Fluid leaking and filling system

A fluid and oil injection device technology, used in engine components, engine lubrication, lubricating oil control valves, etc., can solve problems such as hidden safety hazards, unenvironmental protection, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

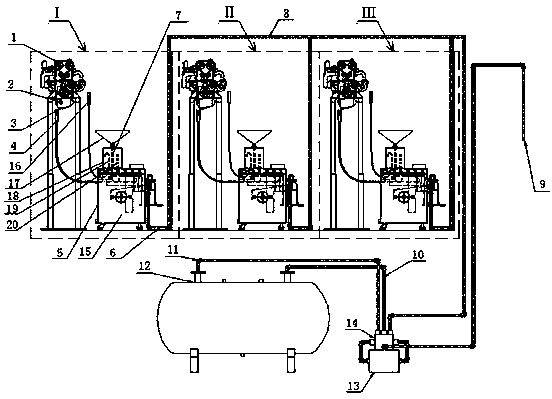

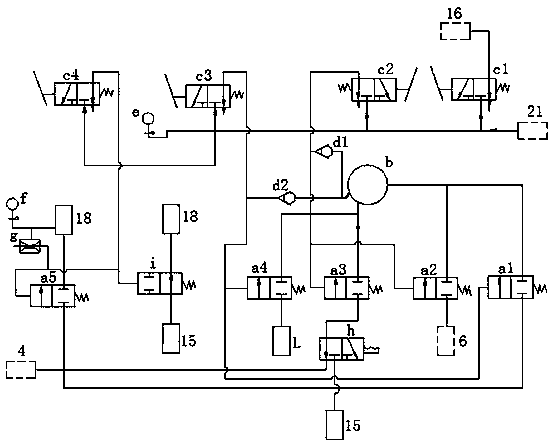

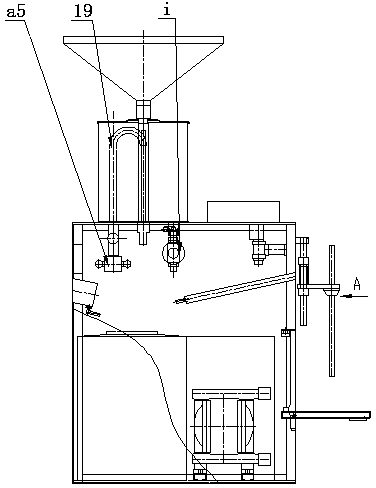

[0019] Such as figure 1 As shown, the fluid discharge system includes multiple working units Ⅰ, Ⅱ, and Ⅲ, and a waste oil recovery system connected to the working units Ⅰ, Ⅱ, and Ⅲ. , the host 5 is provided with a panel 22, an air gun 16, an oil gun 4, an oil pumping device, an oil filling device, a liquid metering device measuring cylinder 18, a waste engine oil pot 15, a funnel 17; the oil pumping device includes a waste oil pumping device and a waste cleaning Oil pumping device; the waste oil recovery system includes a waste oil storage tank 12, a waste oil recovery oil pump 13, and a valve station control system 14; wherein the oil gun 4 is connected with the oil pumping device and the oil injection device; The air gun 16, the oil extraction device and the oil injection device are all connected to the pressure gas source 21, the measuring cylinder 18 is connected to the waste engine oil oiler 15 through a pipeline, and the waste engine oil oiler 15 is recovered from the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com