Blast-furnace gas pressure regulating process

A technology of pressure regulation and blast furnace gas, which is applied in blast furnace details, blast furnaces, furnaces, etc., can solve the problems of large noise and vibration of the airflow impacting the valve plate, affecting the normal production of the blast furnace, and unstable equipment operation, so as to achieve stable equipment operation and equipment The operation is simple and reliable, and the effect of saving and creating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

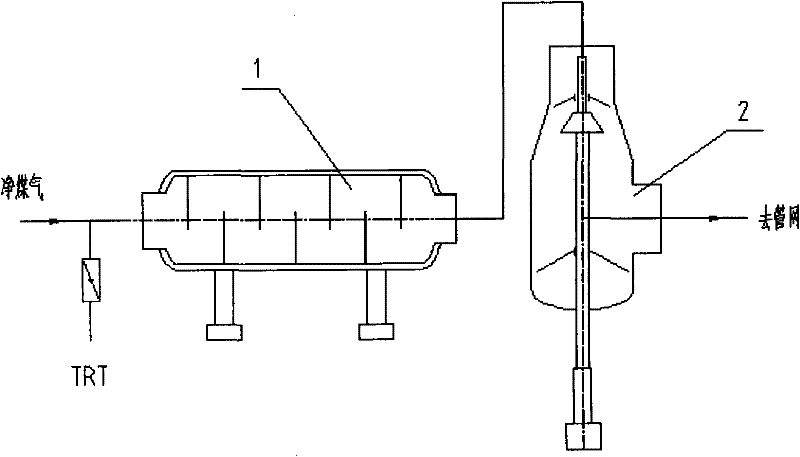

[0012] The present invention will be further described below in conjunction with accompanying drawing.

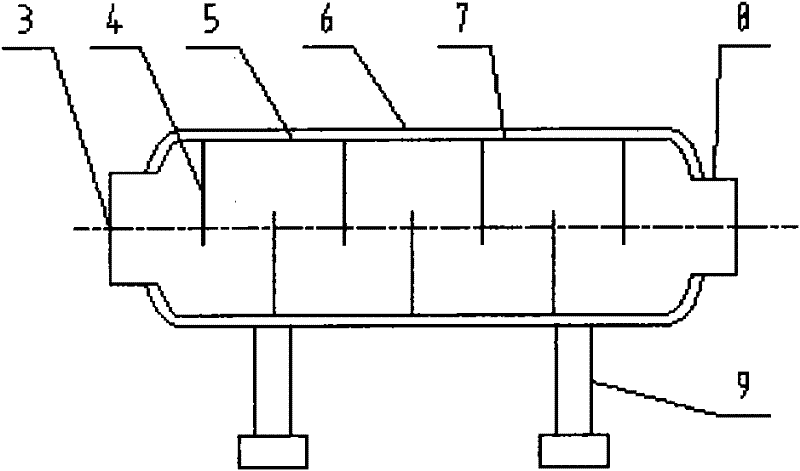

[0013] Such as Figure 1~3 As shown, the blast furnace gas pressure regulation process is mainly composed of pipelines and pressure reducer groups. The main clean gas pipeline is connected to the inlet of the first-stage pressure reducer 1, and the outlet of the first-stage pressure reducer is connected to the second-stage pressure reducer 2 through the pipeline. The inlets are connected, and the outlet of the second-stage pressure reducer is connected to the gas pipeline network through pipelines.

[0014] The first stage pressure reducer is a clapboard type, mainly composed of an inlet pipe 3, an outlet pipe 8, an inner shell 5, an outer shell 6, and a clapboard 4, and the inner and outer shells are filled with sound-absorbing materials 7, and the clapboard pressure reducer consists of Bearing 9 bears the weight and is installed horizontally.

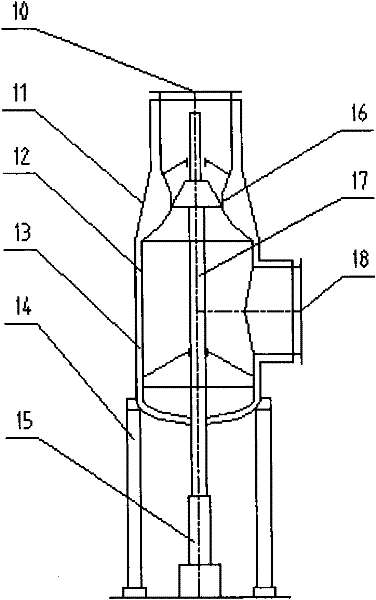

[0015] The second-stage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com