A method for recovering re from re-containing superalloy waste

A technology of superalloy and scrap, applied in the field of recycling Re, can solve the problems of equipment damage and difficult to use effectively, and achieve the effect of short time required, good recovery effect and short required cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

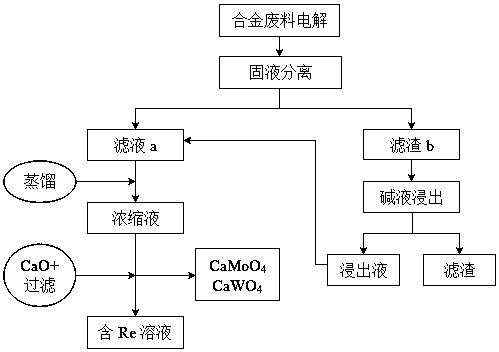

[0028] Step 1: Dissolve LiCl in a mixed solution of methanol and water (the volume ratio of methanol to water is 9:1), and use the mixed solution as the electrolyte to perform direct current electrolysis on the superalloy waste. During the electrolysis process, the superalloy waste is used as the anode , graphite is the cathode; Step 2: Filter and separate the obtained solution system to obtain filtrate a and filter residue b; Step 3: Use ammonia water with pH=11 to leach the filter residue b, heat and stir at the same time, and filter after half an hour , obtain the leach solution of filter residue b, repeat the leaching process for three times like this, the leaching rate of rhenium in the filter residue after three leachings is 81.84%; Step 4: mix the leach solution of filter residue b with filtrate a, then heat and distill and concentrate to improve the Re, Concentration of W and Mo; Step 5: Add excess calcium oxide powder to the concentrated solution, stir and heat to 100°...

Embodiment 2

[0030] Step 1: Dissolve LiCl in a mixed solution of methanol and water (the volume ratio of methanol to water is 9:1), and use the mixed solution as the electrolyte to perform direct current electrolysis on the superalloy waste. During the electrolysis process, the superalloy waste is used as the anode , graphite is the cathode; step 2: filter and separate the obtained solution system to obtain filtrate a and filter residue b; step 3: use KOH solution with pH=10.8 to leach filter residue b, heat and stir at the same time, and carry out after half an hour Filtrate to obtain the leachate of filter residue b, repeat the leaching process three times, and the leaching rate of rhenium in the filter residue after three leachings is 61.99%; Step 4: Mix the leachate of filter residue b with filtrate a, then heat and distill and concentrate to increase the Re in the mixture. , W, and Mo concentrations; Step 5: Add excess calcium oxide powder to the concentrated solution, stir and react a...

Embodiment 3

[0032]Step 1: Dissolve LiCl in a mixed solution of methanol and water (the volume ratio of methanol to water is 9:1), and use the mixed solution as the electrolyte to perform direct current electrolysis on the superalloy waste. During the electrolysis process, the superalloy waste is used as the anode , graphite is the cathode; Step 2: Filter and separate the obtained solution system to obtain filtrate a and filter residue b; Step 3: Use KOH solution with pH=11.2, methanol and water volume ratio of 9:1 to filter residue b. , heated and stirred at the same time, and filtered after half an hour to obtain the leaching solution of filter residue b, so repeated leaching treatment three times, the leaching rate of rhenium in filter residue b after three leachings was 74.53%; Step 4: Mix the leaching solution of filter residue b with filtrate a , and then heated and distilled to concentrate to increase the concentration of Re, W, and Mo in the mixed solution; Step 5: Add excess calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com