Oil-free directly-ignited burner for induced heating coal powder boiler

An ignition burner and induction heating technology, applied in the field of pulverized coal boilers, can solve the problems of large maintenance workload of fuel oil system, reduce power generation economy, increase power generation cost, etc., achieve small daily maintenance, reduce ignition power consumption, operation stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The utility model relates to an induction heating oil-free direct ignition burner for a pulverized coal boiler, which has a power supply system, a cooling water system and an igniter body.

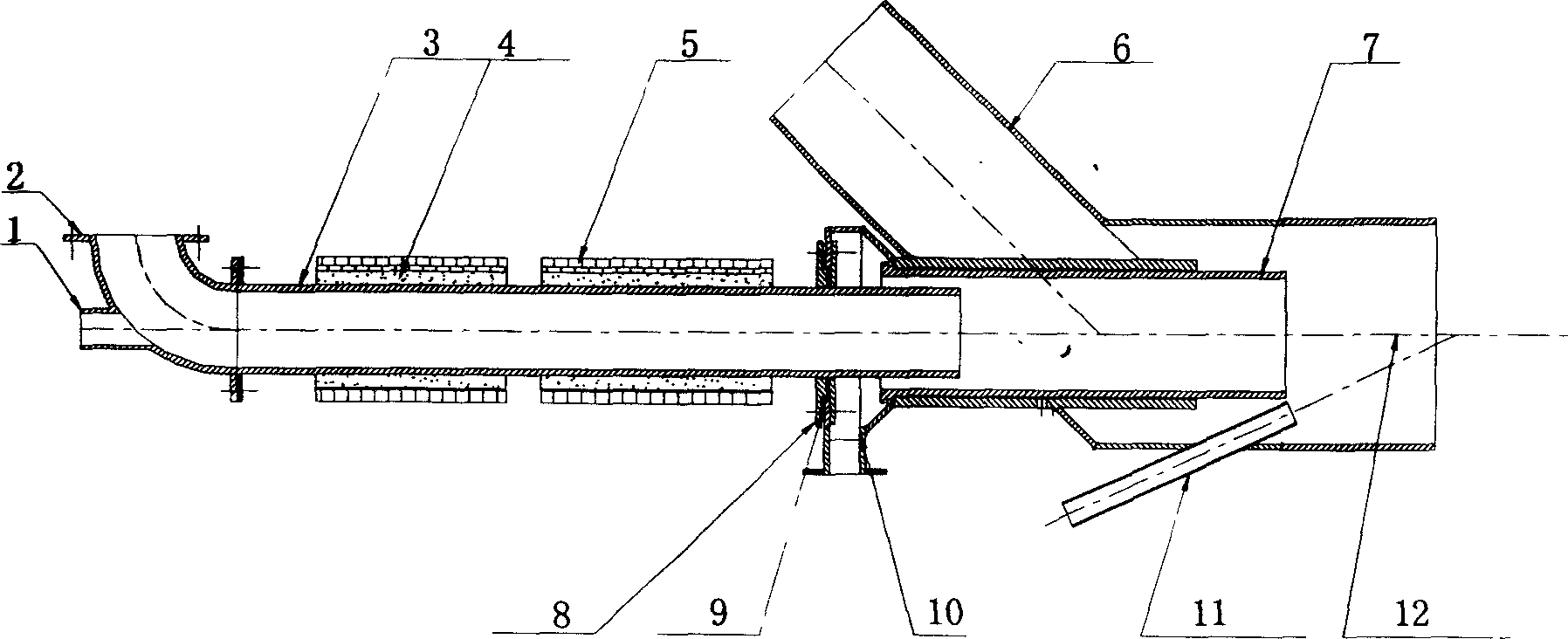

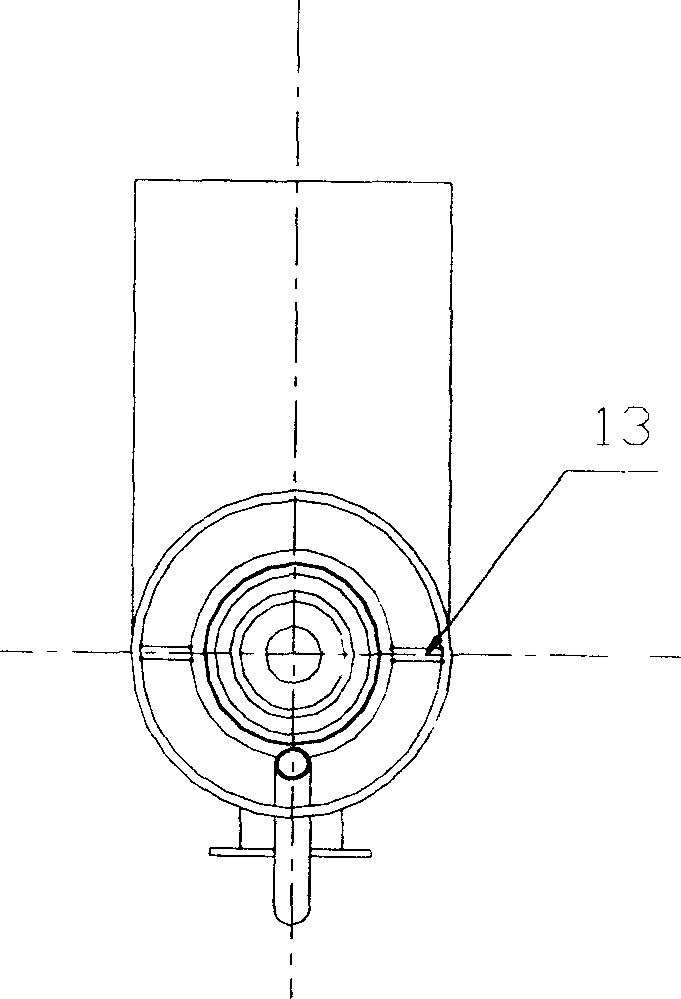

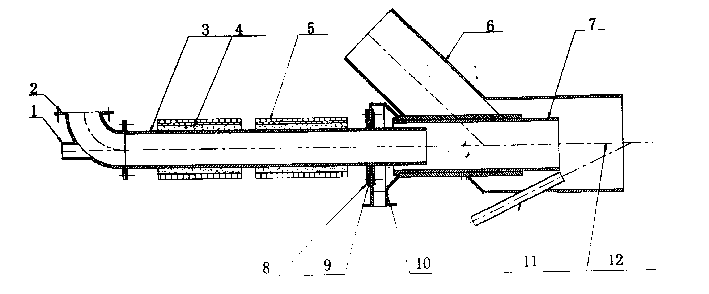

[0020] like figure 1 As shown, the igniter body has a primary igniter and a secondary igniter, and the primary igniter has a pulverized coal inlet 2 with an observation hole 1 and a metal induction tube 3 in turn. Layer 4, an inductor 5 is provided on the outer side of the insulation layer, a sealing flange 8 and an annular air chamber 10 are arranged outside the outlet of the metal induction tube 5, a sealing material 9 is provided between the flanges 8, and a stable combustion chamber is provided at the outlet of the annular air chamber 10 Chamber 7, the igniter secondary has secondary pulverized coal inlet 6, fire viewing hole 11, secondary ignition chamber 12 in turn, and a diversion partition 13 is provided between the secondary ignition chamber 12 and the stable combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com