High-temperature air lighting system under bed for fluidized bed and circulating fluidized bed boiler

A circulating fluidized bed, high-temperature air technology, applied in fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve the problems that affect the conservation of petroleum resources, poor ignition safety, and large daily maintenance. , to achieve significant social benefits, easy ignition, and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

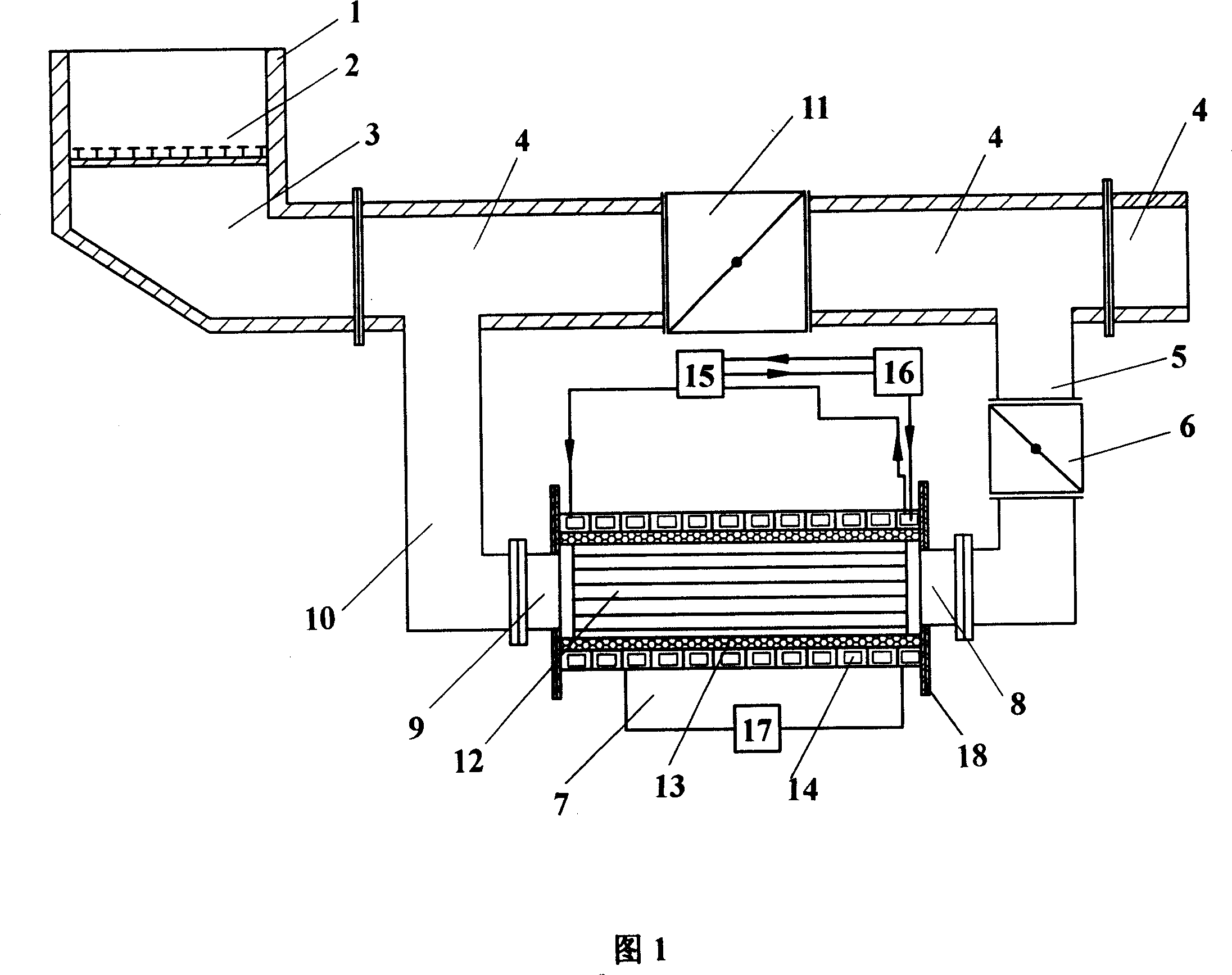

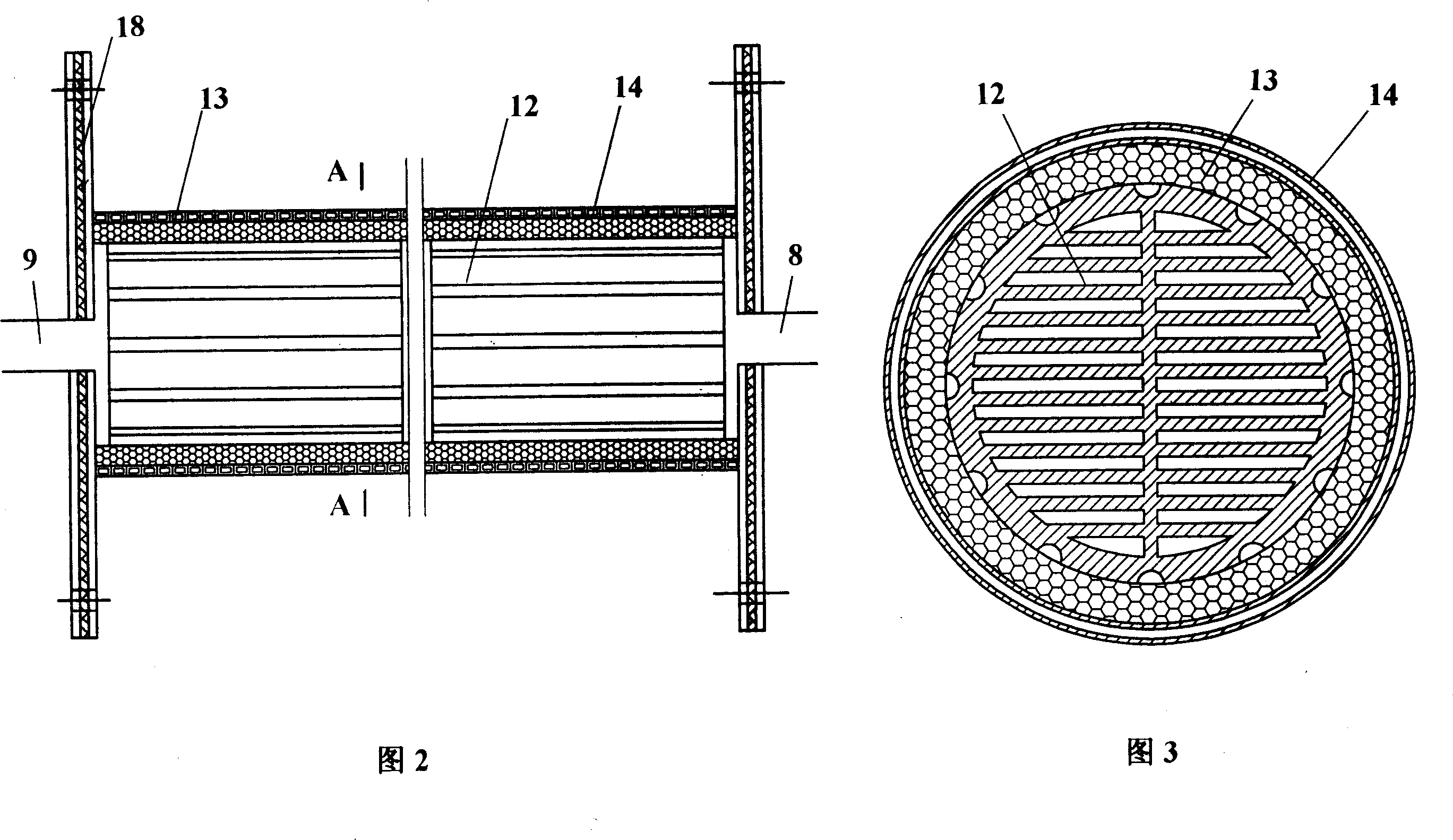

[0031] Referring to accompanying drawings 1, 2, and 3, the ignition system under the high-temperature air bed of the fluidized bed and circulating fluidized bed boiler is composed of a boiler main body 1, an air distribution plate 2, an air chamber 3, and a primary air duct 4. The air duct is connected with an ignition air duct 5, and the ignition air duct communicates with the air inlet 8 of the electromagnetic induction heater 7 through the ignition air valve 6, and the air outlet 9 of the electromagnetic induction heater communicates with the high-temperature ignition air duct 10, and the high-temperature ignition The air duct communicates with the primary air duct; a primary air valve 11 is connected to the primary air duct between the junction of the primary air duct and the ignition air duct and the junction of the primary air duct and the high-temperature ignition air duct .

[0032] The electromagnetic induction heater consists of a heating body 12 made of magnetically...

Embodiment 2

[0035] Example 2: Ignition system under high temperature air bed for 75t / h circulating fluidized bed boiler

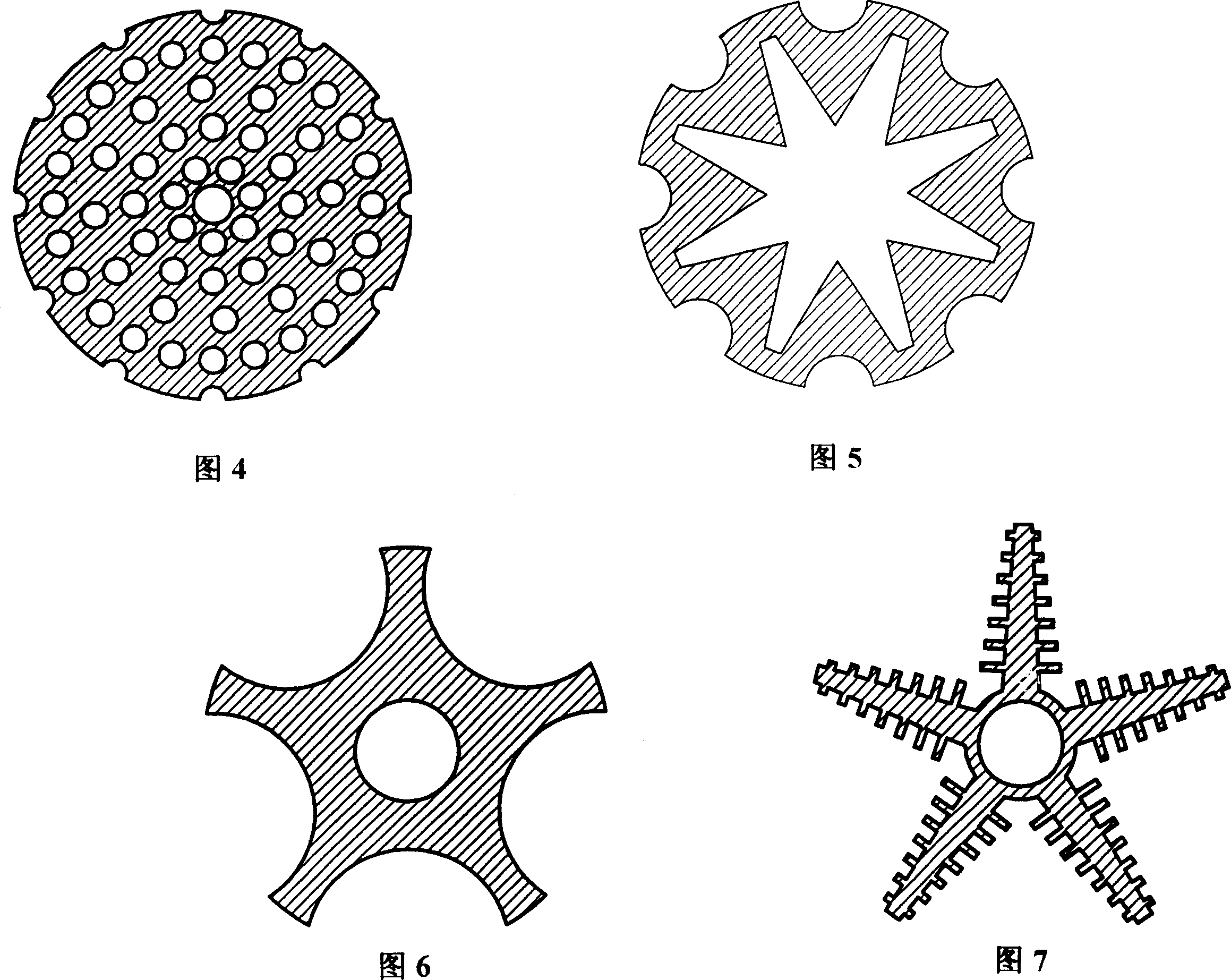

[0036] The overall structure of the ignition system under the high-temperature air bed of a 75t / h circulating fluidized bed boiler is the same as that of Example 1. In this example, the heating body of the electromagnetic induction heater is made of 3YC52 material with high temperature resistance, oxidation resistance and good magnetic conductivity. Its cross-sectional shape is the clapboard shape shown in Figure 3; the heating body is 1.8m long, 0.5m in diameter, and has 13 built-in clapboards; the insulation layer adopts a high-strength non-magnetic ceramic tube; the power circuit uses a 250kw / 1000HZ intermediate frequency SCR adjustable power supply. Two electromagnetic induction heaters are arranged in parallel in the system.

Embodiment 3

[0037] Example 3: Ignition system under high temperature air bed for 220t / h circulating fluidized bed boiler

[0038]The overall structure of the ignition system under the high-temperature air bed of a 220t / h circulating fluidized bed boiler is the same as that of Example 1. In this example, the heating body of the electromagnetic induction heater is Ni-Fe-Cr- It is made of Al-based superalloy material, and its cross-sectional shape is the round-hole honeycomb shape shown in Figure 4; the heating body is 1.8m long and 0.5m in diameter, and there are 56 holes with a diameter of 20mm in total, and 24 holes are opened on the edge of the heating body. A semicircular hole with a diameter of 20mm; the insulation layer adopts a high-strength non-magnetic and high-temperature resistant furnace lining; the power circuit uses a 600kw / 1000HZ IGBT intermediate frequency power adjustable power supply. Four electromagnetic induction heaters are arranged in parallel in the system.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com