Quaternary amino cation modified polysiloxane softening agent and preparation method thereof

A polysiloxane and cationic technology, applied in the field of softeners, can solve the problems of single softness, elasticity, low bulkiness, high yellowing, etc., and achieve the effect of excellent low hydrophobicity and improved wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

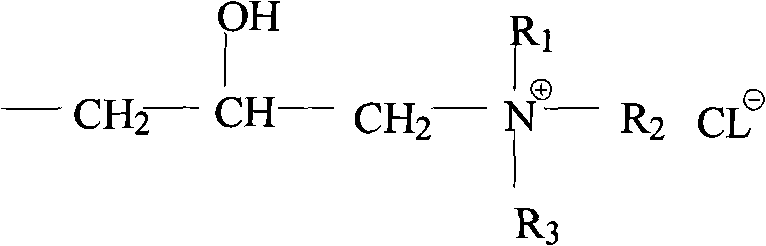

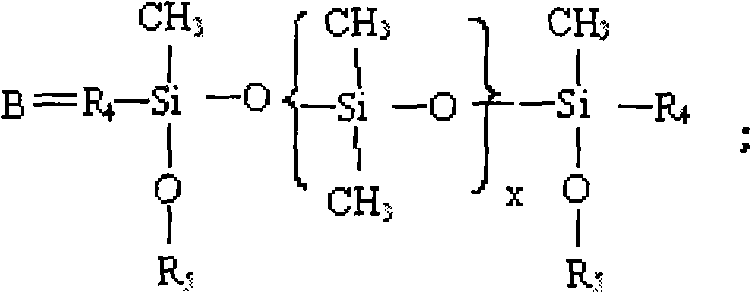

[0043] A quaternary ammonium cationic modified polysiloxane softener, characterized in that the softener has the following structural formula:

[0044] A 1 BA 2

[0045]

[0046] R 4 =-CH 2 -CH 2 -CH 2 -NH 2 ;

[0047] R 3 =-CH 3 ;

[0048] The preparation method of above-mentioned quaternary ammonium cationic modified polysiloxane softening agent comprises the following steps:

[0049] (1) Mix hydroxyl silicone oils of different molecular weights and aminopropylmethyldimethoxysilane at a molar ratio of 1:2, and react at 25°C for 24 hours to obtain a siloxane intermediate, which is a hydroxylamino-sealed end, its degree of polymerization is 60;

[0050] (2) The siloxane intermediate obtained in step (1) was reacted with 2,3-epoxypropyltrimethylammonium chloride in a molar ratio of 1:2 in an isopropanol solvent for 2 hours, and the whole reaction Carried out under the protection of nitrogen, and finally vacuumized to remove part of the solvent to obtain a transp...

Embodiment 2

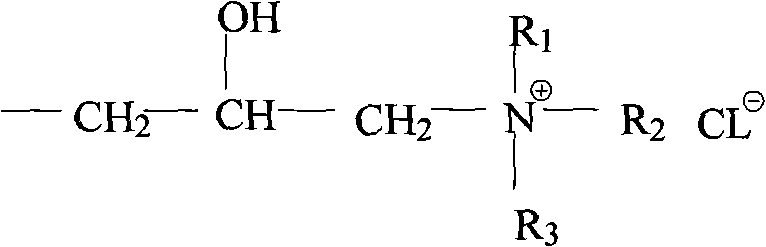

[0053] A quaternary ammonium cationic modified polysiloxane softener, characterized in that the softener has the following structural formula:

[0054] A 1 BA 2

[0055]

[0056] R 4 =-CH 2 -CH 2 -CH 2 -NH-CH 2 -CH 2 -NH 2

[0057] R 5 =-CH 2 -CH 3

[0058] The preparation method of above-mentioned quaternary ammonium cationic modified polysiloxane softening agent comprises the following steps:

[0059] (1) Mix hydroxyl silicone oils of different molecular weights and N-(β-aminoethyl)-γ-aminopropylmethyldiethoxysilane at a molar ratio of 1:2, and react at 105°C for 4 hours to obtain silicon oxide An alkane intermediate, the siloxane is hydroxyl-terminated, and its degree of polymerization is 100;

[0060] (2) The siloxane intermediate obtained in the step (1) is reacted with 2,3-epoxypropyltrimethylammonium chloride in a diethylene glycol monobutyl ether solvent in a molar ratio of 1:4 for 10 Hours, the whole reaction was carried out under the protection of ni...

Embodiment 3

[0063] A quaternary ammonium cationic modified polysiloxane softener, characterized in that the softener has the following structural formula:

[0064] A 1 BA 2

[0065]

[0066]

[0067] R 4 =-CH 2 -CH 2 -CH 2 -NH 2 ;

[0068] R 5 =-CH 3

[0069] The preparation method of above-mentioned quaternary ammonium cationic modified polysiloxane softening agent comprises the following steps:

[0070] (1) Mix hydroxyl silicone oils of different molecular weights and aminopropylmethyldimethoxysilane at a molar ratio of 1:1, and react at 50°C for 12 hours to obtain a siloxane intermediate. end, its degree of polymerization is 10;

[0071] (2) The siloxane intermediate obtained in step (1) was reacted with 2,3-epoxypropyltrimethylammonium chloride in a molar ratio of 1:2 in an isopropanol solvent for 5 hours. Carried out under the protection of nitrogen, and finally vacuumized to remove part of the solvent to obtain a transparent modified polysiloxane product with a vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com