Method for preparing expanded graphite/silicon carbon material from graphite negative electrode of waste battery

A technology of expanded graphite and silicon carbon materials, applied in the field of lithium ion batteries, can solve the problems of structural damage, reversible capacity of silicon anode materials, poor cycle stability and rate performance, active material shedding, etc., to reduce shedding and improve mechanical strength. and toughness, the effect of environmental protection in the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

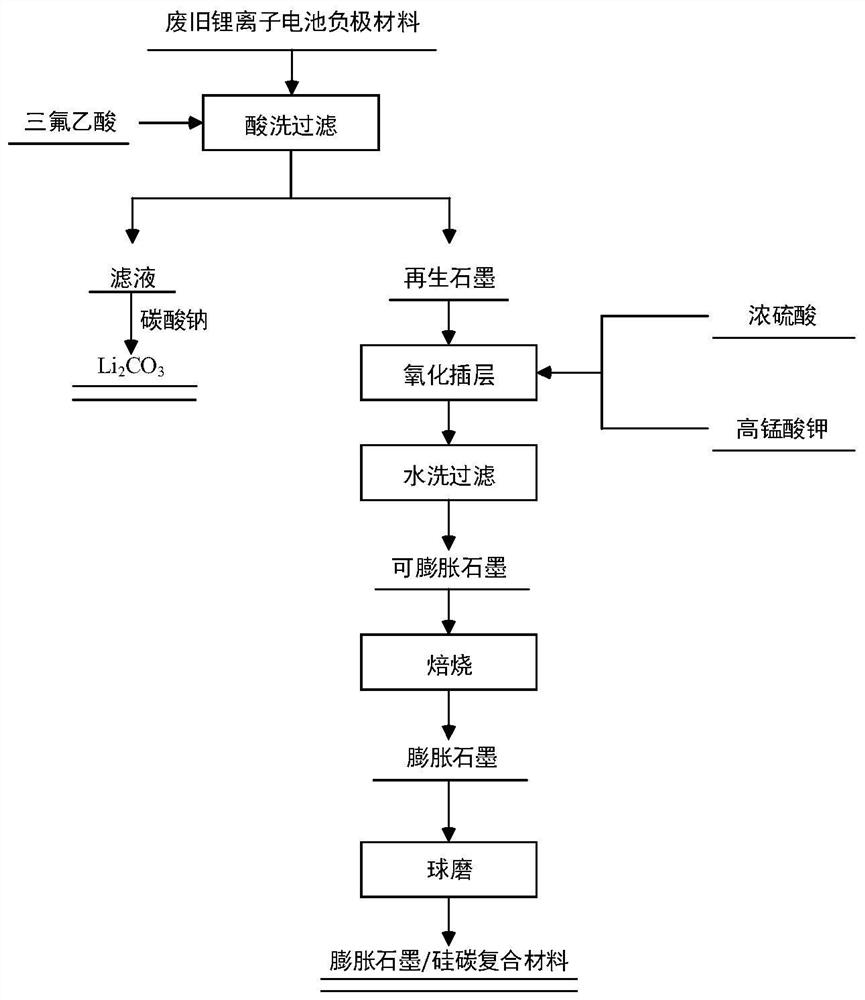

[0040] This embodiment includes the following steps:

[0041] (1) Pickling the graphite negative electrode of the waste lithium-ion battery at 40°C with a solid-to-liquid ratio of 1:80g / mL in sulfuric acid with a mass fraction of 2mol / L for 30min, filtering and drying to obtain a high-purity regenerated graphite material;

[0042] (2) Gained regenerated graphite material is placed in the mixed solution of oxidant and intercalant to react, graphite (g): intercalant (mL): oxidant (g)=1:10:0.3, wherein intercalant is Concentrated nitric acid and concentrated phosphoric acid, the volume ratio is 1:3, the oxidizing agent is potassium permanganate, stirred and reacted for 60 minutes, after the reaction is completed, washed with water until neutral, filtered, and dried to obtain expandable graphite;

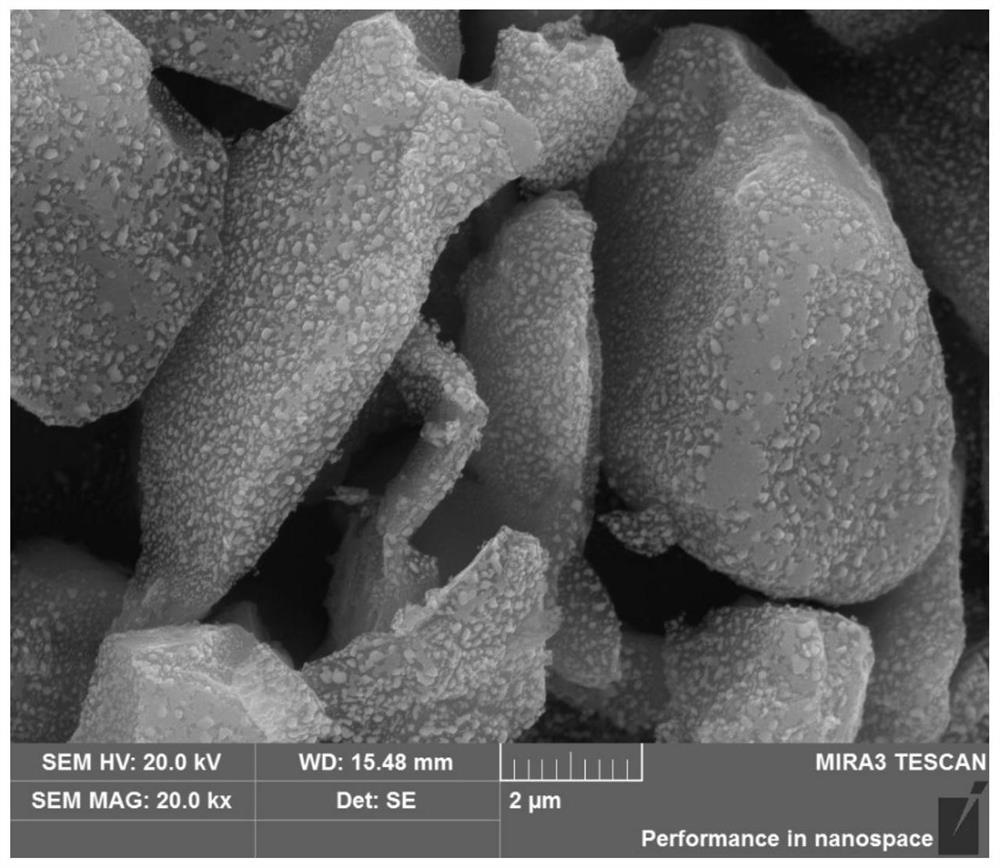

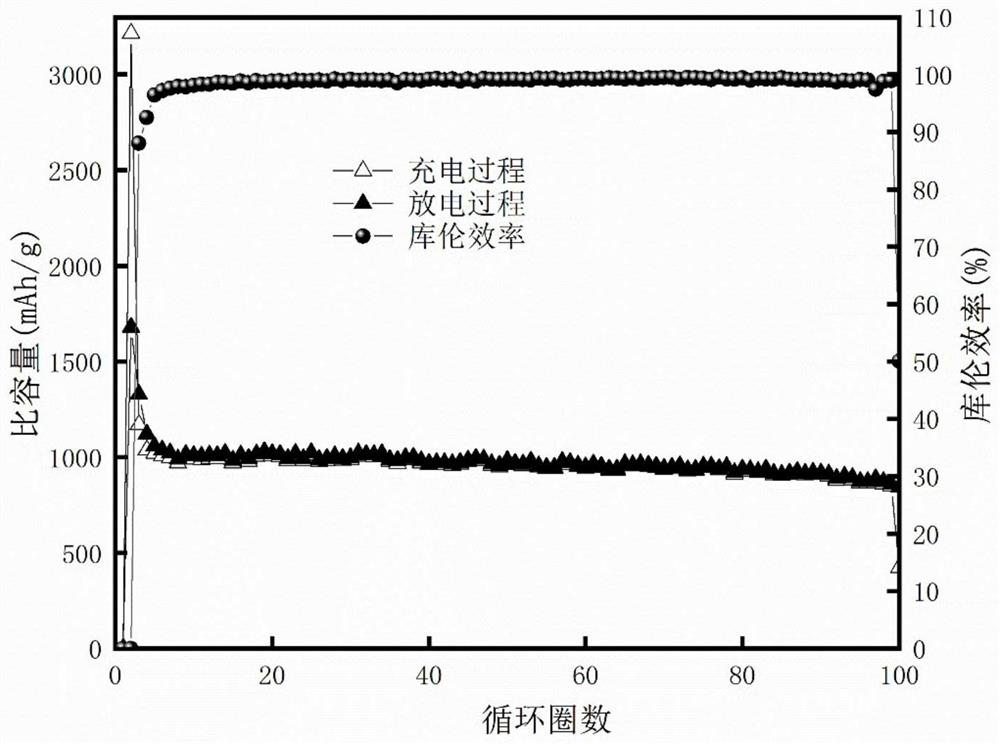

[0043] (3) Put the obtained expandable graphite in a muffle furnace and roast at 900°C for 1 min to obtain expanded graphite; then the mass ratio of expanded graphite to silicon carbon ...

Embodiment 2

[0046] (1) Pickling the graphite negative electrode of the waste lithium-ion battery in 3mol / L trifluoroacetic acid at 40°C with a solid-to-liquid ratio of 1:80 for 30min, filtering and drying to obtain a high-purity regenerated graphite material;

[0047] (2) Gained regenerated graphite material is placed in the mixed solution of oxidizing agent and intercalating agent to react, graphite (g): intercalating agent (mL): oxidizing agent (g)=1:20:5, wherein intercalating agent is Concentrated sulfuric acid and concentrated phosphoric acid, the volume ratio is 1:3, the oxidant is potassium permanganate, stirred and reacted for 50 minutes, after the reaction is completed, washed with water until neutral, filtered, and dried to obtain expandable graphite;

[0048] (3) The obtained expandable graphite is placed in a muffle furnace and roasted at 1000°C for 30s to obtain expanded graphite; then the mass ratio of expanded graphite to silicon carbon material is 1:9, and the mass ratio of...

Embodiment 3

[0051] (1) Pickling the graphite negative electrode of the waste lithium-ion battery in 2mol / L trifluoroacetic acid at 40°C with a solid-to-liquid ratio of 1:80g / mL for 30min, filtering and drying to obtain a high-purity regenerated graphite material;

[0052] (2) Gained regenerated graphite material is placed in the mixed solution of oxidizing agent and intercalating agent to react, graphite (g): intercalating agent (mL): oxidizing agent (g)=1:10:0.5, wherein intercalating agent is Concentrated sulfuric acid, the oxidizing agent is potassium permanganate, stirred and reacted for 80 minutes, after the reaction was completed, washed with water until neutral, filtered, and dried to obtain expandable graphite;

[0053] (3) Put the obtained expandable graphite in a muffle furnace and roast at 1000°C for 30s to obtain expanded graphite; then, the mass ratio of expanded graphite and silicon carbon material is 2:8, and the mass ratio of ball milled bead powder is 20:1, and the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com