Patents

Literature

30results about How to "Low stain resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat insulation coating

InactiveCN101348639AImprove physical performanceGood weather resistanceReflecting/signal paintsLatex particleCordierite

The invention relates to thermal insulating paint which comprises the following compositions and contents in mass portion: 10.0 to 18.0 portions of water, 0.3 to 1.0 portion of wetting-dispersing agent, 0.3 to 1.0 portion of propanediol, 0.05 to 0.2 portion of a disinfecting agent, 0 to 5.0 portions of French chalk, 2.0 to 10.0 portions of titanium pigment, 1.0 to 5.0 portions of aciform cordierite powder, 5.0 to 15.0 portions of hollow glass bead, 0.1 to 0.2 portion of defoamer, 25.0 to 35.0 portions of modified acrylic acid latex, 0.15 to 0.3 portion of thickening agent, 0.15 to 0.3 portion of a flow agent and 0.1 to 1.0 portion of pH adjusting agent, wherein the modified acrylic acid latex is elastic acrylic acid latex by modifying fluorosilcone monomers and is provided with a core-shell structure and has the silicon fluoride distributed on the surface layer of latex particles. The thermal insulating paint is particularly suitable for forming a decorative surface layer in an external thermal insulating system of an external wall.

Owner:CHINA NAT OFFSHORE OIL CORP +2

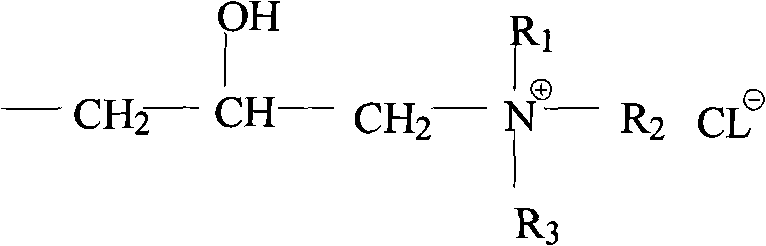

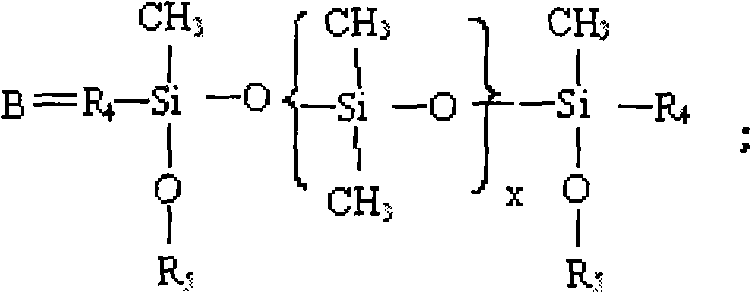

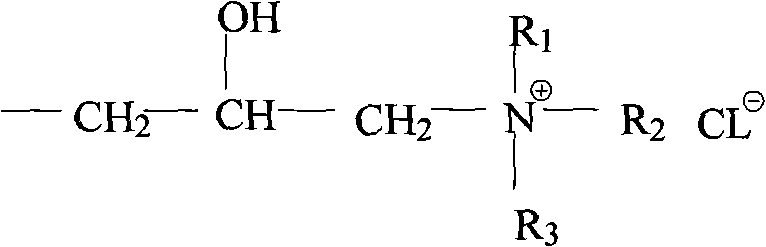

Quaternary amino cation modified polysiloxane softening agent and preparation method thereof

ActiveCN101565896AReduce hydrophobicityReduced antistatic propertiesFibre treatmentOrganic acidAminosilochrome

The invention relates to a quaternary amino cation modified polysiloxane softening agent and a preparation method thereof. The structural formula of the softening agent is A1BA2. The preparation method comprises the following steps: (1) mixing hydroxy silicone oil and silane coupling agent according to a molar ratio of 1:1-1:4, and carrying out reaction on the mixture for 4 to 24 hours at the temperature of between 25 and 105 DEG C to obtain an amino terminated siloxane intermediate; (2) carrying out reaction on the amino terminated siloxane intermediate and epoxy quaternary ammonium salt for 2 to 10 hours in a solvent under the protection of nitrogen during the whole reaction, and finally vacuumizing the mixture and removing partial solvent to obtain a sticky transparent modified polysiloxane product; and (3) diluting the modified polysiloxane product by water and organic acid to obtain transparent emulsion, and adding an emulsifying agent which is 5 to 10 percent of weight of the emulsion into the emulsion to obtain a product. Compared with the prior art, the softening agent has the advantages of good softness, fluffy feeling, hydrophilicity, extremely low yellowing property, and the like.

Owner:上海氟聚化学产品股份有限公司

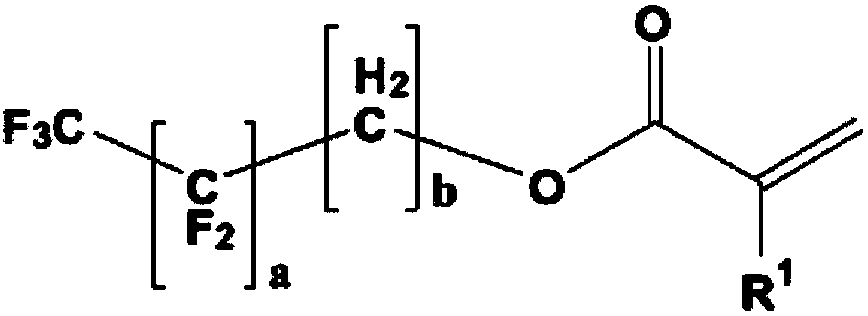

Preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy

InactiveCN102659995ALower surface energyLow water and oil repellencyPolyurea/polyurethane coatingsAcid valueBottle

The invention discloses a preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy. The preparation method comprises the following steps: (1), adding a (methyl) acrylate monomer, a monohydroxy (methyl) acrylate monomer, a fluorinated acrylate monomer and part of an initiator into a three-opening bottle, reacting for 3-5 hours at a temperature of 70-90 DEG C, supplementing the initiator, and further reacting for 1.5-3 hours; (2), adding polyisocyanate into another three-opening bottle, and reacting for 4-5 hours at a temperature of 30-50 DEG C; (3), dripping a reaction product in the step (2) into a reaction product in the step (1), and reacting for 10-12 hours; and (4), testing a reaction product in the step (3), determining the acid value, adding a salt-forming agent and deionized water in a certain ratio, shearing and removing the solvent. The ultraviolet-curable water-borne fluorinated paint combines performances of polyurethane and acrylate paint, is free of solvent emission, meets environment-friendly requirements, and is simple and feasible to spray and short in film-forming and curing time.

Owner:NANCHANG HANGKONG UNIVERSITY

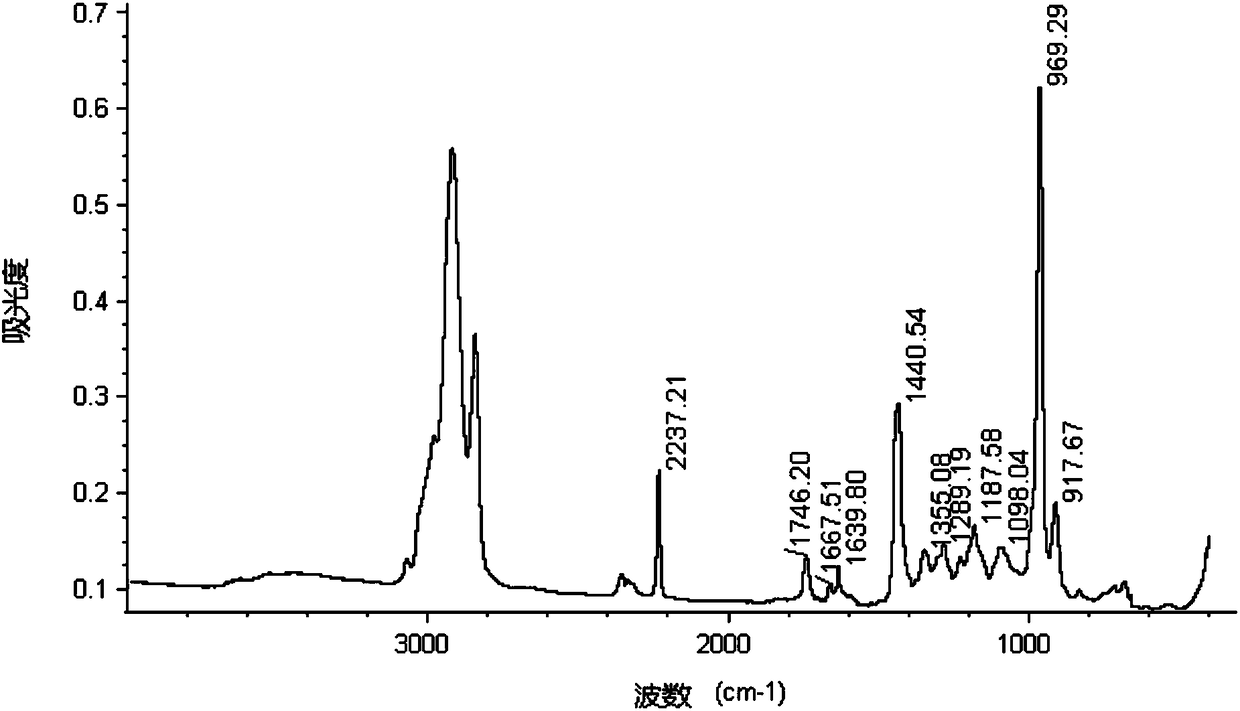

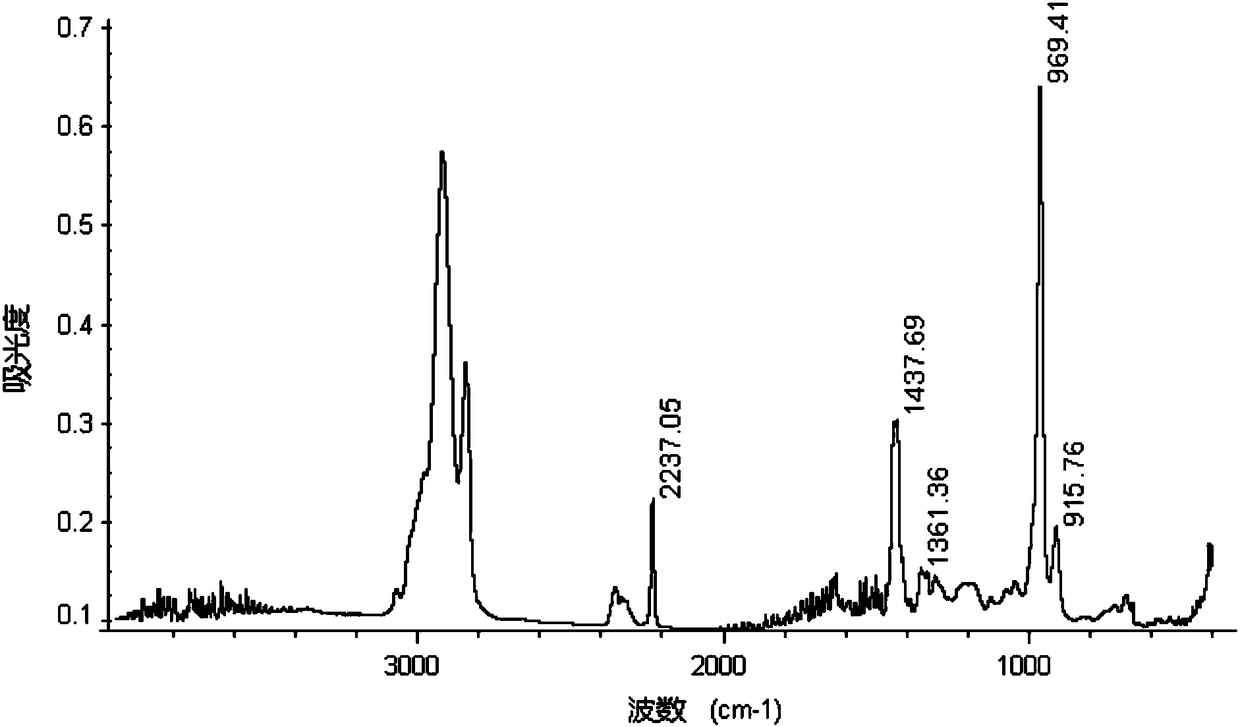

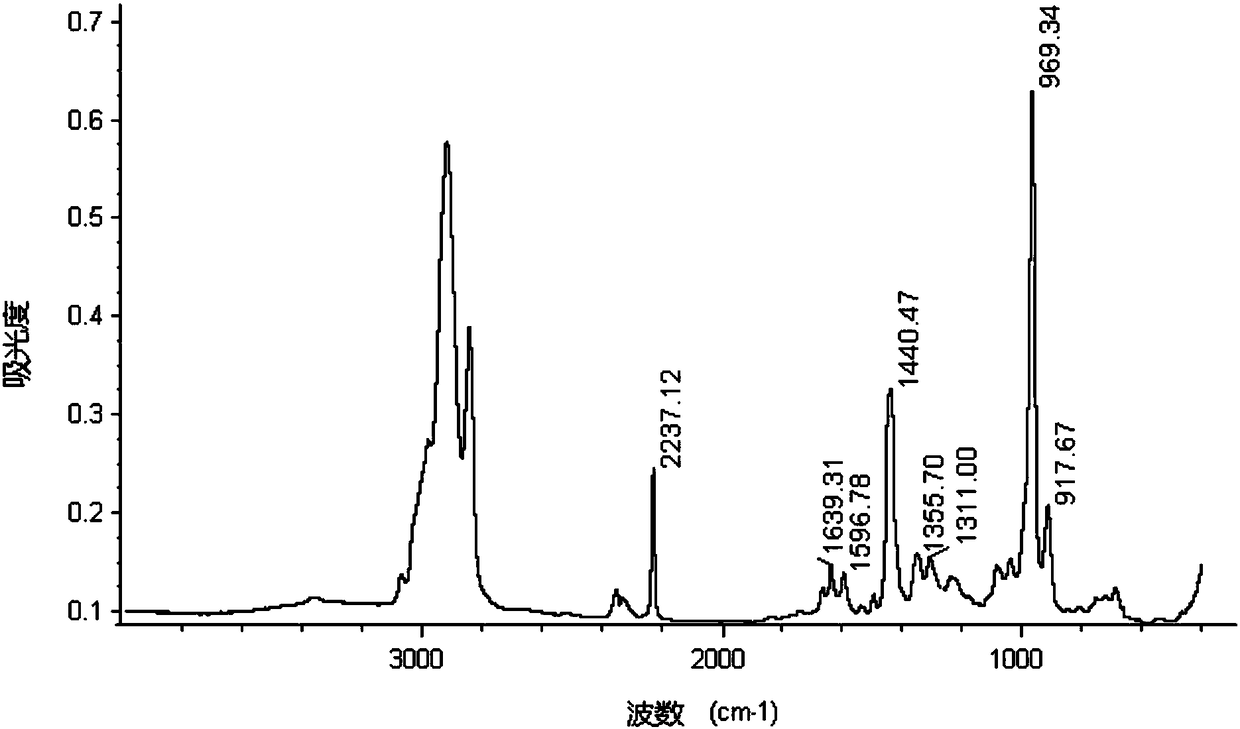

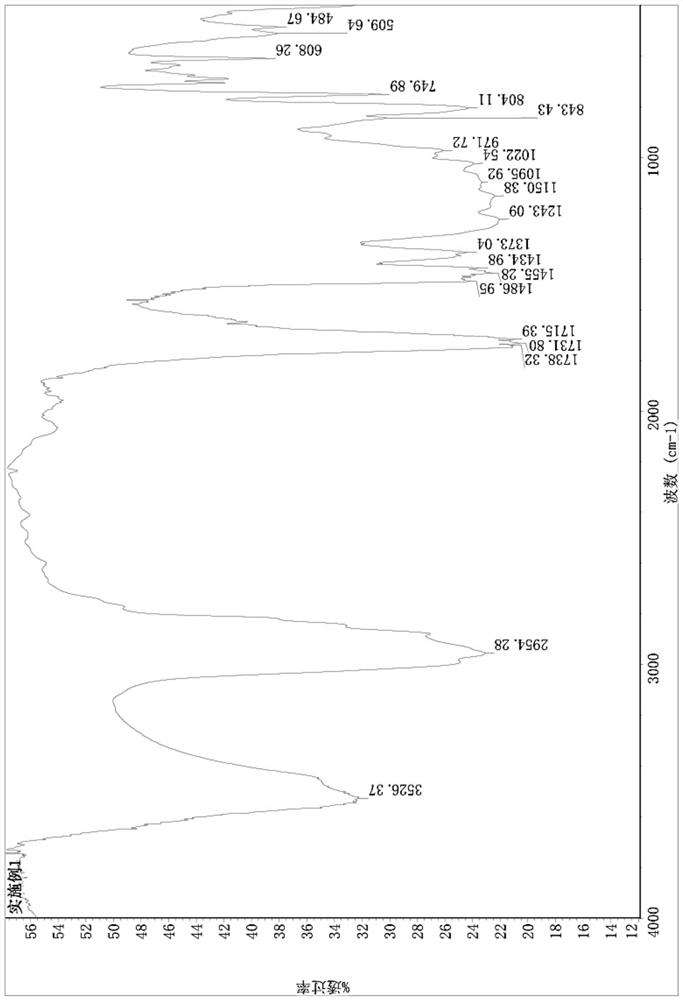

Fluorine-silicon modified acrylic resin as well as preparation method and application thereof

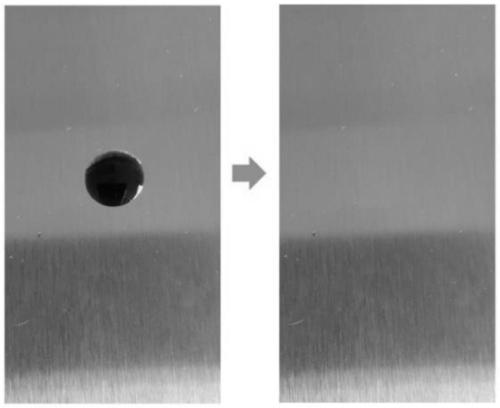

ActiveCN111393588AEasy to use in constructionHigh impact resistance self-healing functionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses fluorosilicone modified acrylic resin as well as a preparation method and an application thereof. The fluorine-silicon modified acrylic resin is prepared from the following components: methacrylate monomers, fluorine-containing acrylate monomers, acrylate-based silicone oil, allyl silicone oil, a polymerized active silane coupling agent, methacrylic acid, hydroxyl-containing active crosslinking monomers, glycidyl methacrylate, trimethylolpropane trimethacrylate, an initiator, a chain transfer agent and a solvent. The fluorine-containing acrylate monomer is composed of aC2-C3 short-chain fluorine-containing alkyl acrylate monomer and a C10-C12 long-chain fluorine-containing alkyl acrylate monomer. The fluorine-silicon modified acrylic resin prepared by the inventionhas the characteristic of high low viscosity, is convenient to construct and use, and reduces the generation of VOC. The coating prepared from the modified acrylic resin has the characteristics of high impact-resistant self-repairing function, icing prevention, low surface energy, hydrophobicity, oleophobicity, stain resistance, high and low temperature resistance and the like.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Four sides elasticity chamois flannel

InactiveCN101191273AEasy to stretchEasy to replyMonocomponent polyurethanes artificial filamentWoven fabricsFiberExtensibility

The invention relates to a neoprene suede nap and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads are wrapped yarns taking sea-island filament as urethane elastic fiber core yarns, and the sea-island filament is made to become elastic sea-island filament; weft yarns are wrapped yarns taking PTT polyester as urethane elastic fiber core yarns, thereby the PTT is made to have good tension and restoring force and advanced performances like softness, fluffiness, easy dyeing, easy washing and so on are fully displayed; because a little urethane elastic fiber is arranged inside the PTT, resilience of the PTT is strengthened. The invention utilizes stain resistance better than chinlon fiber, antistatic property better than nylon, fluffiness, resilience, chromaticity, good stain removal and antifouling properties, easy dyeing, soft hand feeling, abundance in elasticity, and extensibility same as urethane elastic fiber of the PTT fiber to prepare the suede nap through coating according to mixture ratio; advantages of the two fibers are given full play; due to addition of the PTT fiber, the cost of raw materials and processing costs like energy consumption and so on can be reduced; due to addition of the urethane elastic fiber, the resilience can be guaranteed; by weaving of the suede nap, disadvantages of thin fabrics are avoided.

Owner:YANGZHOU JIYUAN TEXTILE

Method for preparing fluorine-containing nitrile rubber with low-temperature emulsion polymerization

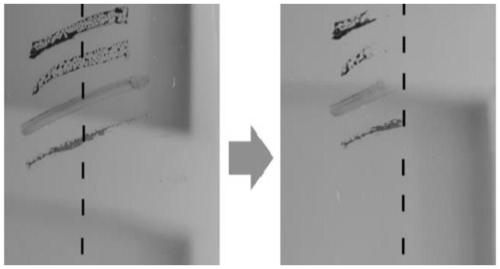

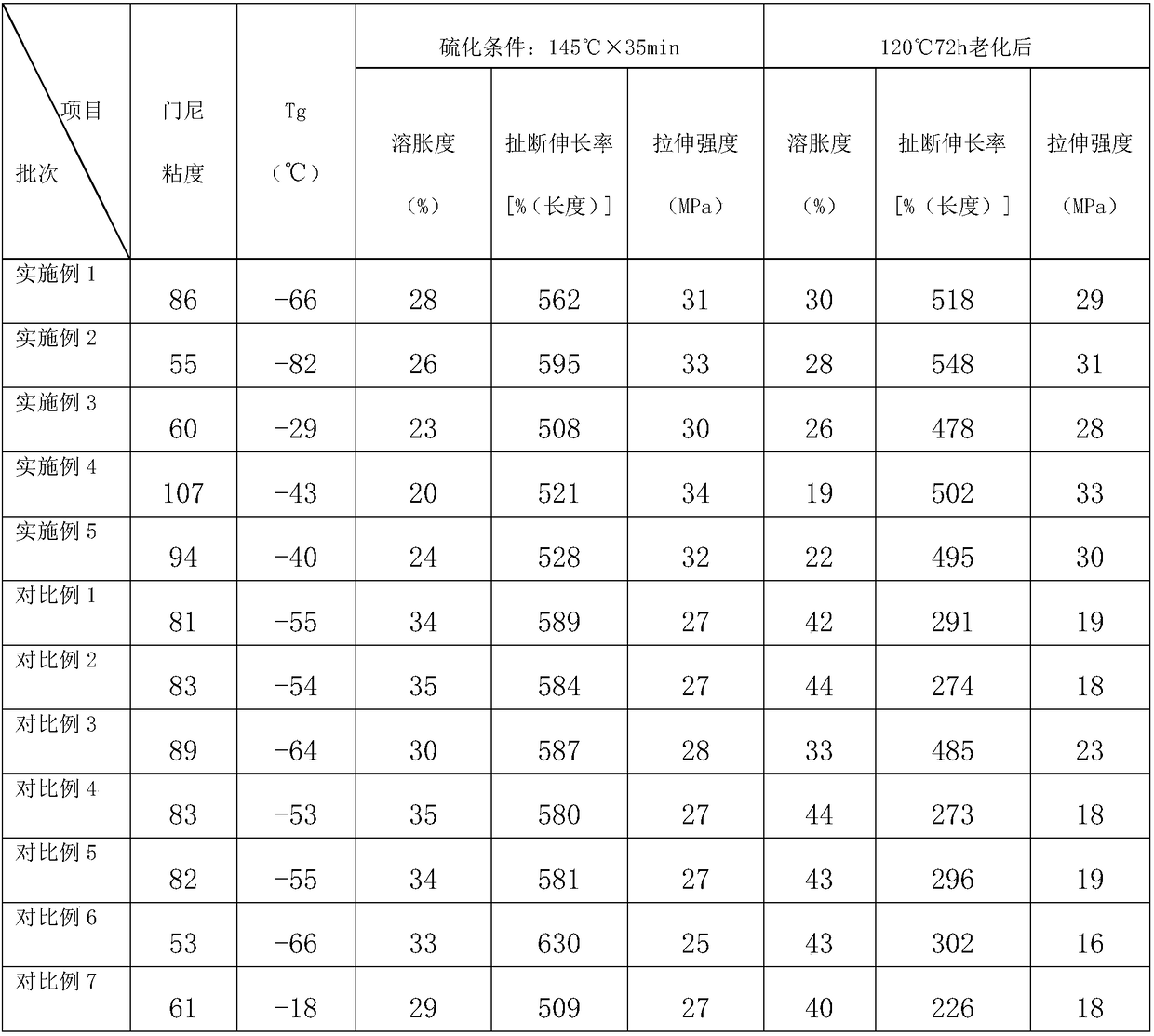

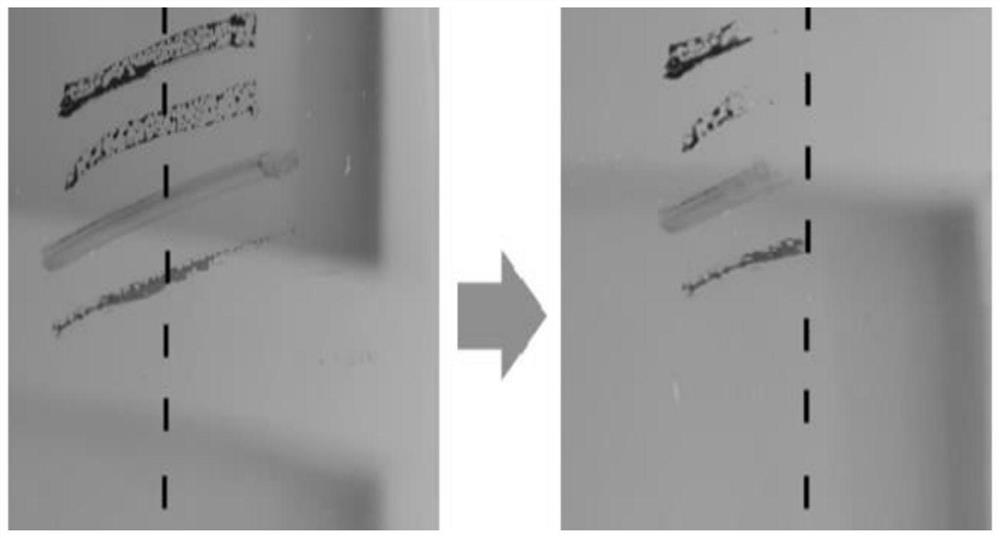

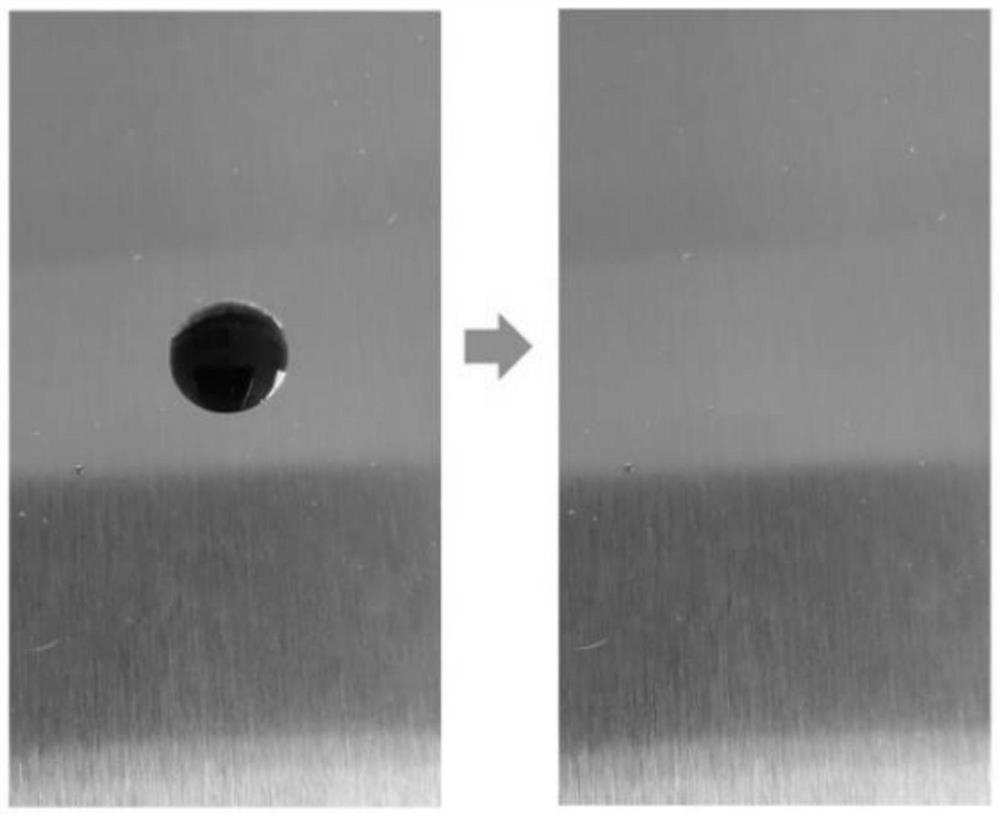

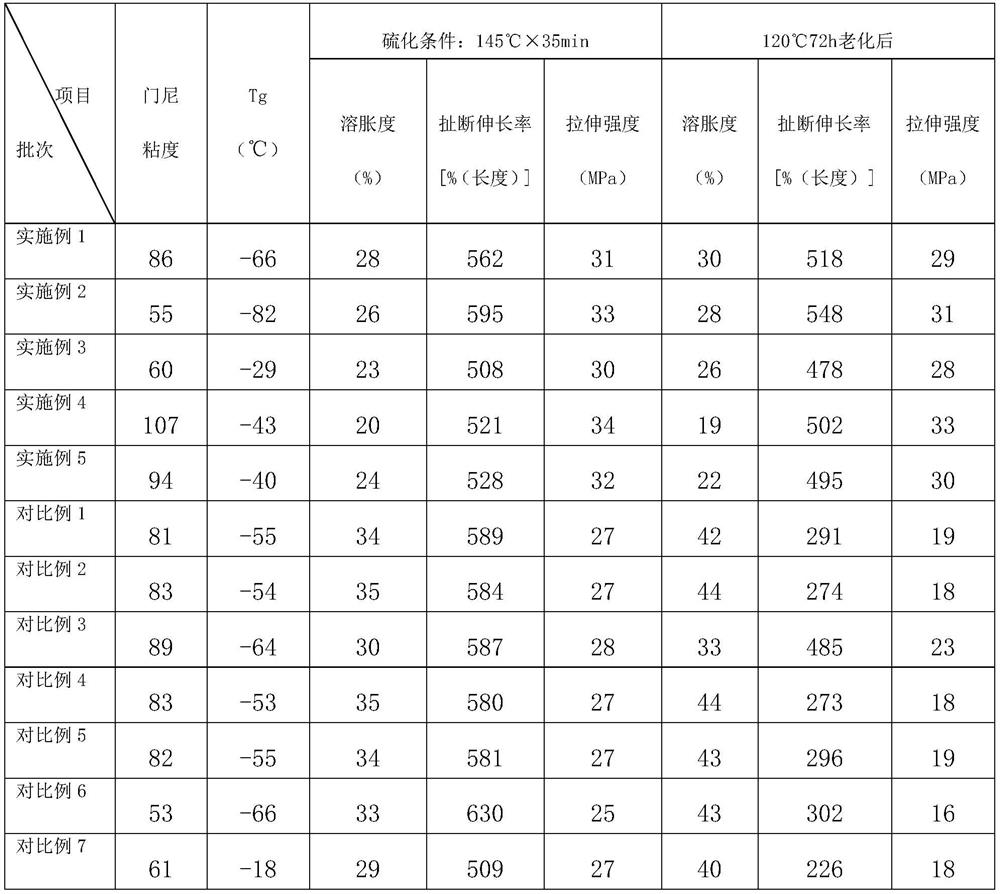

The invention provides a method for preparing fluorine-containing nitrile rubber with low-temperature emulsion polymerization. The method utilizes a fluorine-containing monomer emulsion polymerizationmethod to prepare the fluorine-containing nitrile rubber. In the polymerization process, a chelating titanate coupling agent is adopted, so that the ternary polymerization efficiency of a fluorine-containing monomer, acrylonitrile and butadiene can be remarkably improved. For the fluorine-containing nitrile rubber prepared by the method, the comprehensive properties of the nitrile rubber can be improved to a relatively large degree. For prepared fluorine-containing nitrile rubber, the oil resistance is good, the tensile strength is high, the oil resistance is improved by 20 percent or above compared with the fluorine-containing nitrile rubber prepared by an ordinary method, the Mooney viscosity is 50-100, the tensile strength is 30MPa or above, the elongation at break is 500 percent or above, meanwhile, the high-low temperature resistance is outstanding, the ageing-resistant performance is excellent, the glass-transition temperature is lowered by 10 DEG C or above, and the fluorine-containing nitrile rubber also has the characteristics of good elasticity, high stretching strength, low compression permanent deformation, good abrasive resistance, good weather ability, good pollutionresistance and narrow molecular weight distribution.

Owner:PETROCHINA CO LTD

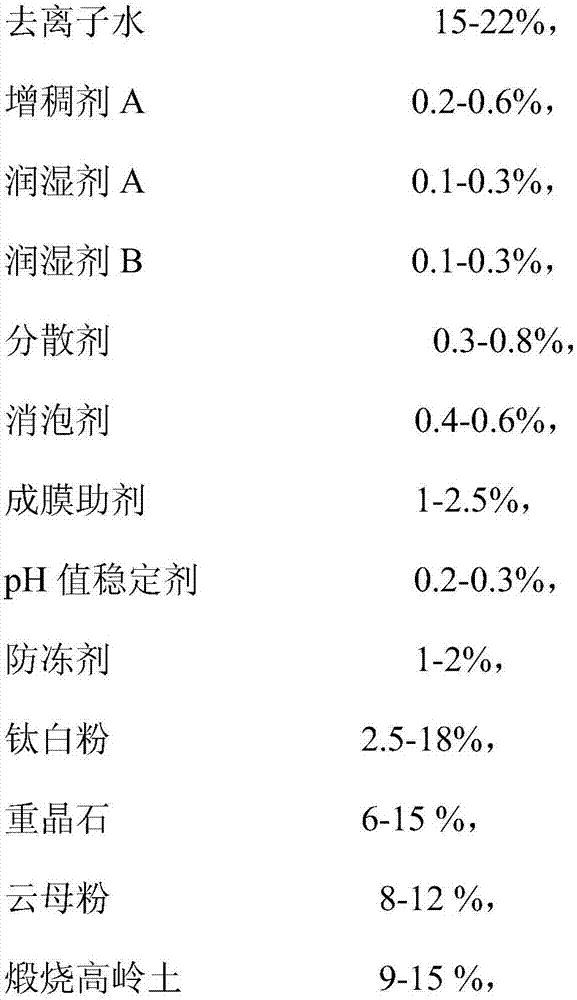

Super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint and preparation method thereof

InactiveCN106978025AStrong dustproof abilityImprove heat resistanceAntifouling/underwater paintsPaints with biocidesMildewPolymer emulsion

The invention discloses super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint and a preparation method thereof. The super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint comprises deionized water, a thickener A, a wetting agent A, a wetting agent B, a dispersant, a defoamer, a film forming aid, a pH stabilizer, an antifreezing agent, titanium dioxide, barite, mica powder, calcined kaolin, a modified polymer emulsion, a thickener B, a leveling agent, a bactericidal mildew preventive and deionized water according to mass percents. The super-weatherability anti-acid rain raindrop imprint-resistant external wall water paint has acid and alkali resistance, weatherability, water resistance, mildew proof effects, raindrop imprint resistance, scrubbing resistance, environmental friendliness and energy saving.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method for preparing fluorine-containing nitrile rubber through low-temperature emulsion polymerization

The invention provides a method for preparing fluorine-containing nitrile rubber by adopting a low-temperature emulsion polymerization method and a product obtained by using the method. The fluorine-containing nitrile rubber is prepared by adopting a fluorine-containing monomer emulsion polymerization method. In the polymerization process, a chelating titanate coupling agent is adopted, so that the ternary copolymerization efficiency of a fluorine-containing monomer and acrylonitrile and butadiene can be remarkably improved. A molecular weight regulator needs to be added for multiple times, and preferably, at the first time, 0.2-1 part of the molecular weight regulator is added; and when the conversion rate reaches 40%-65%, 0.05-0.2 part of the molecular weight regulator is supplemented. The comprehensive performance of the fluorine-containing nitrile rubber prepared according to the method is improved, the prepared fluorine-containing nitrile rubber is high in oil resistance and highin tensile strength, compared with fluorine-containing nitrile rubber prepared according to a common method, the oil resistance of the fluorine-containing nitrile rubber prepared according to the method provided by the invention is improved by 20% or above, and the tensile strength is 30 MPa or above, and meanwhile, the fluorine-containing nitrile rubber is outstanding in high and low temperatureresistance and excellent in ageing resistance, and has the characteristics of being good in elasticity, high in stretching strength, low in compression set, good in abrasion resistance, good in weather resistance, good in stain resistance and narrow in molecular weight distribution.

Owner:PETROCHINA CO LTD

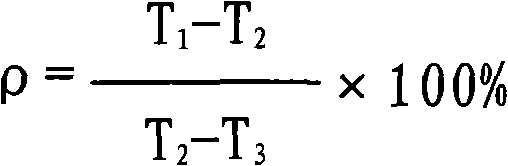

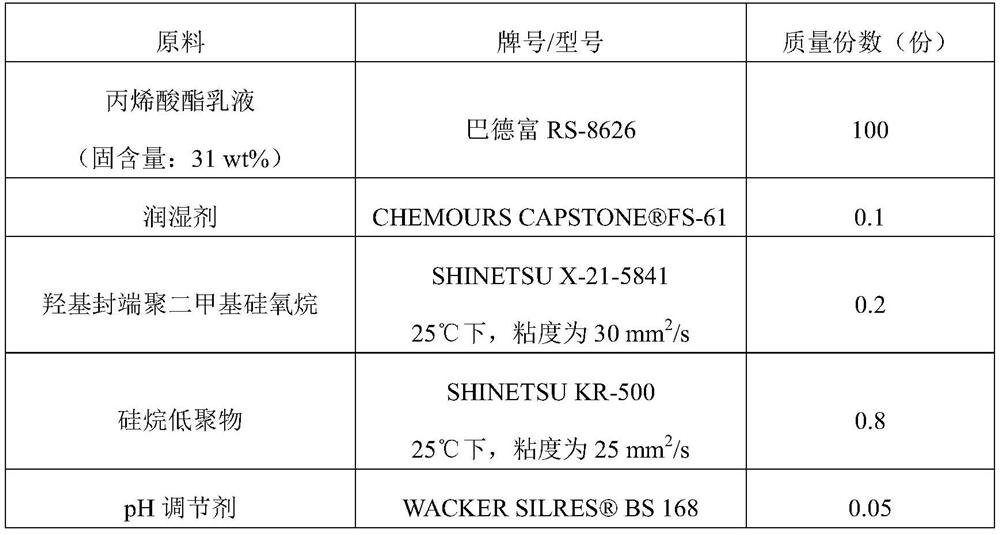

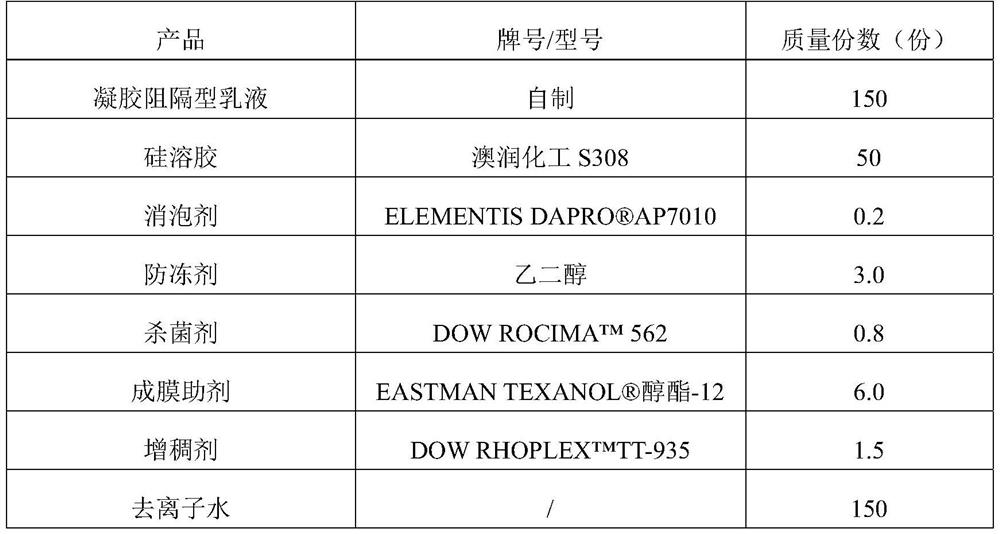

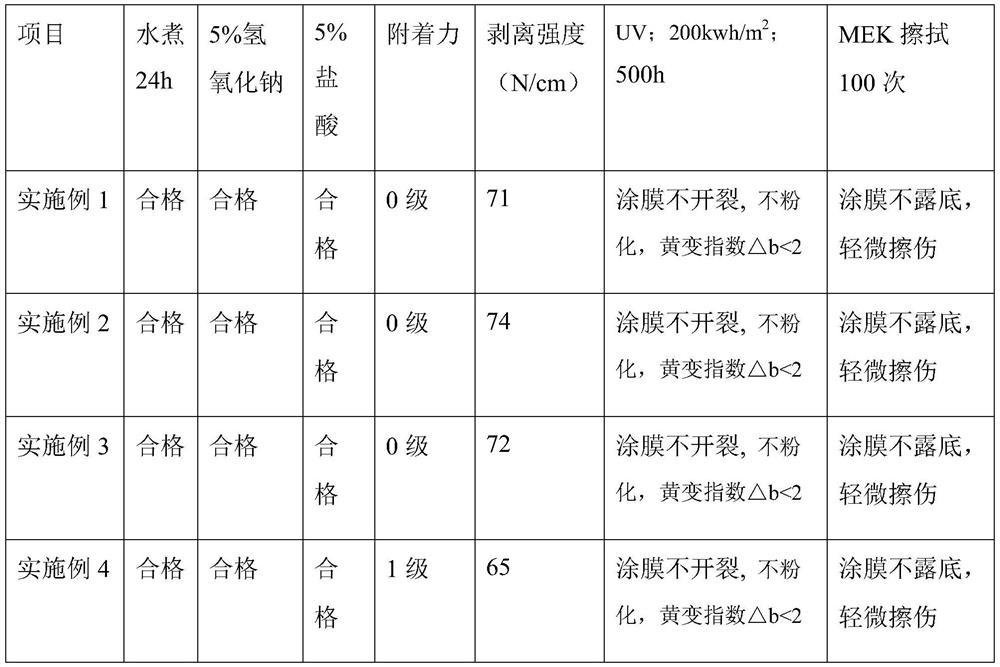

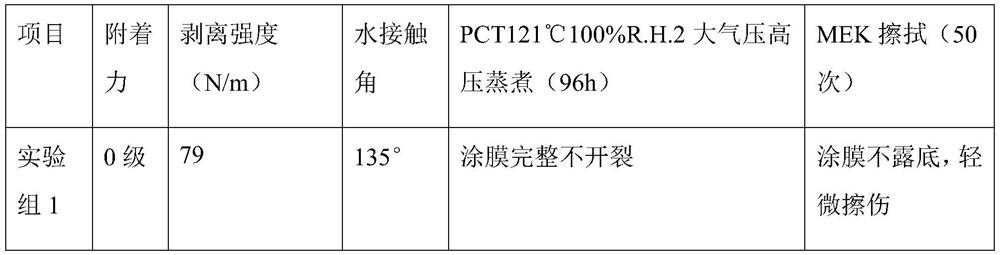

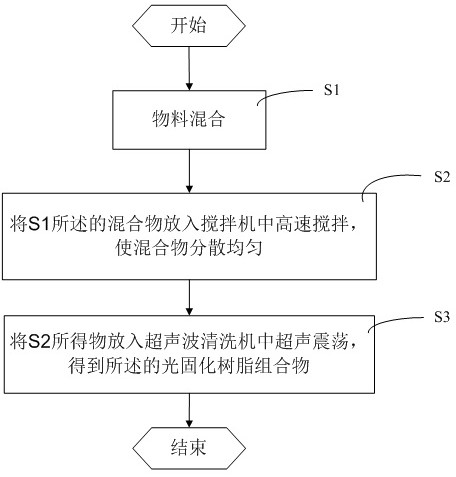

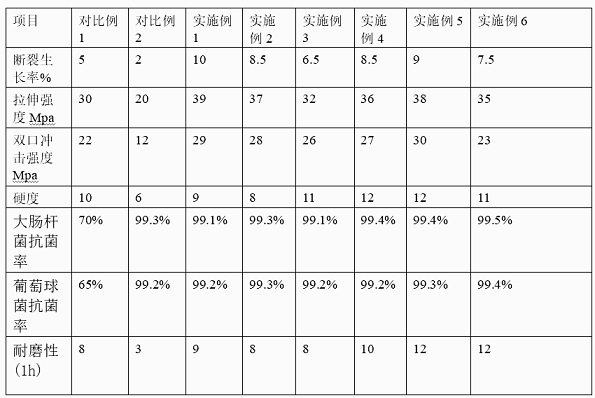

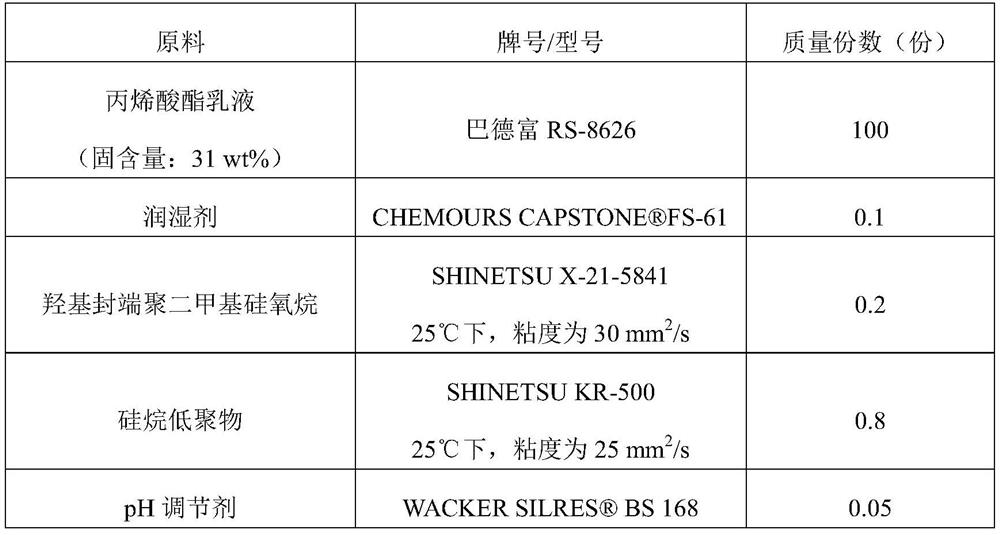

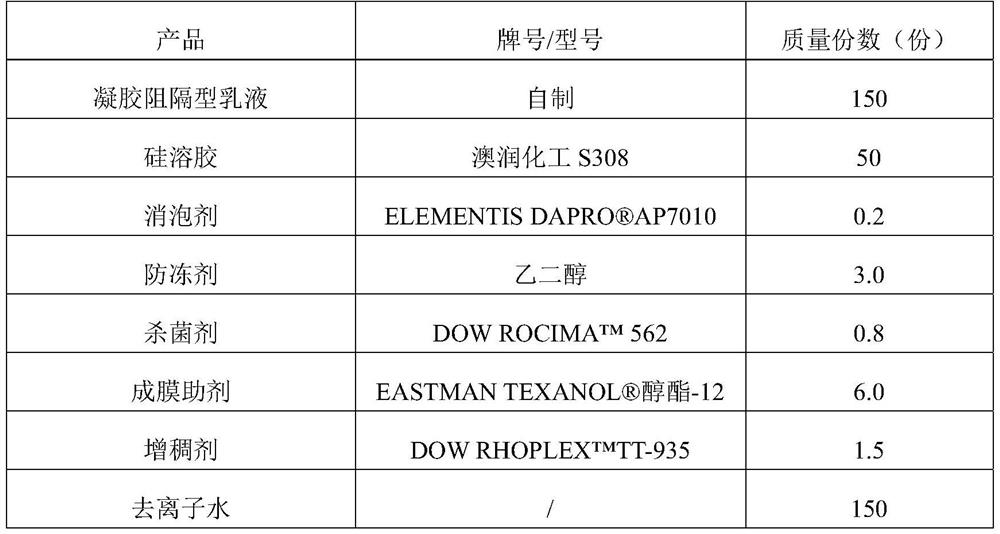

Gel barrier type self-cleaning dustproof finish paint composition as well as preparation method and application thereof

ActiveCN113122090ASimple preparation processThe polymerization process has no effectCoatingsHydrophilic coatingMeth-

The invention relates to a gel barrier type self-cleaning dustproof finish paint composition. The composition comprises a gel barrier emulsion and silica sol, wherein the gel barrier emulsion has a core-shell structure, and the core-shell structure comprises a core layer and a shell layer; the core layer comprises acrylate emulsion colloidal particles; the shell layer comprises a hydrophobic gel layer; and the hydrophobic gel layer comprises a mixture of polymethylsilane and a silane oligomer. The invention also relates to a preparation method of the gel barrier type self-cleaning dustproof finish paint composition and application of the gel barrier type self-cleaning dustproof finish paint composition in exterior wall coatings. The problem that a hydrophilic coating is high in water permeability is effectively solved, the stain resistance value can be as low as 5-8, and the water permeability can be controlled to be 0.2-0.5 ml.

Owner:CARPOLY CHEM GRP

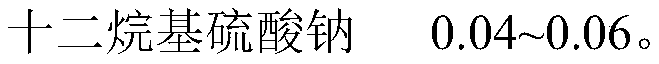

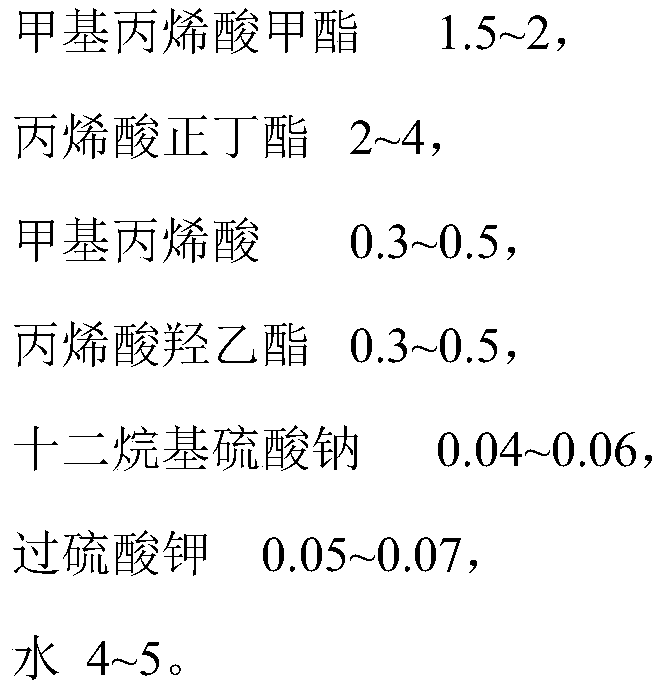

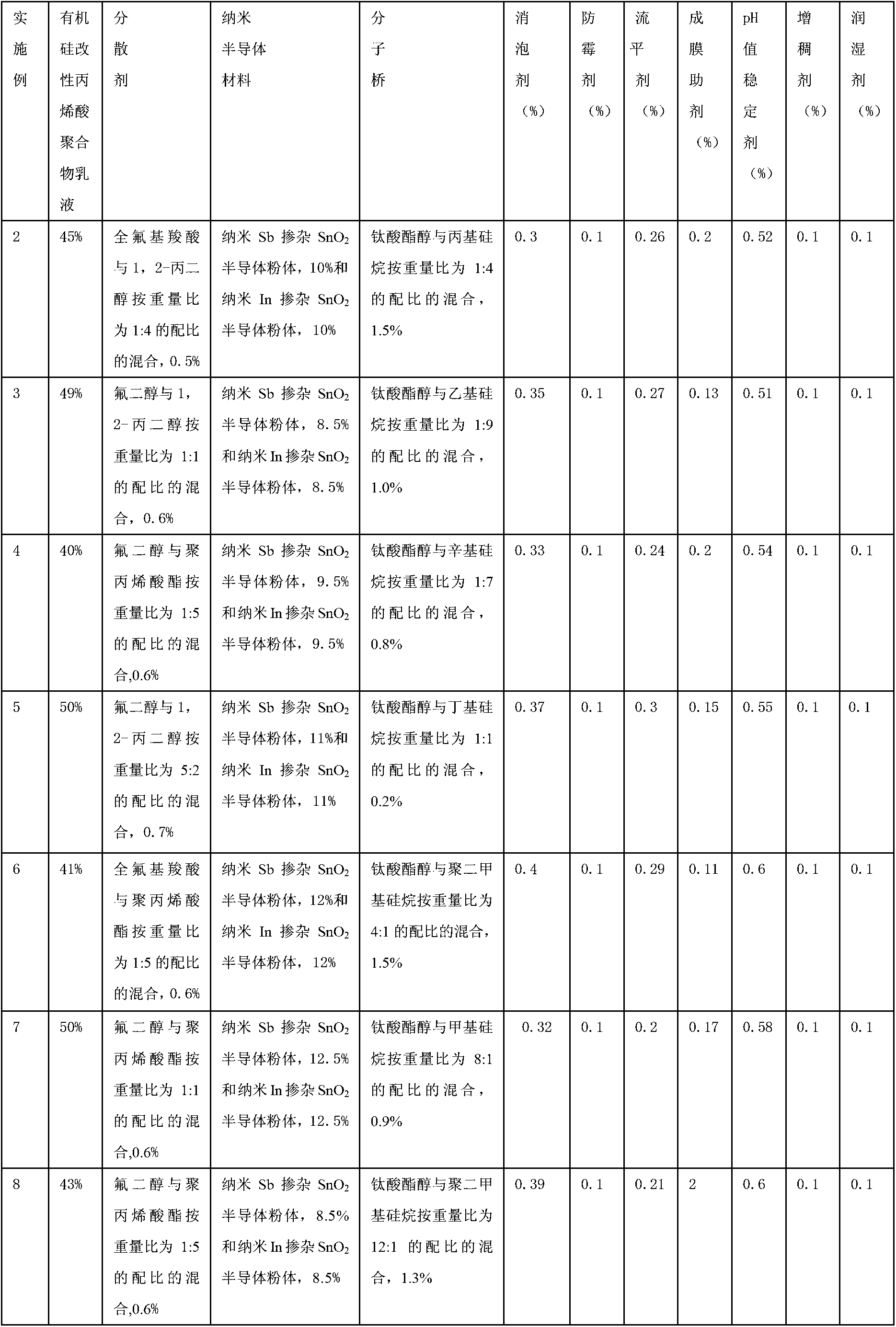

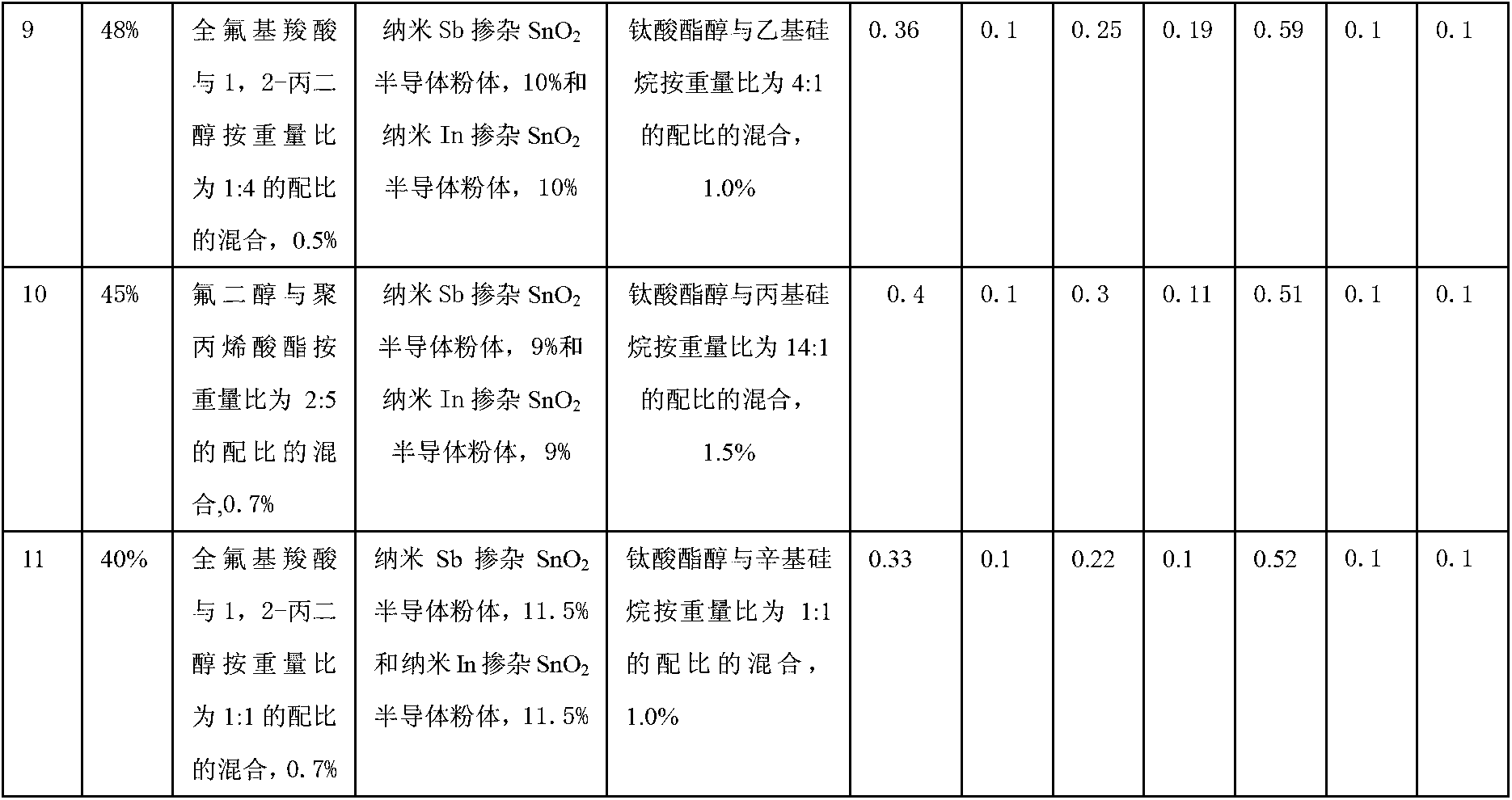

Infrared shielding type glass heat-insulating coating and preparation method thereof

InactiveCN101864230AHigh light transmittanceHigh infrared reflectivityReflecting/signal paintsSemiconductor materialsMetallurgy

The invention relates to an infrared shielding type glass heat-insulating coating which is prepared from the following raw materials in percentage by weight: 40 to 50 percent of organic silicon modified acrylic polymer emulsion, 17 to 25 percent of nanometer semiconductor material, 0.1 to 1.5 percent of molecular bridge and 0.5 to 0.7 percent of dispersant. The coating enhances the transmission rate of a coating layer for visible light, so that the light transmission rate of the coating layer reaches 90 percent. The coating layer achieves high infrared reflectivity and shielding rate: the reflectivity thereof for infrared rays reaches 85 percent, and the coating layer with the high infrared reflectivity has high heat-insulating effect; coated glass can not be penetrated by an infrared night vision instrument due to the high infrared shielding rate of the coating layer, and indoor privacy is protected. In addition, the coating of the invention has lower heat transfer coefficient, and the heat transfer quantity thereof is lower than 29 percent of solar energy.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

Nanometer metal ceramic coating

InactiveCN111944334AImprove impact resistanceImprove thermal shock resistanceAntifouling/underwater paintsChemical industryCeramic coatingNanoceramic

The invention provides a nanometer metal ceramic coating, belonging to the field of environment-friendly coatings. The nanometer metal ceramic coating is prepared from the following raw materials in parts by weight: 20-45 parts of a nanometer ceramic filler, 20-45 parts of a binder, 5-15 parts of nanometer metal powder and 10-20 parts of water. Compared with the prior art, the nanometer metal ceramic coating has excellent corrosion resistance, high blackness, good energy-saving effect, good surface self-lubricating effect, high contamination resistance, small possibility in falling and cracking, and no influence on heat transfer of four pipes of a boiler.

Owner:北京麦特斯普瑞防腐工程有限公司

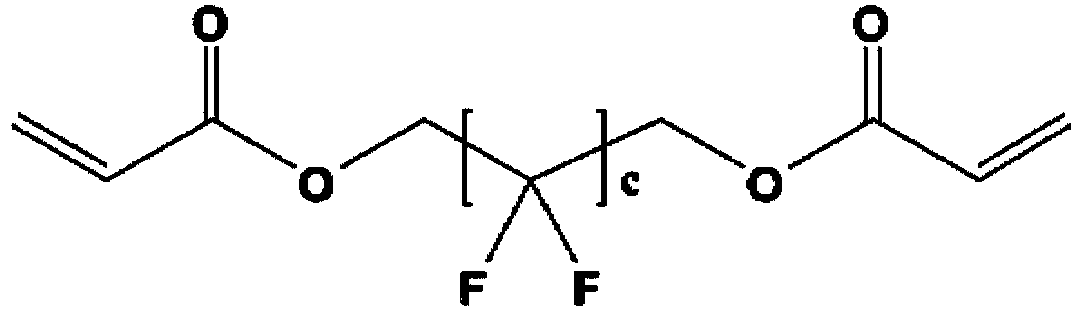

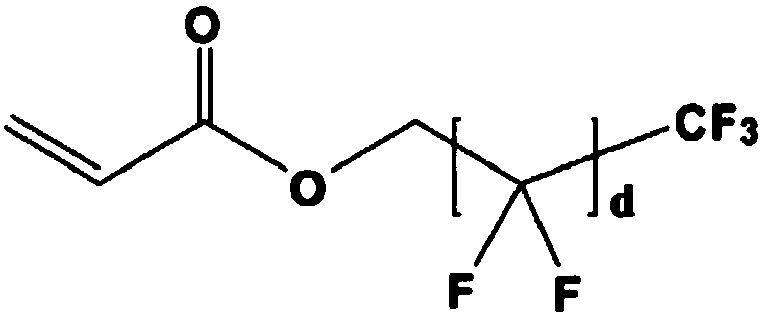

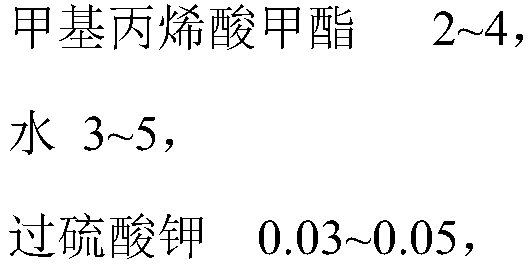

Water-based fluorinated acrylate copolymer emulsion and preparation method thereof

The invention discloses a water-based fluorine-containing acrylate copolymer emulsion and a preparation method thereof. According to the scheme, methyl methacrylate, butyl methacrylate, methacrylic acid and other monomers are copolymerized to prepare a fluorocarbon resin emulsion; fluorine-containing acrylate monomers such as trifluoroethyl acrylate, octafluoropentyl methacrylate and hexafluorobutyl methacrylate are introduced in a preparation scheme, fluorine-containing groups are easy to migrate to the surface and are enriched on the surface, so that a coating film is endowed with excellent hydrophobic performance, and due to the advantages of excellent weather resistance, chemical resistance stability and the like of a fluorine-containing polymer, the hydrophobic property of the coating film is greatly improved. It can be guaranteed that a coating film has the properties of low surface energy, low friction, stain resistance, good water and oil resistance, self-cleaning performance and the like, and the comprehensive practicability is high. And meanwhile, pretreatment and parameter limitation are carried out on the PET film in cooperation with the scheme, so that the adhesive force between the coating film and the PET film is further improved.

Owner:上海水立方新材料有限公司

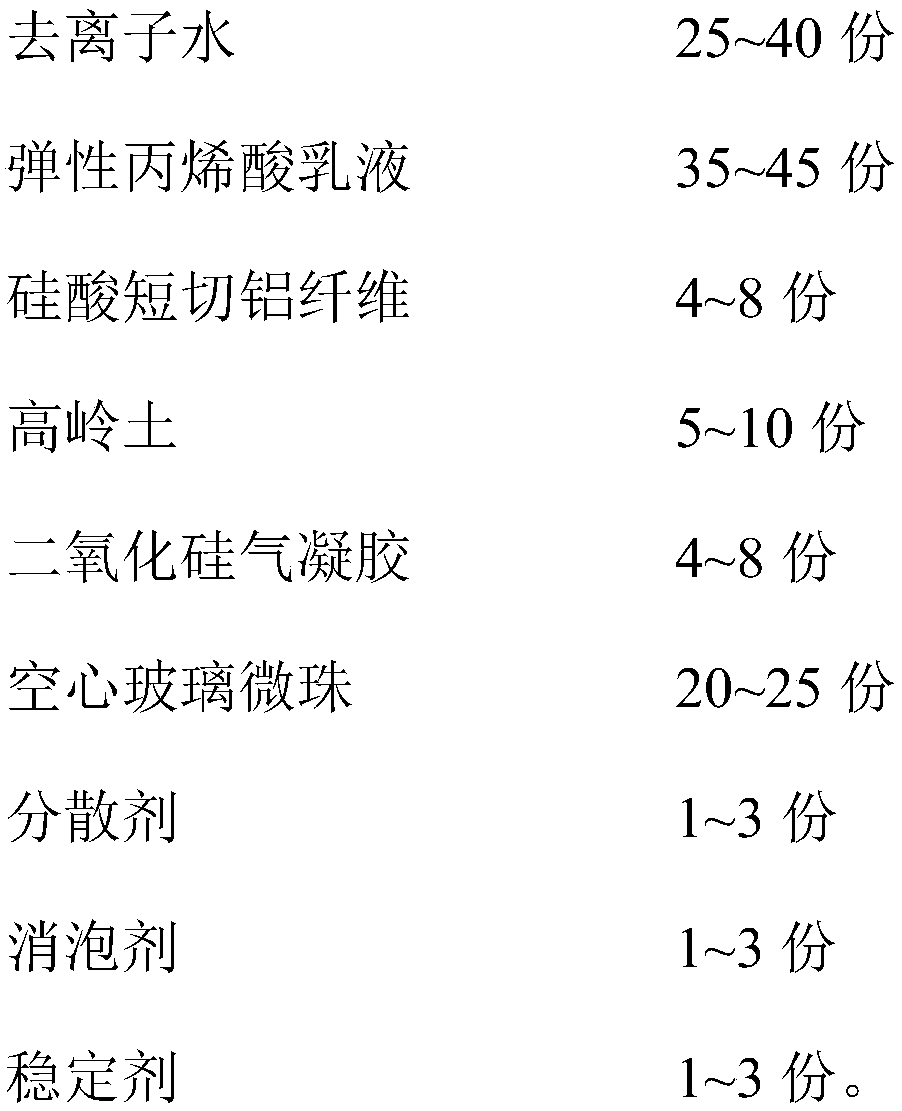

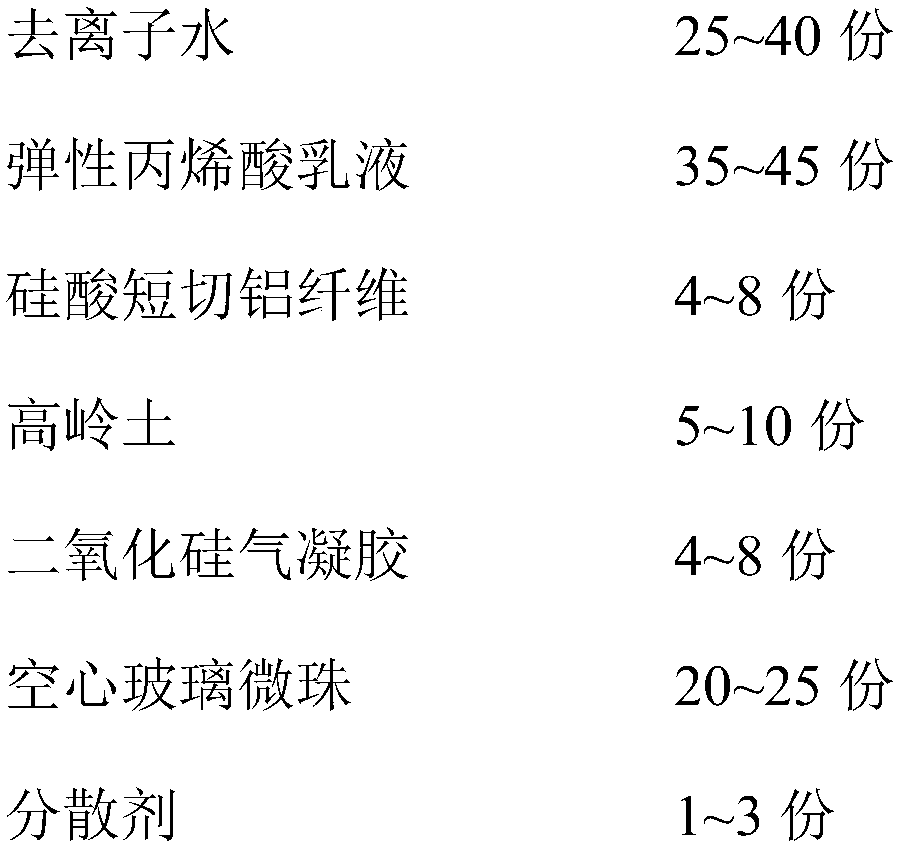

Nanometer heat-insulating coating

The invention discloses a nanometer heat-insulating coating and belongs to the technical field of coatings. The invention aims to solve the technical problem of poor heat insulating effect of the present heat-insulating coating. The nanometer heat-insulating coating contains the following components in parts by weight: 25-40 parts of deionized water, 35-45 parts of elastic acrylic emulsion, 4-8 parts of silicic acid short aluminum fiber, 5-10 parts of kaolin, 4-8 parts of silicon dioxide aerogel, 20-25 parts of hollow glass beads, 1-3 parts of dispersing agent, 1-3 parts of de-foaming agent and 1-3 parts of stabilizer. The nanometer heat-insulating coating prepared according to the invention has the advantages of construction of film, safety, fireproof property, environment-friendly and energy-saving effects, high cost performance, and the like, and can be widely applied to the heat-insulating coatings of interior and exterior walls of buildings, warehouse, refrigeration storage, and the like.

Owner:嘉兴御创电力科技有限公司

Photocurable coating composition, low-refraction layer, and anti-reflection film

ActiveCN107922756AReduce reflectivityLow scratch resistanceAnti-reflective coatingsOptical elementsRefractive indexFluorine containing

Owner:LG CHEM LTD

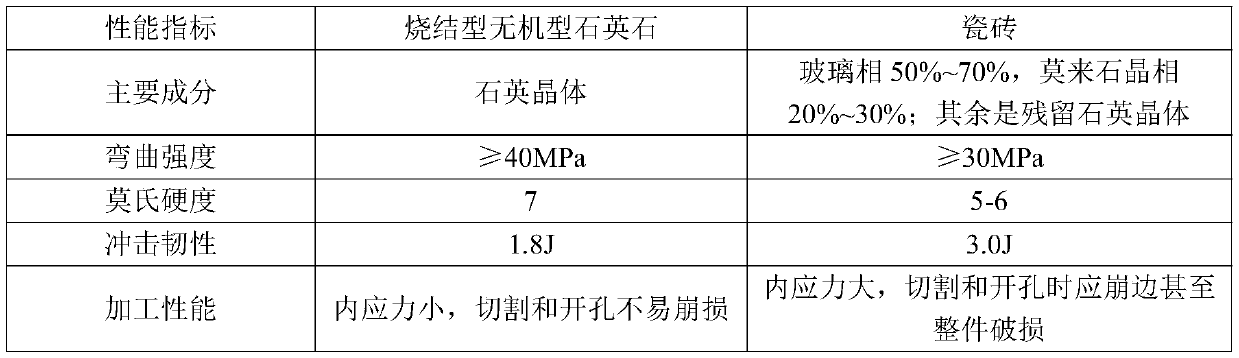

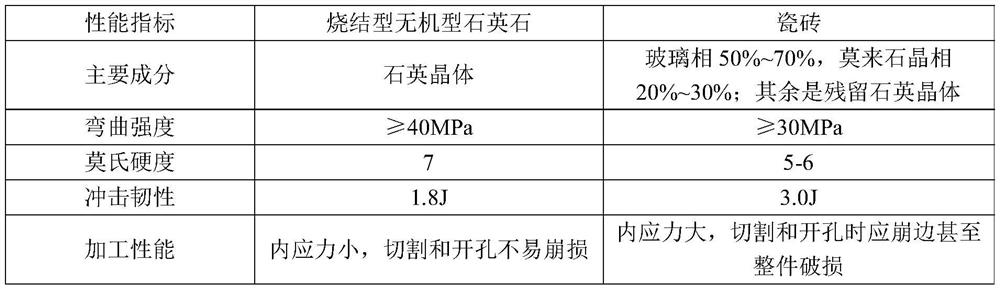

Sintered inorganic quartz stone plate and production process thereof

ActiveCN110776260ALow water absorptionGood antifouling performanceGlass shaping apparatusCorrosionPowder

The invention discloses a sintered inorganic quartz stone plate and a production process thereof. The sintered inorganic quartz stone plate comprises the following raw materials in percentage by weight: 80-93% of 325-400-mesh quartz powder, 0-10% of 1250-mesh quartz powder, 0-10% of colored granite rock powder or quartz powder, 1-5% of feldspar powder, 2-6% of kaolin and 0-2% of a pigment. The production process comprises the following steps: firstly, uniformly mixing all raw materials in a mechanical stirring mode, adding 5-25 parts of water, 0-2 parts of a water reducing agent and 0-2 partsof a blank reinforcing agent in parts by weight, and performing uniform stirring till a mixed material state meeting the condition that molding can be achieved through pinching by hands; and conveyingthe mixed material into a molding press, pressing the mixed material into a flaky blank, conveying the flaky blank into a drying kiln with integrated functions of drying and air exhaust, further feeding the mixed material into a sintering kiln, and performing sintering so as to obtain a finished product which has the characteristics of alkali corrosion resistance, ultraviolet resistance, deformation prevention, low water absorption rate, good antifouling performance, good wearing resistance, high strength and good toughness.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Water-based acrylic fluorescent coating and preparation method thereof

ActiveCN110655841ADoes not affect luminosityChange film formationAntifouling/underwater paintsLuminescent paintsEmulsionNano sio2

The invention provides a water-based acrylic fluorescent coating and a preparation method thereof. The preparation method comprises the following steps: preparing silicon dioxide coated modified fluorescent powder; adding the obtained silicon dioxide coated modified fluorescent powder into a water-based solvent and stirring to obtain modified fluorescent powder suspension; adding the modified fluorescent powder suspension into an emulsion containing an acrylate monomer, adding an initiator, carrying out a reaction, and adjusting the pH value to 6.5-7.5 to obtain a stable nano SiO2 / acrylate composite emulsion, wherein the component of the emulsion B comprises methyl methacrylate, and the component of the emulsion C comprises n-butyl acrylate; and uniformly mixing the obtained nano SiO2 / acrylate composite emulsion with a curing agent and an auxiliary agent to obtain the water-based acrylic fluorescent coating. The silicon dioxide is adopted to coat and modify fluorescent powder, the modified fluorescent powder is used as a core, and the acrylate copolymer is used as a shell, so that the luminescence property of the fluorescent powder is enhanced, and the stability of the emulsion isimproved.

Owner:广西经正科技开发有限责任公司

Infrared shielding type glass heat-insulating coating and preparation method thereof

InactiveCN101864230BHigh light transmittanceHigh infrared reflectivityReflecting/signal paintsSemiconductor materialsAcrylic polymer

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

A sintered inorganic quartz stone plate and its production process

ActiveCN110776260BWith alkali corrosion resistanceUV resistantGlass shaping apparatusKaolin clayStone dust

A sintered inorganic quartz stone plate and its production process according to the present invention, according to the weight percentage, its raw materials are: 325 mesh-400 mesh quartz powder 80%-93%, 1250 mesh quartz powder 0-10%, colored Granite stone powder or quartz powder: 0% to 10%, feldspar powder: 1% to 5%, kaolin: 2% to 6%, pigment: 0 to 2%, firstly mix all the raw materials evenly by mechanical stirring, according to Parts by weight, for every 100 parts of the mixture, add 5‑25 parts of water, 0 to 2 parts of water reducing agent, and 0 to 2 parts of green body strengthening agent, and stir evenly until the mixture can be molded by hand; then the mixture It is sent to the molding press to be pressed into a sheet-shaped green body, and then sent to a drying kiln with integrated functions of drying and ventilation, and then fired into a kiln. The fired finished product has alkali corrosion resistance, UV resistance, Not easy to deform, low water absorption, good antifouling performance, good wear resistance, high strength and good toughness.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

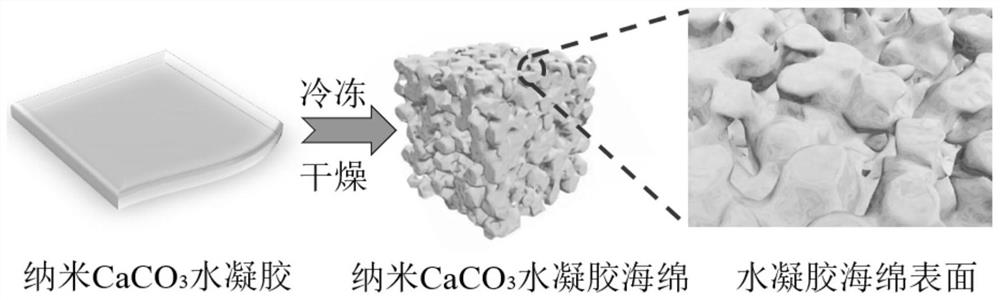

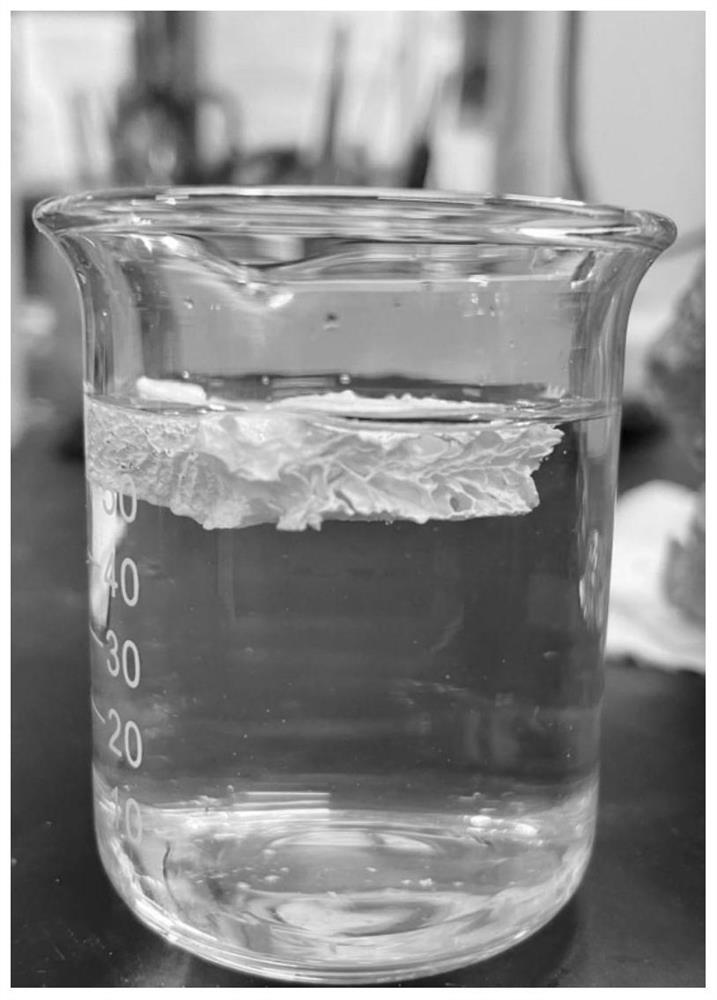

A kind of preparation method and application of in-situ growth nano calcium carbonate hydrogel sponge marine antifouling material

ActiveCN113307989BImprove mechanical propertiesImprove surface propertiesAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholEnvironmental engineering

The invention discloses a preparation method of an in-situ growth nano calcium carbonate hydrogel sponge marine antifouling material, comprising the following steps: S1. Dispersing chitin in Ca(OH) 2 / Na 2 CO 3 / urea solution, mix evenly, freeze and thaw 2 to 4 times to obtain a white paste-like chitin and nano-calcium carbonate mixed solution; S2. Add the quaternary ammonium salt to the mixed solution in step S1, and mix well to obtain a paste-like white mixture S3. adding polyvinyl alcohol to the mixture in step S2, after mixing uniformly, dissolving, pouring in the mold, freezing and thawing 2 to 4 times to obtain a hydrogel of polyvinyl alcohol and quaternized chitin physically cross-linked; After soaking in glutaraldehyde aqueous solution, it is obtained. The invention prepares a marine anti-fouling gel with low surface performance, anti-fouling performance, mechanical performance and low elastic modulus at the same time, and has a great application prospect in marine anti-fouling.

Owner:SUN YAT SEN UNIV

Abrasive and durable floor tile

InactiveCN106587723AResilientGuaranteed flatnessCovering/liningsFlooringPotassium hexafluorophosphateBarium titanate

The invention relates to an abrasive and durable floor tile. The abrasive and durable floor tile is prepared from the following raw materials in parts by weight: 55-65 parts of silicon dioxide, 6-8 parts of hemp fiber, 5-10 parts of iron oxide, 1-3 parts of magnesium sulfate, 3-5 parts of calcium carbonate, 2-4 parts of barium titanate, 5-8 parts of crude talc, 10-15 parts of water and 3-6 parts of an additive, wherein the additive consists of potassium hexafluorophosphate, polymeric aluminium sulfate, phenolic resin and urea-formaldehyde glue according to the ratio of 1:(1.2-1.4):(1.1-1.2):(0.5-0.8) in parts by weight. Through combined use of the specific additive, silicon dioxide and other raw materials, the obtained product is extremely good in combining effect, is easy to form and easier to produce; and the abrasive and durable floor tile is high in hardness and low in probability of abrasion, has a certain toughness and low probability of breakage, can keep the surface flatness for a long time, and is longer in service life, energy-saving and environment-friendly in preparation, bright in product color, resistant to dirt and easy to clean.

Owner:方彩燕

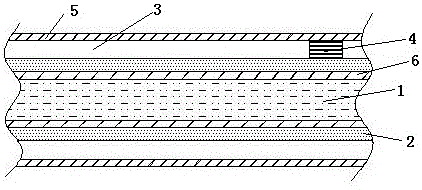

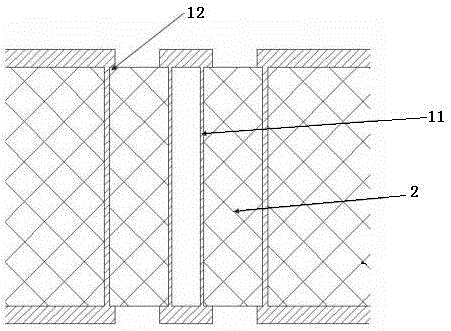

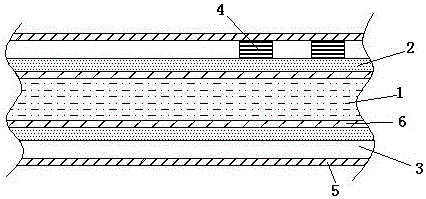

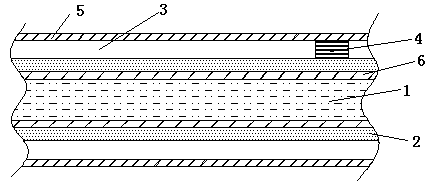

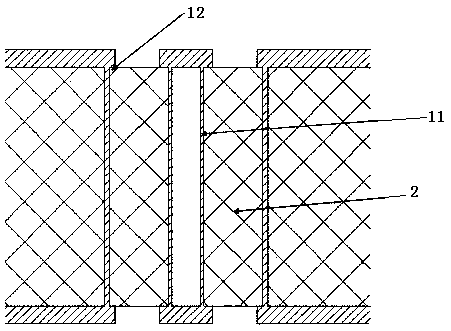

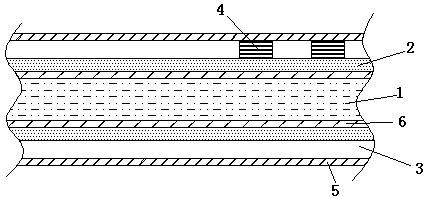

High-fidelity and high-frequency circuit board

ActiveCN106170175AGood high and low temperature resistanceImprove complexation effectPrinted circuit detailsPrinted circuit aspectsInsulation layerEngineering

The invention provides a high-fidelity and high-frequency circuit board. The circuit board comprises a circuit layer, and insulation layers arranged on the front and back of the circuit layer. At least one metal layer is arranged on each insulation layer. At least one high-frequency sub-board is in press fit with part of the metal layer located at the top.

Owner:惠州润众科技股份有限公司

A kind of waterborne acrylic fluorescent paint and preparation method thereof

ActiveCN110655841BDoes not affect luminosityChange film formationAntifouling/underwater paintsLuminescent paintsEmulsionFluorescence

Owner:广西经正科技开发有限责任公司

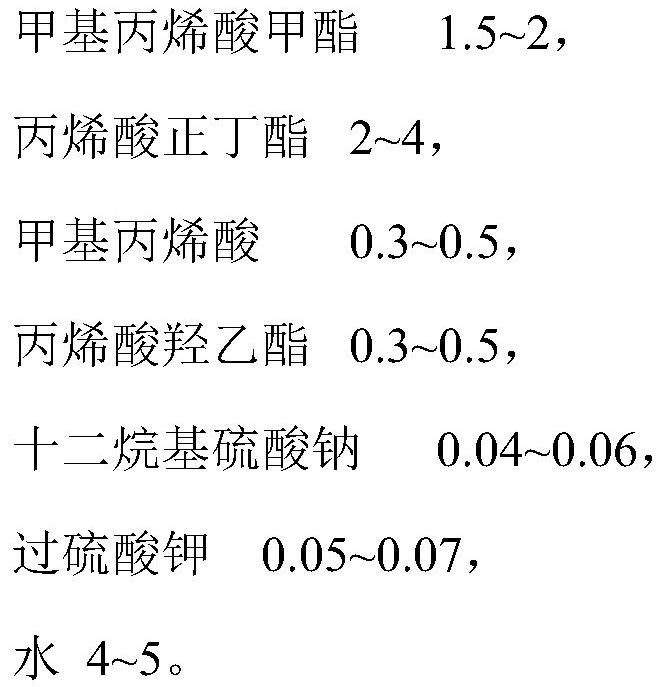

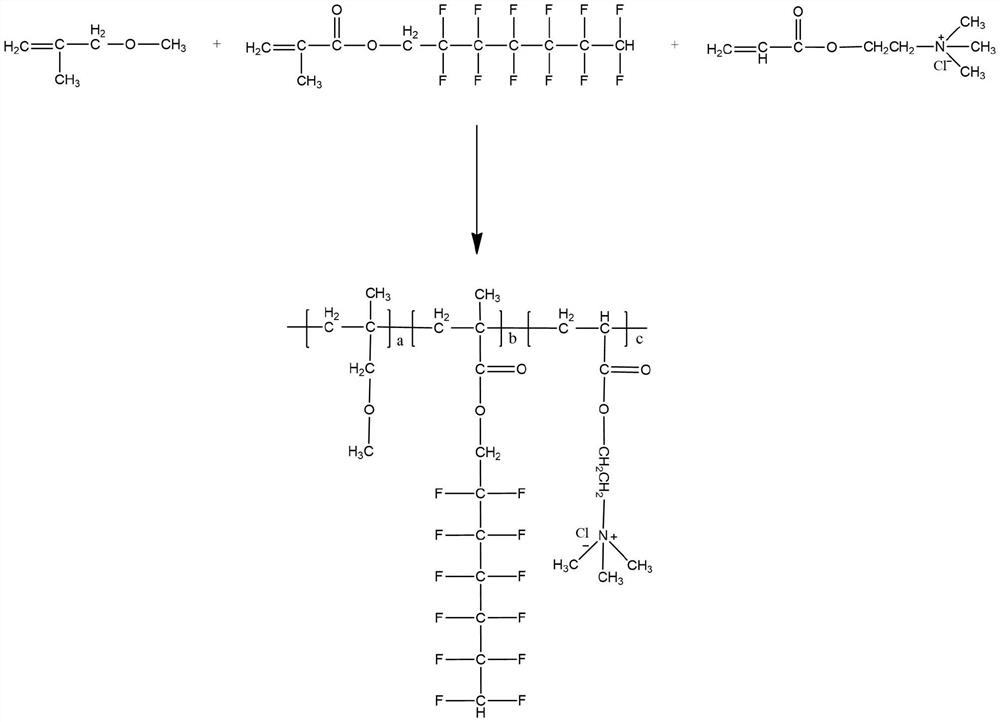

Environment-friendly self-cleaning coating for shower room and preparation method of environment-friendly self-cleaning coating

InactiveCN113480909AGood film formingSurface performance is stableAntifouling/underwater paintsPaints with biocidesMethacrylateEngineering

The invention discloses an environment-friendly self-cleaning coating for a shower room and a preparation method of the environment-friendly self-cleaning coating, and relates to the field of self-cleaning coatings. The self-cleaning coating has good film-forming property and can be cured to form a film on a substrate to form the self-cleaning coating, and a large number of C-F bonds existing on dodecafluoroheptyl methacrylate are utilized. The introduced fluorine atoms are small in radius, strong in electronegativity and high in C-F bond energy, have the minimum Van der Waals radius besides hydrogen, and also have a shielding protection effect on carbon chains, so that the self-cleaning coating can be endowed with excellent low surface energy, water resistance, oil resistance, lubricity, heat resistance, chemical resistance and stain resistance, and therefore, the self-cleaning coating has a good self-cleaning function and is convenient to clean after being used in the shower room, meanwhile, the self-cleaning coating can be endowed with good antibacterial property by utilizing quaternary ammonium salt groups in the antibacterial monomers, bacterium breeding in the shower room is avoided, and the probability that people get ill is reduced.

Owner:浙江精筑环保科技有限公司

Method for preparing fluorine-containing nitrile rubber by low-temperature emulsion polymerization

The invention provides a method for preparing fluorine-containing nitrile rubber by adopting a low-temperature emulsion polymerization method and a product obtained by using the method. The fluorine-containing nitrile rubber is prepared by adopting a fluorine-containing monomer emulsion polymerization method. In the polymerization process, a chelating titanate coupling agent is adopted, so that the ternary copolymerization efficiency of a fluorine-containing monomer and acrylonitrile and butadiene can be remarkably improved. A molecular weight regulator needs to be added for multiple times, and preferably, at the first time, 0.2-1 part of the molecular weight regulator is added; and when the conversion rate reaches 40%-65%, 0.05-0.2 part of the molecular weight regulator is supplemented. The comprehensive performance of the fluorine-containing nitrile rubber prepared according to the method is improved, the prepared fluorine-containing nitrile rubber is high in oil resistance and highin tensile strength, compared with fluorine-containing nitrile rubber prepared according to a common method, the oil resistance of the fluorine-containing nitrile rubber prepared according to the method provided by the invention is improved by 20% or above, and the tensile strength is 30 MPa or above, and meanwhile, the fluorine-containing nitrile rubber is outstanding in high and low temperatureresistance and excellent in ageing resistance, and has the characteristics of being good in elasticity, high in stretching strength, low in compression set, good in abrasion resistance, good in weather resistance, good in stain resistance and narrow in molecular weight distribution.

Owner:PETROCHINA CO LTD

3D printing resin for antibacterial wear-resistant shoes

PendingCN114437298AIncrease coefficient of frictionExcellent low coefficient of frictionAdditive manufacturing apparatusPolymer scienceButadiene Dioxide

The invention provides a 3D printing resin for antibacterial wear-resistant shoes. The 3D printing resin is applied to the field of 3D printing. The 3D printing resin comprises the following raw materials in parts by weight: 20-40 parts of carboxyl-terminated butadiene modified acrylate, 10-30 parts of fluoroalkane modified acrylate monomers, 10-15 parts of a reactive diluent, 1-2 parts of a polymerization inhibitor, 2-3 parts of a photoinitiator, 3-5 parts of a pigment, 10-15 parts of a filler, 0.5-2 parts of an antibacterial finishing agent and 5-10 parts of a silane coupling agent. According to the obtained 3D printing resin for the antibacterial and wear-resistant shoes, the resin is compounded with high elasticity and wear resistance required by shoe materials, meanwhile, the antibacterial property requirement is met, and the 3D printing resin can be used in the field of 3D printing shoes.

Owner:深圳锐沣科技有限公司

A kind of gel barrier type self-cleaning dust-proof topcoat composition and preparation method and application

ActiveCN113122090BSimple preparation processThe polymerization process has no effectCoatingsHydrophilic coatingOligomer

The invention relates to a gel barrier type self-cleaning dustproof topcoat composition, comprising a gel barrier emulsion and a silica sol; wherein the gel barrier emulsion has a core-shell structure, and the core-shell structure includes a core layer and a shell layer The core layer includes acrylate emulsion particles; the shell layer includes a hydrophobic gel layer; the hydrophobic gel layer includes a mixture of polymethylsilane and silane oligomers. The present invention also relates to a preparation method of the above-mentioned gel-barrier self-cleaning and dust-proof topcoat composition and its application in exterior wall coatings. The invention effectively solves the problem of high water permeability of the hydrophilic coating, the stain resistance value can be as low as 5-8, and the water permeability can be controlled at 0.2-0.5ml.

Owner:CARPOLY CHEM GRP

A high-fidelity high-frequency circuit board

ActiveCN106170175BGood high and low temperature resistanceImprove complexation effectPrinted circuit detailsPrinted circuit aspectsInsulation layerEngineering

The invention provides a high-fidelity and high-frequency circuit board. The circuit board comprises a circuit layer, and insulation layers arranged on the front and back of the circuit layer. At least one metal layer is arranged on each insulation layer. At least one high-frequency sub-board is in press fit with part of the metal layer located at the top.

Owner:惠州润众科技股份有限公司

A kind of fluorosilicone modified acrylic resin and its preparation method and application

ActiveCN111393588BEasy to use in constructionHigh impact resistance self-healing functionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses a fluorosilicon modified acrylic resin, its preparation method and application. This fluorosilicone modified acrylic resin is made of the following components: methacrylate monomer, fluorine-containing acrylate monomer, acrylate-based silicone oil, allyl silicone oil, polymerization active silane coupling agent, methyl Acrylic acid, active cross-linking monomer containing hydroxyl group, glycidyl methacrylate, trimethylolpropane trimethacrylate, initiator, chain transfer agent, solvent; fluorine-containing acrylate monomer is composed of C2~C3 It is composed of short-chain fluorine-containing alkyl acrylate monomers and C10-C12 long-chain fluorine-containing alkyl acrylate monomers. The fluorine-silicon modified acrylic resin prepared by the invention has the characteristics of high viscosity and low viscosity, is convenient for construction and use, and reduces the generation of VOC. The coating prepared with this modified acrylic resin has the characteristics of high impact resistance self-healing function, anti-icing, low surface energy, hydrophobic and oleophobic, stain resistance, high and low temperature resistance, etc.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

A kind of low-temperature emulsion polymerization prepares the method for fluorine-containing nitrile rubber

The invention provides a method for preparing fluorine-containing nitrile rubber with low-temperature emulsion polymerization. The method utilizes a fluorine-containing monomer emulsion polymerizationmethod to prepare the fluorine-containing nitrile rubber. In the polymerization process, a chelating titanate coupling agent is adopted, so that the ternary polymerization efficiency of a fluorine-containing monomer, acrylonitrile and butadiene can be remarkably improved. For the fluorine-containing nitrile rubber prepared by the method, the comprehensive properties of the nitrile rubber can be improved to a relatively large degree. For prepared fluorine-containing nitrile rubber, the oil resistance is good, the tensile strength is high, the oil resistance is improved by 20 percent or above compared with the fluorine-containing nitrile rubber prepared by an ordinary method, the Mooney viscosity is 50-100, the tensile strength is 30MPa or above, the elongation at break is 500 percent or above, meanwhile, the high-low temperature resistance is outstanding, the ageing-resistant performance is excellent, the glass-transition temperature is lowered by 10 DEG C or above, and the fluorine-containing nitrile rubber also has the characteristics of good elasticity, high stretching strength, low compression permanent deformation, good abrasive resistance, good weather ability, good pollutionresistance and narrow molecular weight distribution.

Owner:PETROCHINA CO LTD

Building external wall heat preservation coating and preparation method thereof

InactiveCN108893023ALow thermal conductivityImprove insulation effectAntifouling/underwater paintsPaints with biocidesPotassiumPolyethylene glycol

The invention discloses a building external wall heat preservation coating and a preparation method thereof. The coating is prepared from, by weight, 40-60 parts of silicone acrylic emulsion, 45-55 parts of expanded perlite, 1-5 parts of triethylene glycol monodecyl ether, 1-5 parts of potassium ricinoleate, 4-8 parts of copper(II) dimethyldithiocarbamate and 5-10 parts of starch aluminium octenylsuccinate. The thermal conductivity coefficient of the heat preservation coating is low, the heat preservation performance of the coating is obviously improved, the water resistance, acid and alkali resistance and washing resistance are good, the raw materials are wide in source, and the coating is low in cost, good in pollution resistance, environmentally friendly and free of pollution.

Owner:李晟隆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com