A sintered inorganic quartz stone plate and its production process

A quartz stone plate and production process technology, applied in manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems of easy chipping and damage, large brittleness of tiles, large processing loss, etc., and achieves good wear resistance and water absorption. Low rate, low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] 1. Formula (according to weight percentage):

[0024] 325 mesh (or 400 mesh) quartz powder 88%

[0025] 1250 mesh quartz powder 1.5%

[0026] Colored granite stone powder or quartz powder (used to form patterns): 3%

[0027] Feldspar powder: 2%

[0028] Kaolin: 5%

[0029] Pigment: 0.5%

[0030] 2. The difference between the sintered inorganic quartz stone plate in the present invention and the mainstream quartz stone product in the market—resin type quartz stone plate product:

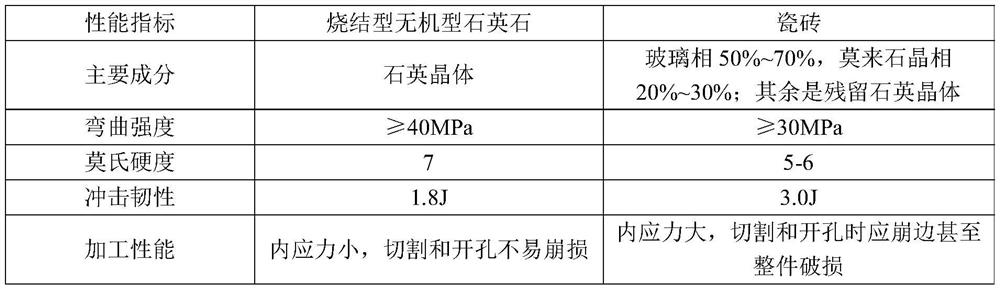

[0031] Resin-type quartz stone plate is to use unsaturated polyester resin to bond about 90% of the quartz particles in the system to form a plate with a bending strength exceeding 30MPa; the sintered inorganic quartz stone pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com