Environment-friendly self-cleaning coating for shower room and preparation method of environment-friendly self-cleaning coating

A self-cleaning coating and shower room technology, applied in coatings, anti-fouling/underwater coatings, paints containing biocides, etc., can solve problems such as breeding bacteria, humid environment, and unfavorable people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

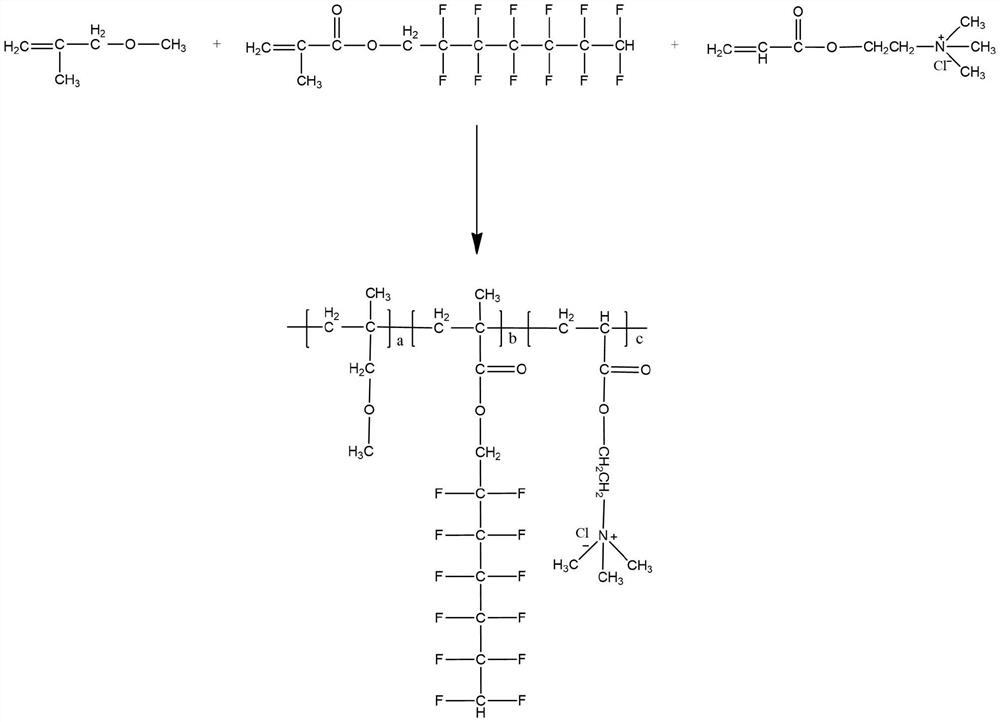

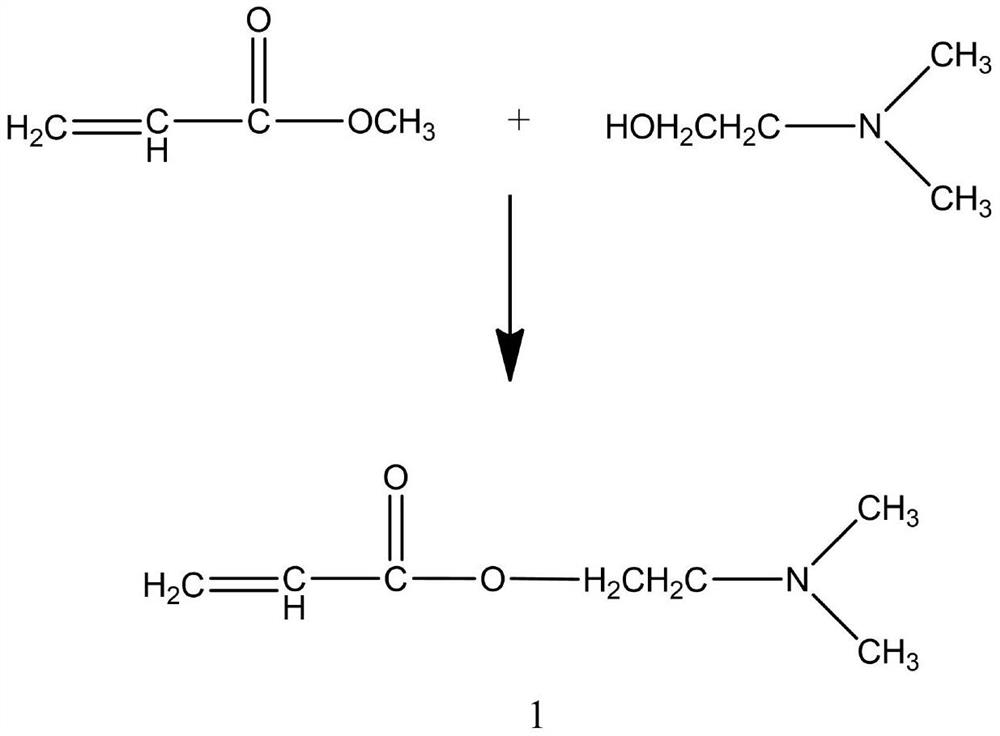

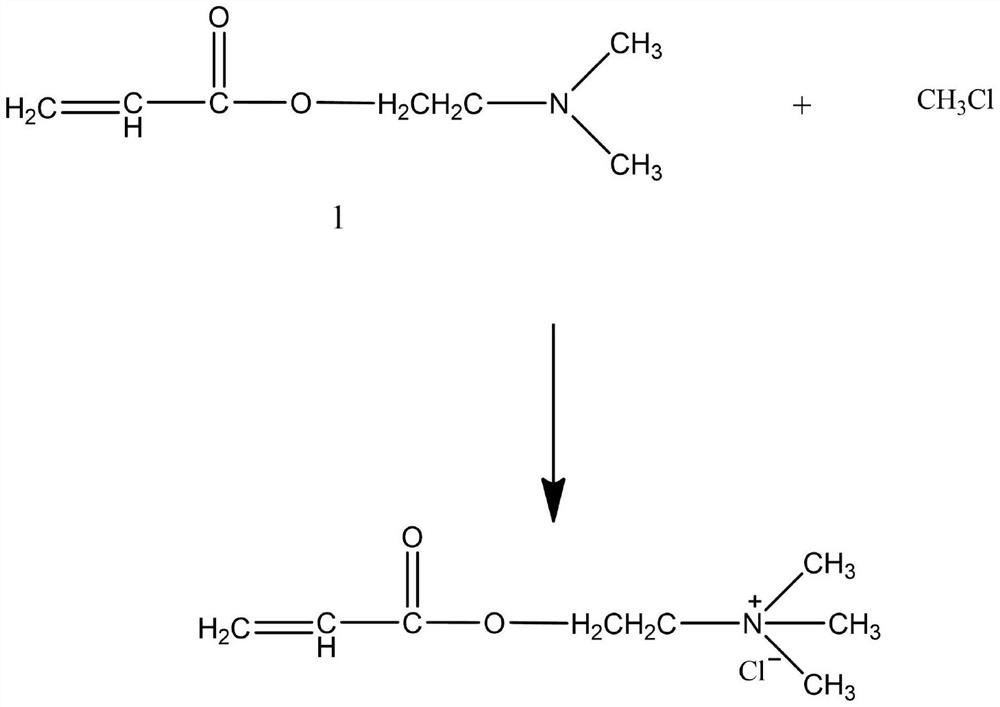

[0043] This embodiment is an antibacterial monomer, and the preparation process of the antibacterial monomer is as follows:

[0044]S1: Add dimethylaminoethanol, methyl acrylate, polymerization inhibitor a and catalyst to a three-necked flask equipped with a thermometer, a magnetic stirrer, a condensing reflux tube and a fractionating column. The temperature of the reaction system is raised to boiling, the temperature is controlled at 85°C, the temperature at the top of the fractionation column is 63.5°C, and the reaction is refluxed for 5 hours at a reflux ratio of 4:1 until no fraction is discharged, and then the pressure is reduced to 0.05MPa, and the temperature at the top of the fractionation column is controlled. at 37°C, reflux under the condition of reflux ratio of 4:1 until no distillate is discharged, and then the pressure is reduced to 3.3×10 3 Pa, control the temperature at the top of the fractionation column to be 88°C, collect fractions to obtain intermediate pro...

Embodiment 2

[0047] This embodiment is an antibacterial monomer, and the preparation process of the antibacterial monomer is as follows:

[0048] S1: Add dimethylaminoethanol, methyl acrylate, polymerization inhibitor a and catalyst to a three-necked flask equipped with a thermometer, a magnetic stirrer, a condensing reflux tube and a fractionating column. The temperature of the reaction system is raised to boiling, the temperature is controlled at 100°C, the temperature at the top of the fractionating column is 66°C, and the reaction is refluxed for 5.5 hours under the condition of a reflux ratio of 4:1, until no fraction is discharged, and then the pressure is reduced to 0.05MPa, and the top of the fractionating column is controlled to The temperature was 41°C, refluxed under the condition of reflux ratio 4:1 until no distillate was discharged, and then the pressure was reduced to 3.3×10 3 Pa, control the temperature at the top of the fractionation column to be 89°C, collect fractions to...

Embodiment 3

[0051] This embodiment is an antibacterial monomer, and the preparation process of the antibacterial monomer is as follows:

[0052] S1: Add dimethylaminoethanol, methyl acrylate, polymerization inhibitor a and catalyst to a three-necked flask equipped with a thermometer, a magnetic stirrer, a condensing reflux tube and a fractionating column. The temperature of the reaction system is raised to boiling, the temperature is controlled at 115°C, the temperature at the top of the fractionation column is 70°C, and the reaction is refluxed for 6 hours at a reflux ratio of 4:1 until no fraction is discharged, and then the pressure is reduced to 0.05MPa, and the temperature at the top of the fractionation column is controlled. at 45°C, reflux under the condition of reflux ratio of 4:1 until no distillate is discharged, and then the pressure is reduced to 3.3×10 3 Pa, control the temperature at the top of the fractionation column to be 90°C, collect fractions to obtain intermediate pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com