Sewage treatment system and treatment method in combination with membrane bioreactor and phosphorus recovery process

A membrane bioreactor, sewage treatment method technology, applied in biological water/sewage treatment, biological sludge treatment, water/sewage treatment, etc. use, enhance biodegradability, simple effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

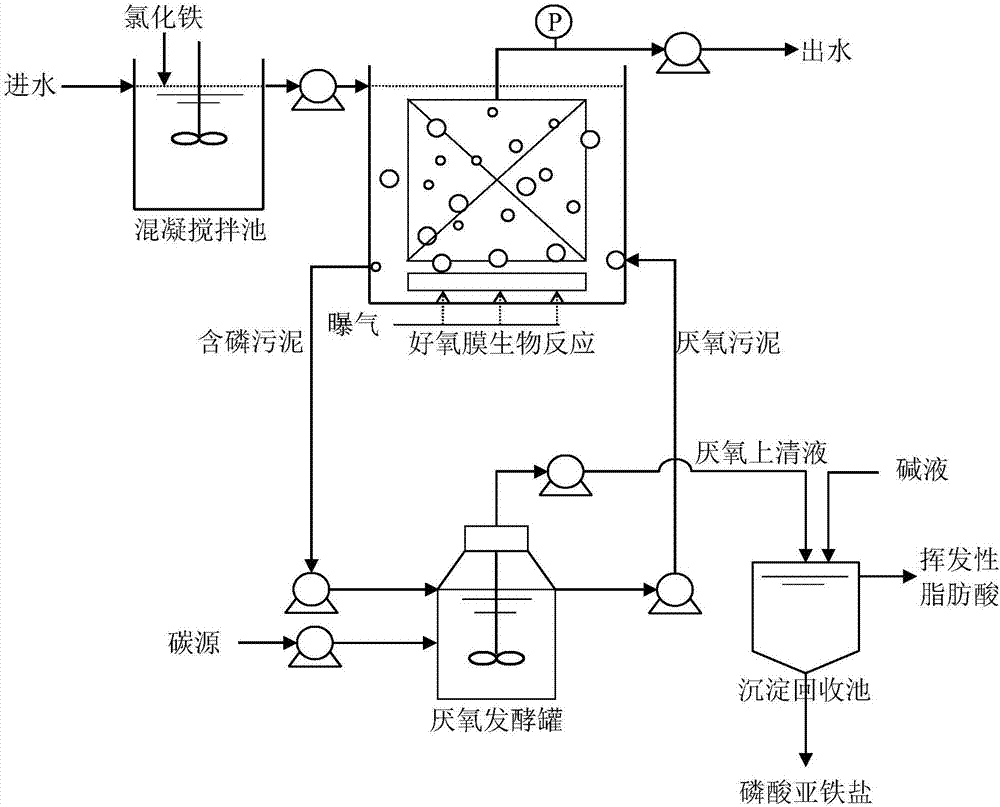

[0033] like figure 1 As shown, a sewage treatment system combining membrane bioreactor and phosphorus recovery process, including: coagulation tank, membrane bioreactor, anaerobic fermentation tank and sedimentation recovery tank, connected in sequence, wherein,

[0034] The coagulation tank and the membrane bioreactor are connected through the raw water pump and the pumping pipeline, and the bottom of the membrane bioreactor is equipped with an aeration head, which is connected to the external air flow meter and the air pump in turn through the air pipeline;

[0035] The membrane module is vertically submerged in the reactor, and is sequentially connected to the suction pressure gauge and the suction pump outside the reactor through the suction pipeline;

[0036] The membrane bioreactor and the anaerobic fermentation tank are connected by two channels: one channel includes the pumping pipeline and the sludge pump for pumping the phosphorus-containing sludge in the membrane bi...

Embodiment 2

[0039] Adopt the sewage treatment method that a kind of membrane bioreactor of the treatment system of embodiment 1 combines with phosphorus recovery process, comprise:

[0040] (1) Municipal sewage is pumped into the coagulation tank and mixed with ferric chloride, and stirred rapidly (speed>200RPM) to form flocs and ferric phosphate co-precipitates. The hydraulic retention time of the coagulation tank is 1-2 minutes.

[0041] (2) The mixed liquid in the coagulation tank is pumped into the membrane bioreactor. Membrane bioreactors are inoculated with activated sludge (4-5g / L) to degrade pollutants in sewage. After being filtered by the membrane module, the co-precipitated ferric phosphate is trapped in the membrane bioreactor and mixed with activated sludge to form phosphorus-containing sludge. The treated water is pumped out by the suction pump through membrane separation technology. Water flow control to 0.4 ~ 0.5m3 / m 2 -d. The hydraulic retention time of the reactor ...

Embodiment 3

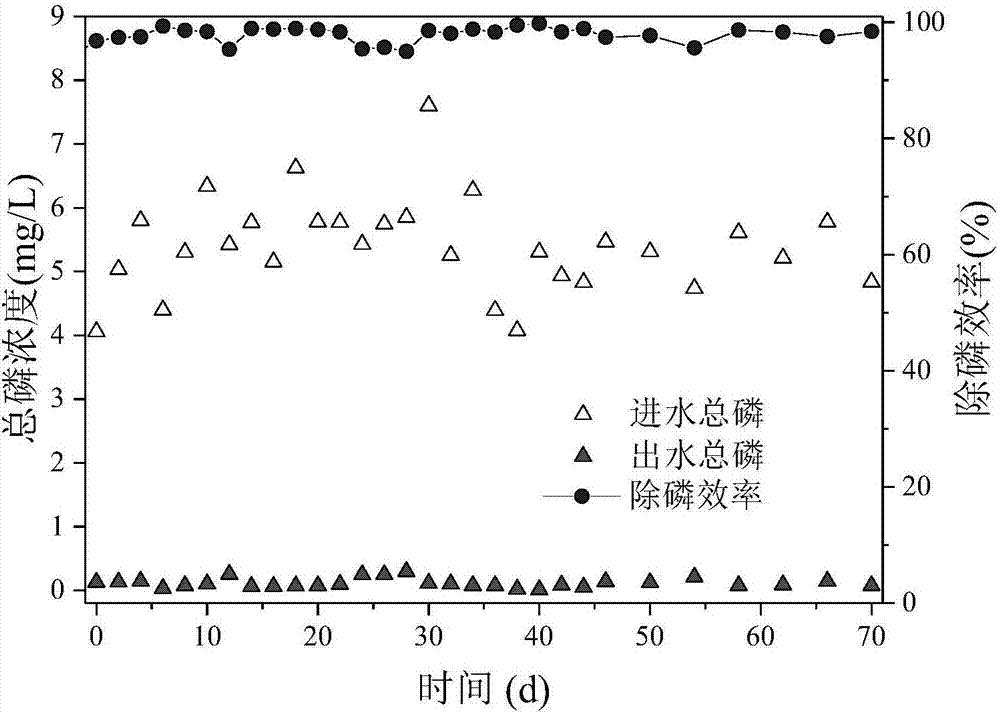

[0044] Embodiment 3: periodic operation membrane bioreactor and phosphorus recovery system

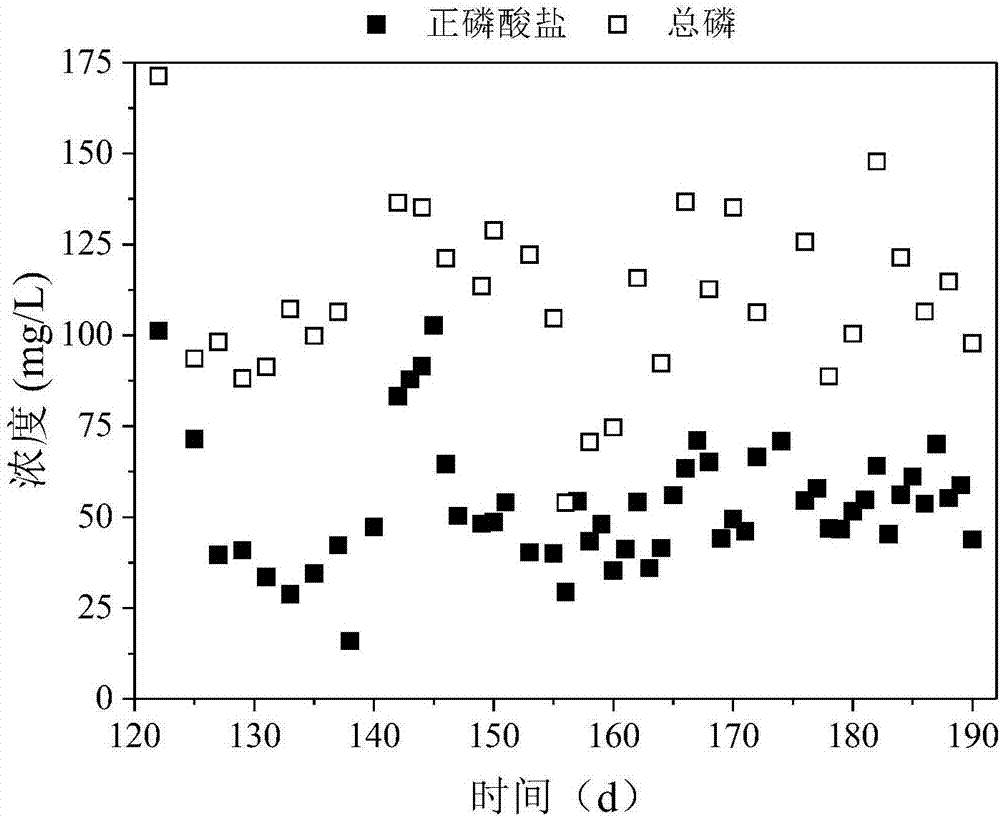

[0045] Using the scheme of Example 2, the reactor continued to operate for 70 days, and the removal and recovery effects of phosphorus in municipal sewage were observed. The hydraulic retention time of the membrane bioreactor is 12 hours, the sludge retention time is 30 days, and the effluent flux is controlled to 0.42m 3 / m 2 -d. Add kitchen waste as a carbon source, and the dosage is 2g / L. The result is as figure 2 and image 3 shown. The total phosphorus concentration in the influent is about 5.40mg / L. The total phosphorus concentration in the effluent is about 0.11mg / L. 97.9% of the total phosphorus in the sewage is trapped in the membrane bioreactor and mixed with the activated sludge to form phosphorus-containing sludge. The total phosphorus concentration of the sludge reaches 101mg / L. Through anaerobic fermentation, the pH of the solution is reduced to 4.5-5.0, and an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com