Acoustic technology based furnace box temperature online monitoring system

A furnace temperature and monitoring system technology, applied in lighting and heating equipment, combustion control and other directions, can solve the problems of harsh measurement environment, high cost, low plane resolution, etc., to achieve no aging phenomenon, high accuracy, measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

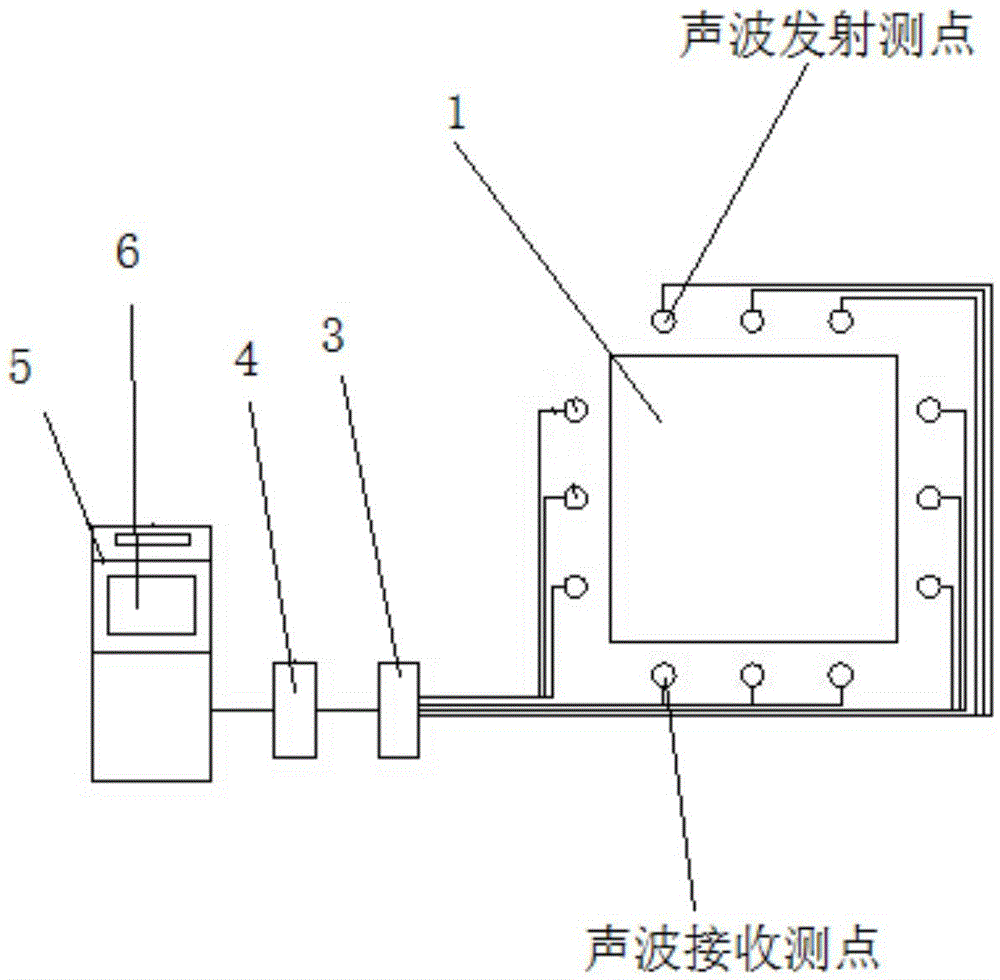

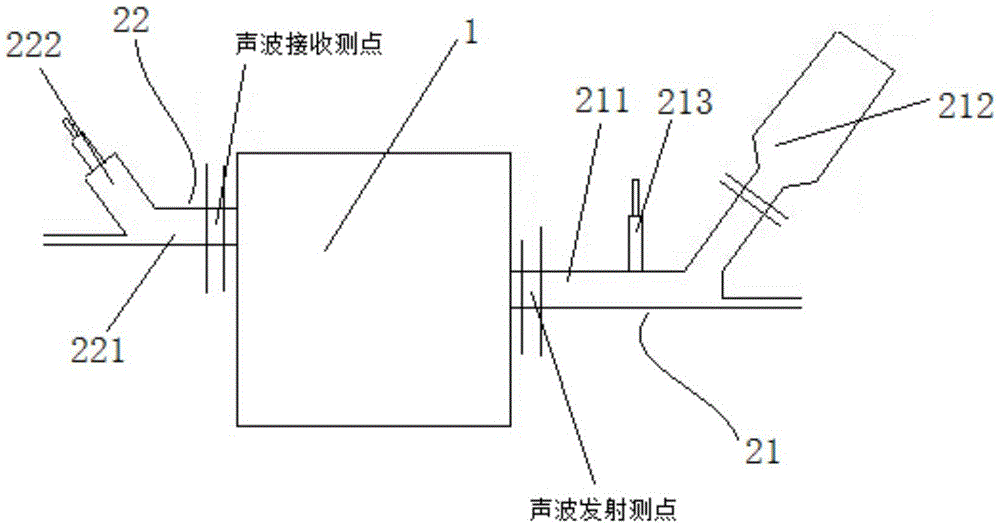

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] This example is attached figure 1 And attached figure 2 as shown,

[0025] A furnace temperature online monitoring system based on acoustic technology, which includes:

[0026] Hearth 1;

[0027] A temperature detection device, the temperature detection device is arranged in the furnace 1, the temperature detection device includes a sound wave generating device 21 and a sound wave receiving device 22, and the sound wave generating device is used to send a sound wave temperature detection signal for detecting the furnace chamber 1, the acoustic wave receiving device 22 is used to receive the acoustic wave temperature detection signal sent by the acoustic wave generating device 21;

[0028] The signal is transferred into the processor 3, which is used to convert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com