shunting diesel locomotive. The high-power alternating-current transmission shunting diesel locomotive comprises an upper body, a lower body, an auxiliary room, a cab, an electric room, a main transformer room, an engine room, a power room, a cooling room, a bearing type fuel tank, bogies and a frame. The upper body is composed of the auxiliary room, the cab, the electric room, the main transformer room, the engine room, the power room and the cooling room; the lower body is composed of the bearing type fuel tank and the bogies; the auxiliary room is arranged at the rear end of the cab, the electric room, the main transformer room and the main engine room are arranged at the front end of the cab, and the power room is arranged between the main engine room and the cooling room; dividing walls are arranged between the rooms; the bogies are arranged on the two sides of the bearing type fuel tank; the frame is arranged between the upper body and the lower body. The high-power alternating-current transmission shunting diesel locomotive is compact and reasonable in structure, convenient and fast to assessable, reliable in connection, suitable for large or medium shunting yards, also suitable for various severe climatic environments, small in routine maintenance quantity and easy to use and popularize.

Owner:CRRC QISHUYAN CO LTD

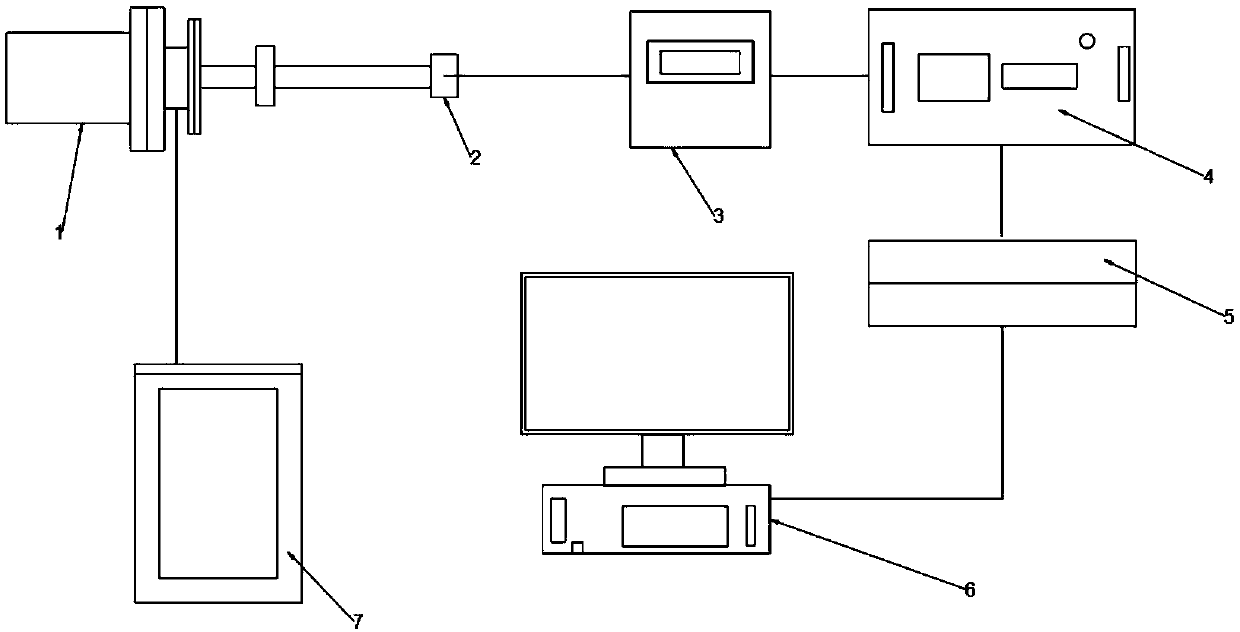

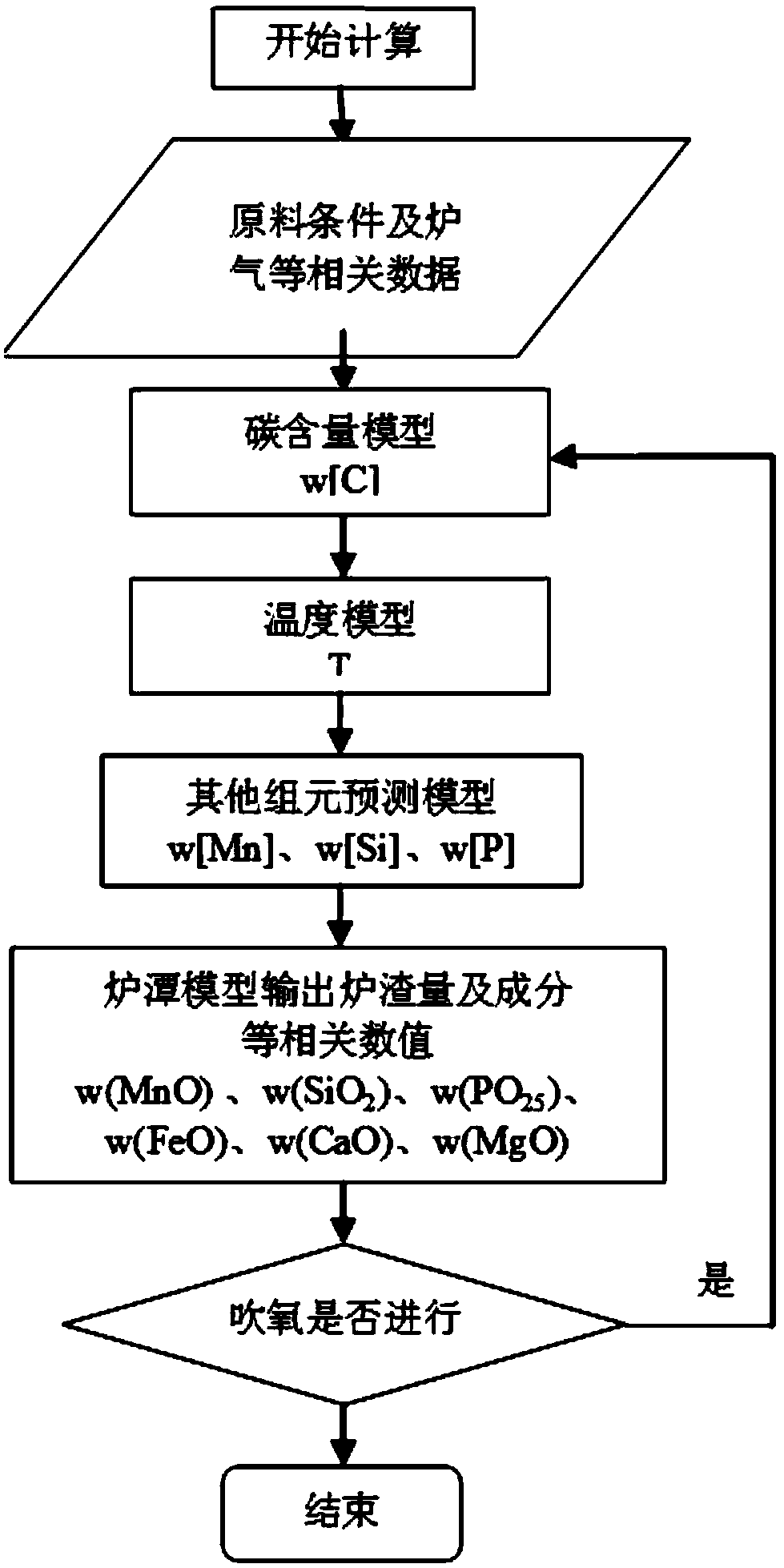

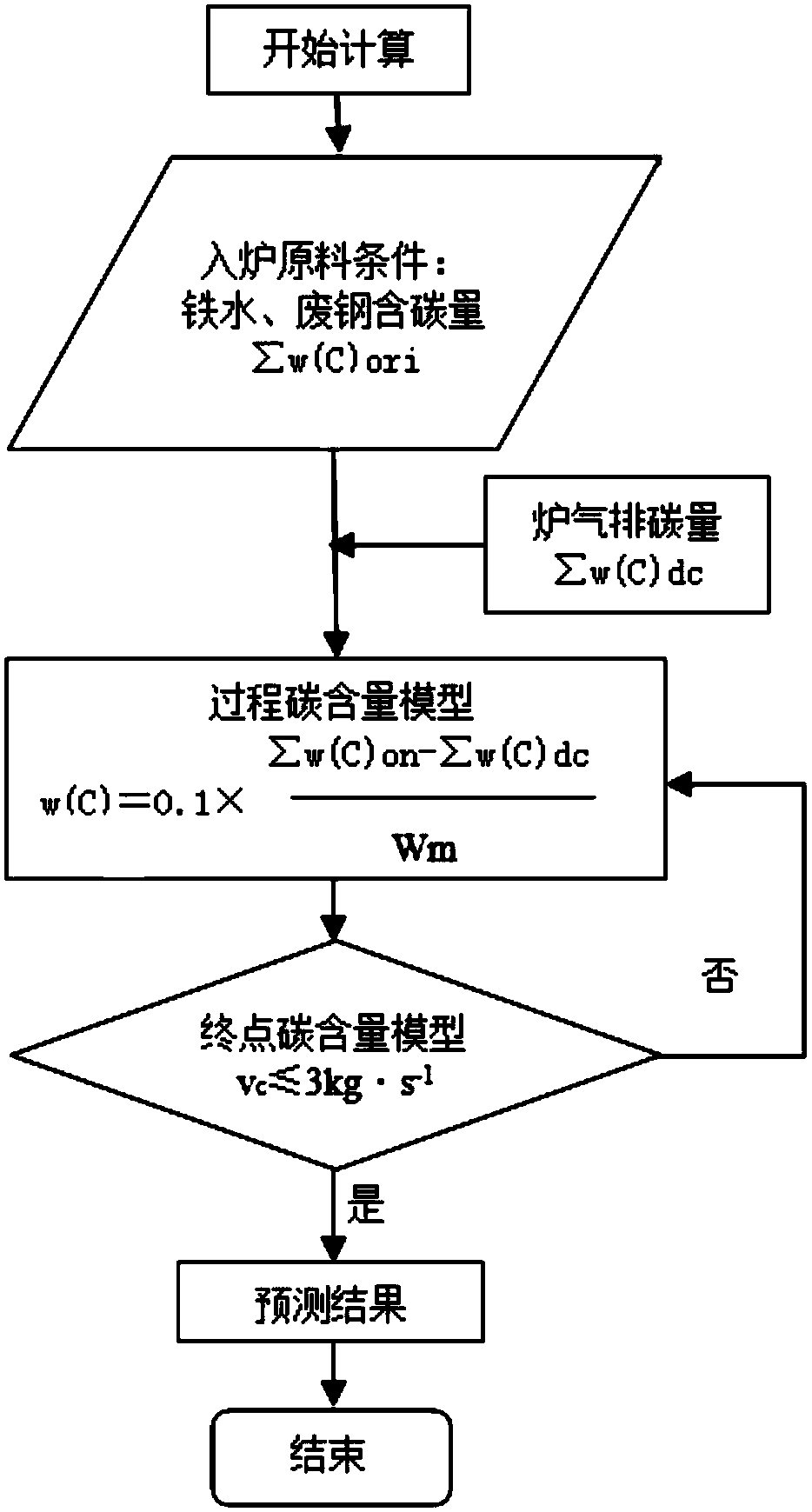

Intelligent steelmaking system based on converter fume and gas analysis technology

PendingCN109581988AAutomatically and accurately record statisticsMeet the needs of converter intelligent steelmakingSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingGas analysis

The invention discloses a professional detection instrument for fume and gas analysis, and relates to the technical field of ferrous metallurgy. The professional detection instrument for fume and gasanalysis mainly solves the problems of automation and intelligence during steel-making and smelting operations of a converter. The professional detection instrument for the fume and gas analysis comprises a fume and gas analyzer, and a converter audio frequency slag melting monitoring system; the converter audio frequency slag melting monitoring system comprises a converter, and the upper part ofthe right side of the converter is sequentially provided with a water inlet, an audio sampling device, and a nitrogen inlet from left to right. The invention further discloses an intelligent steelmaking system, a main program of the intelligent steelmaking system, and an implementing method of the intelligent steelmaking system which are based on the converter fume and gas analysis technology of the professional detection instrument for the fume and gas analysis. According to the professional detection instrument for the fume and gas analysis, precision of endpoint control and the hit rate areincreased, thus stability and reliability of production are improved, production efficiency is improved, cleanliness of molten steel and quality of steel are improved, and full-automatic steelmakingis realized.

Owner:重庆布鲁斯格智能科技有限公司

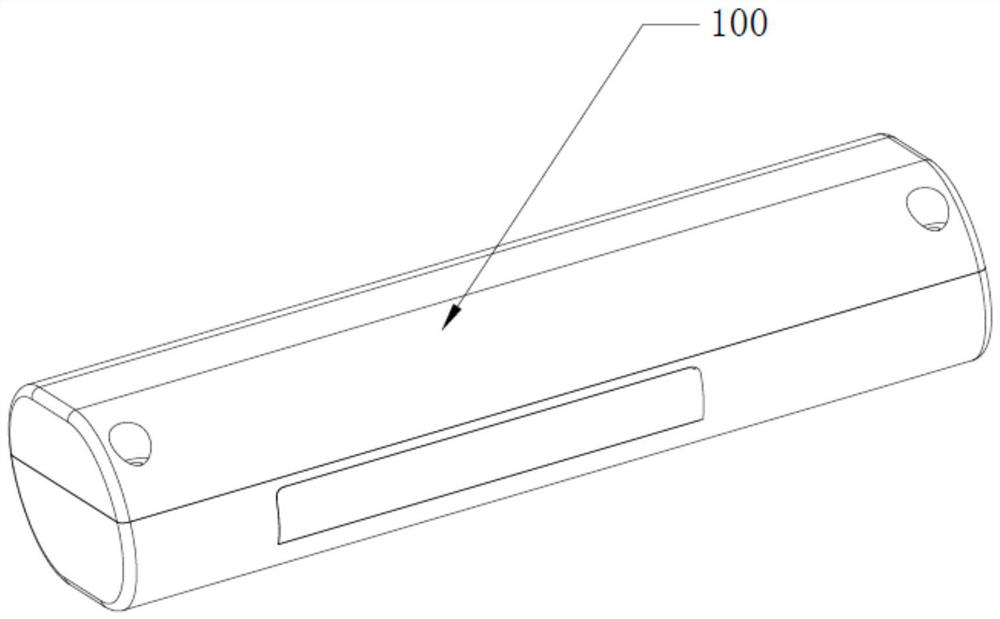

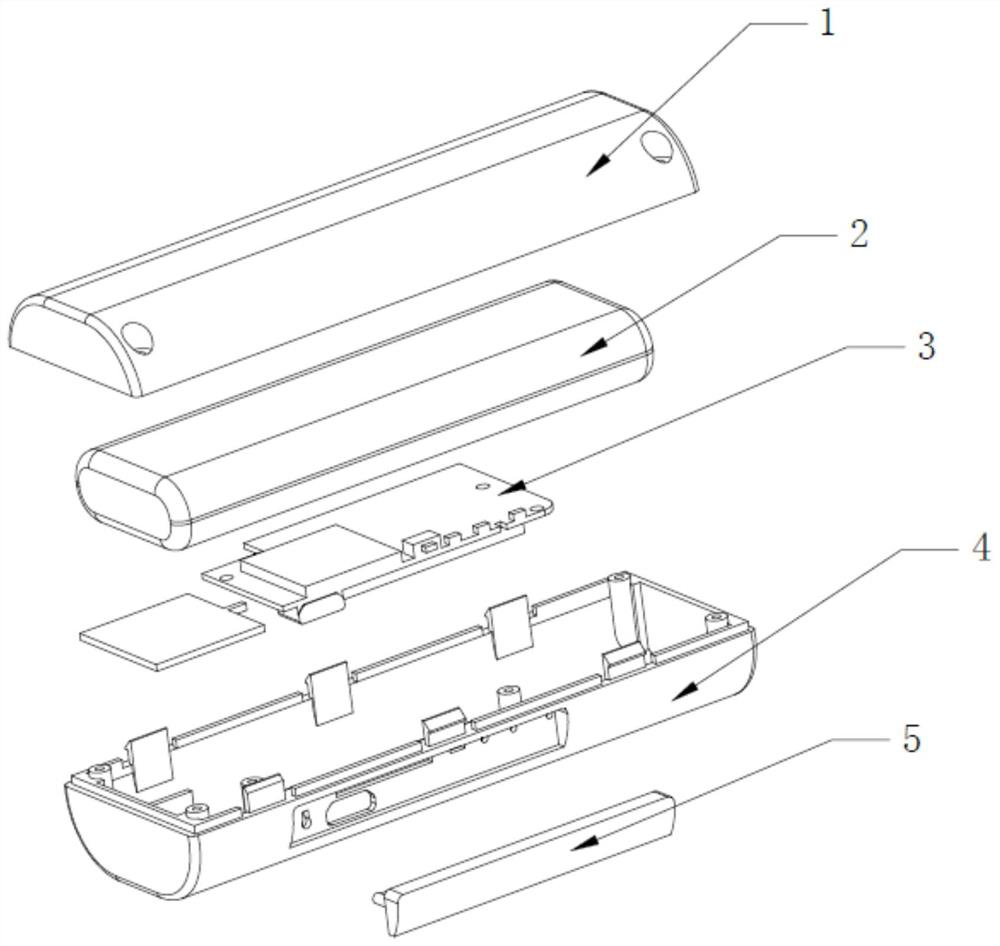

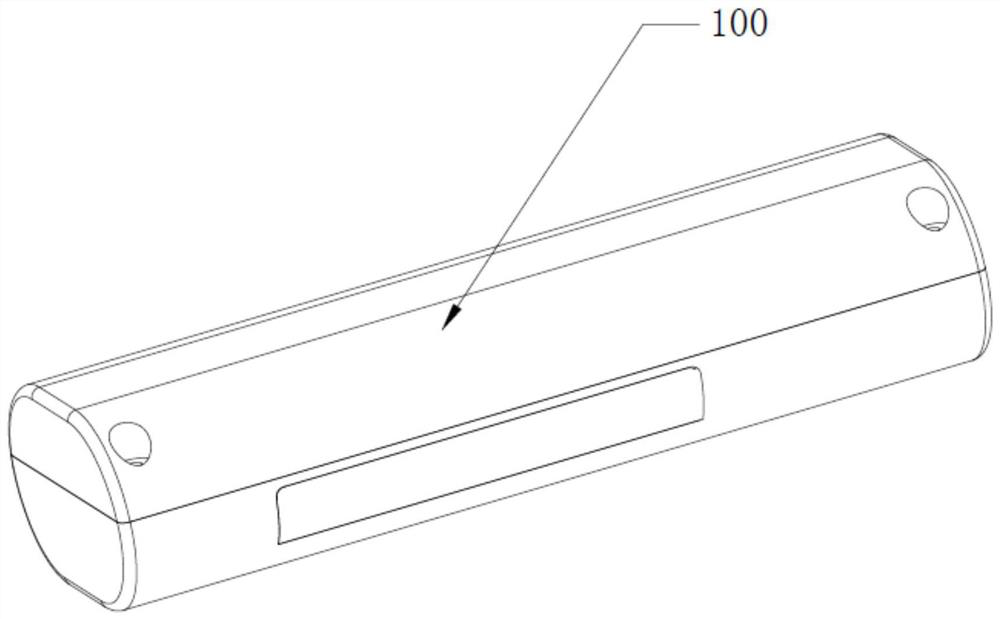

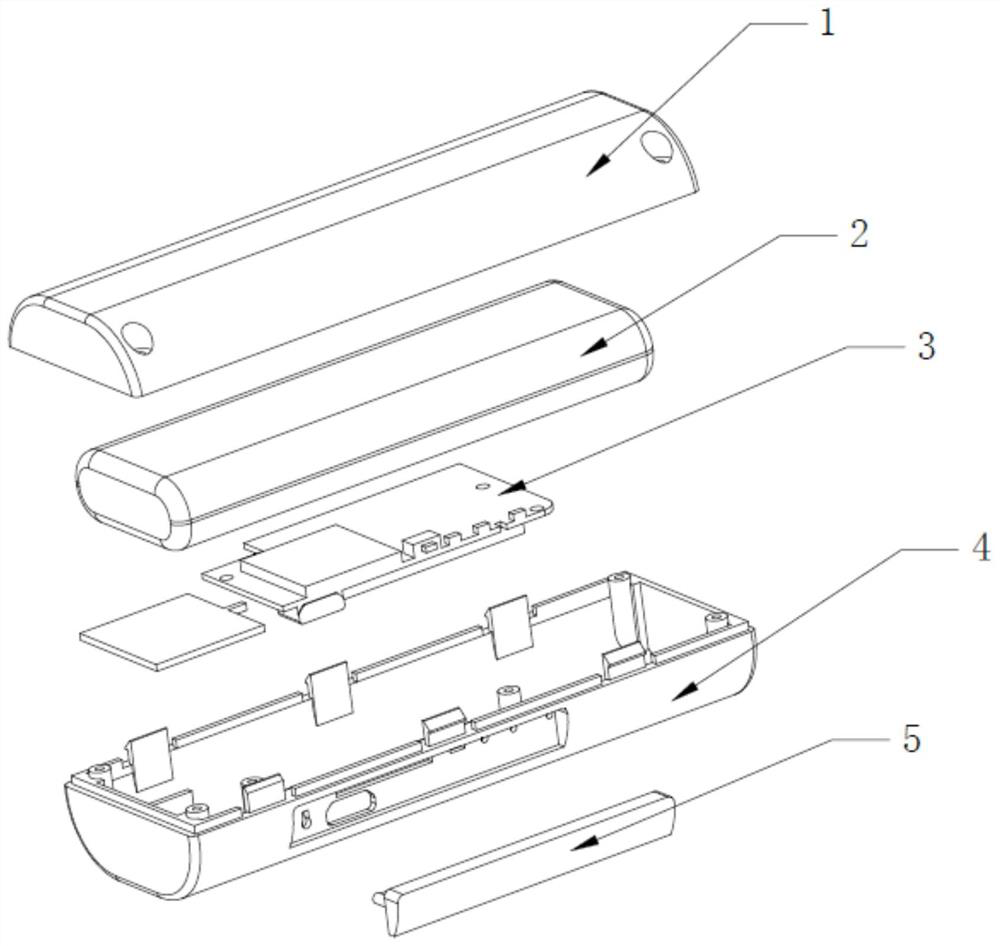

Gun off-position detector, system and dynamic early warning management and control method thereof

ActiveCN111915863APerformance is not affectedSimple structureAlarmsLocation information based serviceComputer hardwareEngineering

The invention provides a gun off-position detector, a system and a dynamic early warning management and control method thereof. The positioner comprises an off-position detector body and an off-position detection assembly; the off-position detection assembly comprises a power source body and a control circuit board, and the control circuit board is used for obtaining an off-position monitoring instruction sent by a monitoring center platform to carry out off-position detection of the gun, and feeding back position information of the gun to the monitoring center platform; the control circuit board comprises a control module, a UWB positioning module, a GSM communication module, an alarm module and a wireless radio frequency module. The system comprises the gun off-position detector. According to the method, the system is adopted for positioning. The gun off-position detector has gun in-place detection and off-place alarm functions, has the characteristics of high stability, high accuracy, timely alarm and the like, and can efficiently protect the use safety of guns.

Owner:中安创科(深圳)技术有限公司

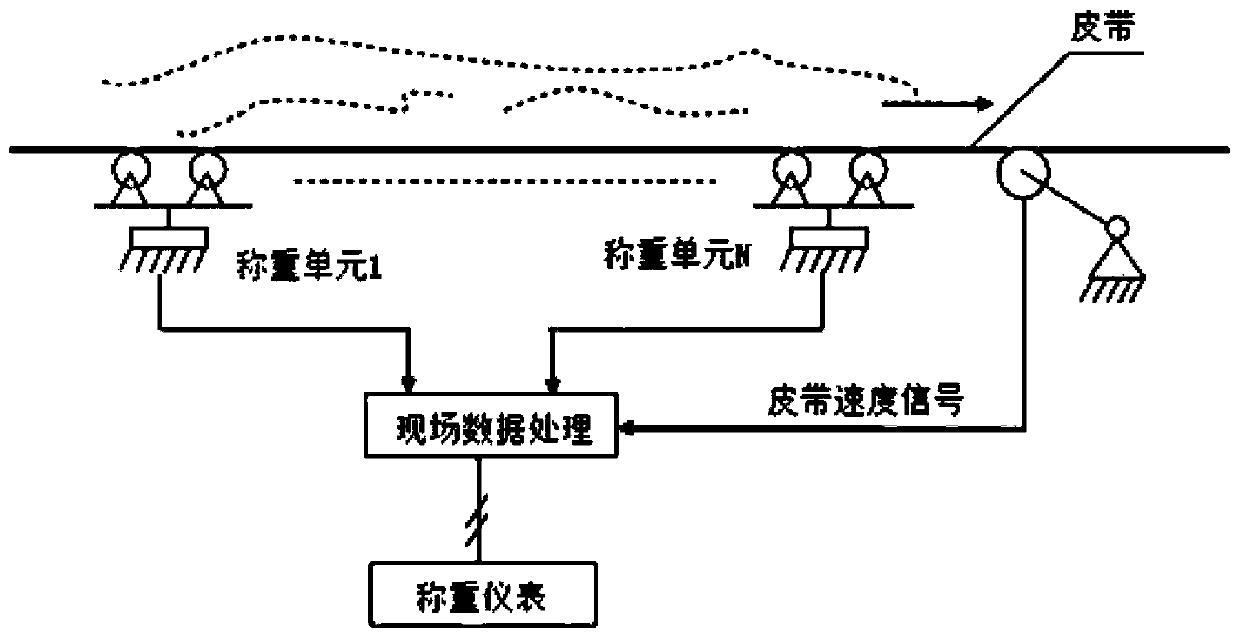

Array type belt conveyor weighing device and installation process thereof

InactiveCN111157085ALower coplanarity requirementsDown to coplanarityWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowControl engineeringBelt speed

The invention discloses an array type belt conveyor weighing device and an installation process thereof. The electronic scale comprises a scale frame, a weighing instrument, a weighing sensor and a speed measuring sensor, the weighing sensor and the speed measuring sensor are suspended on the scale frame; the weighing instrument is connected with the weighing sensor and the speed measuring sensorand directly provides voltage for the two sensors, the weighing sensor processes weight signals into corresponding weight data and sends the weight data to the weighing instrument, and the speed sensor sends out pulses with the frequency in direct proportion to the belt speed and directly sends the pulses to the weighing instrument. The calibration method is fast and effective; the influence of the factor degree of the belt on the belt weigher is comprehensively compensated, the array structure enables the error to be minimized, the weighing precision to be obviously improved, the long-term stability is good, the influence of belt tension change is effectively inhibited, the requirement for the installation position is relaxed, the requirement for the coplanarity of the weighing carrier rollers is reduced, carrier rollers and equipment are not affected by material sticking, and the daily maintenance amount is reduced.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG +1

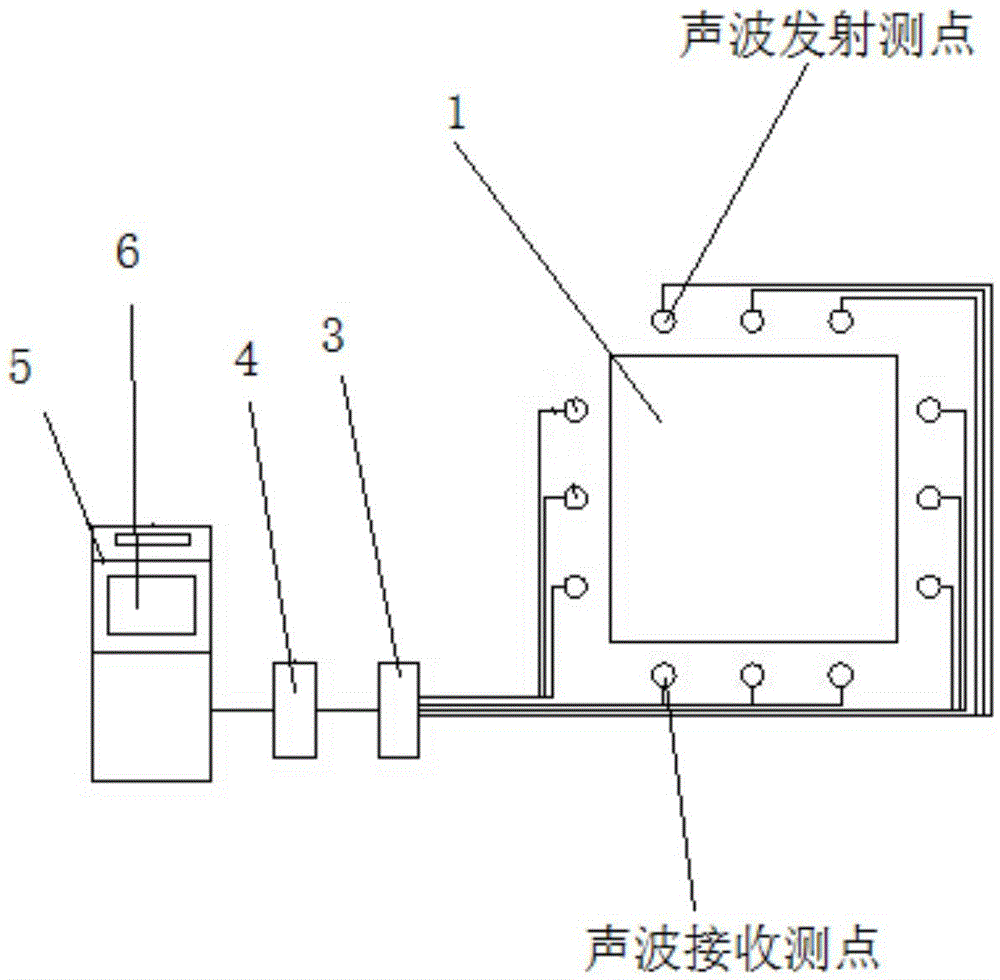

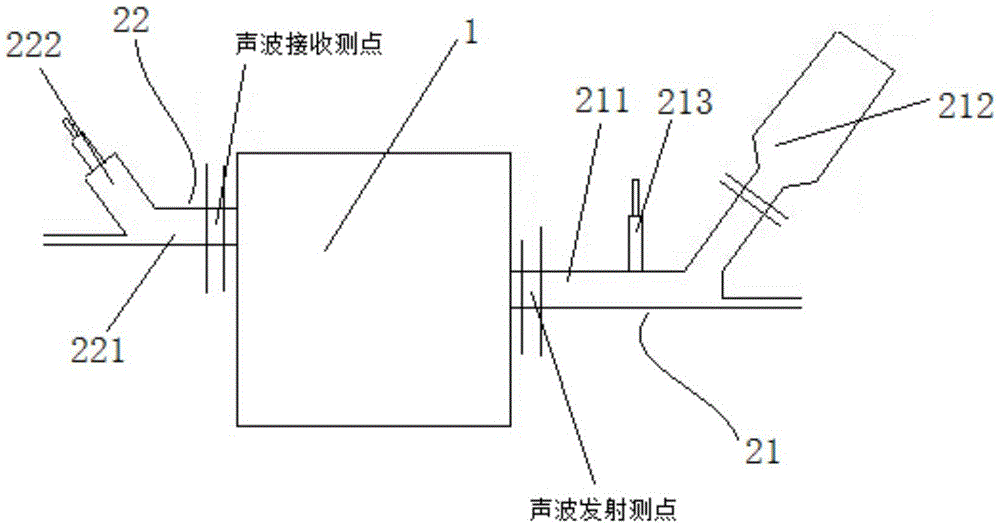

Acoustic technology based furnace box temperature online monitoring system

InactiveCN105605611ADoes not affect operationHigh sensitivityCombustion regulationAcoustic transmissionSound sources

The invention provides an acoustic technology based furnace box temperature online monitoring system. The acoustic technology based furnace box temperature online monitoring system is an independent system without affecting operation of any unit equipment. An acoustic source used for temperature detection is an autonomously designed electric acoustic source which is high in power, adjustable in frequency range and capable of providing sufficient sound pressure levels. An acoustic wave detector which is an electret enhanced acoustic transmission detector is high in sensitivity and resistant to high temperature. An acoustic wave guide tube has functions of insulation of heat and combustion by-products and protection of a microphone.

Owner:JIANGSU ZHONGNENG POWER EQUIP

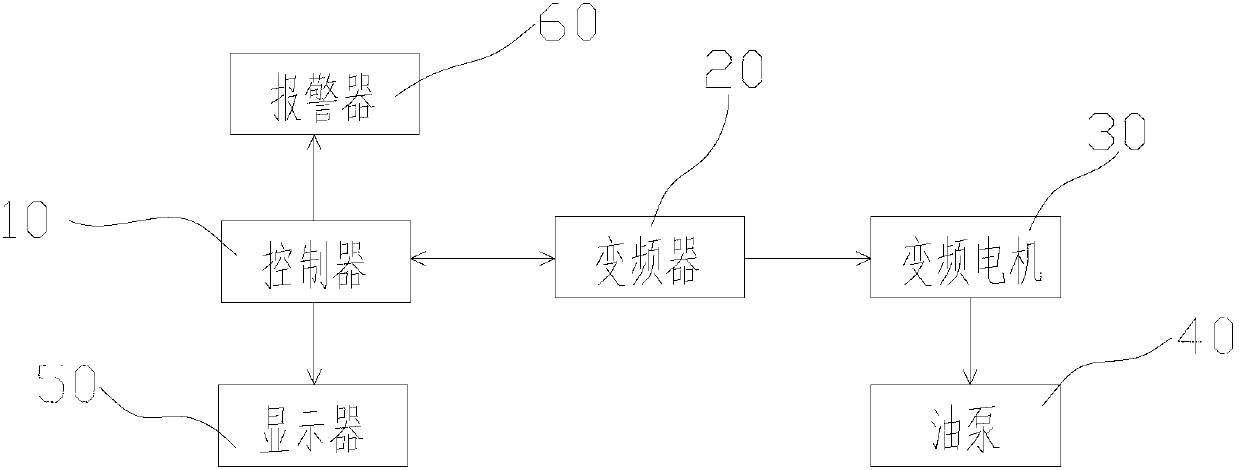

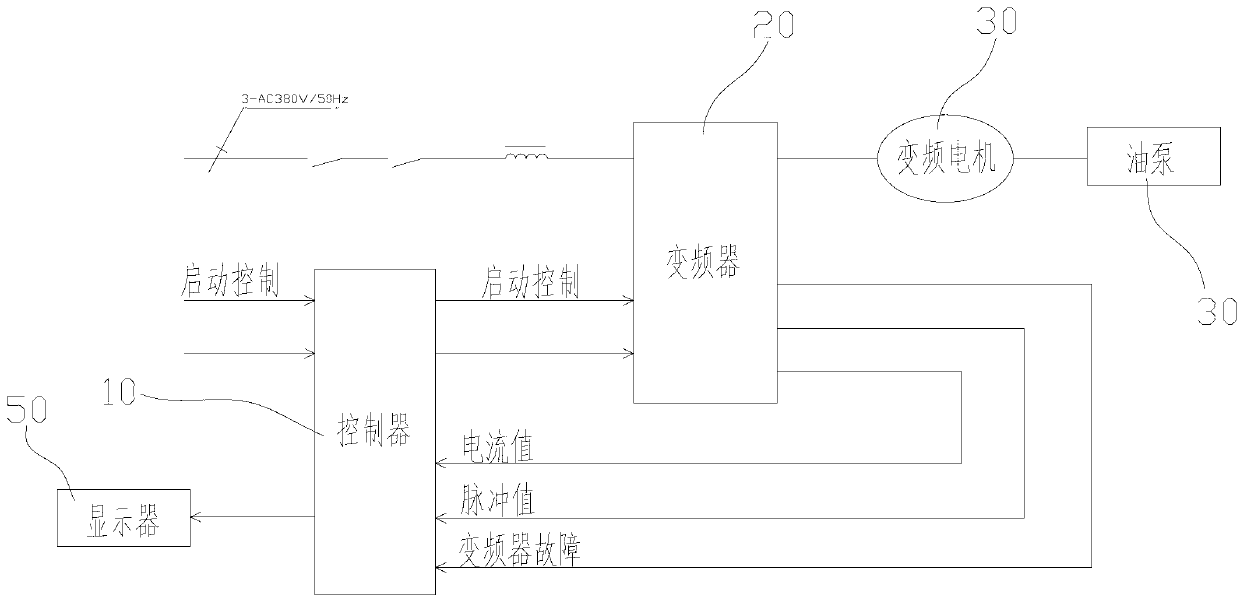

Oil pump driving-controlling system for multifunctional drilling machine

InactiveCN103277307ASmooth startStop smoothAC motor controlMachines/enginesFrequency changerStart stop

The invention discloses an oil pump driving-controlling system for a multifunctional drilling machine, which is connected with a hydraulic system of the drilling machine and comprises a controller, a frequency changer, a variable frequency motor and an oil pump, wherein the controller sends a variable frequency adjusting signal to the frequency changer; and the frequency changer receives the variable frequency adjusting signal and adjusts the frequency of a working power supply of the variable frequency motor according to the variable frequency adjusting signal, so that the rotation speed of the variable frequency motor is changed and further the output flow rate of the oil pump which is connected with the variable frequency motor is changed. The oil pump driving-controlling system has the advantages that the multifunctional drilling machine has a soft starting-stopping mode by changing the oil pump driving mode, so that the impact current does not exist and the stepless speed regulation can be realized; and compared with the prior art, the oil pump driving-controlling system has the advantages that the working performance is obviously improved, the fault rate is low, the equipment operation cost is low, the energy consumption is small, and the energy-saving effect is obvious.

Owner:CHTC JOVE HEAVY IND

Electrochemical oxidation device for treating desulfurized wastewater

InactiveCN106277487AEfficient removalQuick breakdownTreatment involving filtrationWaste water treatment from gaseous effluentsElectrochemical responseSolenoid valve

The invention relates to an electrochemical oxidation device for treating desulfurized wastewater. The device comprises: a pre-treatment system, an electrochemical reaction system, an adsorption system and an electric control system. The pre-treatment system comprises: a sand filter and a conveying pump. The electrochemical reaction system comprises: an electrode plate, a reaction groove body, a reaction storage tank and a liquid level meter. The adsorption system comprises: a stone coal active carbon adsorption device, a coconut shell active carbon adsorption device and a peat active carbon adsorption device. The electric control system comprises: a liquid level meter, a solenoid valve, a flow meter, a conductivity meter, a pH (Potential of Hydrogen) meter and an electric control cabinet body. The electrochemical oxidation device for treating the desulfurized wastewater is used in the fields of power plants and treatment of the produced desulfurized wastewater, and has the advantages of land saving, integrated design, relatively high automation degree and simplicity in operation.

Owner:北京中力信达环境技术有限公司

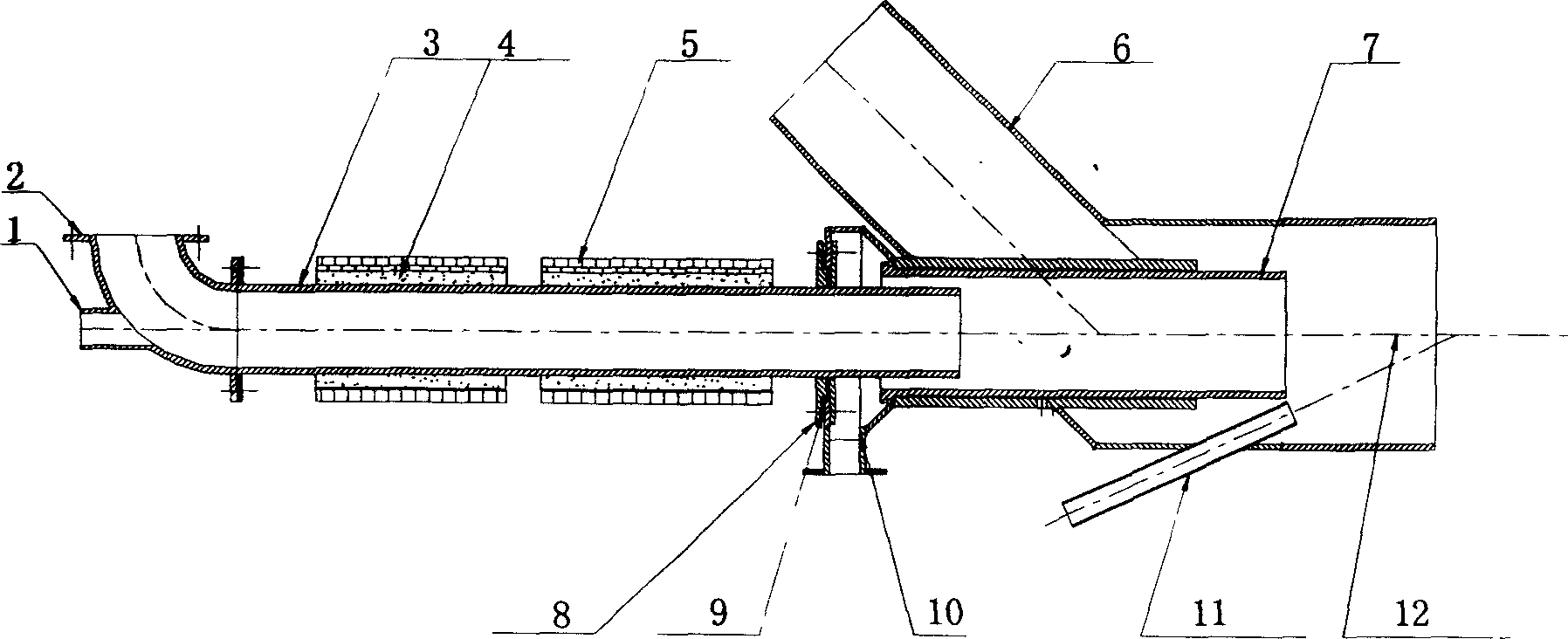

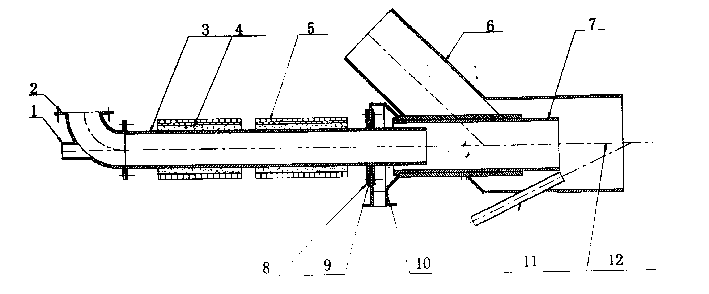

Oil-free directly-ignited burner for induced heating coal powder boiler

The oil-free directly-ignited burner for induced heating coal powder boiler has power source system, cooling water system and igniter. The igniter includes one first stage and one second stage, the first stage has the first coal powder inlet, inducing metal pipe with heat insulating layer, inducer outside the heat insulating layer, sealing flange with sealing material outside the inducing metal pipe outlet, ring blast chamber, and combustion stabilizing chamber in the outlet of the ring blast chamber; the second stage has the second coal powder inlet, fire observing hole, the second igniter and flow guiding partition set between second igniter and the combustion stabilizing chamber. The present invention has the advantages of cold start and flow stabilization of coal powder boiler without oil, gas and other supplementary material, convenient regulation, stable running, multistage ignition, low running cost, less maintenance and high reliability.

Owner:ZHEJIANG UNIV

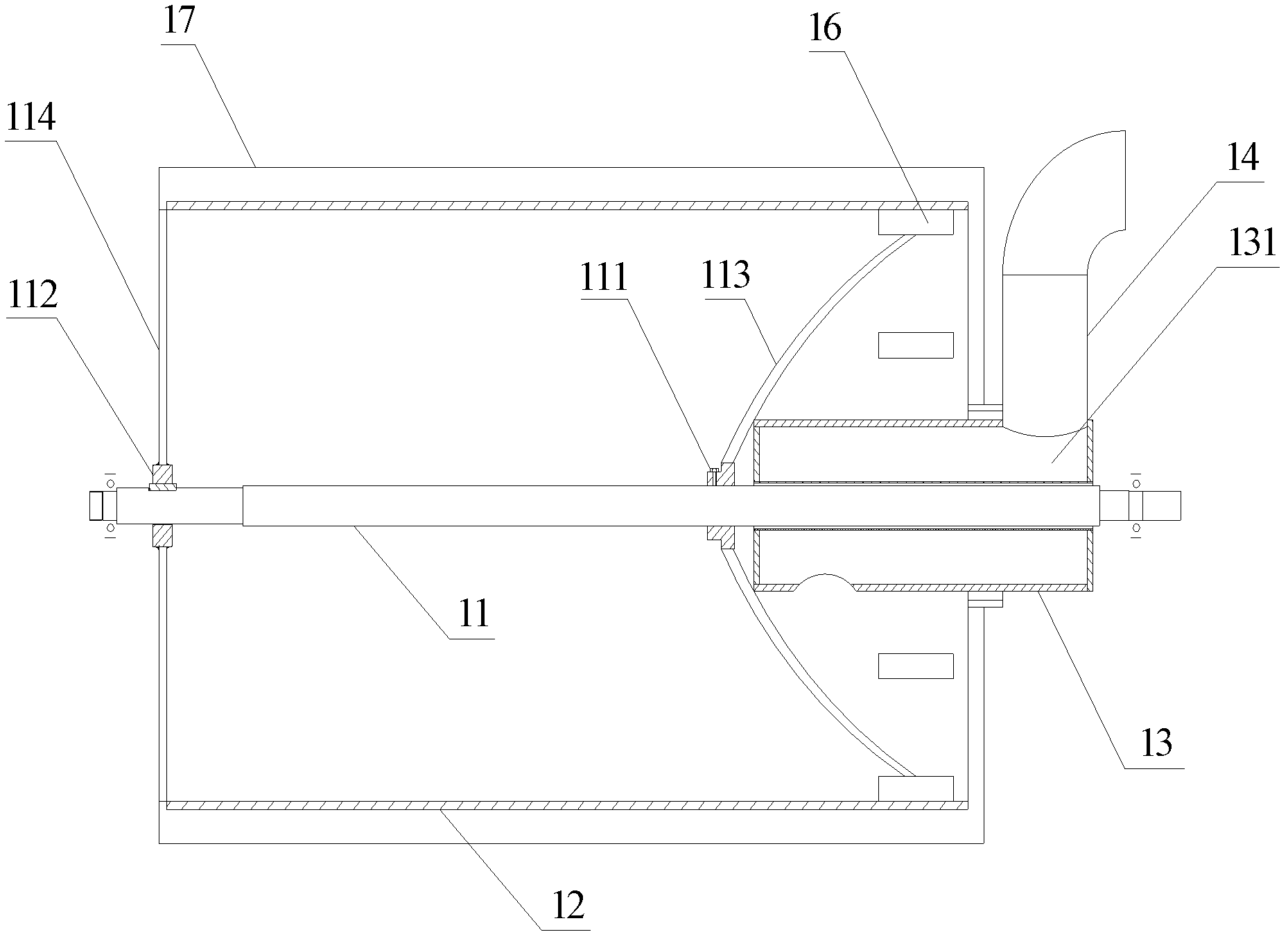

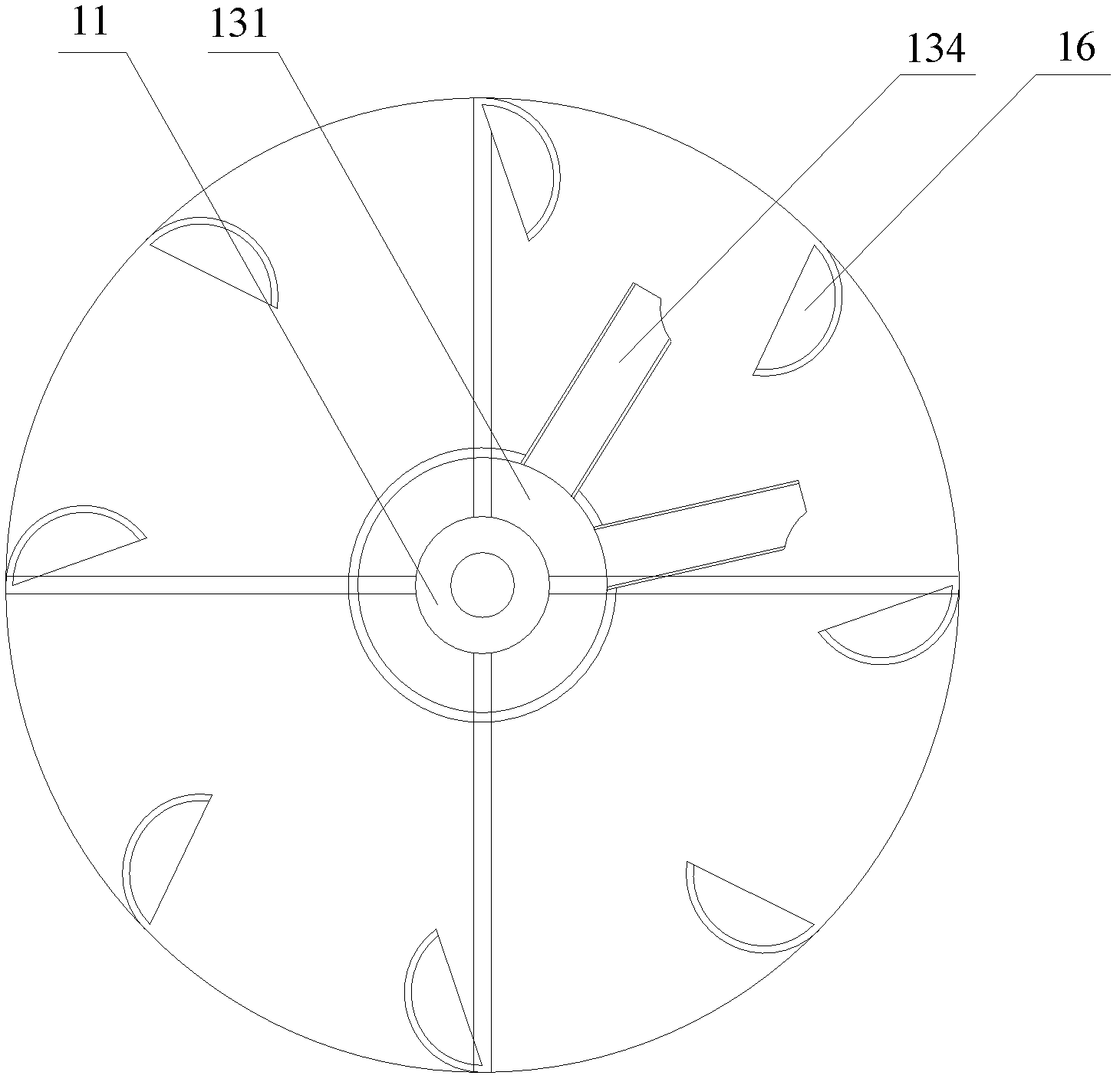

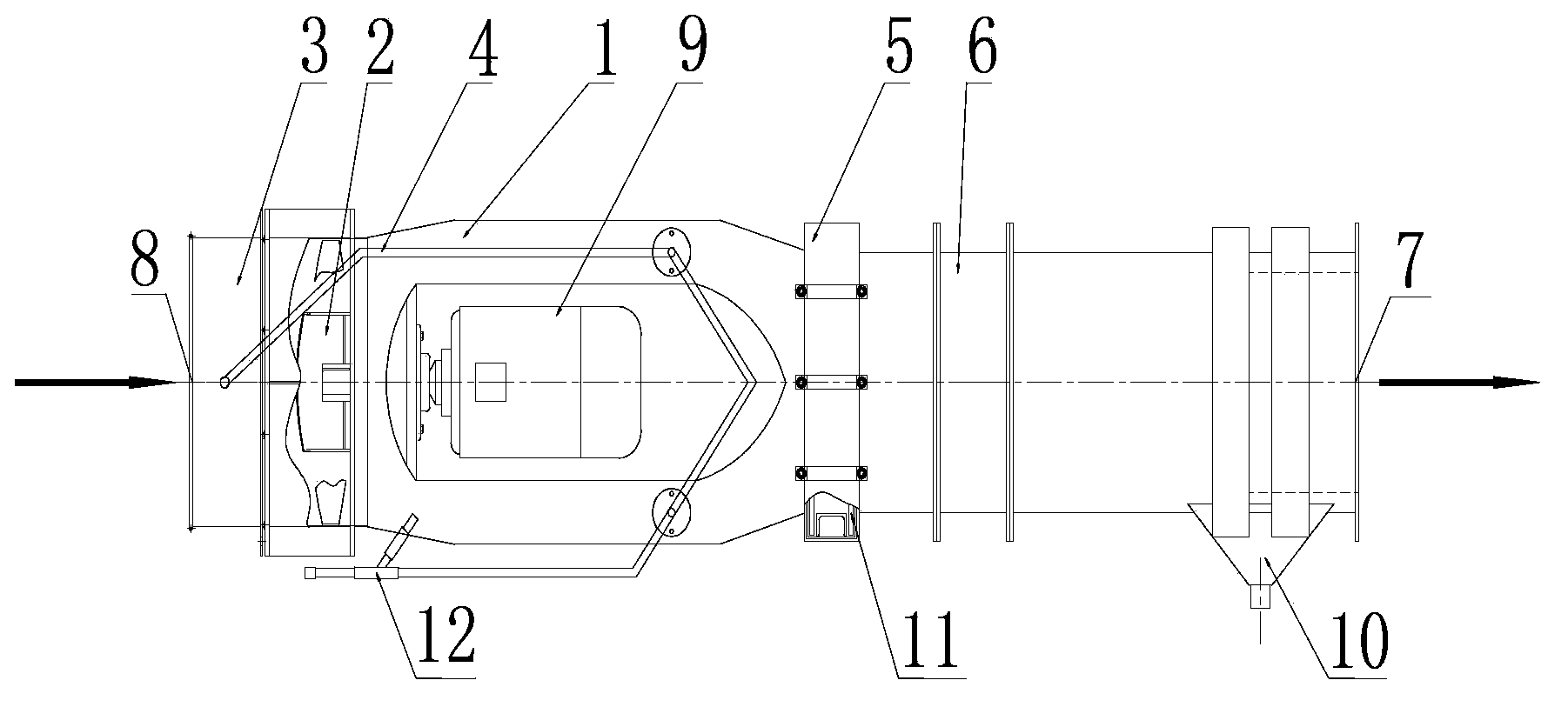

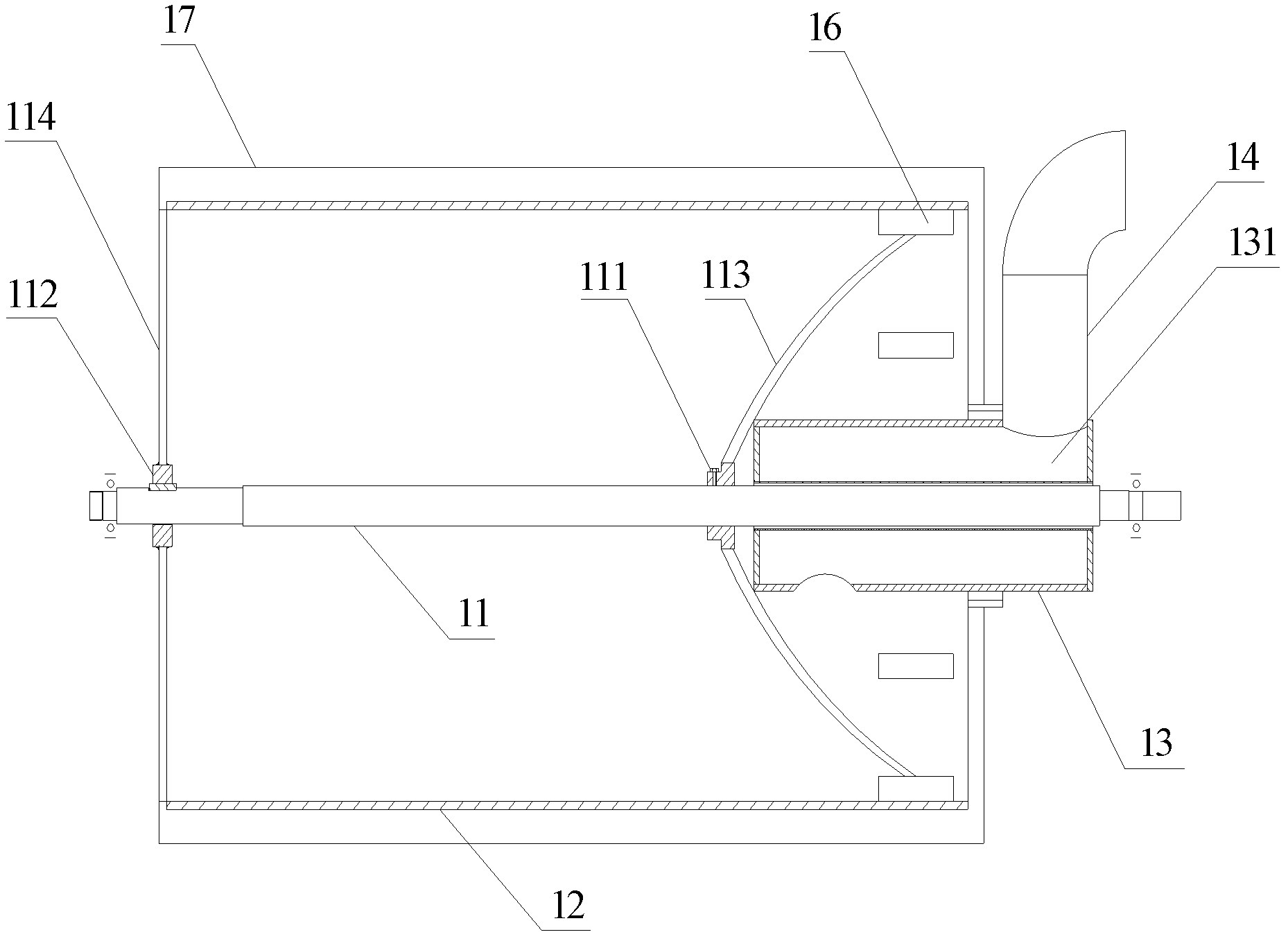

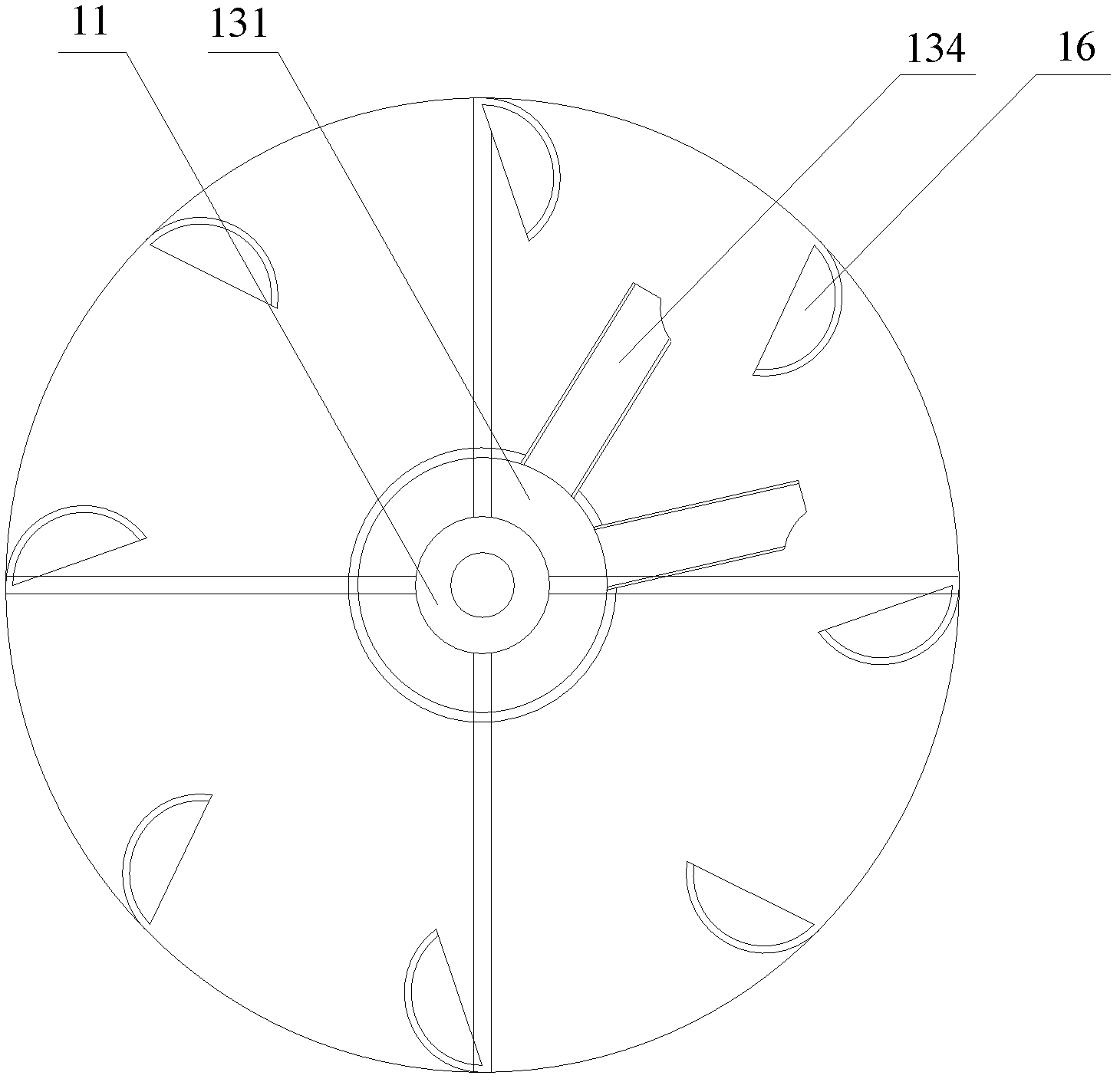

Grillage machine

InactiveCN103071327ASimple structureLittle daily maintenanceMoving filtering element filtersAgricultural engineeringSewage

The invention discloses a grillage machine which comprises a support and a screen drum arranged on the support through a rotating shaft, wherein the inner wall of the screen drum is provided with a spiral guide plate, one end of the rotating shaft positioned at an initiating end of the spiral guide plate is provided with a sleeve, the sleeve may be rotatably sleeved on the rotating shaft, a water accommodating chamber is formed between the sleeve and the rotating shaft and is in fixed connection with a sewage pipeline, the sidewall of the sleeve is provided with a plurality of nozzles, a plurality of water buckets are fixed on the inner wall of the screen drum, and the openings of the water buckets are corresponding to the nozzles. With such a structure, the grillage machine disclosed in the invention has the advantages of a simple structure, small routine maintenance load, no need for extra power during operation and low operation cost.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

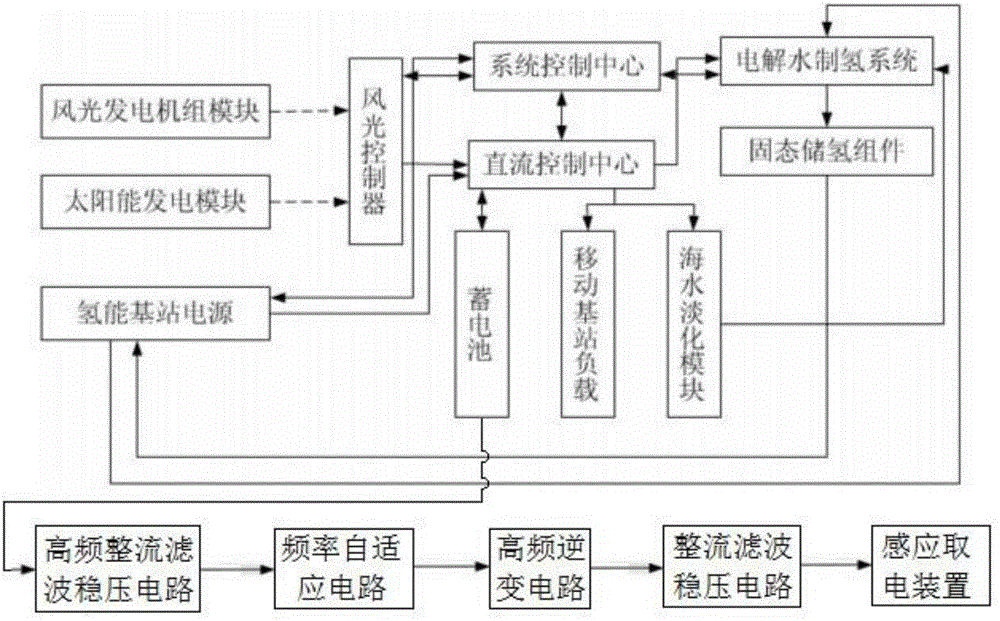

Wireless video transmission power supply system for construction site

InactiveCN106374816ASolve power problemsSolve the problem of not being able to lay a large number of cablesGeneral water supply conservationPV power plantsVideo monitoringElectrolysis

The invention discloses a wireless video transmission power supply system for a construction site. The wireless video transmission power supply system comprises a wind generating set module, a solar power generation module, a wind power and solar energy controller, a hydrogen energy base station power supply, a water electrolysis hydrogen-production system, a solid-state hydrogen storage system, a system control center, seawater desalting equipment and a wireless transmission module, wherein the wind generating set module and the solar power generation module are connected with the wind power and solar energy controller through the wireless transmission module; a storage battery is connected to an induction power-taking apparatus through a high-frequency rectifying filtering circuit, a frequency adaptive circuit, a high-frequency inversion circuit and a rectifying filtering and voltage-stabilizing circuit in sequence; and the induction power-taking apparatus supplies power to the video monitoring systems in different places of the construction site. According to the wireless video transmission power supply system, a wind power and solar energy power generation technology is adopted to solve the power supply problem; the redundant electric quantity is converted into hydrogen through the water electrolysis hydrogen-production system to be stored; and a wireless transmission technology is adopted, so that the problem that a large quantity of cables cannot be laid is solved.

Owner:徐志勇

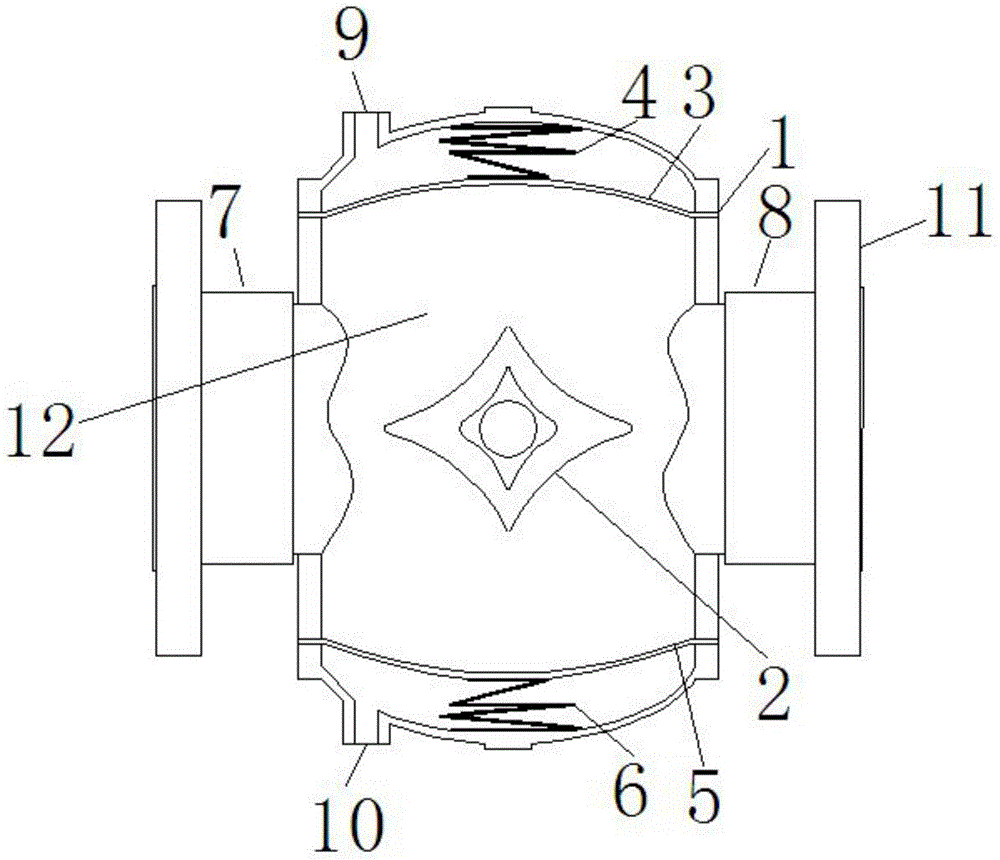

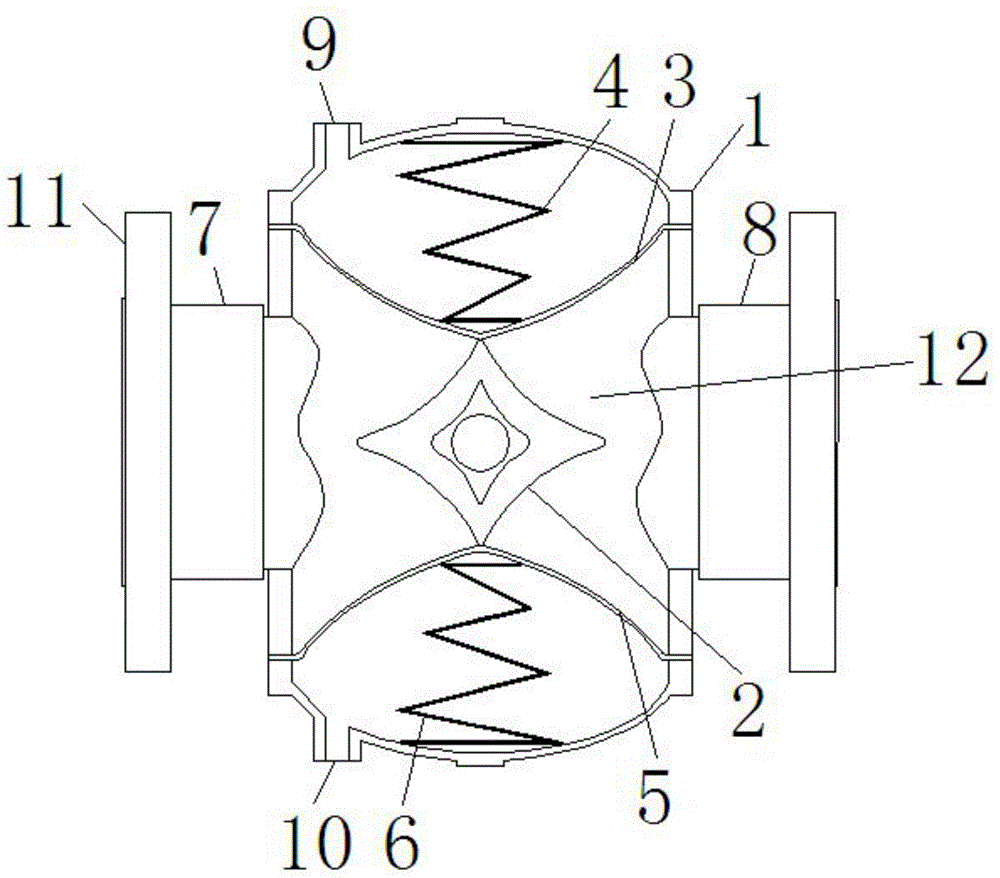

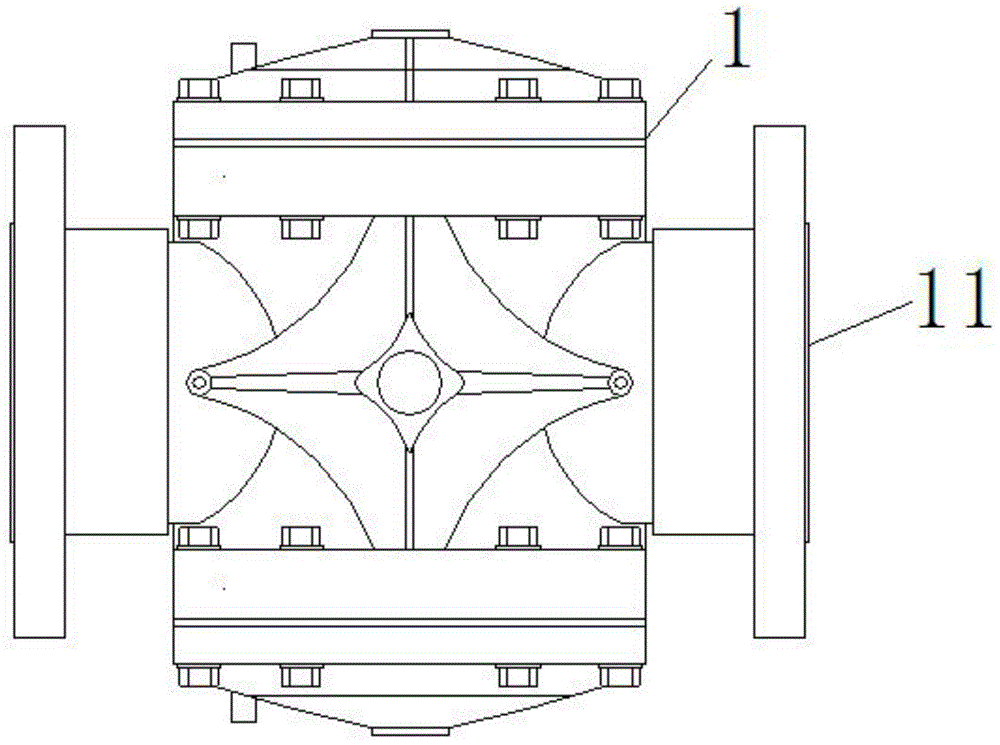

V-shaped double-sided diaphragm valve

InactiveCN106195322ARealize the control functionEasy to useDiaphragm valvesEngine diaphragmsDiaphragm valveAtmospheric pressure

The invention relates to a V-shaped double-sided diaphragm valve. The V-shaped double-sided diaphragm valve comprises a diaphragm valve body, wherein a sprue is formed in the middle of the diaphragm valve body; an upper rubber diaphragm is arranged at the position, above the sprue, in the diaphragm valve body; an upper spring is arranged between the upper rubber diaphragm and the inner top wall of the diaphragm valve body; a lower rubber diaphragm is arranged at the position, below the sprue, in the diaphragm valve body; a lower spring is arranged between the lower rubber diaphragm and the inner bottom wall of the diaphragm valve body; one end of the diaphragm valve body in the horizontal direction is a water inlet, and the other end of the diaphragm valve body in the horizontal direction is a water outlet; the upper rubber diaphragm and the lower rubber diaphragm are symmetrically arranged; the left end and the right end of the upper rubber diaphragm are both horizontally arranged at the upper part of the diaphragm valve body; the left end and the right end of the lower rubber diaphragm are both horizontally arranged at the lower part of the diaphragm valve body; a hydraulic power control opening or an air pressure control opening is formed in each of the upper end and the lower end of the diaphragm valve body. The V-shaped double-sided diaphragm valve is suitable for large-caliber occasions, and is excellent in corrosion resistance, steady and reliable in operation, low in manufacturing cost and less in daily maintenance.

Owner:江苏开能华宇环保设备有限公司

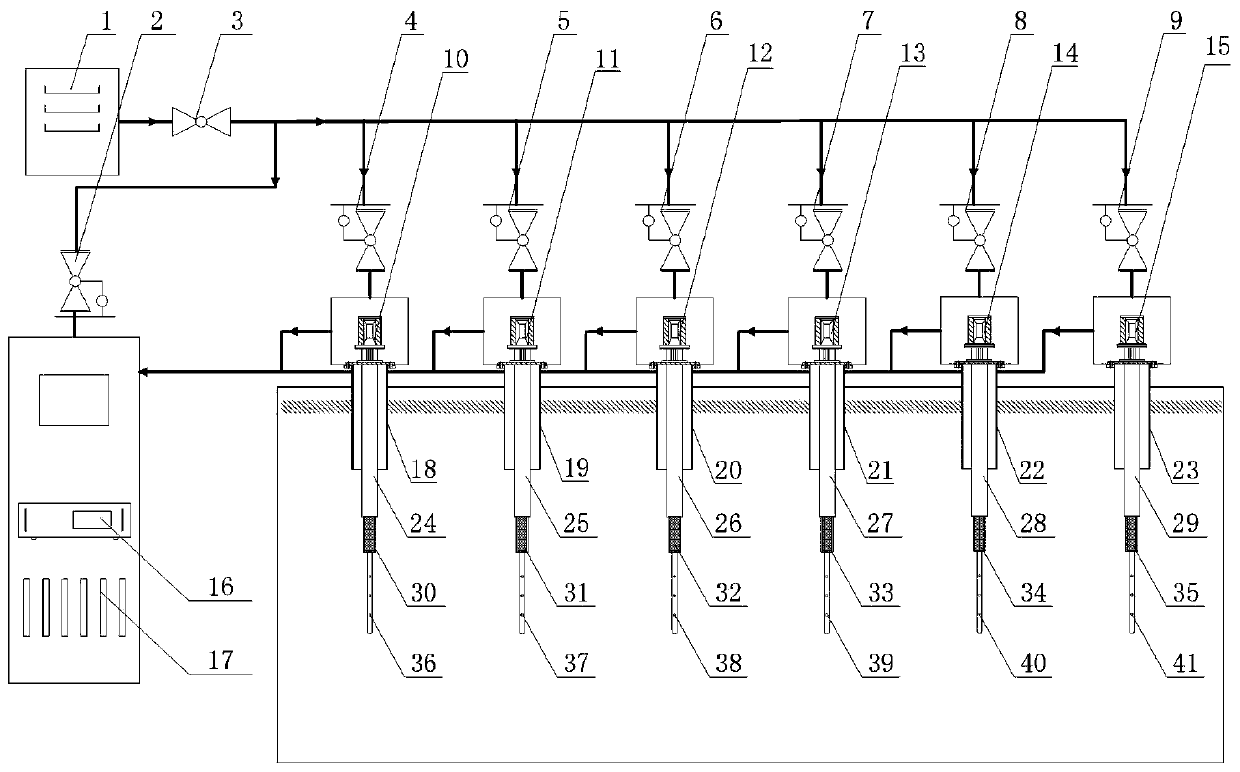

High-precision constant-current dilution time-sharing synchronous partition type CO measuring system for flue of coal-fired power plant

PendingCN111504730ATimely and more reasonable adjustmentBurn fullyWithdrawing sample devicesCleaning using gasesThermodynamicsProcess engineering

The invention discloses a high-precision constant-current dilution time-sharing synchronous partition type CO measuring system for a flue of a coal-fired power plant. The system comprises a zero gas system; a main pressure regulating valve is arranged on a pipeline at an outlet end; the main pressure regulating valve is connected with two passages through a pipeline, wherein one passage comprisesa plurality of partition pressure regulating valves which are connected in parallel and are arranged in sequence, high-precision constant-flow dilution devices and partition sampling devices, and theother passage is provided with a blowback pressure regulating valve and a multi-channel time-sharing synchronization system sequentially; the high-precision constant-flow dilution devices are connected with the multi-channel time-sharing synchronization system through a pipeline; the high-precision constant-current dilution devices and the partition sampling devices are connected and are in one-to-one correspondence with each other; the multi-channel time-sharing synchronization system comprises a high-precision CO instrument; the multiple partition sampling devices are uniformly arranged in the flue; and each partition sampling device comprises a partition sampling cavity, a filter element and a sampling probe rod. With the system adopted, the CO gas concentrations of different areas in the flue can be quickly and accurately detected, and a data basis is provided for judging whether the flue gas emission of the thermal power plant reaches standards or not.

Owner:HUANENG INT POWER CO LTD YUHUAN POWER PLANT +1

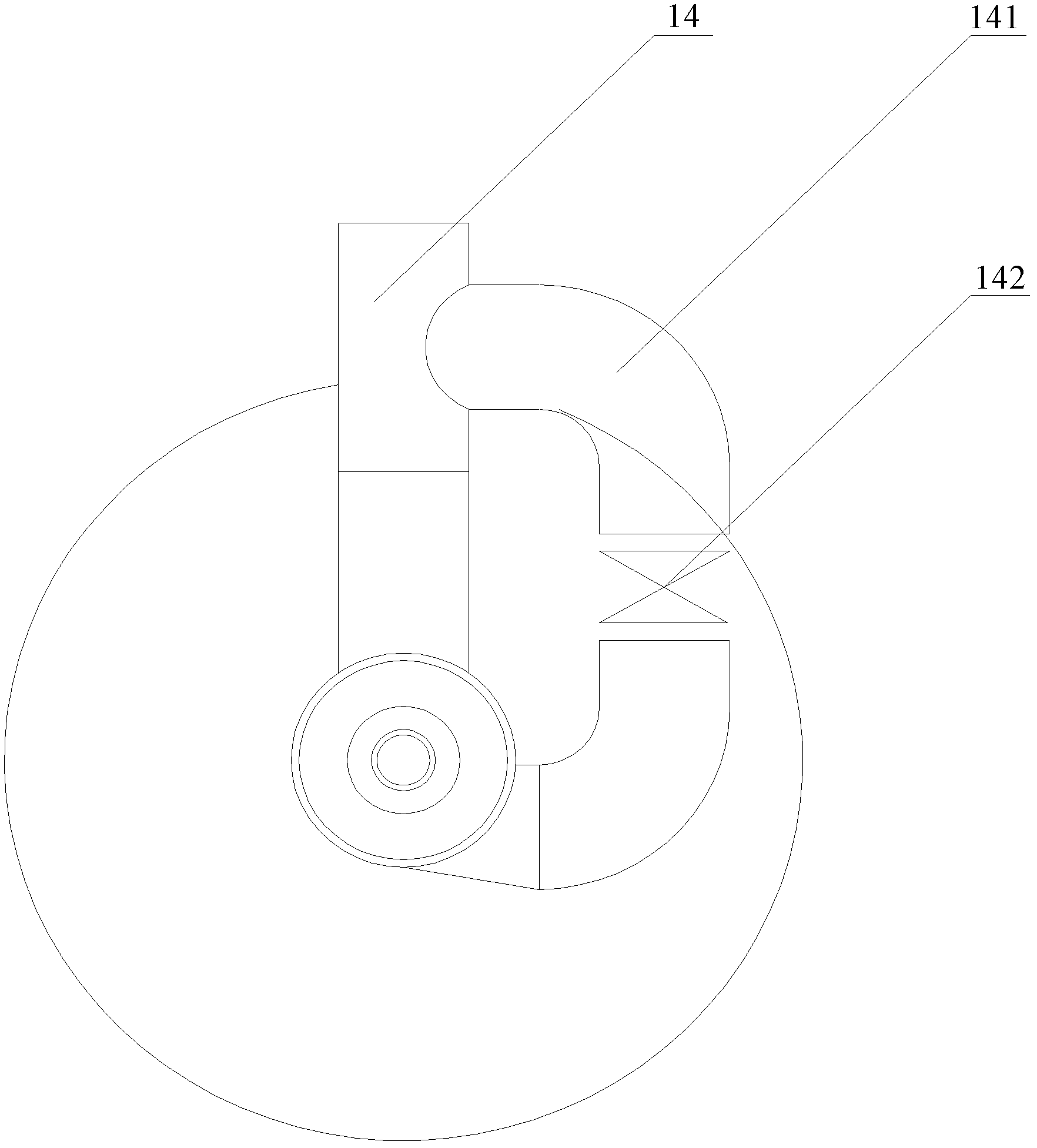

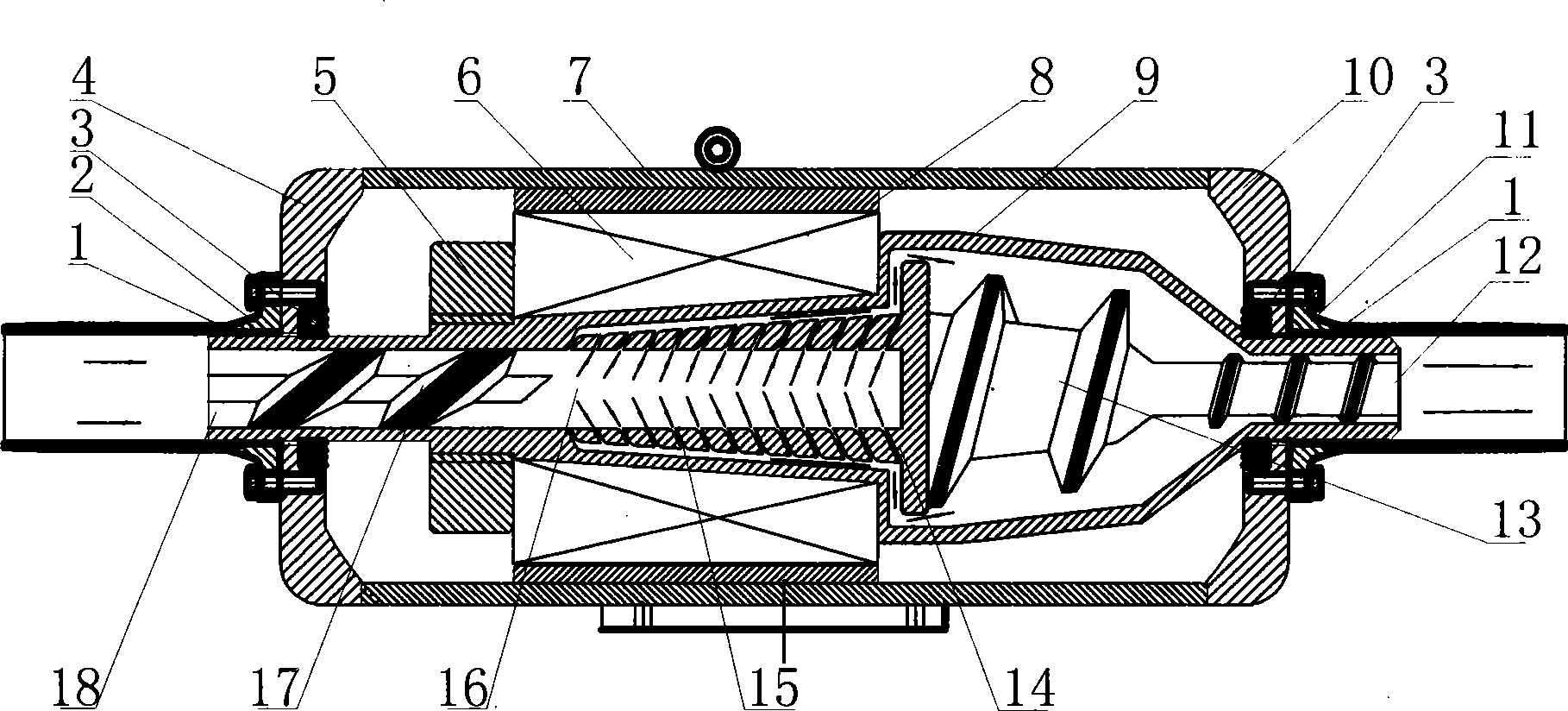

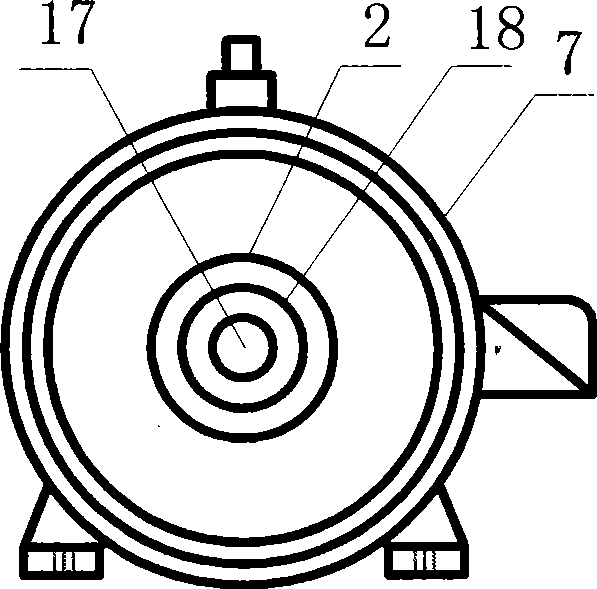

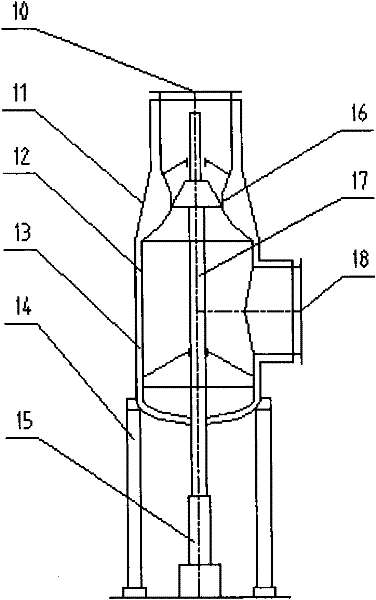

Non-impeller hollow screw axis centrifugal cavity pump

ActiveCN101463822AHigh speedReduce resistancePump componentsRadial flow pumpsImpellerAgricultural irrigation

The invention relates to a hollow spiral shaft eccentric cavity pump without a vane wheel. A front spiral diversion body and a rear spiral diversion body are arranged in a conical hollow shaft provided with a water inlet and a water outlet and are respectively fixedly connected with the inner wall of the conical hollow shaft; the front end of the rear spiral diversion body is provided with a cavity conical body, and the front end of the cavity conical body is fixedly connected with the inner wall of the conical hollow shaft; and the wall of the cavity conical body is provided with a plurality of apopores. A rotor sleeve is arranged outside the conical hollow shaft, a rotor is arranged in the housing sheathed on the conical hollow shaft, and both ends of the conical hollow shaft are supported by bearings. The pump of the invention has the advantages of scientific and reasonable integral design, simple structure, convenient production, low material consumption, high material quality, low cost, easy assembly and disassembly, low daily maintenance, stable and reliable performance, energy saving and high efficiency and practicability. The pump of the invention is applicable to families, factories and mines, enterprises and institutions, agricultural irrigation, running water and other relative work units.

Owner:大连恒基新润水务有限公司

A firearm out-of-position detector, system and dynamic early warning control method thereof

ActiveCN111915863BPerformance is not affectedSimple structureAlarmsLocation information based serviceRF moduleControl circuit

The invention provides a gun out-of-position detector, system and dynamic early warning management and control method thereof. The locator includes an out-of-position detector body and an out-of-position detection component. The out-of-position detection component includes a power supply main body and a control circuit board for the control circuit board To obtain the out-of-position monitoring command sent by the monitoring center platform, detect the out-of-position of the gun, and feed back the position information of the gun to the monitoring center platform; the control circuit board includes a control module, a UWB positioning module, a GSM communication module, an alarm module, radio frequency module. The system includes the firearm out-of-position detector described above. The method of the present invention uses the above-mentioned system for positioning. The invention has the functions of gun in-position detection and out-of-position alarm, has the characteristics of strong stability, high precision, timely alarm and the like, and can effectively protect the use safety of guns.

Owner:中安创科(深圳)技术有限公司

Microwave heating oil-free directly igniting burner for pulverized-coal fired boiler

InactiveCN1858491ASave fuelLittle daily maintenanceIncandescent ignitionPulverulent fuel combustion burnersCombustion chamberEngineering

The microwave heated oil-free directly igniting burner for pulverized coal boiler includes one power source system, one cooling water system and one igniter body. The igniter body has one first stage, one second stage and one third stage, the first stage has coal powder inlet and pipe with microwave heating layer and gasket; the second stage has primary air-coal powder inlet, igniting chamber, coal powder outlet and coal powder splitting plate; and the third igniter has igniting chamber, coal powder outlet, coal powder splitting plate and secondary air chamber. The present invention has the advantages of cold ignition and stable combustion without need of oil, gas and other auxiliary fuel, convenient regulation, stable running, low cost, etc.

Owner:史更

Balance wheel speed regulating type slow landing jack ladder escape device

InactiveCN1554456AKeep the speed of descent constantSolve the imbalanceBuilding rescueBalance wheelControl theory

The emergency escape device for high rise building consists of jack ladder, guide track, chain wheel, speed varying mechanism, balance wheel speed regulating controller, etc. It is used for person in high rise building to escape in emergency. The present invention has the advantages of low cost, no need of outer driving force, relatively smooth lowering speed and no floating motion.

Owner:镇江市星火电器设备厂

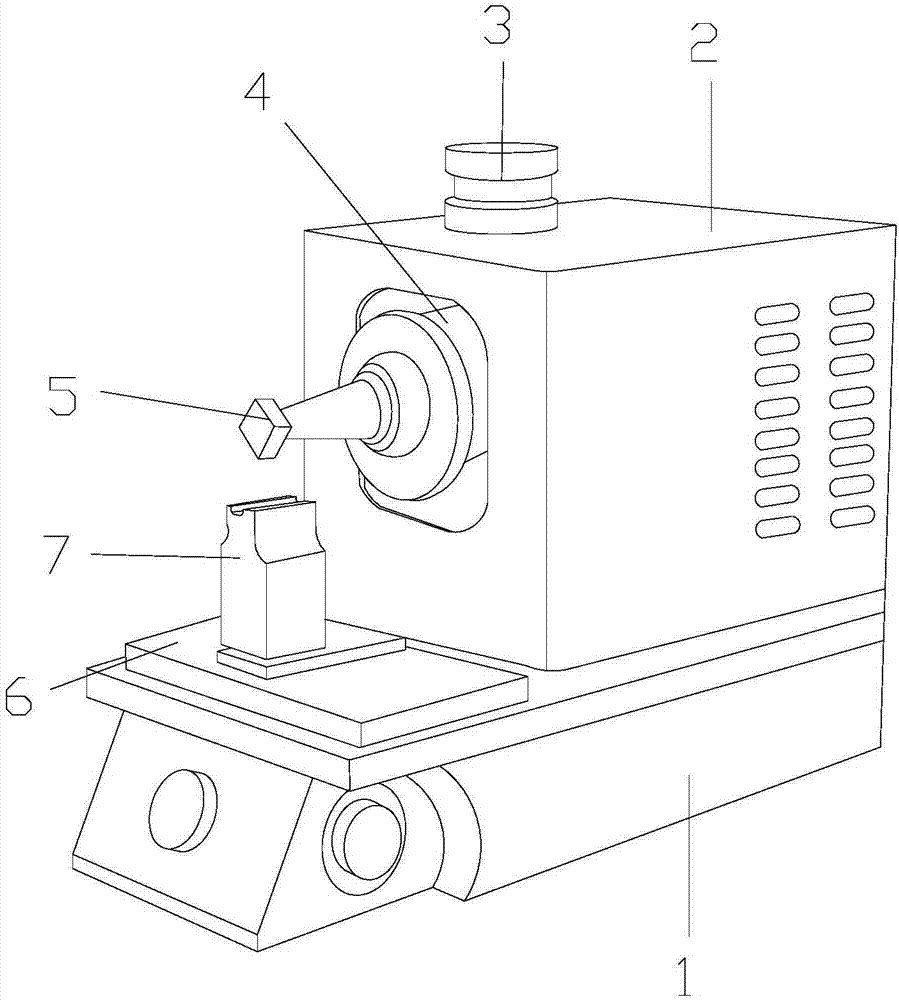

Transformer lug welding equipment

InactiveCN107978948AReduce internal frictionReduce wearLine/current collector detailsCoils manufactureForeign matterTransformer

The invention discloses transformer lug welding equipment. The equipment structurally comprises a frame, a self-lubricating casing, an upper workpiece, a welding mechanism, a welding joint, a cast iron backing plate and a copper bar, the self-lubricating casing is fixedly welded to the right of the upper surface of the frame and is vertical to the frame, and the welding mechanism is movably connected an internal cavity of the self-lubricating casing. Related parts including a pulley connecting device, a touch connection mechanism and a movable lubrication mechanism are cooperated with each other, a bearing part of a connecting rod of the welding mechanism of the equipment can be lubricated in the process that a low-voltage lead of the transformer is welded to a lug connected to a bushing,internal wearing and friction of parts including the bearing are reduced, the amount of daily maintenance is reduced, foreign matters are prevented from entering the internal of the bearing, the bearing is prevented from tarnishing and corrosion, the service life of related parts is prolonged, the normal welding efficiency of the welding mechanism is ensured, and the reliability of the equipment is improved effectively.

Owner:江苏巨力电力设备有限公司

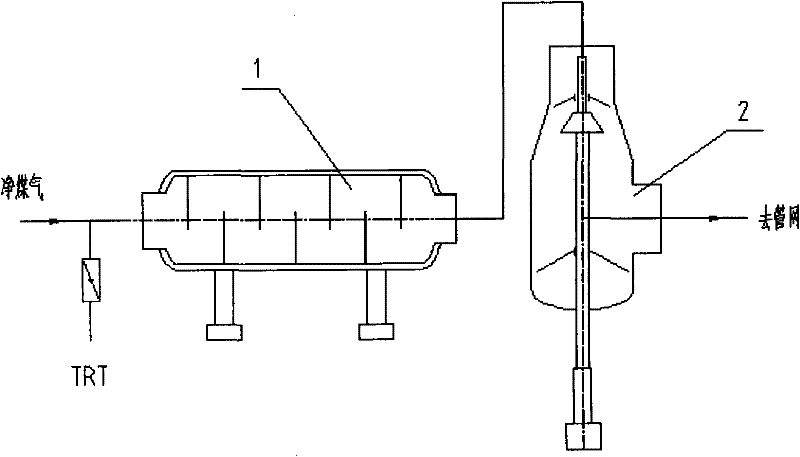

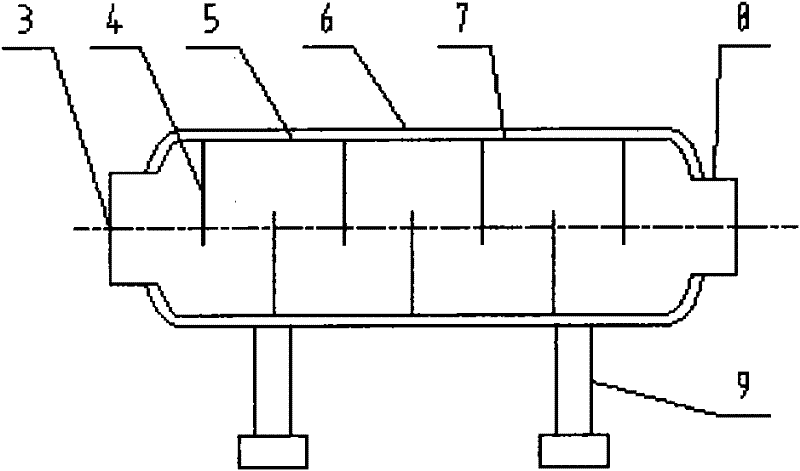

Blast-furnace gas pressure regulating process

ActiveCN102534075ASimple processSimple structureBlast furnace detailsUltrasound attenuationLow noise

The invention provides a blast-furnace gas pressure regulating process, wherein a pipeline and a pressure reducer set are comprised. The pressure reducer set is formed by connecting two stages of pressure reducers in series. The first stage of pressure reducer is of a clapboard type, has a fixed pressure reducing value and mainly comprises an inlet pipeline, an outlet pipeline, an inner shell, anouter shell, a sound attenuation material, a clapboard and a support. The second stage of pressure reducer is of a circular seam type, has an adjustable pressure reduction value and mainly comprises an outlet pipeline, an inlet pipeline, an inner shell, an outer shell, a clock valve body, a sound attenuation material, a seal ring, a transmission device, a support device and the like. According tothe blast-furnace gas pressure regulation process, because the novel pressure redactor set which formed by connecting two stages of novel pressure reducers in series and completely different from a butterfly valve set manufactured by the traditional process, the adverse factors of the butterfly valve set are eliminated. The blast-furnace gas pressure regulating process disclosed by the invention has the advantages of concise flow, simple and reliable equipment operation, low noise, low vibration, guarantee of stable equipment operation, prolonged service life, simple structure of equipment, investment saving, low routine maintenance and considerable benefit saving.

Owner:鞍钢集团工程技术有限公司

Novel waste gas filter

InactiveCN104289057ACompact structureImprove dust removal efficiencyCombination devicesFiberWaste gas

The invention relates to a novel waste gas filer. The filter comprises a middle air box. An explosion-proof axial-flow fan is arranged at the front end of the middle air box. A flow-collecting air duct is arranged at the front end of the explosion-proof axial-flow fan. A water supply spray system is arranged on the middle air box. A fiber grid filter is arranged on the back end of the middle air box. A cyclone dehydration device is arranged on the back end of the fiber grid filter. A gas outlet is arranged on the back end of the cyclone dehydration device. A gas inlet is provided on the front end of the flow-collecting air duct. An explosion-proof motor is arranged in the middle air box. The novel waste gas filter provided by the invention has the advantages of simple structure, high de-dusting efficiency, long service life, and small routine maintenance amount.

Owner:JIANGSU JINTAO ENVIRONMENTAL PROTECTION ENG

Grillage machine

InactiveCN103071327BSimple structureLittle daily maintenanceMoving filtering element filtersAgricultural engineeringSewage

The invention discloses a grillage machine which comprises a support and a screen drum arranged on the support through a rotating shaft, wherein the inner wall of the screen drum is provided with a spiral guide plate, one end of the rotating shaft positioned at an initiating end of the spiral guide plate is provided with a sleeve, the sleeve may be rotatably sleeved on the rotating shaft, a water accommodating chamber is formed between the sleeve and the rotating shaft and is in fixed connection with a sewage pipeline, the sidewall of the sleeve is provided with a plurality of nozzles, a plurality of water buckets are fixed on the inner wall of the screen drum, and the openings of the water buckets are corresponding to the nozzles. With such a structure, the grillage machine disclosed in the invention has the advantages of a simple structure, small routine maintenance load, no need for extra power during operation and low operation cost.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

A New Meter Gauge AC Drive Diesel Locomotive

ActiveCN105151052BAdvanced technologyCompact and reasonableIC engine locomotivesGas turbine locomotivesExpansion tankCooling tower

The invention relates to a diesel locomotive, in particular to a novel meter-gauge AC transmission diesel locomotive. The diesel locomotive includes air conditioner, auxiliary transformer cabinet, radiator, expansion water tank, car body ventilator, diesel engine, muffler, air filter, main generator, resistance brake device, brake valve installation cabinet, electrical cabinet, Seats, consoles, main converter cabinets, cooling towers, sand boxes, fire extinguishers, fuel tanks, batteries, main air cylinders, ECM control boxes, bogies, couplers, obstacle removers, driver's cab 2, auxiliary rooms, cooling rooms , power room, motor room, electrical room, driver's cab and frame, the diesel locomotive has advanced technology, compact and reasonable structure, convenient and quick assembly, reliable connection, suitable for meter-gauge lines, and can adapt to various harsh weather environments. At the same time, the amount of daily maintenance is relatively small, and it is easy to use and promote.

Owner:CRRC QISHUYAN CO LTD

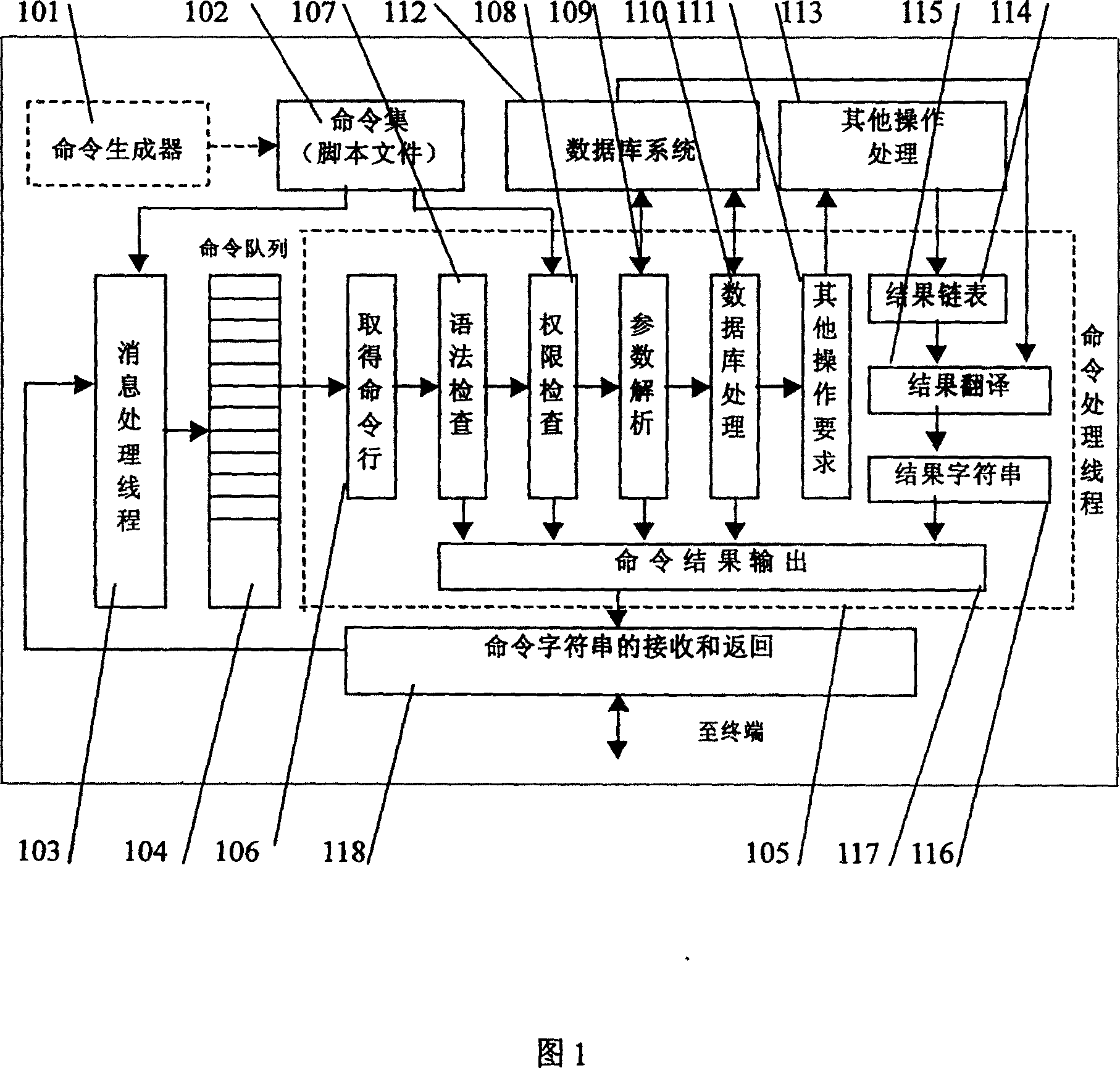

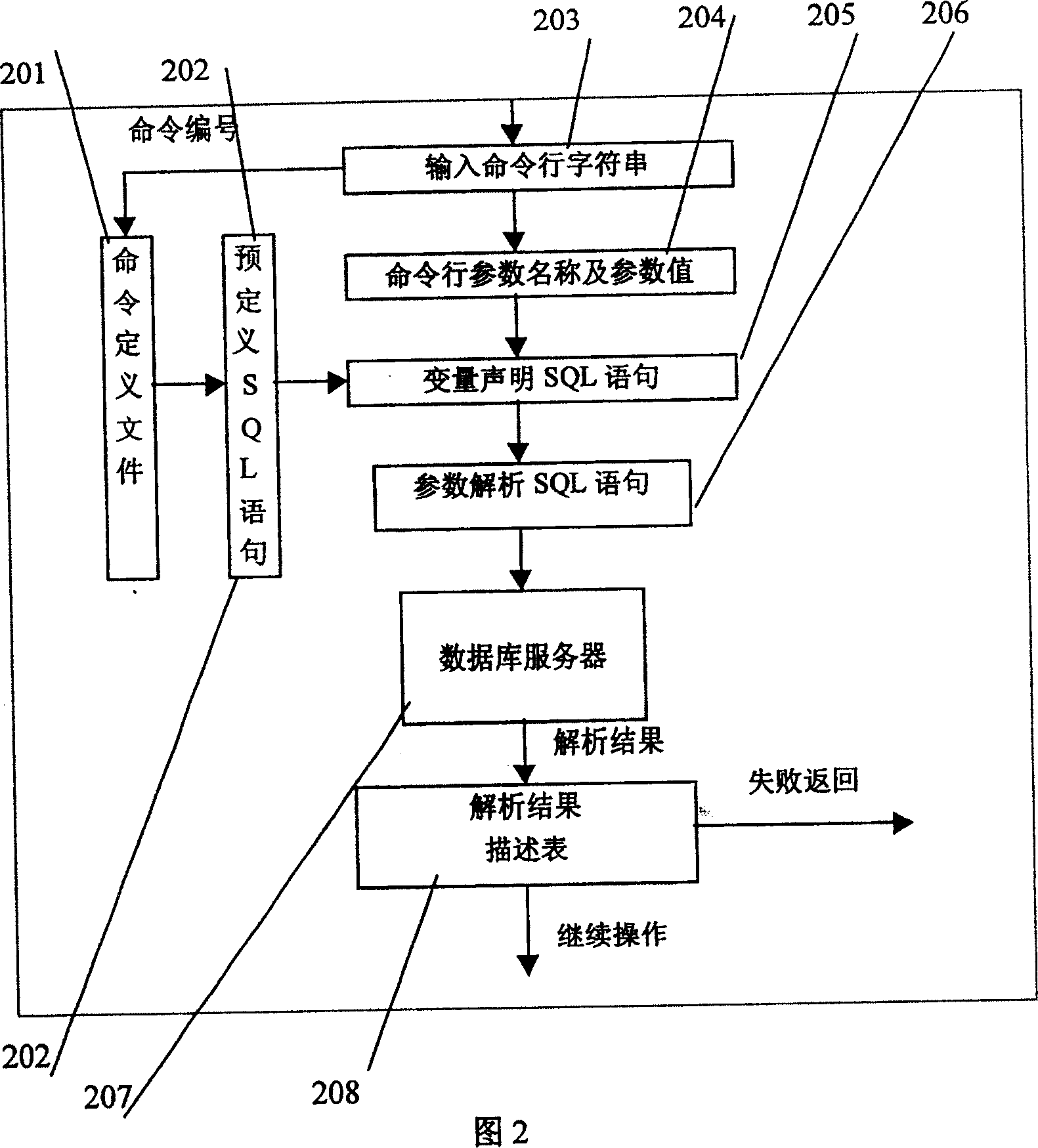

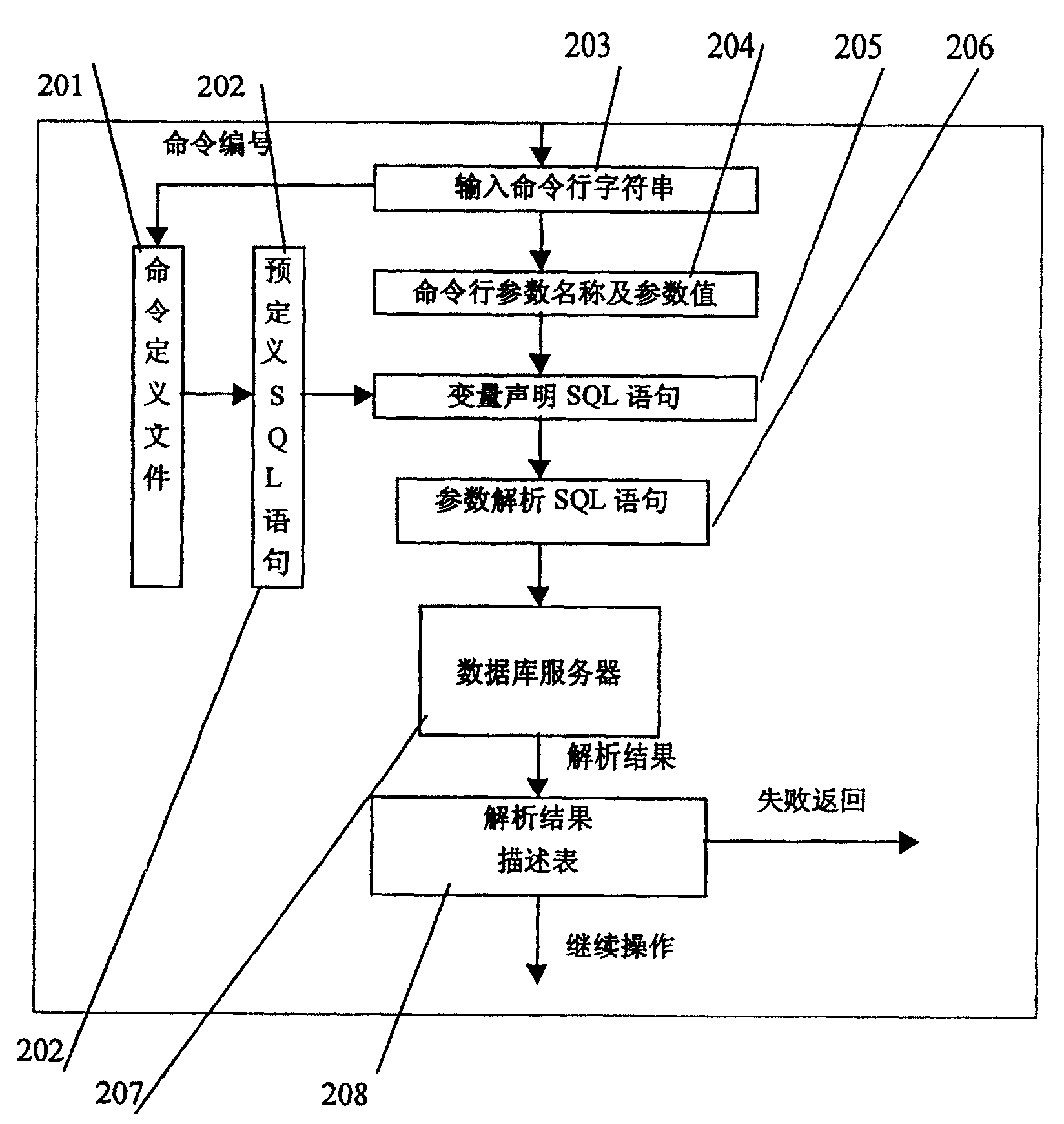

Implement method of the man machine command based on plain text command script files

InactiveCN1329818CImprove reusabilitySpeed up developmentProgram control using stored programsMemory systemsMan machineOperating system

The implementation of man-machine command based on pure text command script file includes command defining script, command creation and command execution and analysis. Specifically, it includes the command creator to create script file containing command set and to define the analysis mode of command parameters as one section of SQL statement stored in the script file; and to analyze the SQL statement of SQL script containing command parameters and to send the result to command executing module during command creation and analysis. So, the parameters analysis of any man-machine command may be defined in a text file completely and the development, maintenance and upgrading of the command is the increase and amendment of the text file in the same man-machine command executor and creator.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com