High-precision constant-current dilution time-sharing synchronous partition type CO measuring system for flue of coal-fired power plant

A technology of coal-fired power plants and measurement systems, which is applied in the direction of measuring devices, analysis materials, and cleaning methods using gas flow, etc., can solve problems such as uneven distribution, severe fluctuations in CO concentration, and measurement errors, so as to prevent surface ash from clogging, The effect of saving resources and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

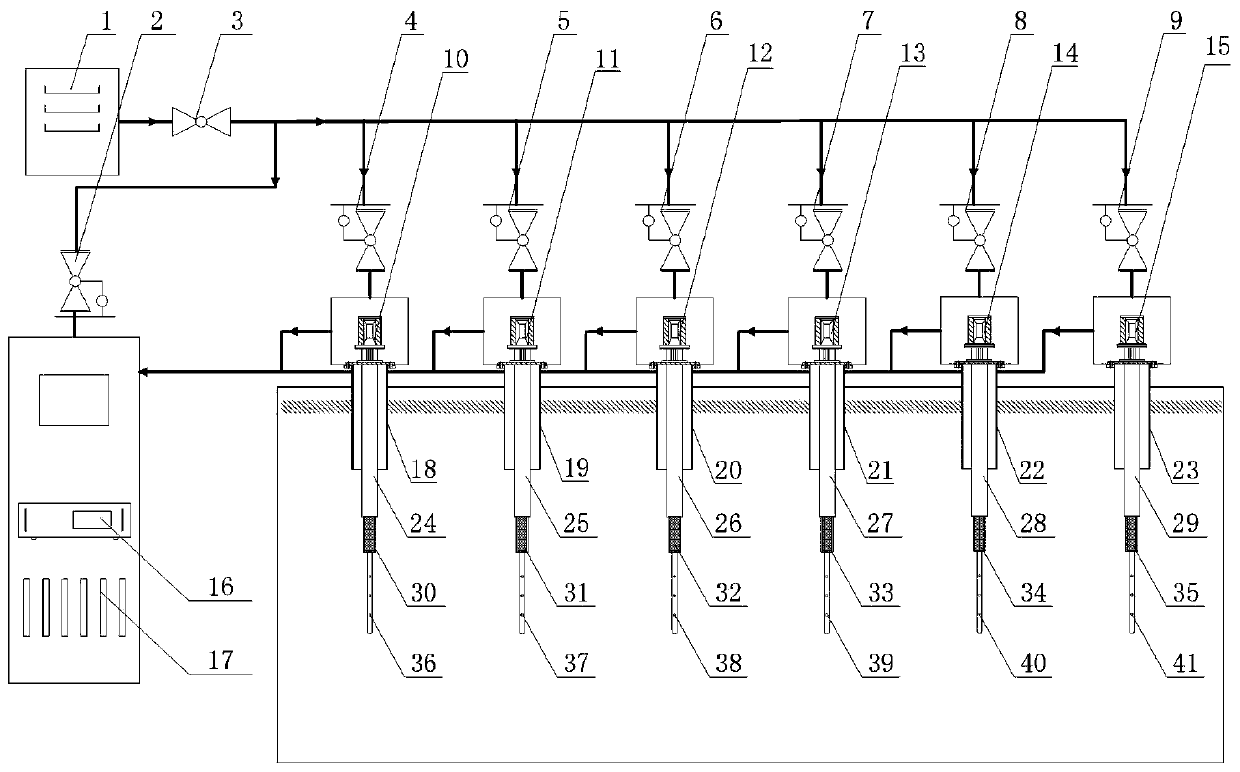

[0035]In this embodiment, the number of the partition pressure regulating valves, high-precision constant flow dilution devices and partition sampling devices are all six, and the partition pressure regulating valves are respectively the first partition pressure regulating valve 4 and the second partition pressure regulating valve. Pressure regulating valve 5, pressure regulating valve 6 for the third zone, pressure regulating valve 7 for the fourth zone, pressure regulating valve 8 for the fifth zone, and pressure regulating valve 9 for the sixth zone; A high precision constant current dilution device 10, a second high precision constant current dilution device 11, a third high precision constant current dilution device 12, a fourth high precision constant current dilution device 13, a fifth high precision constant current dilution device 14 and a Six high-precision constant current dilution devices 15; the partition sampling devices are respectively the first partition sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com