Intelligent steelmaking system based on converter fume and gas analysis technology

A technology for flue gas analysis and converter flue gas is applied in the field of iron and steel metallurgy, which can solve the problems of reducing oxygen supply intensity, high equipment investment cost, and wide application, and achieves the effect of improving quality, output and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

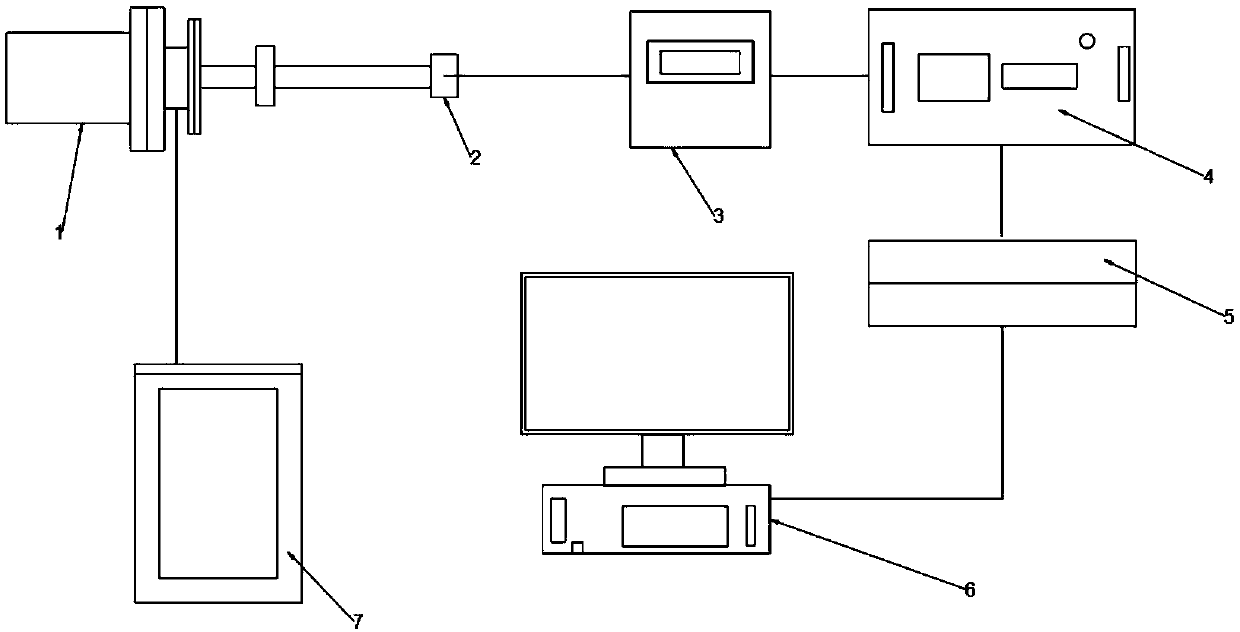

[0091] see figure 1 , In an embodiment of the present invention, a flue gas analysis professional detection instrument is used to assist the dynamic control of a computer model, and the flue gas analysis professional detection instrument includes a flue gas analysis gas analyzer and a converter audio slag monitoring system.

[0092] Further, the flue gas analysis gas analyzer adopts the laser analysis method, the core original components are imported products, the laser is imported from Germany, and the electronic components are imported from Japan to ensure the accuracy, accuracy and stability of the laser measurement data, which is used for continuous measurement of flue gas Composition detection of CO and CO2 in the medium.

[0093] Install detection equipment at the furnace mouth of the converter, the converter audio slag monitoring system, through the detection equipment installed at the furnace mouth, collect the audio signal of oxygen lance blowing to judge the slag sit...

Embodiment 2

[0097] The intelligent steelmaking system based on the converter flue gas analysis technology of the flue gas analysis professional detection instrument described in Example 1 has two analysis methods: laser and infrared, including equipment installation modules and basic automation modules, as well as process automation modules and equipment. Monitoring and control module, data collection report generation module and mathematical model establishment, learning and command issuing module, the equipment installation module, basic automation module, process automation module, equipment monitoring and control module, data collection report generation module and mathematical model The building, learning and command issuing modules are connected in sequence.

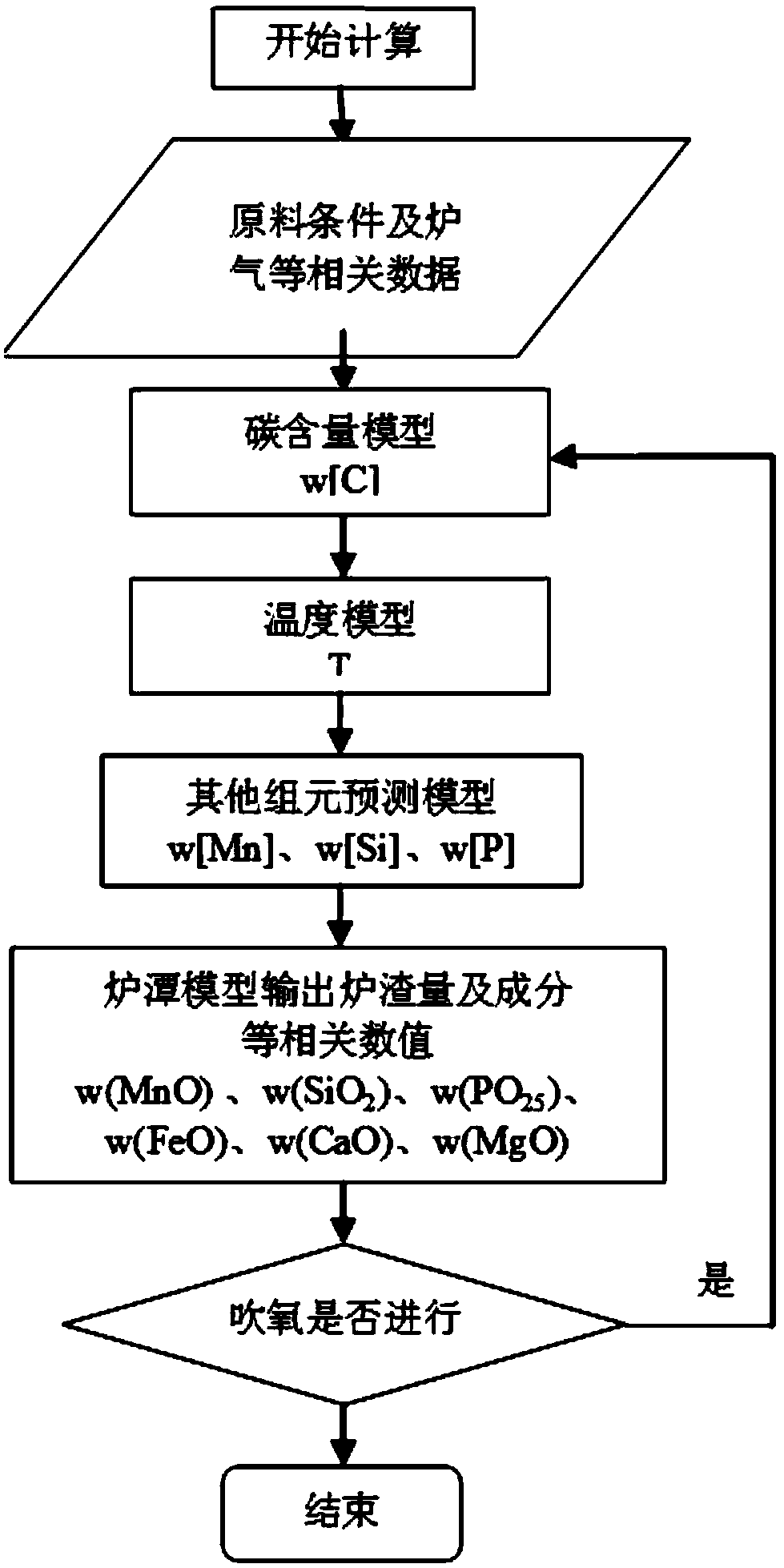

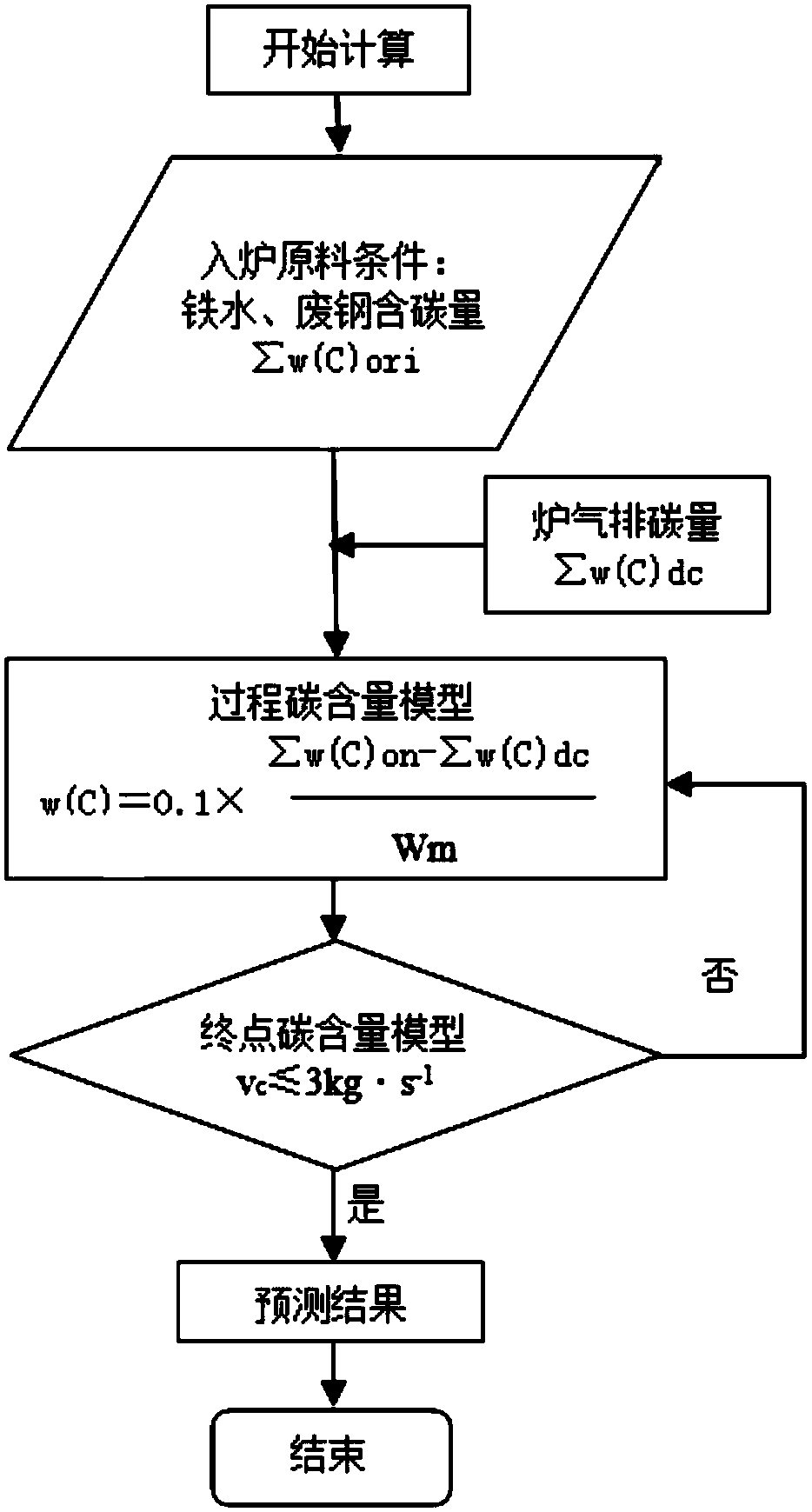

[0098] The main program of the intelligent steelmaking system of converter flue gas analysis technology is as follows:

[0099] Collect and input the initial parameters in advance, calculate the initial temperature and quality...

Embodiment 3

[0126] The implementation method of the intelligent steelmaking system of converter flue gas analysis technology, the specific steps are as follows:

[0127] S1. In order to ensure that the data information provided by the first-level automation system is true, accurate and reliable, the software system of intelligent steelmaking involves other logistics networks and chemical analysis data of the steelmaking plant (first steelmaking) (spectral analysis of the furnace laboratory, molten iron C , S analysis of chemical analysis data) on-site temperature meter data collection, crane electronic scale manufacturer equipment and communication output interface, and the existing primary and secondary communication network lines, power lines and grounding lines are connected to the communication network output interface;

[0128] S2. Use the maintenance time to complete the calibration work of the electronic scale of the trolley for molten iron entering the furnace and the electronic ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com